Patents

Literature

81results about How to "Reduce Design Constraints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

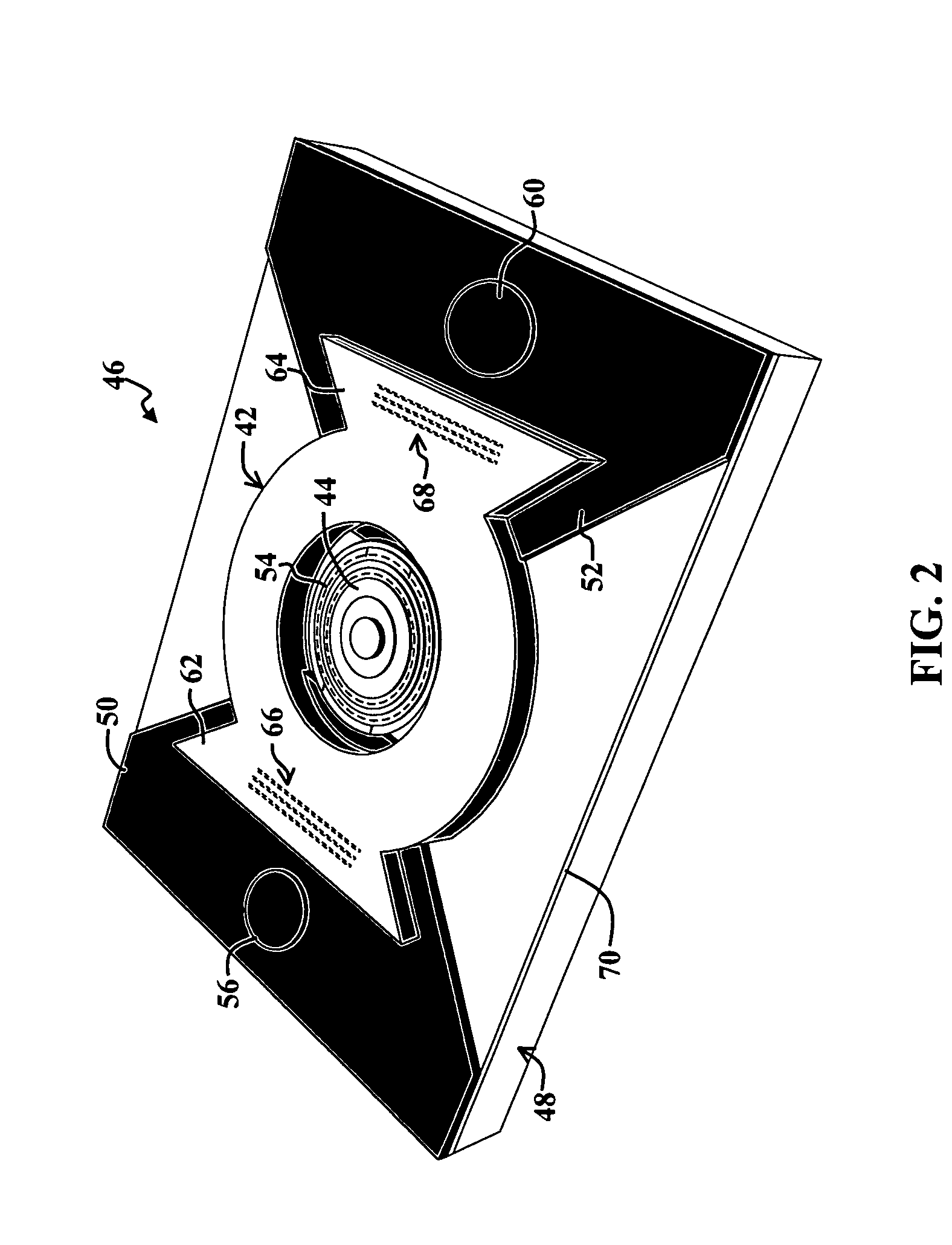

High resolution direct-projection type x-ray microtomography system using synchrotron or laboratory-based x-ray source

ActiveUS7130375B1Large numerical apertureLow efficiencyRadiation beam directing meansX-ray apparatusX-rayMagnification

