Propulsion assembly, aircraft including propulsion assembly and ventilation method thereof

A technology for propulsion components and aircraft, which is applied in the cooling of turbine/propulsion units, jet propulsion units, aircraft parts, etc. Small design constraints, the effect of reducing stamping resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

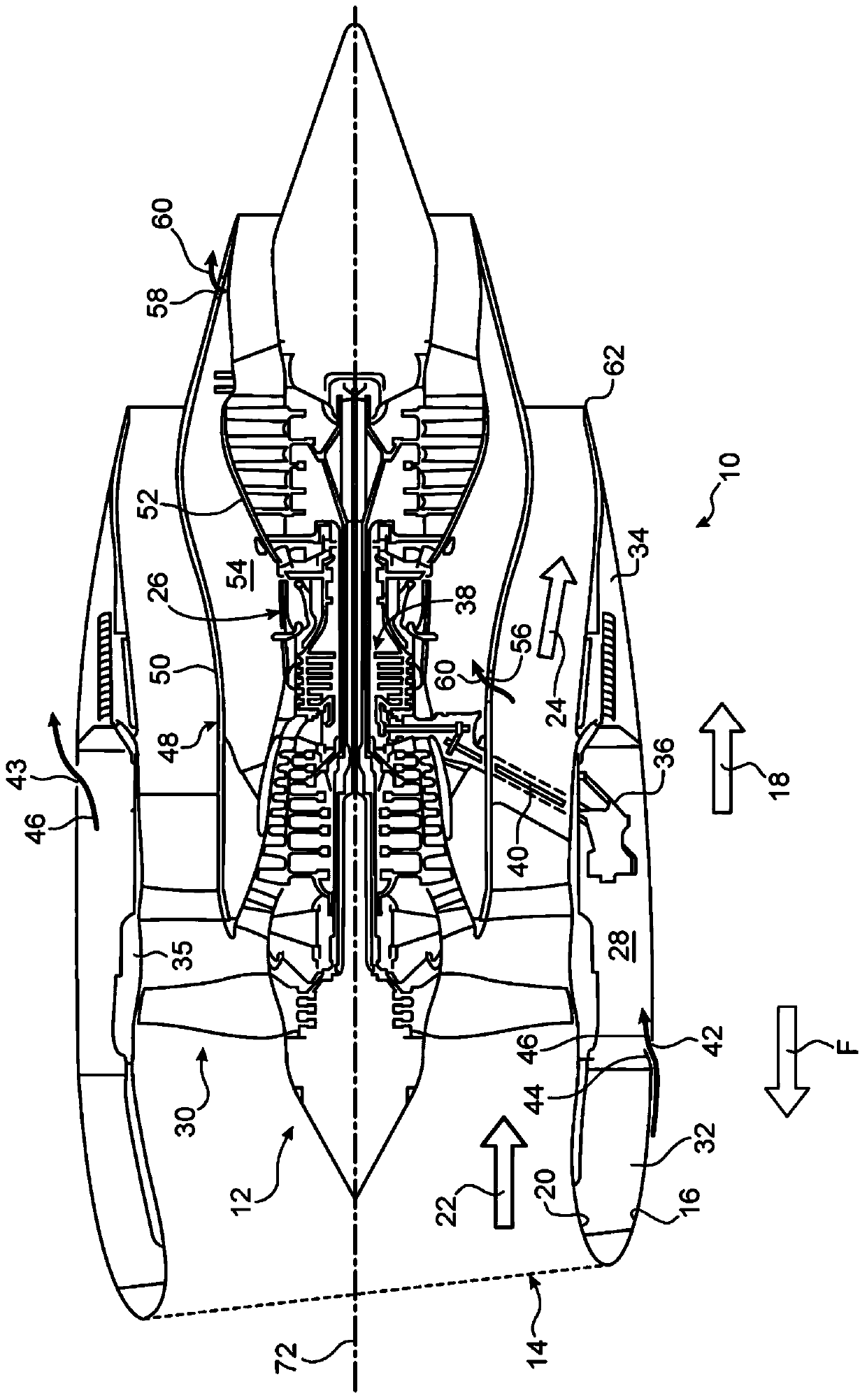

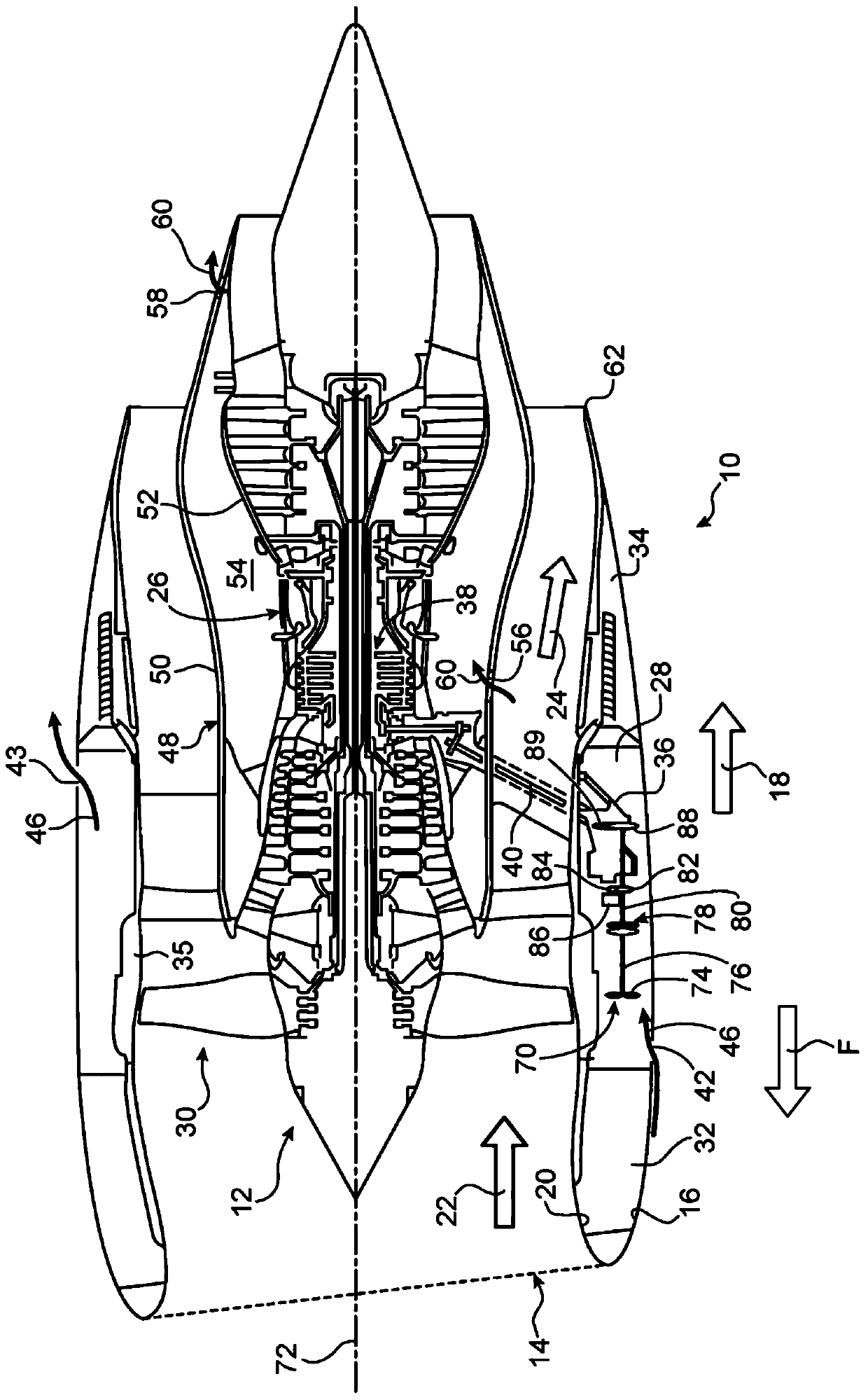

[0071] figure 2 shows the first embodiment of the present invention with figure 1 The propulsion assembly in is similar to the propulsion assembly 10 , but in this propulsion assembly 10 a fan 70 is housed in the inner compartment 28 of the outer fairing 14 in a rearward direction from the air intake aperture 42 .

