Wall diversion hedging Venturi integrated mixer

A Venturi and mixer technology, applied in the field of wall diversion hedging Venturi integrated mixer, can solve the problems of low engine output power, small effective flow area, poor impeller streamline, etc., to improve mixing uniformity, reduce Effects of gas resistance and gas flow field stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

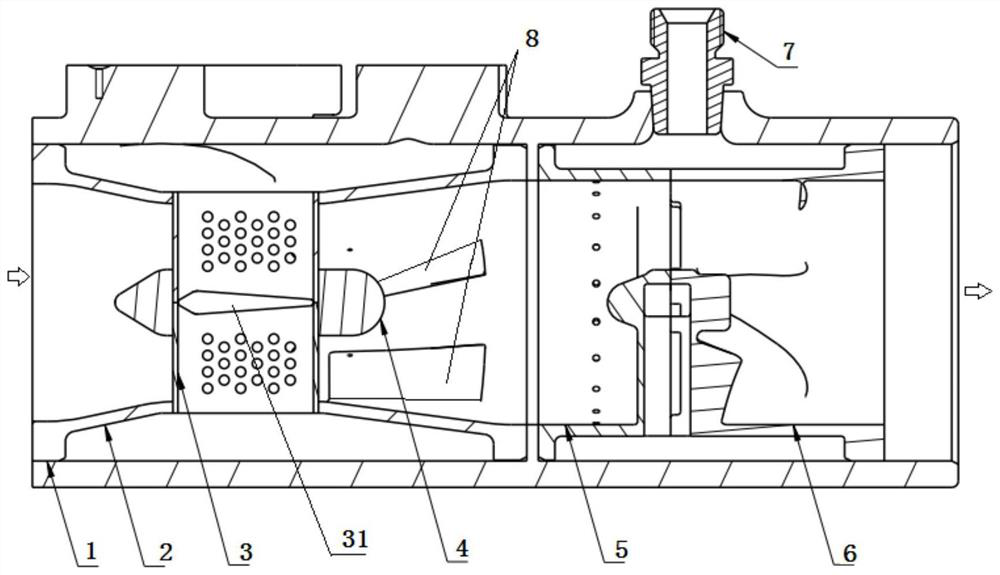

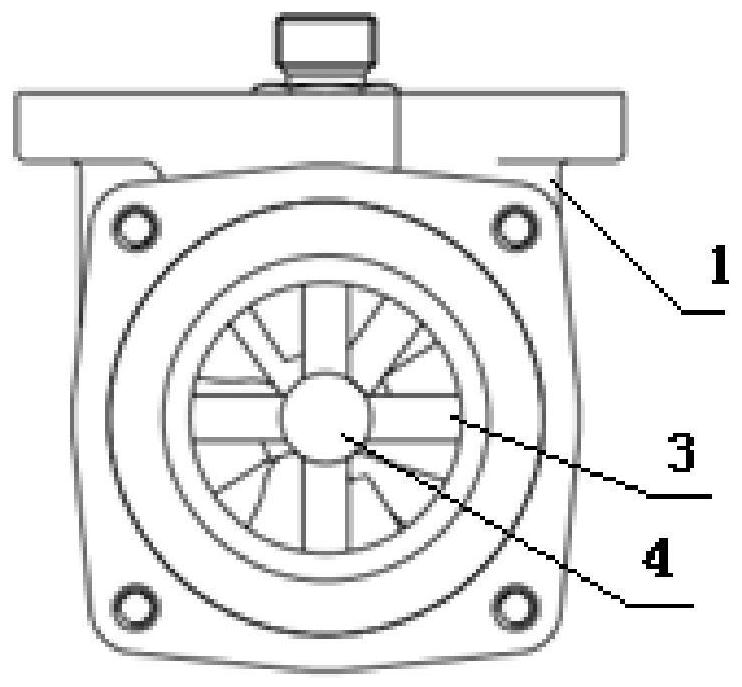

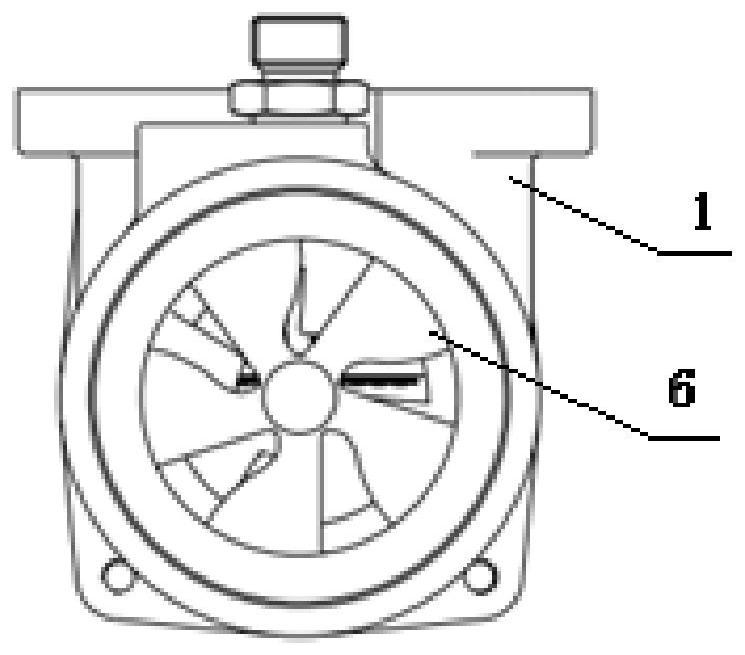

[0037] In one embodiment, a wall-directed hedging type Venturi integrated mixer, comprising a casing 1, an EGR core 2, a ten

[0038] In one embodiment, a wall-surface flow-guided hedging type Venturi integrated mixer, comprising a housing 1, an EGR core 2, a ten

[0039] In one embodiment, a wall-directed hedging type Venturi integrated mixer, comprising a housing 1, an EGR core 2, a ten

[0041] In one embodiment, a wall-directed hedging type Venturi integrated mixer, comprising a housing 1, an EGR core 2, a ten

[0042] In one embodiment, a wall-surface-directed hedging type Venturi integrated mixer, comprising a housing 1, an EGR core 2, a ten

[0044] In one embodiment, a wall-directed hedging type Venturi integrated mixer, comprising a housing 1, an EGR core 2, a ten

[0048] Piezoresistance: EGR exhaust gas 11.1kpa, natural gas 3.8kpa.

[0049] The basic principles and main structural features of the present invention have been shown and described above. The present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com