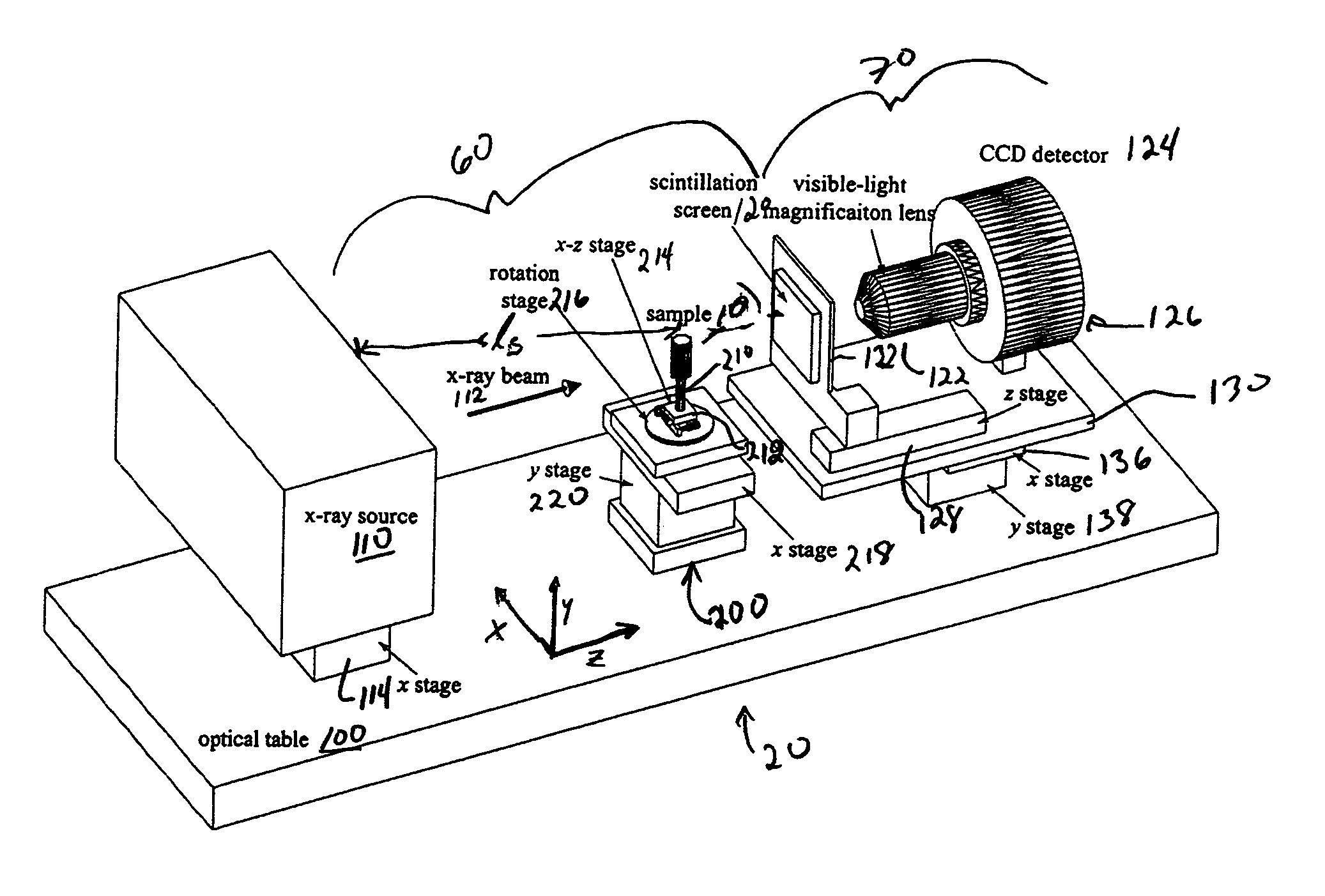

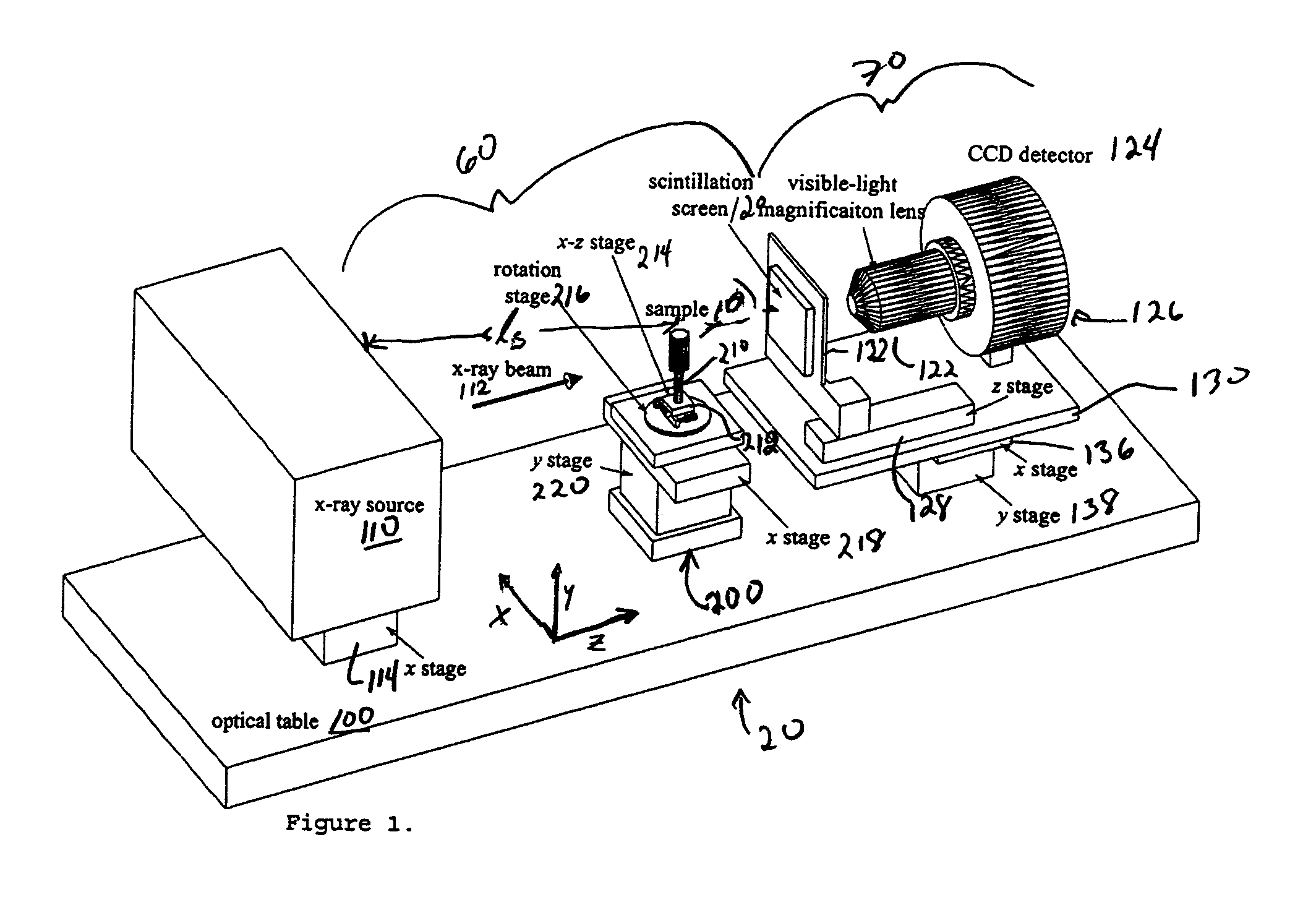

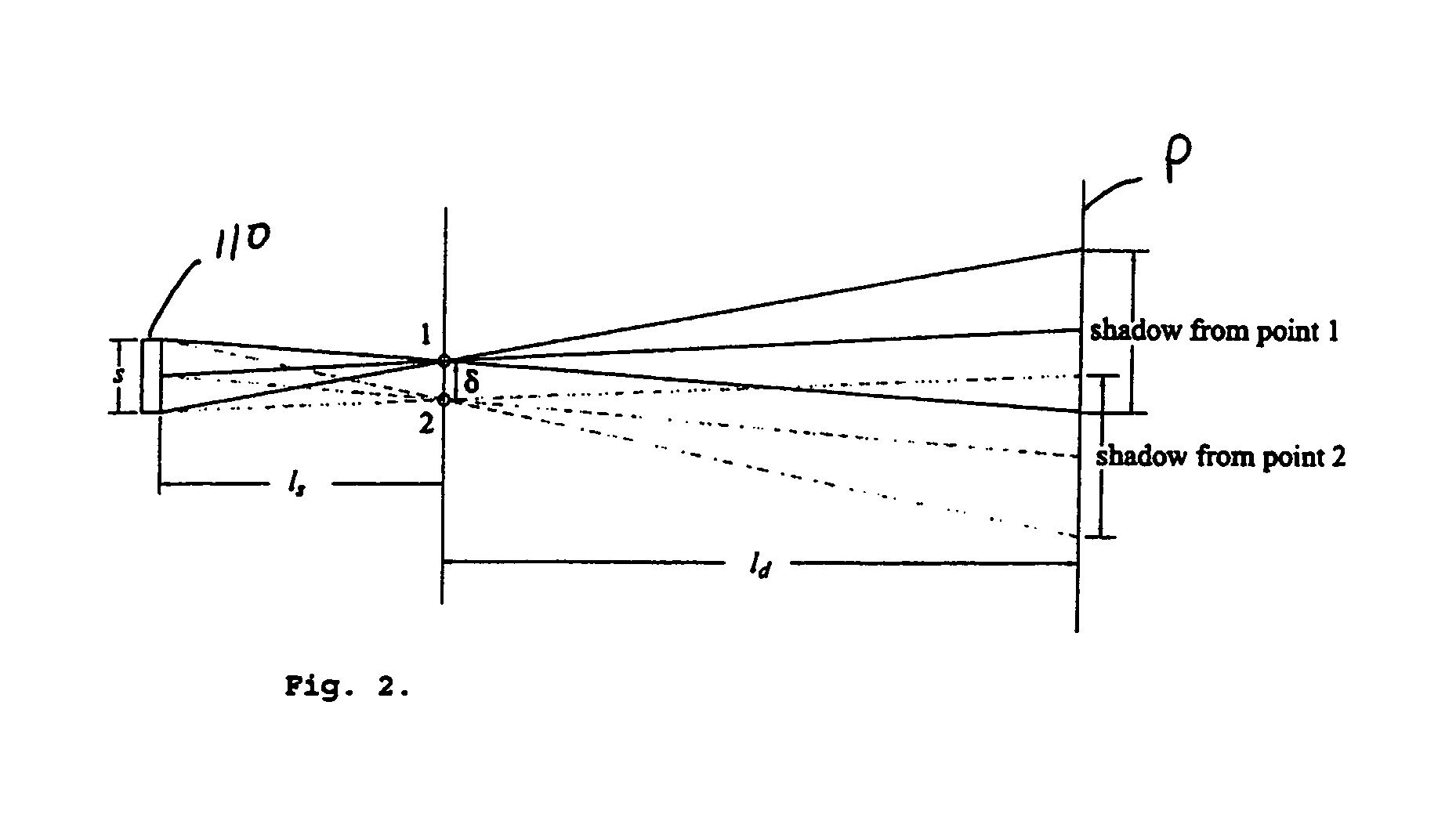

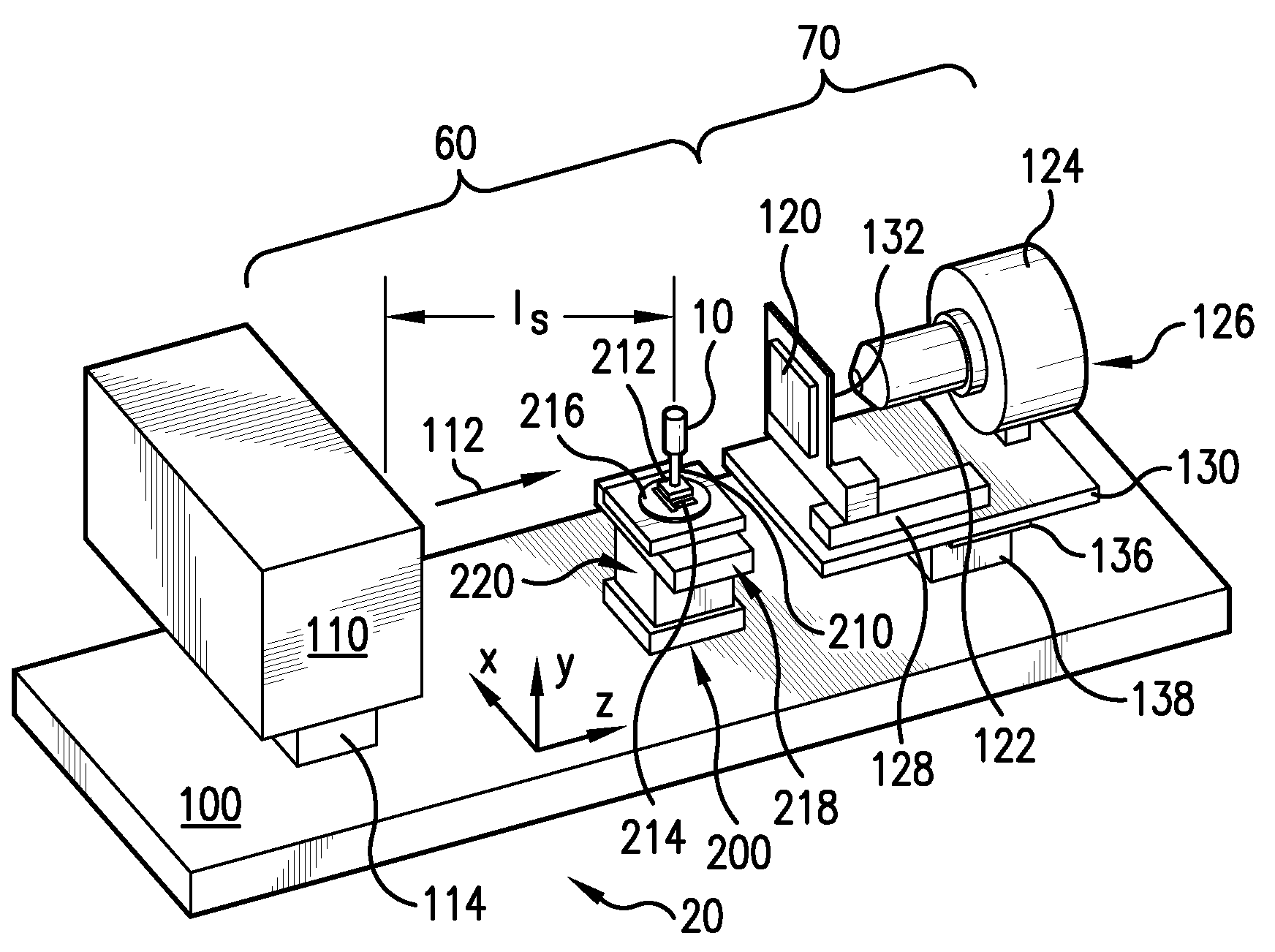

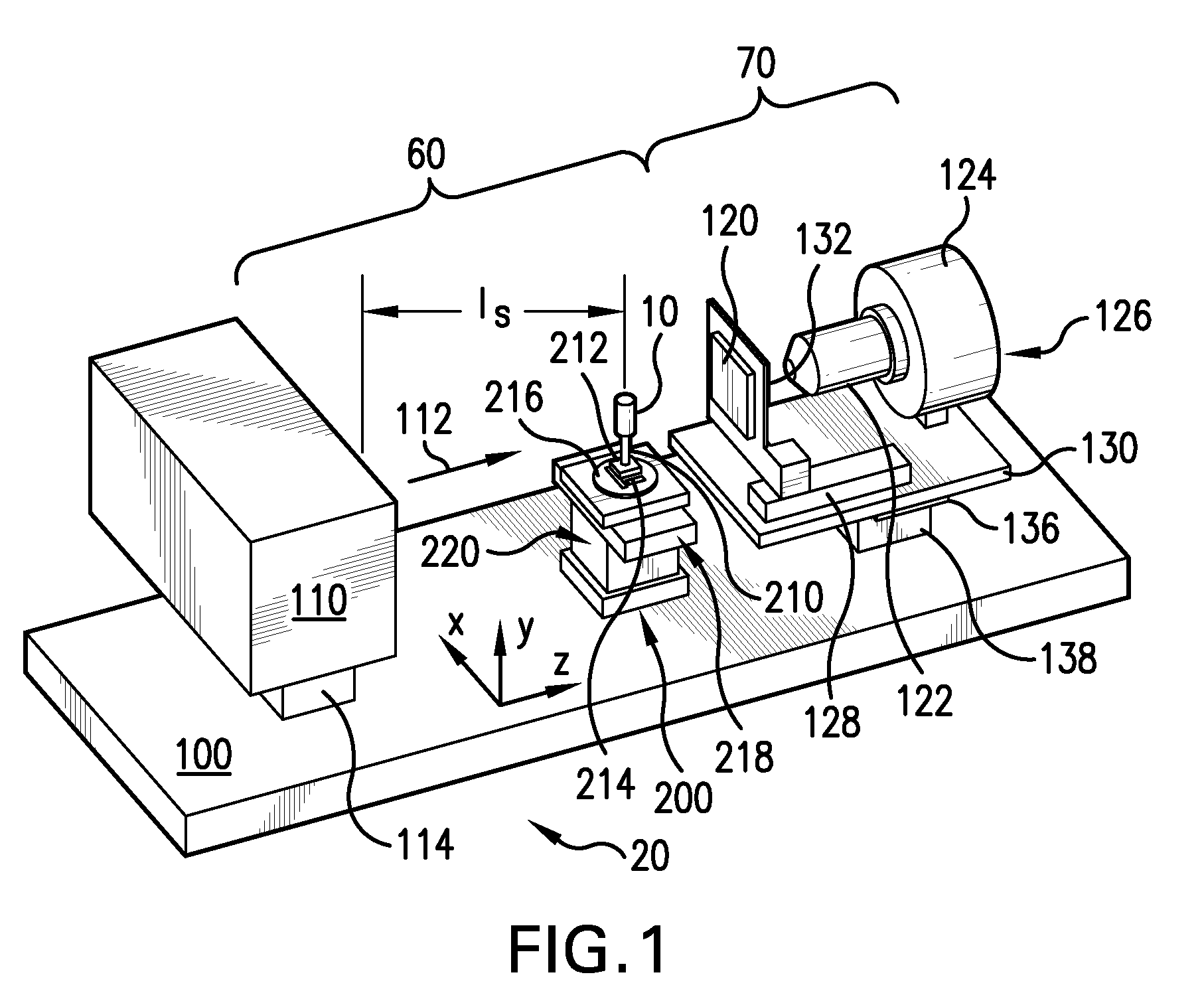

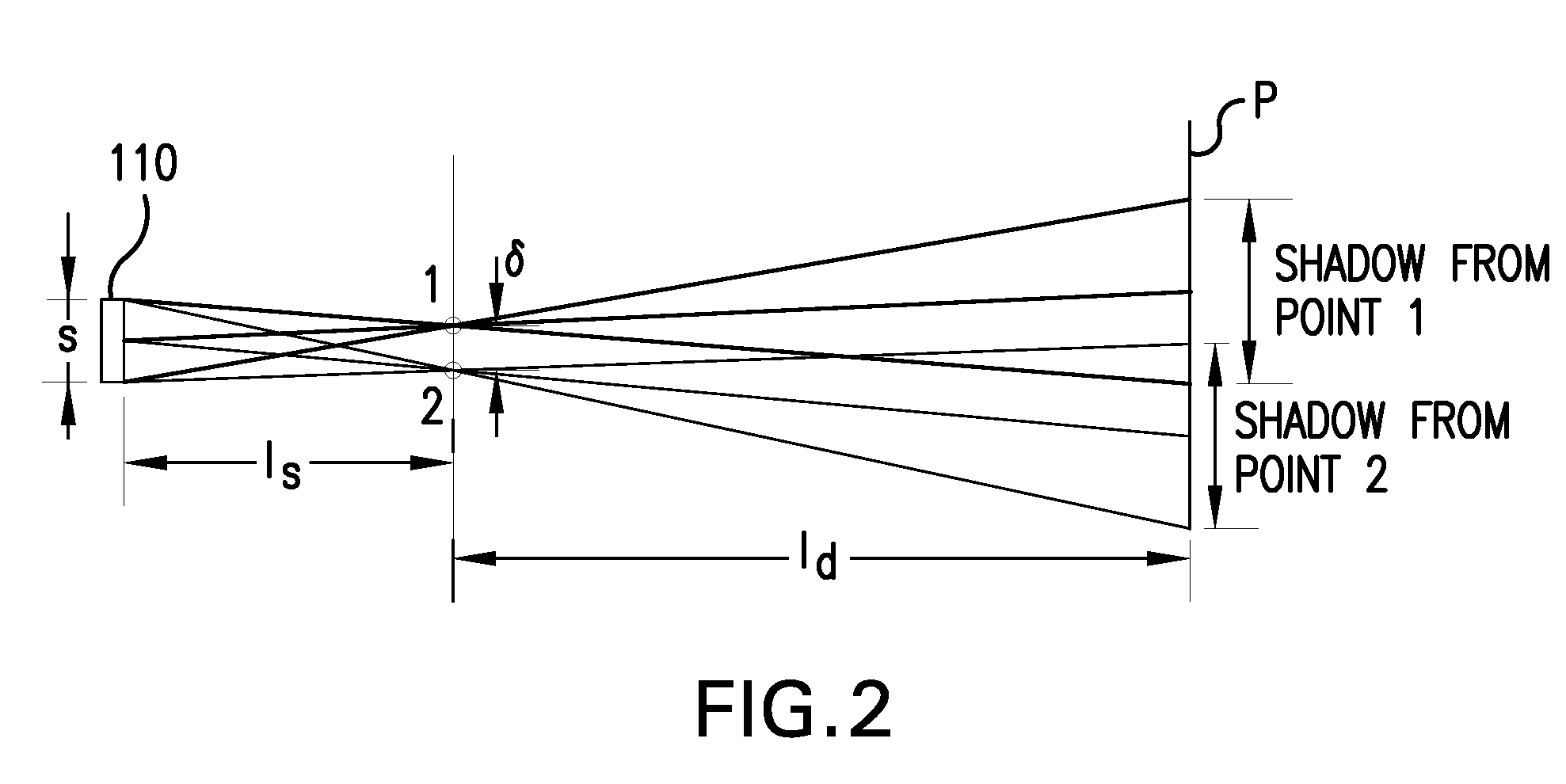

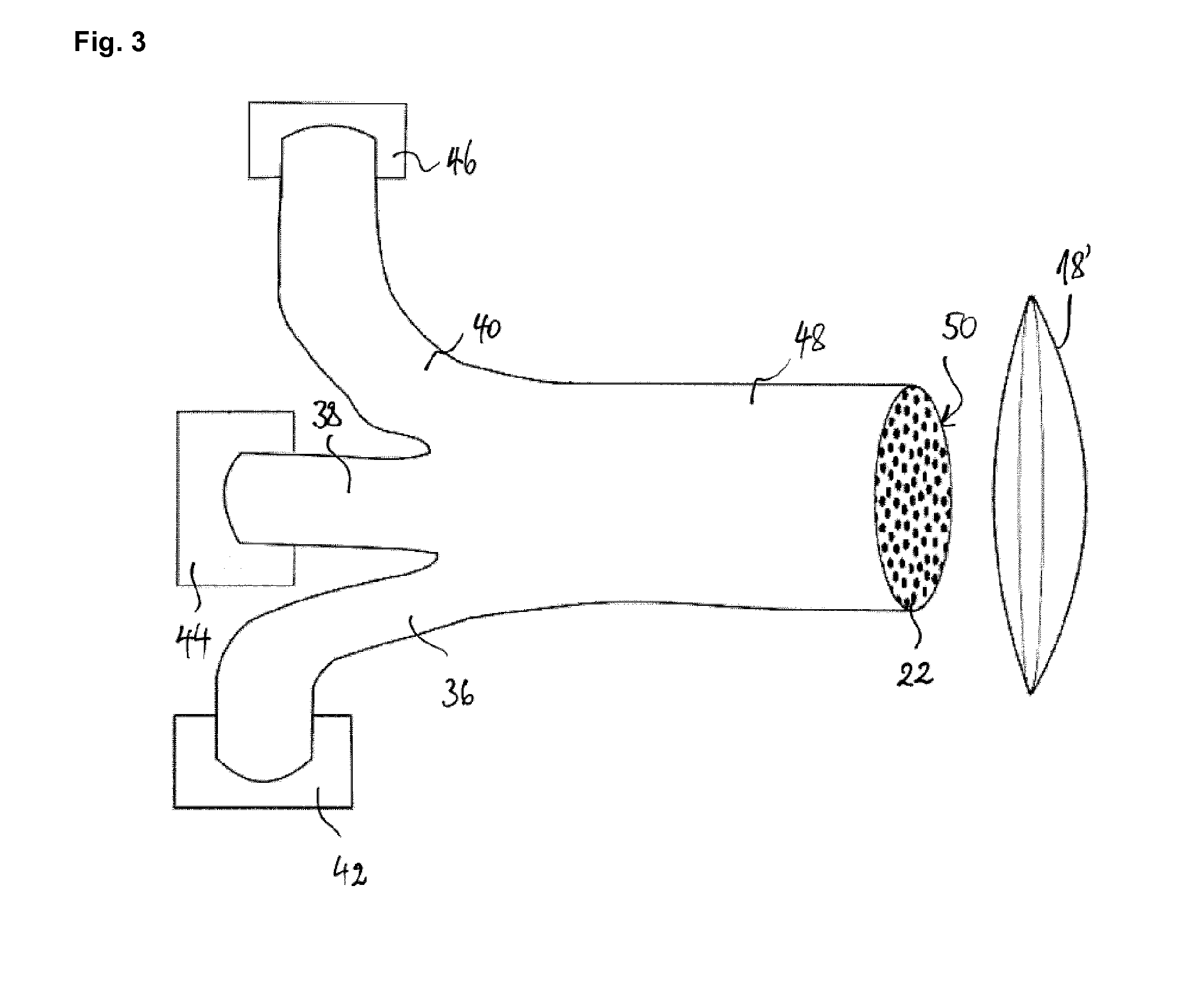

A projection-based x-ray imaging system combines projection magnification and optical magnification in order to ease constraints on source spot size, while improving imaging system footprint and efficiency. The system enables tomographic imaging of the sample especially in a proximity mode where the same is held in close proximity to the scintillator. In this case, a sample holder is provided that can rotate the sample. Further, a z-axis motion stage is also provided that is used to control distance between the sample and the scintillator.

Owner:CARL ZEISS X RAY MICROSCOPY

High resolution direct-projection type x-ray microtomography system using synchrotron or laboratory-based x-ray source

ActiveUS7400704B1Large numerical apertureLow efficiencyPatient positioning for diagnosticsRadiation beam directing meansX-rayMagnification

A projection-based x-ray imaging system combines projection magnification and optical magnification in order to ease constraints on source spot size, while improving imaging system footprint and efficiency. The system