Ultrasonic anti-freezing device of power transmission tower

An antifreeze device and ultrasonic technology, applied in towers, building types, buildings, etc., can solve problems such as limited load carrying capacity, transmission tower load exceeding the actual design, and endangering power supply safety, so as to achieve stable work, reduce the risk of icing, The effect of continuous power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

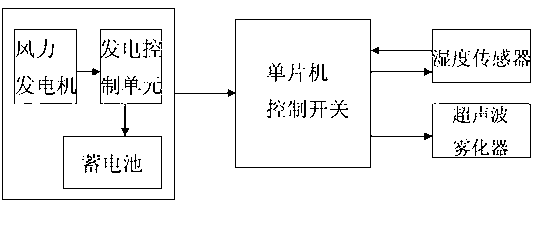

[0011] like figure 1 As shown, the ultrasonic antifreeze device of the transmission tower includes a wind turbine, a humidity sensor, a single-chip microcomputer control switch, and an ultrasonic atomizer. The wind turbine is electrically connected to the ultrasonic atomizer through the single-chip microcomputer control switch, and the humidity sensor is electrically connected to the single-chip microcomputer control switch; The wind turbine includes a wind generator, a power generation control unit, and a storage battery. The power generation control unit is electrically connected to the wind turbine and the storage battery, and the ultrasonic atomizer is installed on the key load-bearing part of the transmission tower.

[0012] When the wind power meets the working requirements of the wind turbine, the wind turbine starts to generate electricity and store energy. When the humidity is greater than the set value, the single-chip microcomputer control switch is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com