A vehicle fuel cell tail gas nitrogen production system and its purging method

A fuel cell and fuel cell cathode technology, which is applied in the direction of fuel cells, fuel cell additives, electrical components, etc., can solve problems such as inapplicability, reduced mileage of the vehicle, and energy waste, so as to prevent and reduce icing risk, the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

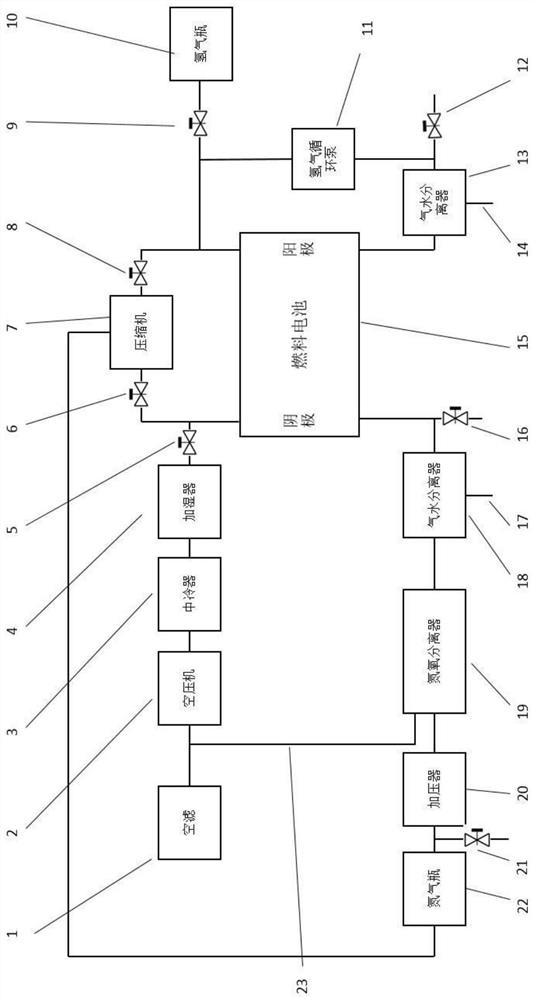

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The present invention is based on the basic idea of using nitrogen production-nitrogen storage-purging, utilizes the characteristics of high nitrogen content and low oxygen content in the tail gas discharged from the cathode of the fuel cell 15, and exhausts the nitrogen production and purge system and the cathode of the fuel cell 15 The pipeline is physically processed, and the generated nitrogen gas is collected into a gas cylinder, and the cathode and anode of the fuel cell 15 are purged after the fuel cell 15 is shut down. After the fuel cell 15 is shut down, the cathode and anode of the fuel cell 15 are purged. At the same time, the oxygen separated in the process of nitrogen production can be transported again to the air intake circuit of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com