enables tomographic imaging of the sample especially in a proximity mode where the same is held in close proximity to the scintillator. In this case, a sample holder is provided that can rotate the sample. Further, a z-axis motion stage is also provided that is used to control distance between the sample and the scintillator.

Owner:CARL ZEISS X RAY MICROSCOPY

Efficient exploding foil initiator and process for making same

InactiveUS20090151584A1Ease of mass productionIncrease EFI reliabilityBlasting cartridgesAmmunitionActuatorMaterial Perforation

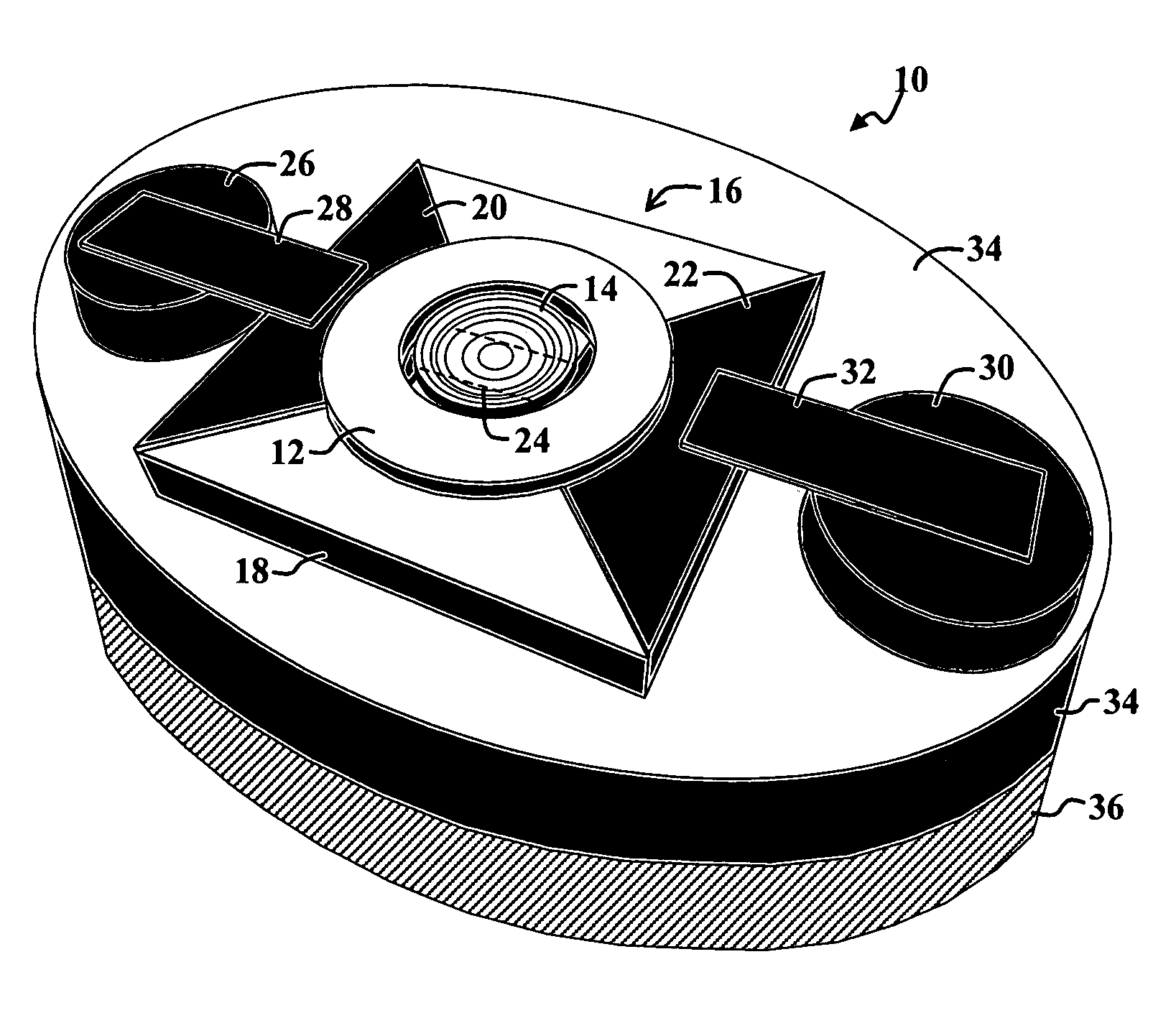

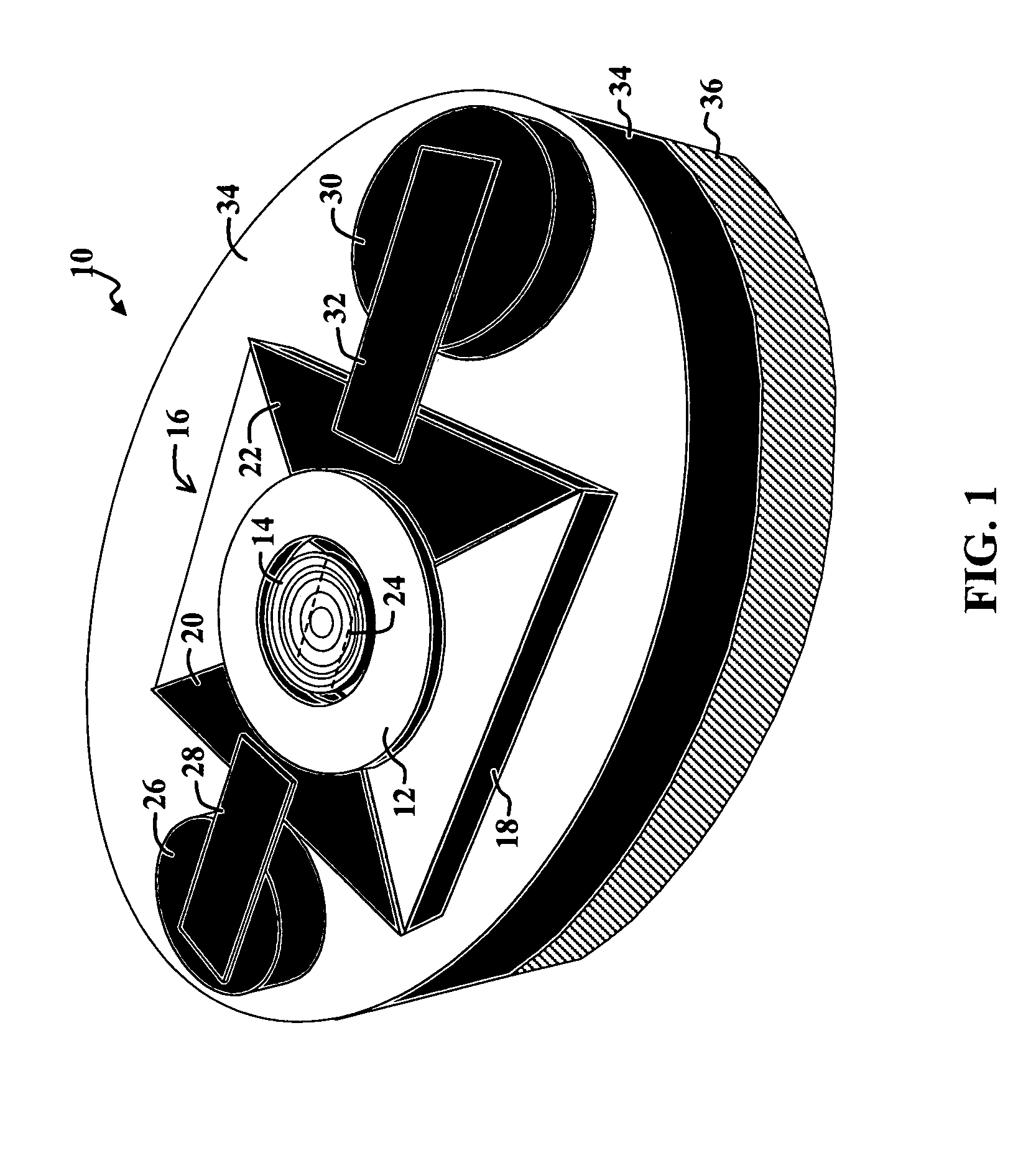

An actuator assembly that includes, in one example embodiment, a substrate with a bridge coupled between a first electrode and a second electrode on the substrate. A lithographically disposed flyer is positioned in proximity to the bridge. In a more specific embodiment, the actuator assembly further includes a lithographically disposed barrel that partially surrounds the flyer. A fireset is coupled to pins that extend through the substrate to the first electrode and the second electrode. The flyer further includes a three-dimensional surface adapted to flatten during flight. The flyer may be concave, convex, or may star shaped, may have perforations therein, or may exhibit another shape or other features.