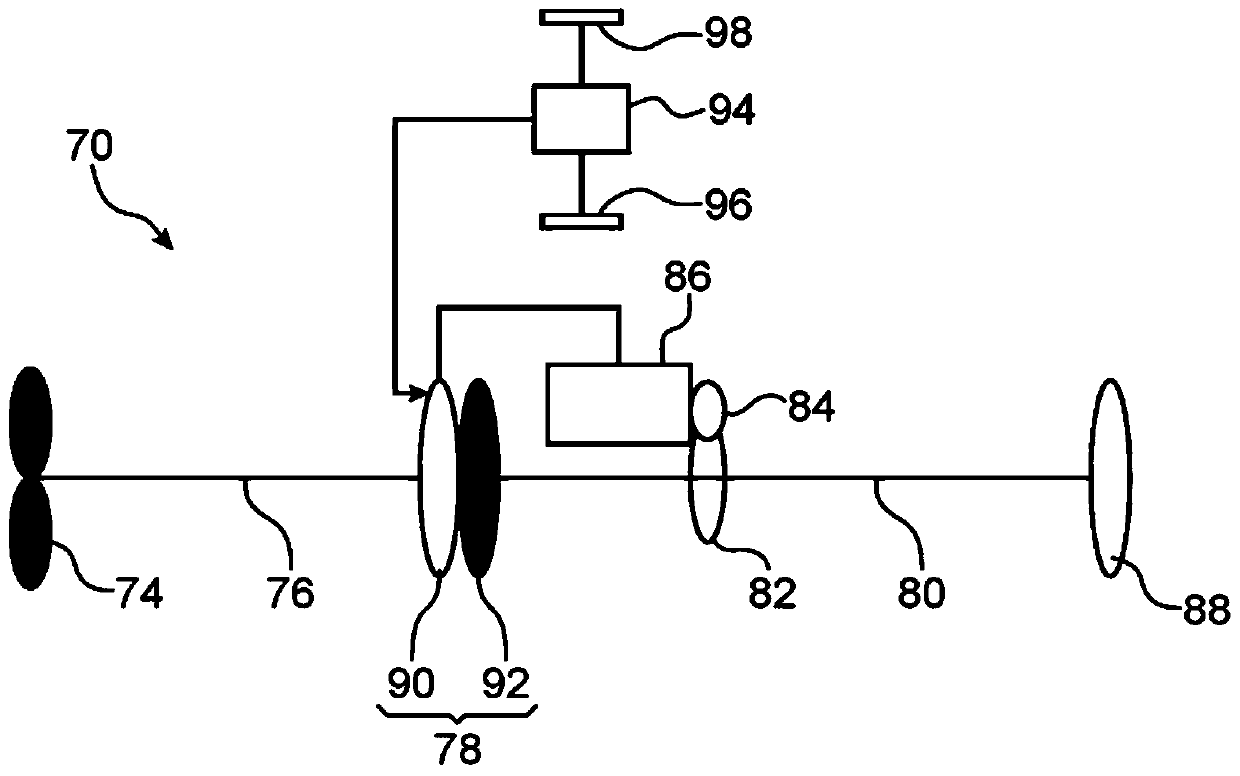

[0072] The fan 70 includes a fan propeller 74, a first shaft 76 fixed to the fan propeller 74, an electromagnetic clutch 78, a second shaft 80 carrying a first gear 82 engaged with a rotor shaft 84 of an electric motor 86, and a first gear 89 engaged with a gear 89. Two gears 88 and 89 form part of the auxiliary gearbox 36 and are driven in rotation by the intermediate shaft 40 .

[0073] In the terminology of the present invention, the first shaft 76, the electromagnetic clutch 78, the second shaft 80 and the second gear 88 form a "coupling and decoupling" for coupling and decoupling the fan propeller 74 and the gear 89 of the auxiliary gearbox 36. Disconnect c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com