Owner:DESAI AMISH

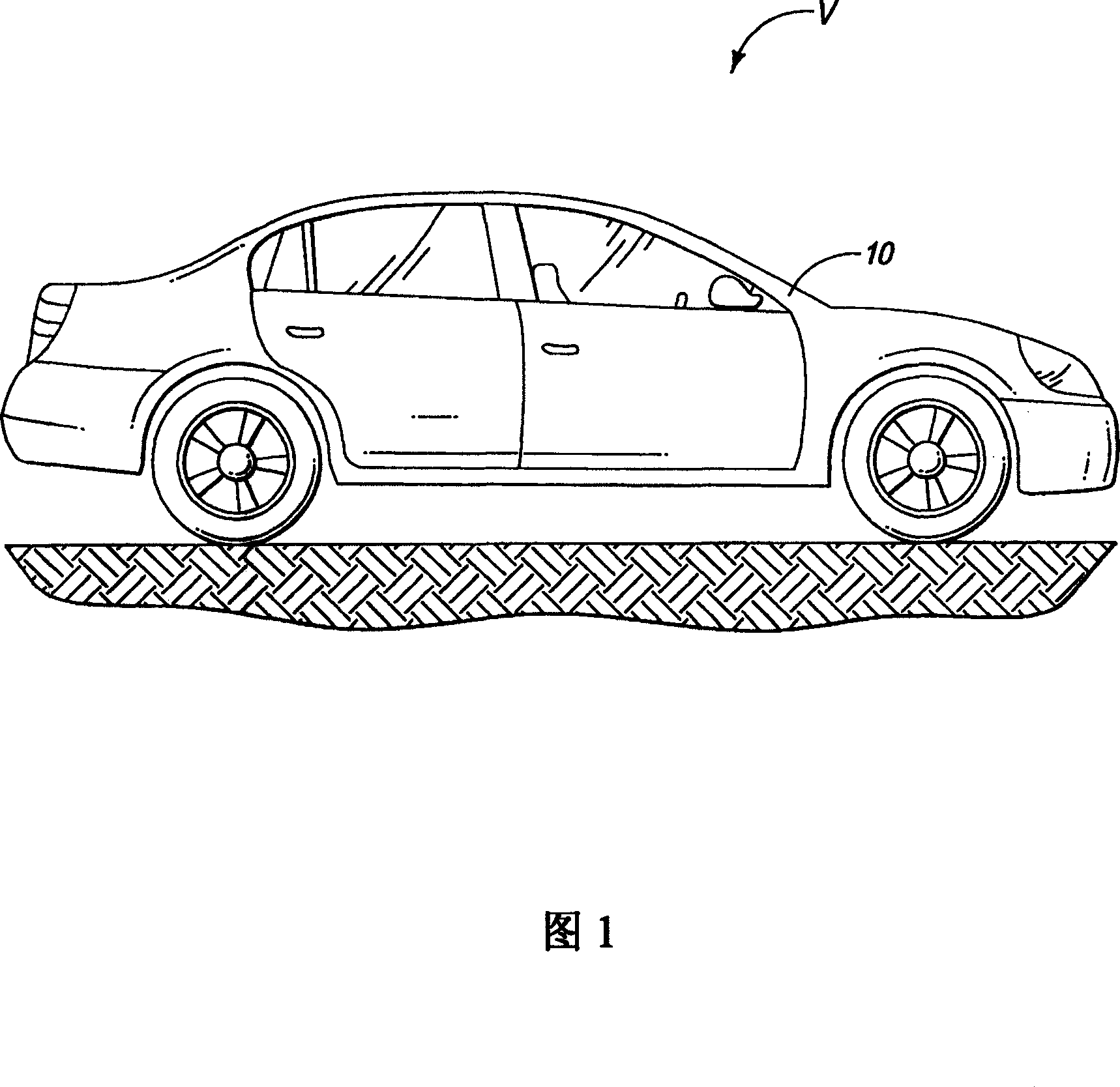

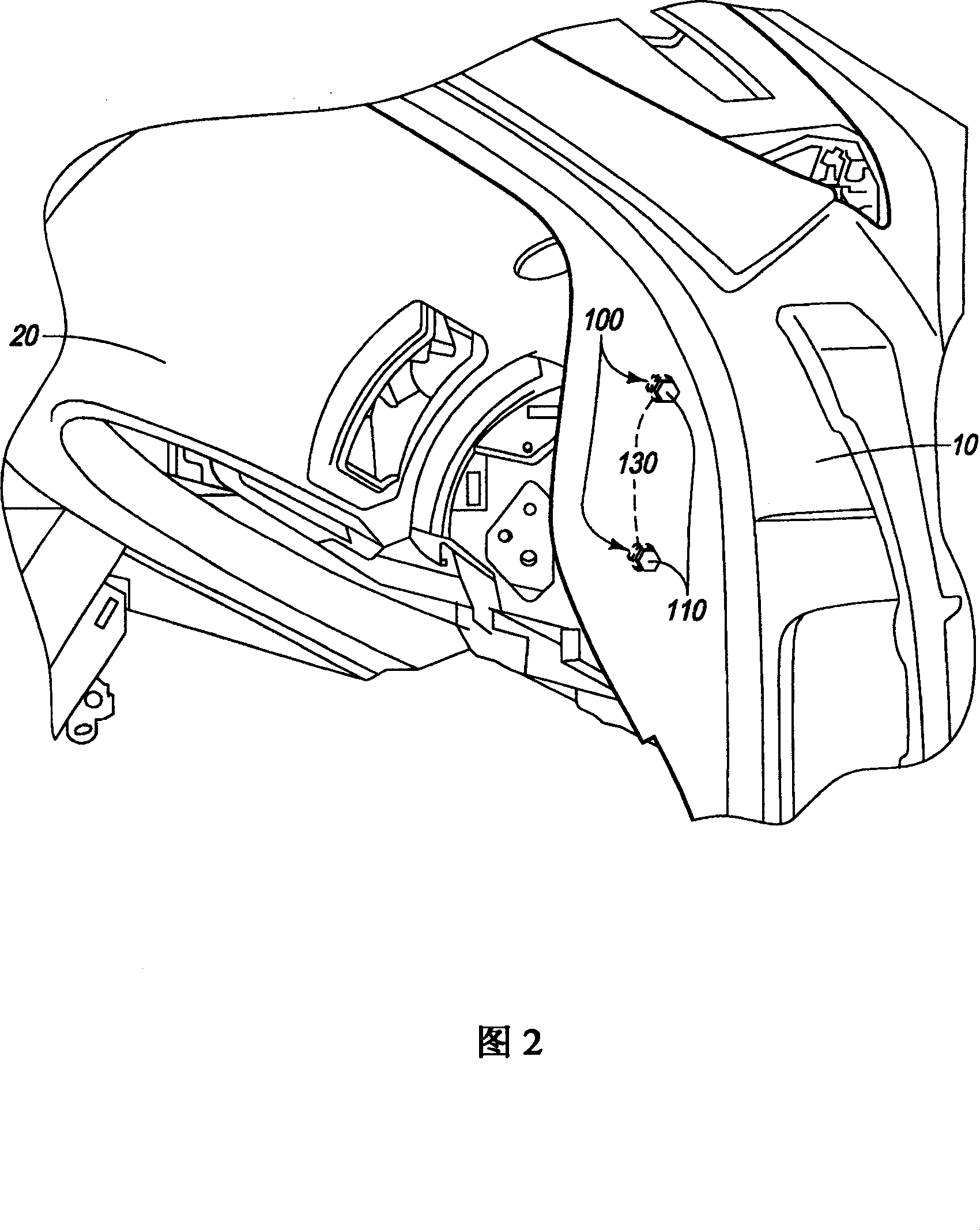

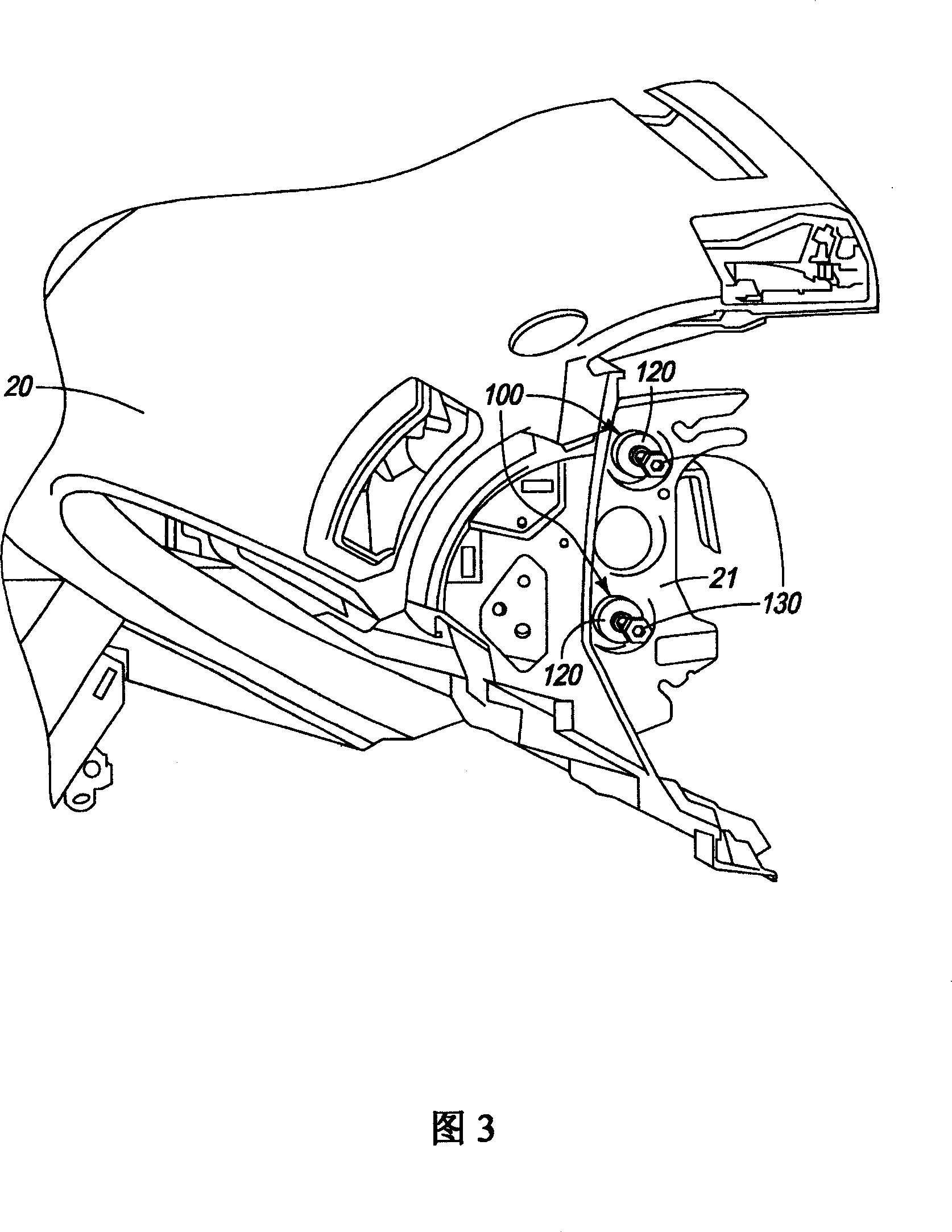

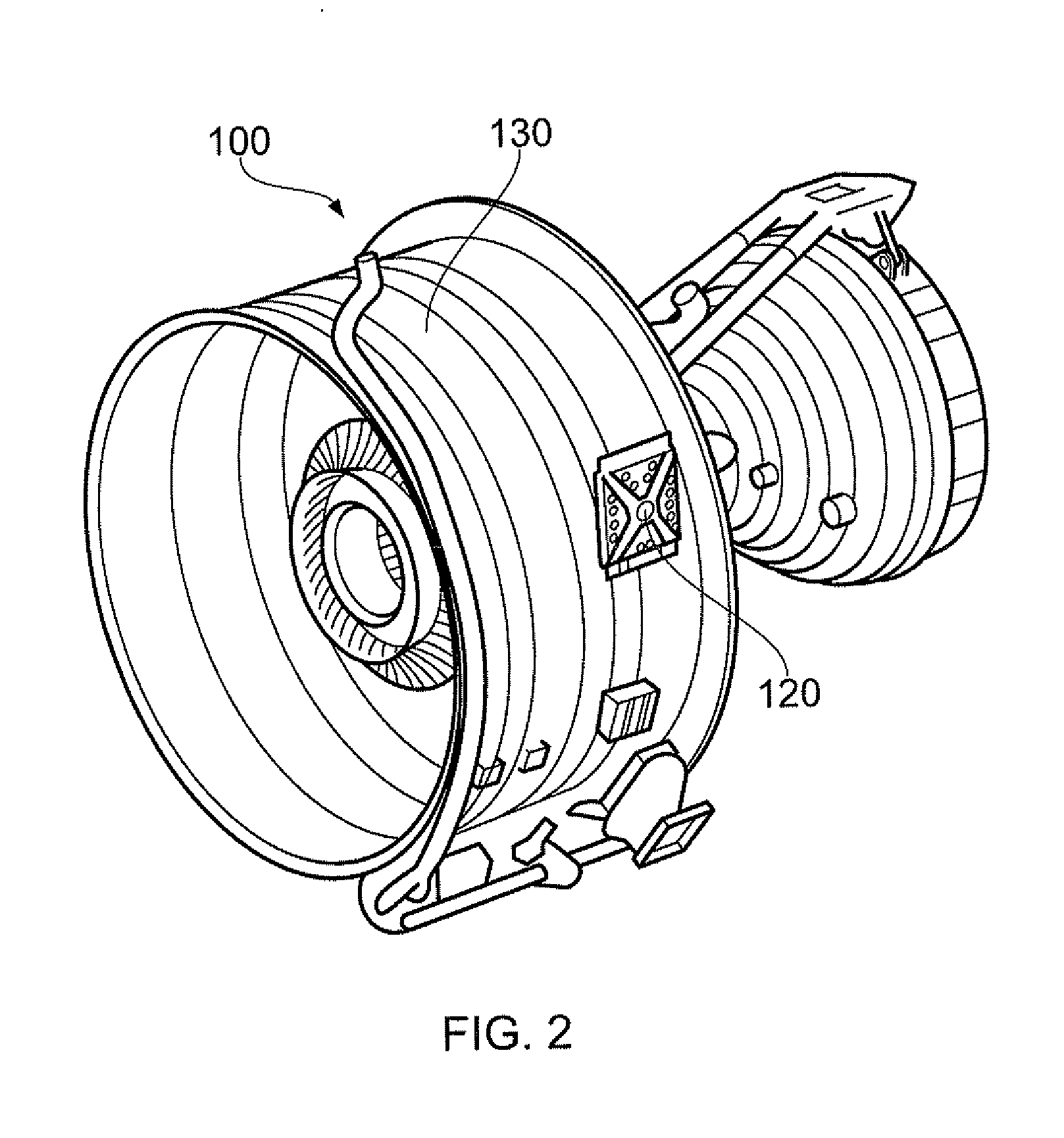

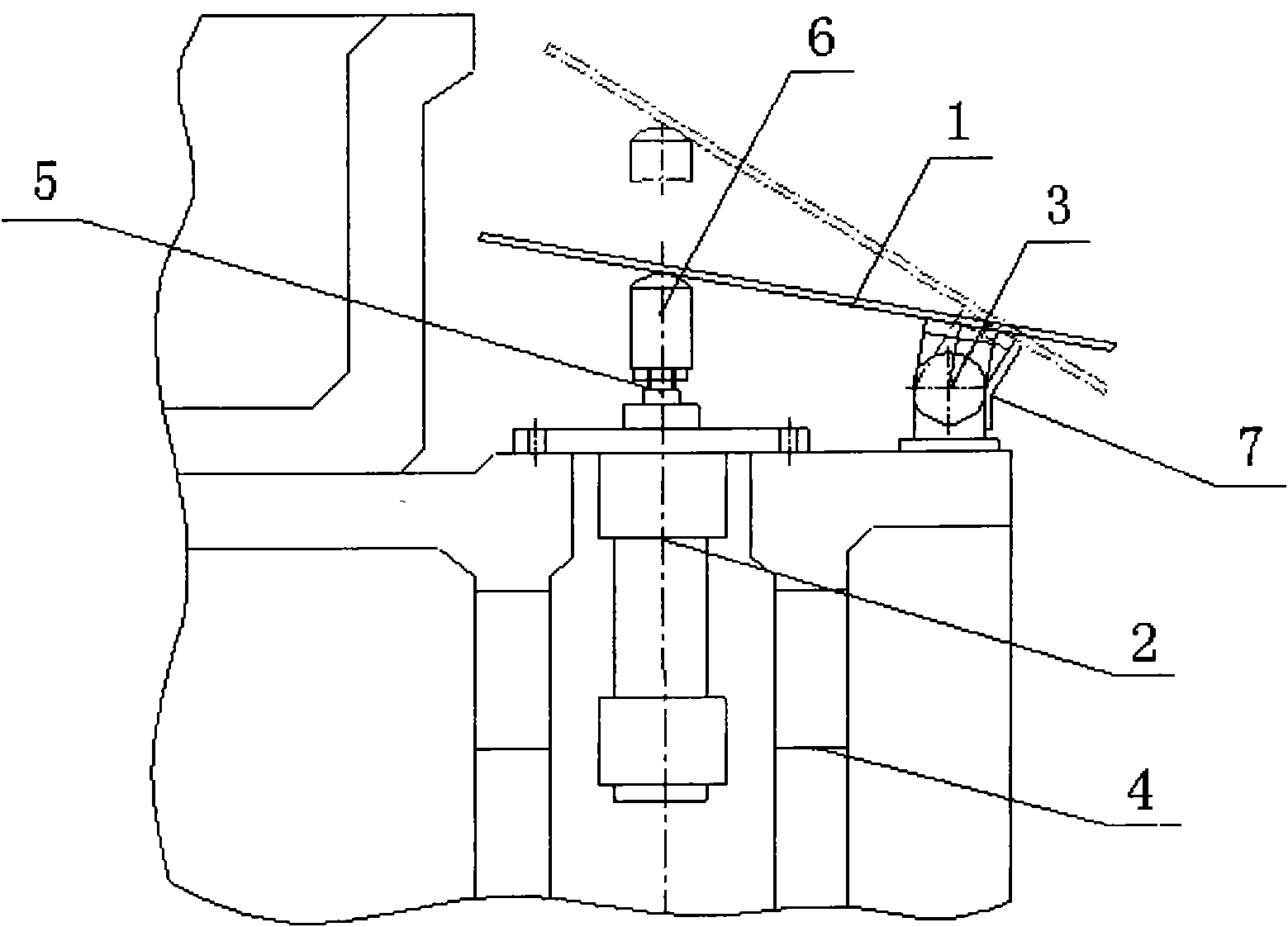

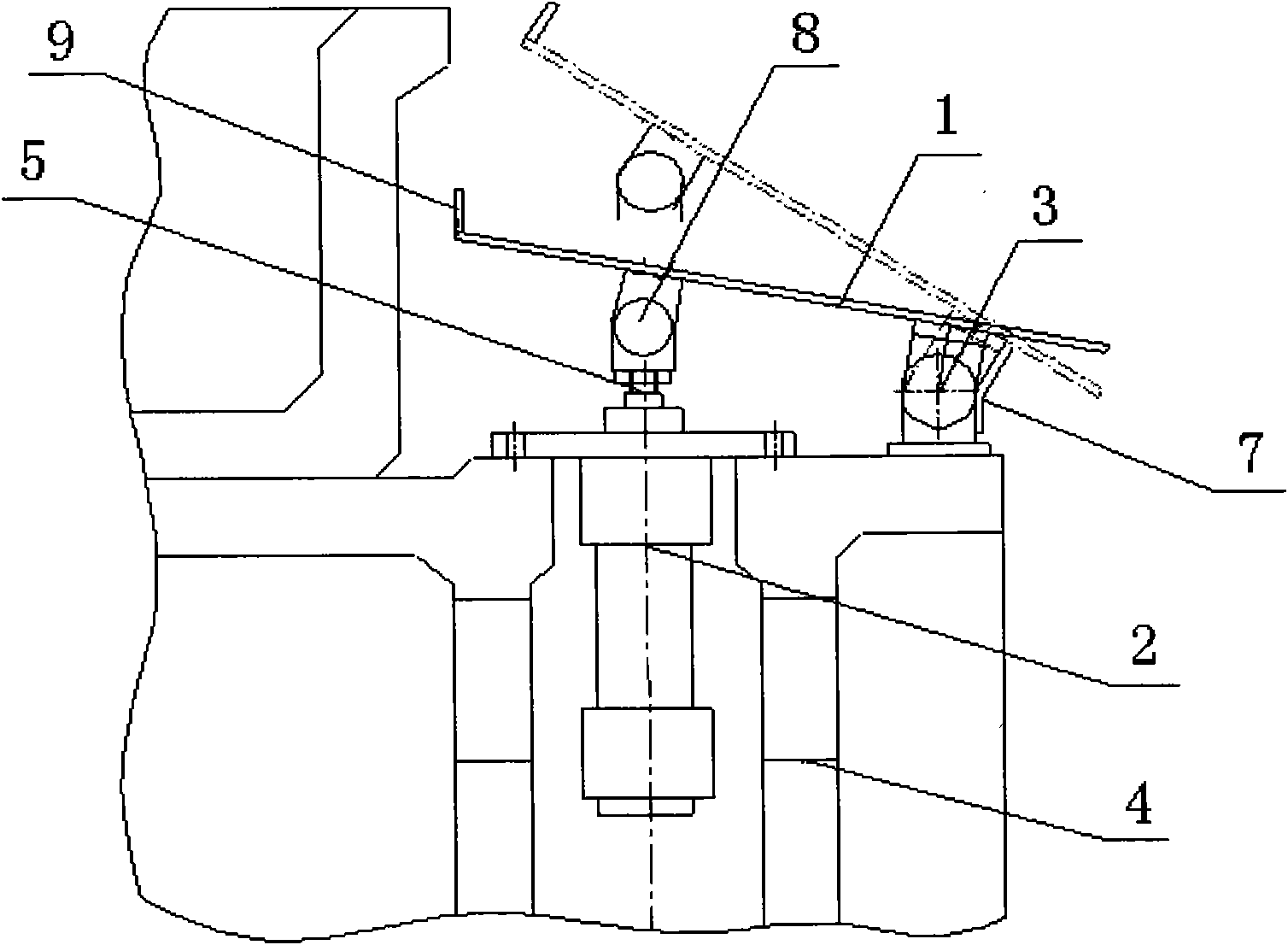

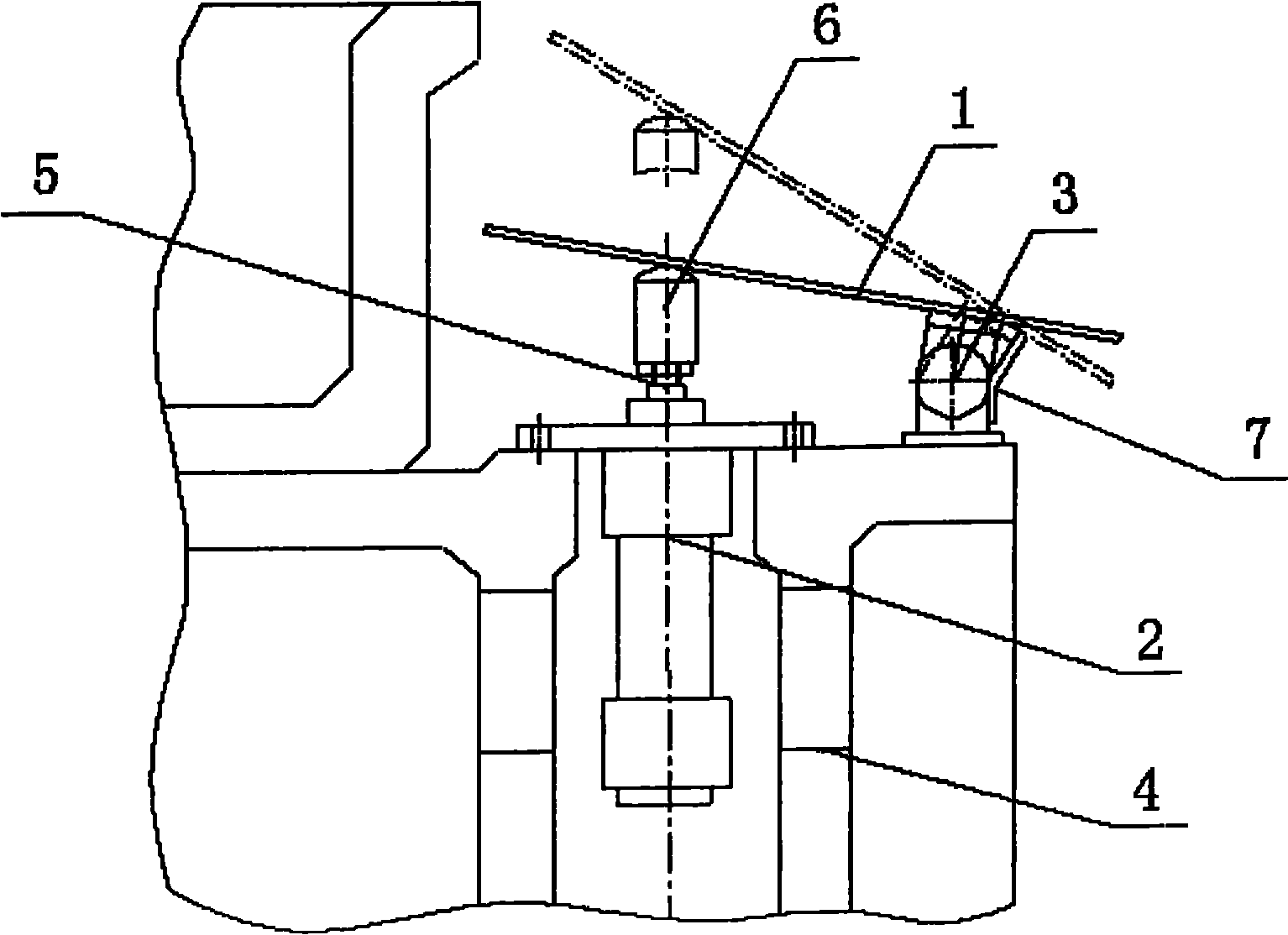

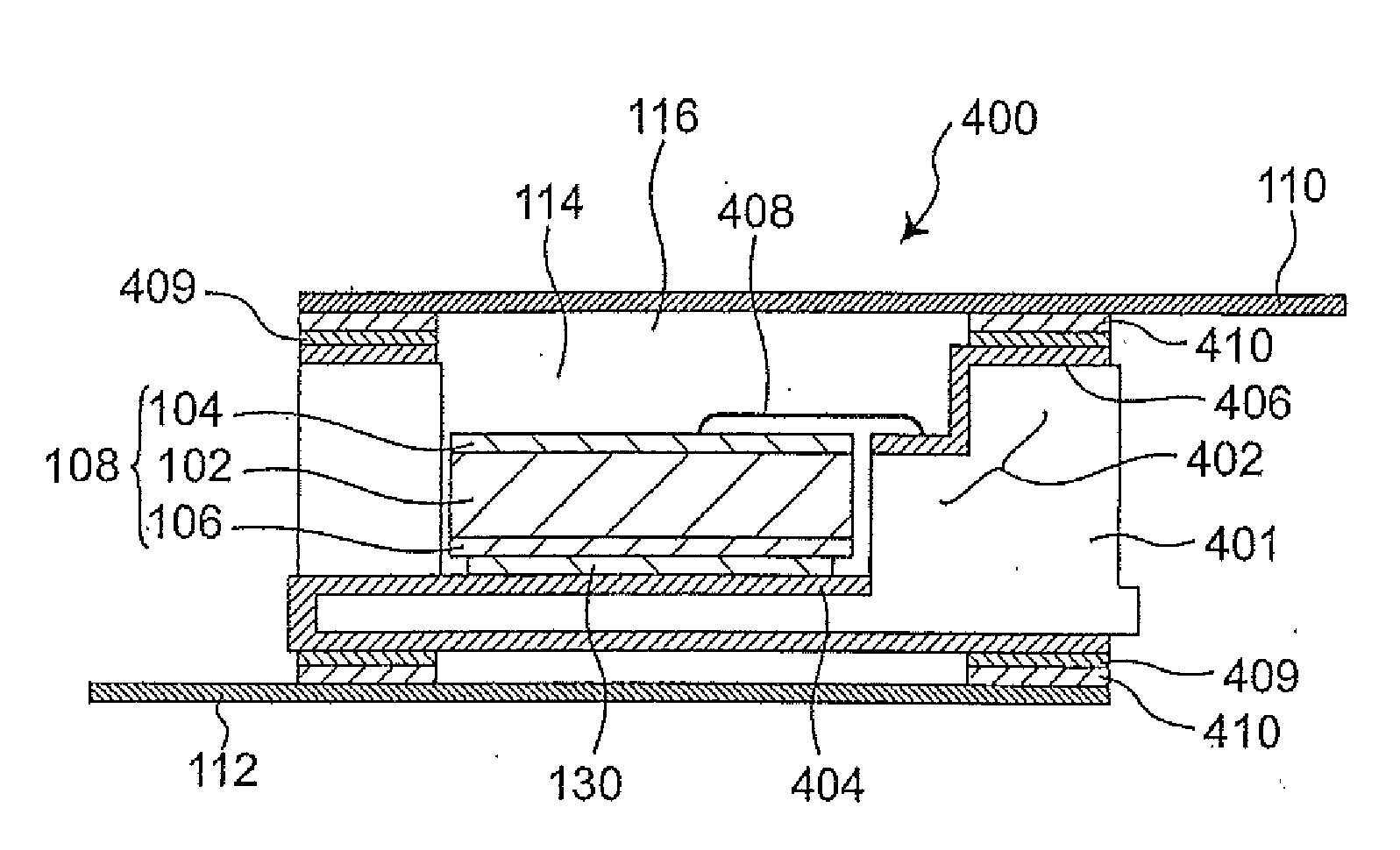

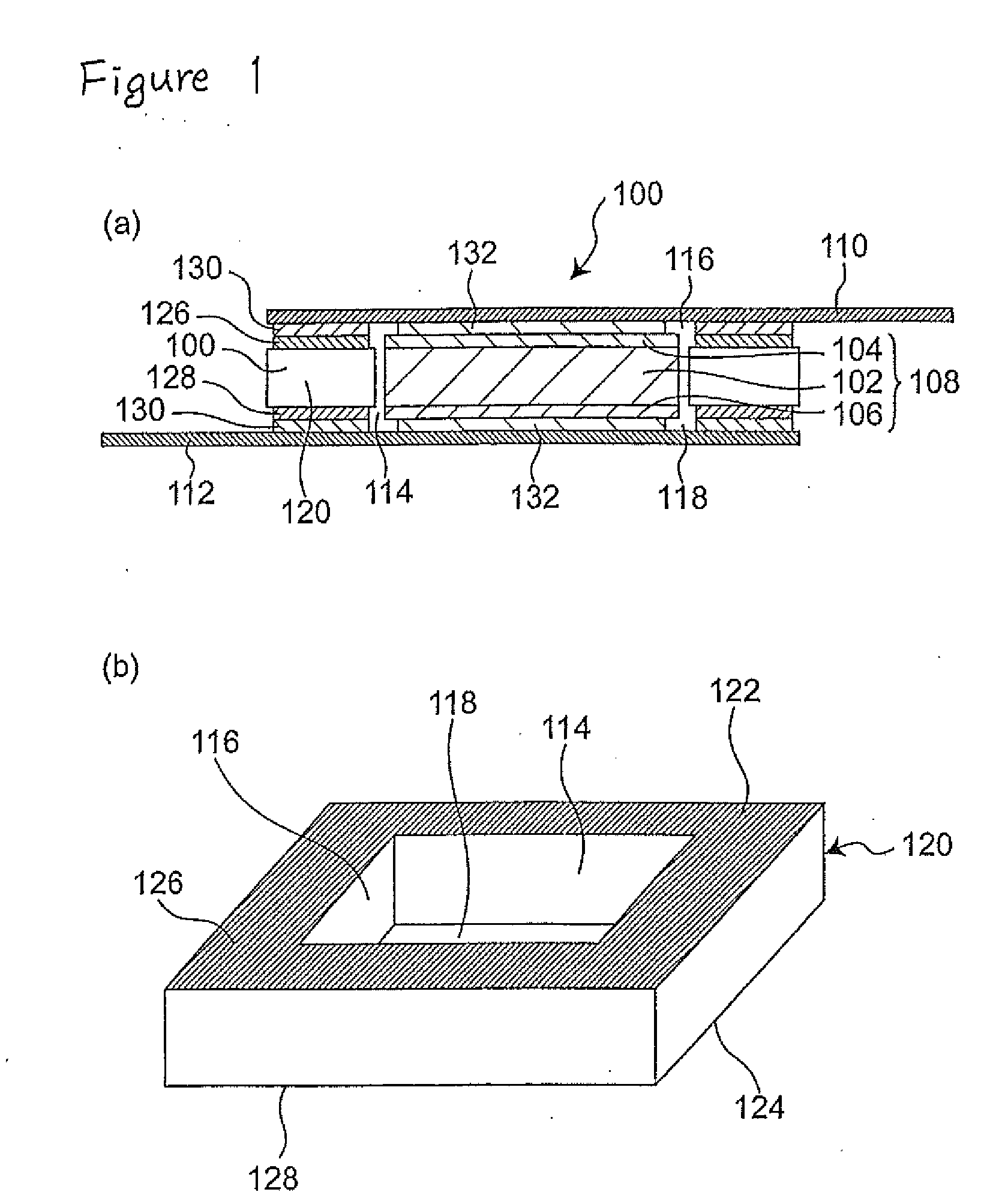

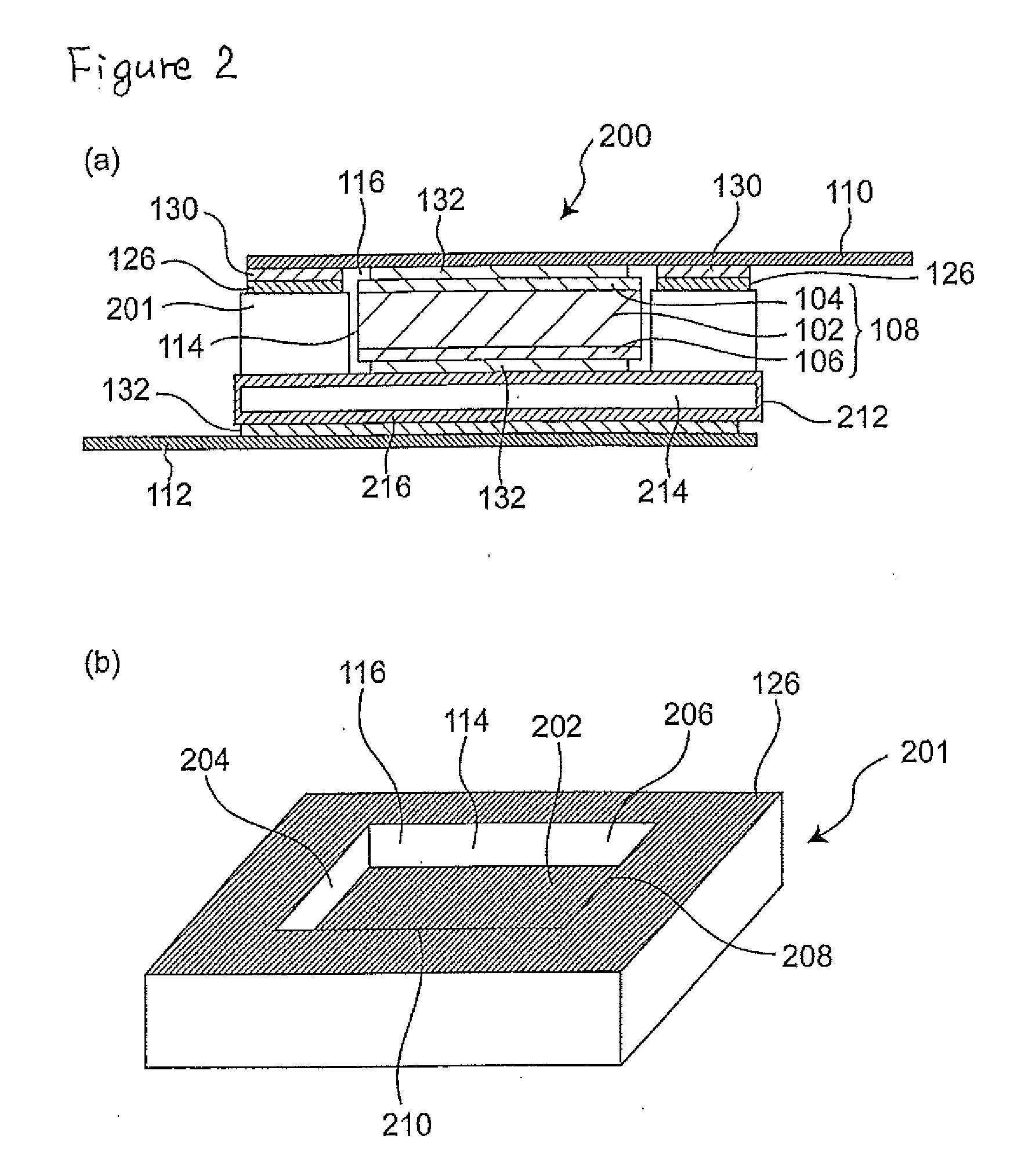

Tolerance compensating mounting device

A tolerance compensating mounting device (100, 100') has a threaded fastener (110, 110'), an outer member (120, 120') including a mounting bore, and a tubular member (130, 130', 230, 330, 430, 530, 630). The tubular member (130, 130', 230, 330, 430, 530, 630) has an internal surface (132a, 132a') rotatably coupled to the threaded fastener (110, 110') and an external surface (134a, 134a') rotatably coupled within the mounting bore of the outer member (120, 120') such that the tubular member (130, 130', 230, 330, 430, 530, 630) rotates about a center axis of the tubular member (130, 130', 230, 330, 430, 530, 630) in synchronization with rotation of the threaded fastener (110, 110') to move with respect to the outer member (120, 120') in a direction protruding from the outer member (120, 120') and then the threaded fastener (110, 110') subsequently rotates with respect to the tubular member (130, 130', 230, 330, 430, 530, 630) upon further rotation of the threaded fastener (110, 110'). The tubular member (130, 130', 230, 330, 430, 530, 630) has a tool engaging structure (138, 138', 238, 338, 438, 538, 638) formed on an axial end surface of the tubular member (130, 130', 230, 330, 430, 530, 630) at a first axial end portion with the tool engaging structure (138, 138', 238, 338, 438, 538, 638) being radially spaced between the external surface (134a, 134a') and the internal surface (132a, 132a') of the tubular member (130, 130', 230, 330, 430, 530, 630).

Owner:NISSAN MOTOR CO LTD

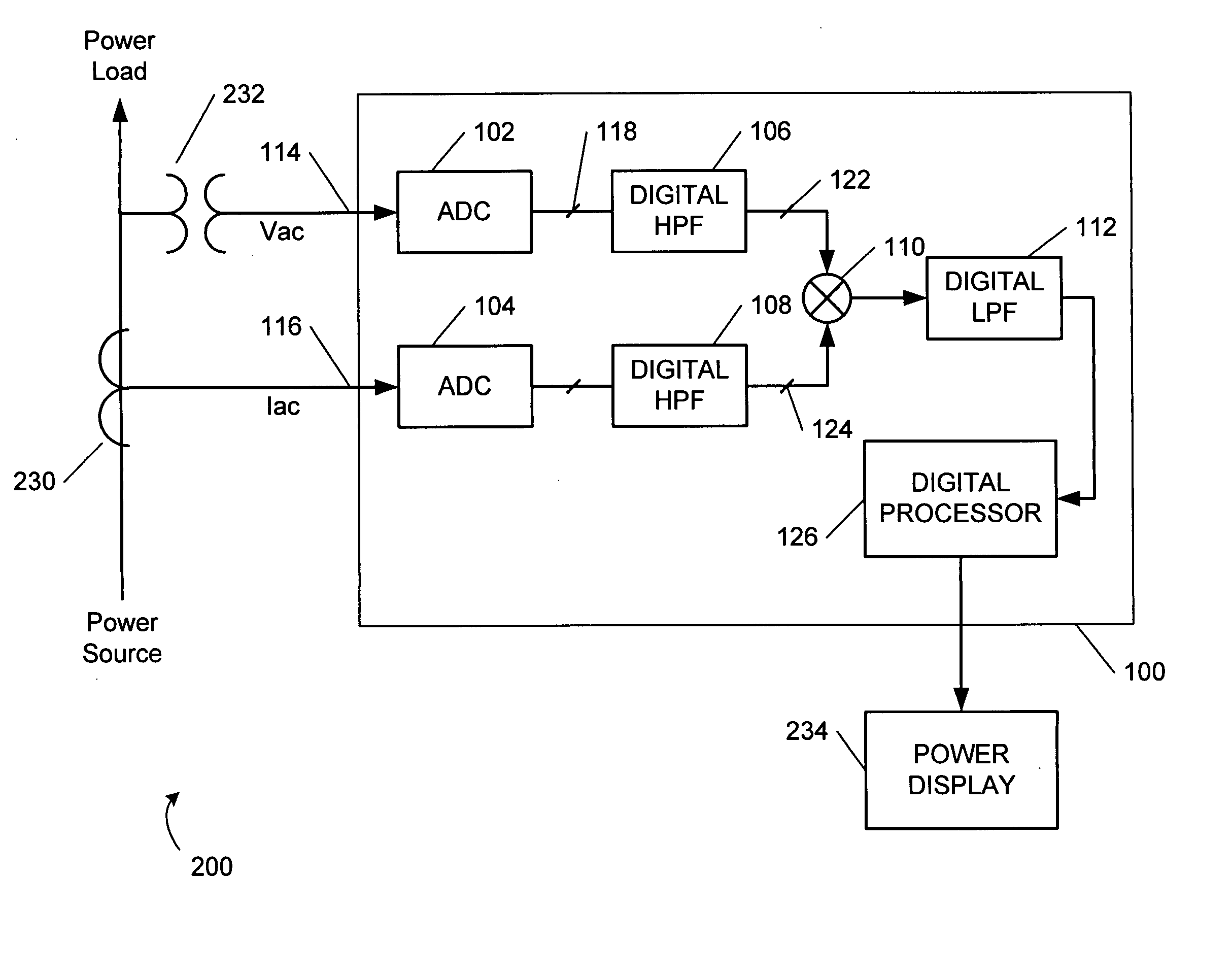

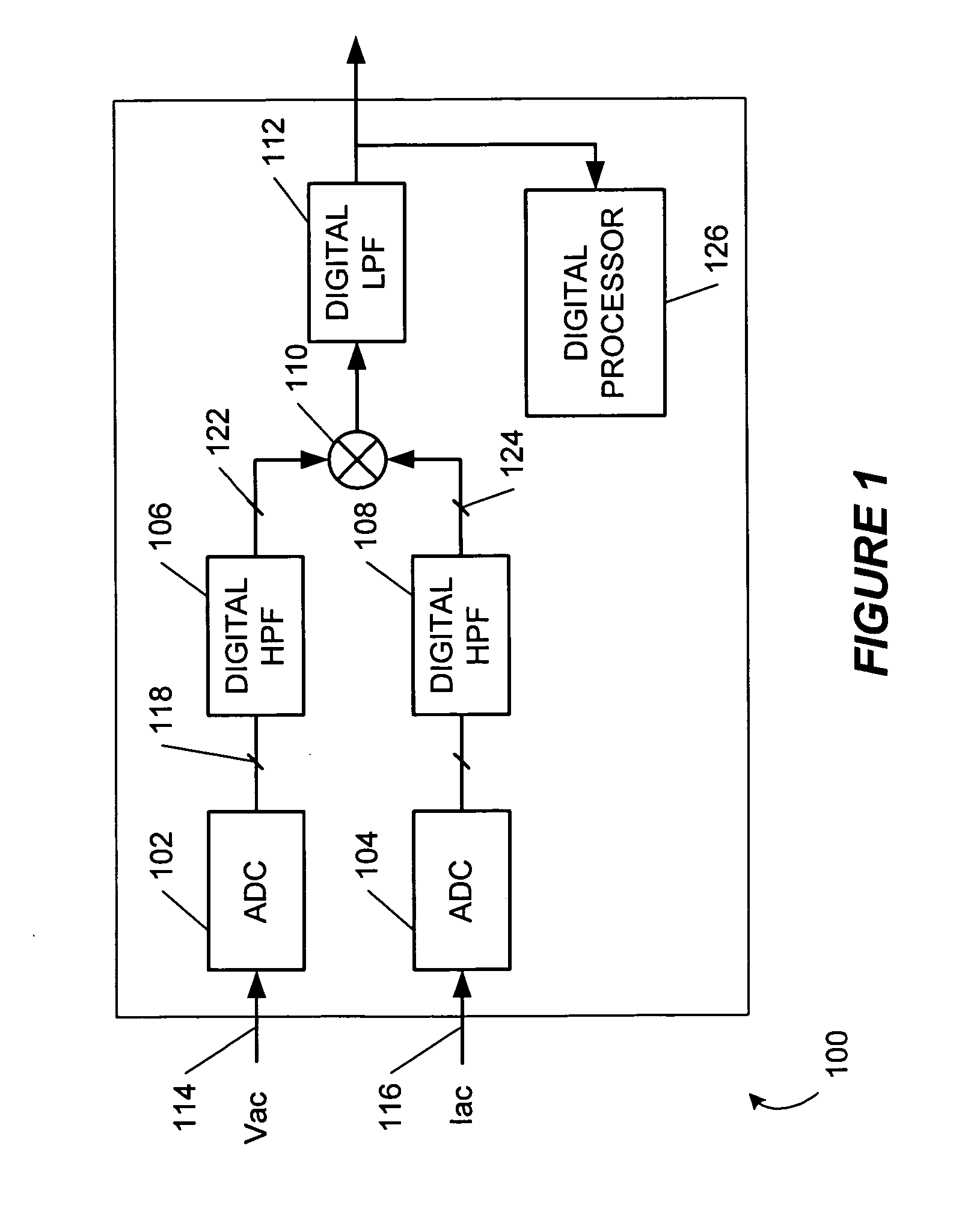

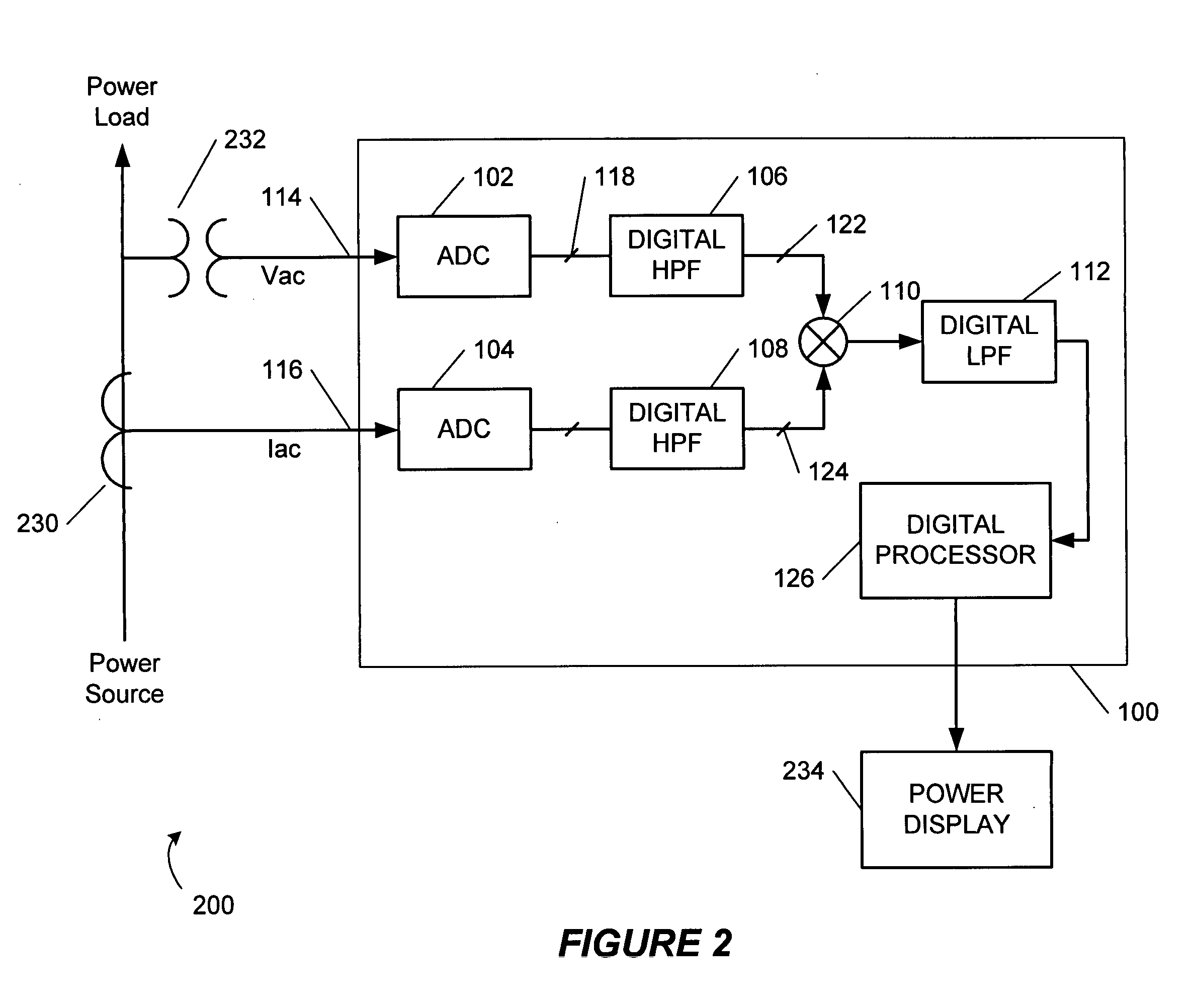

Direct current offset cancellation and phase equalization for power metering devices

InactiveUS20060028197A1Reduce criticalityFrequency bandwidth is limitedCurrent/voltage measurementDynamo-electric motor metersCurrent channelOffset cancellation

Owner:MICROCHIP TECH INC

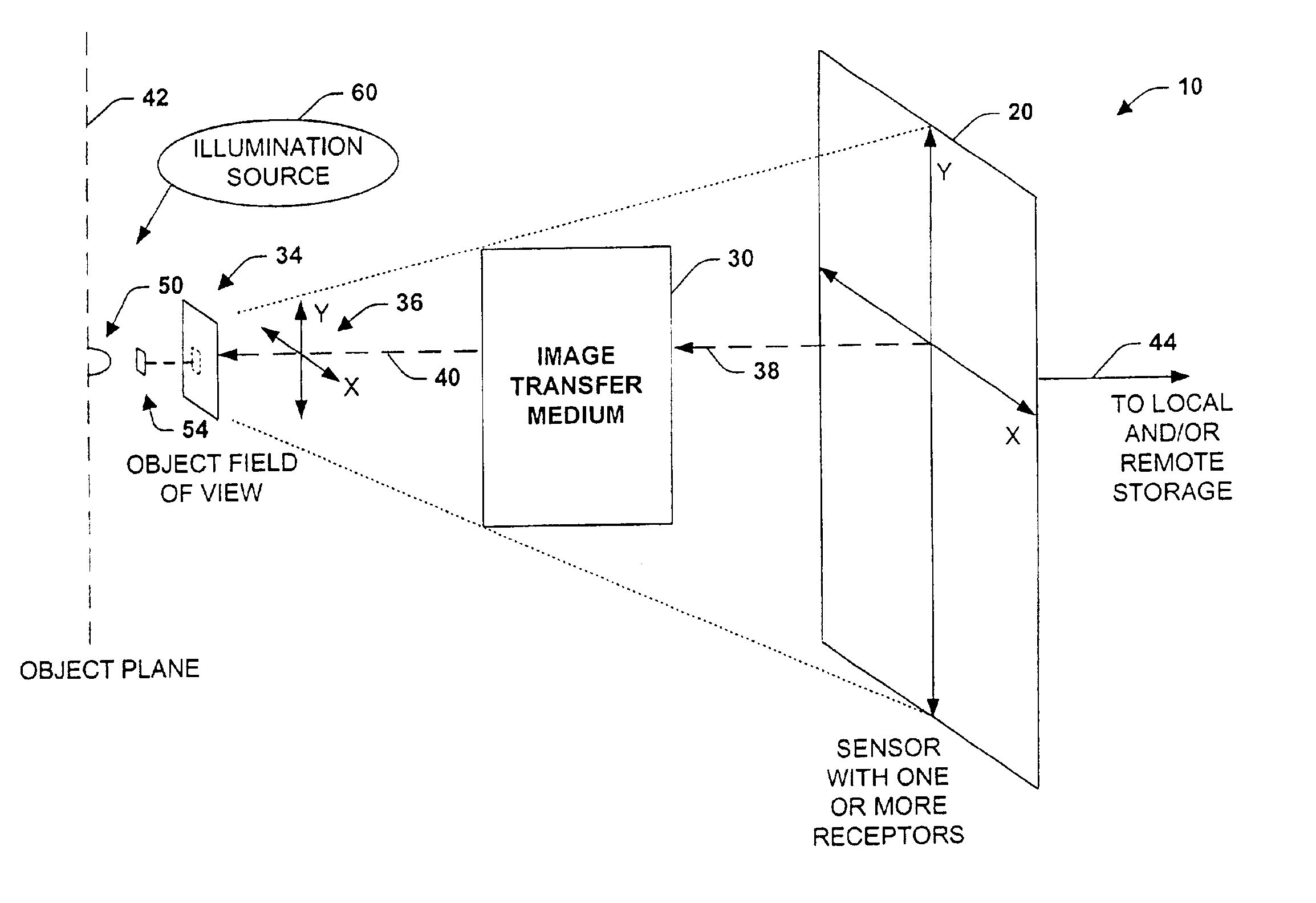

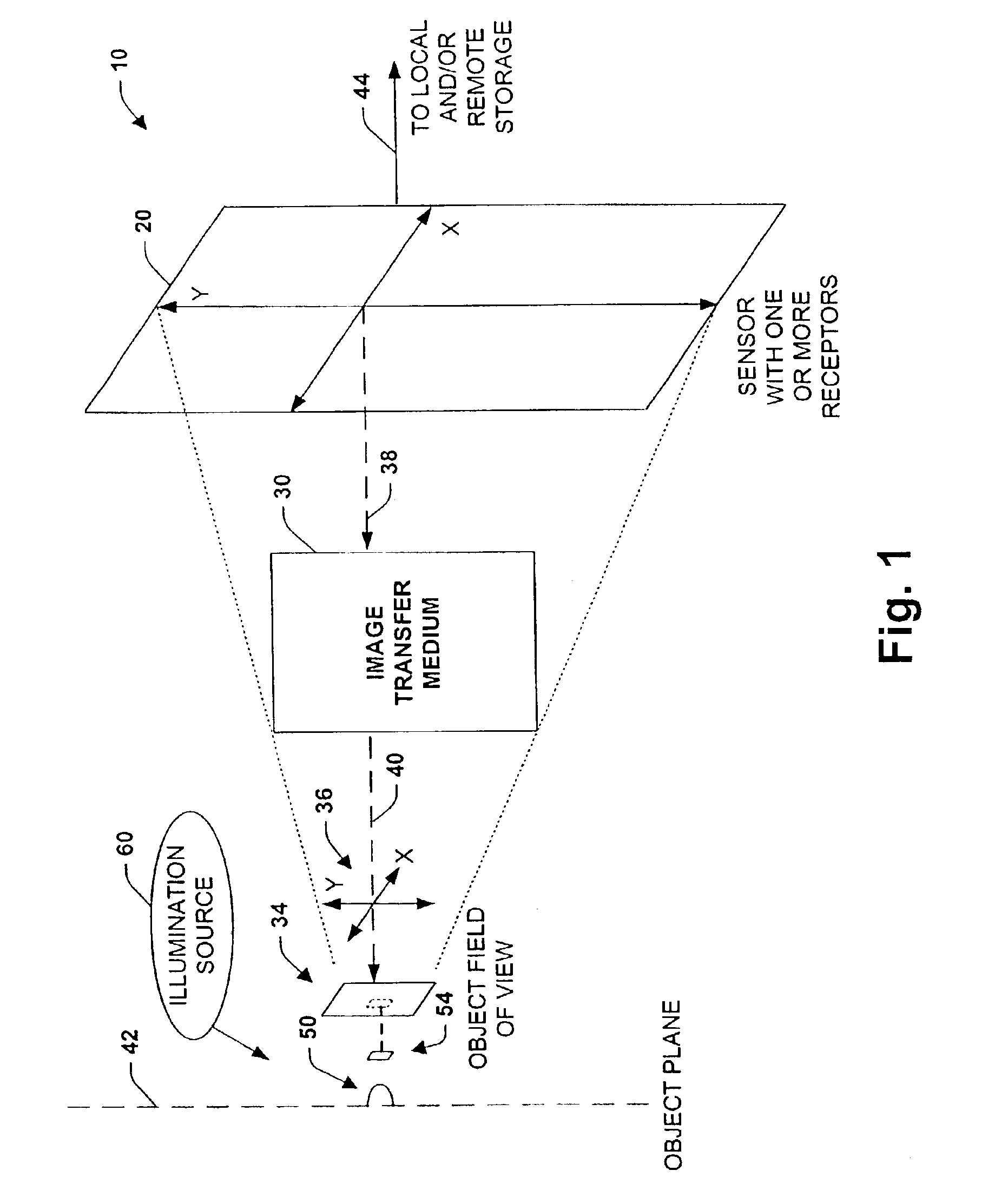

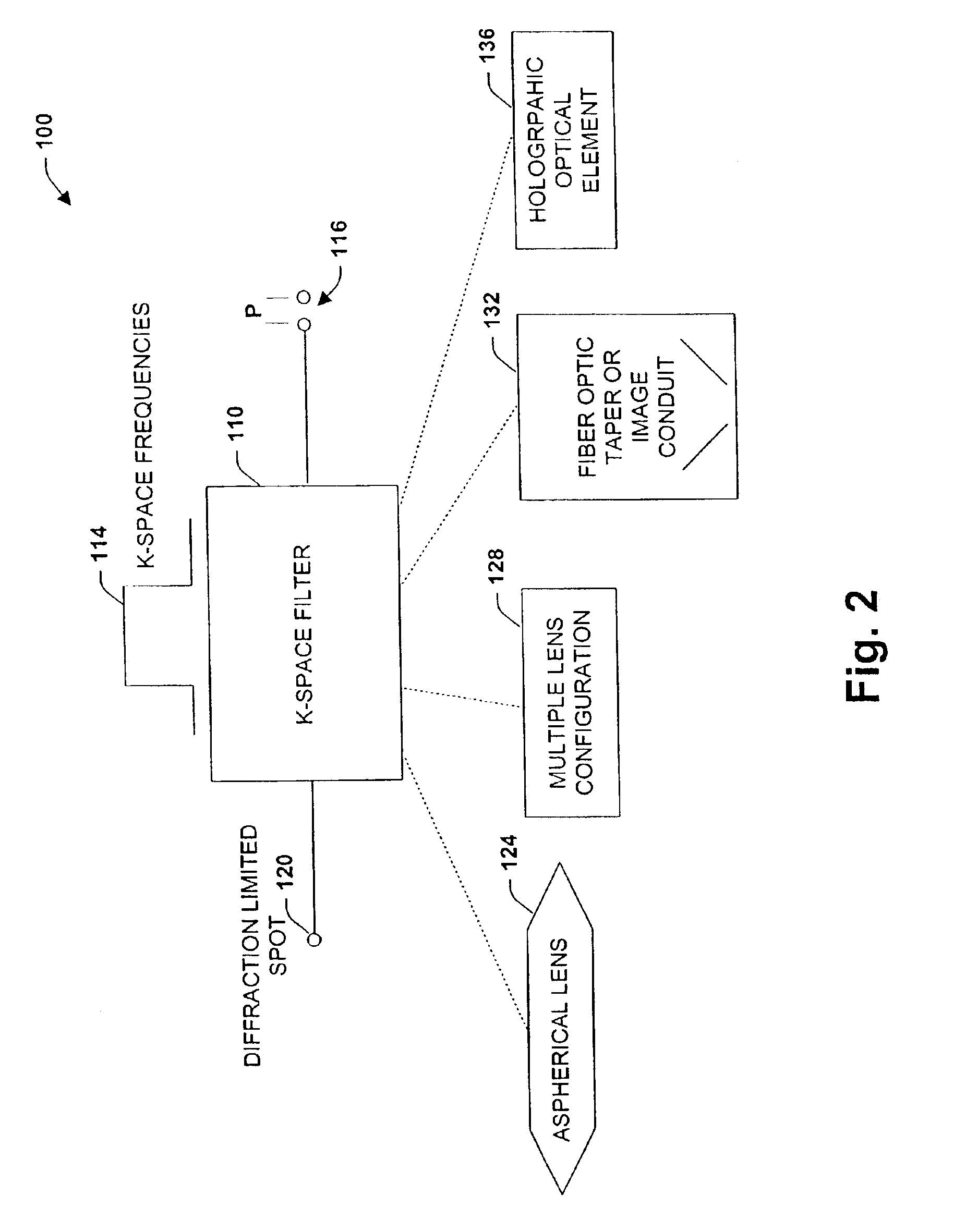

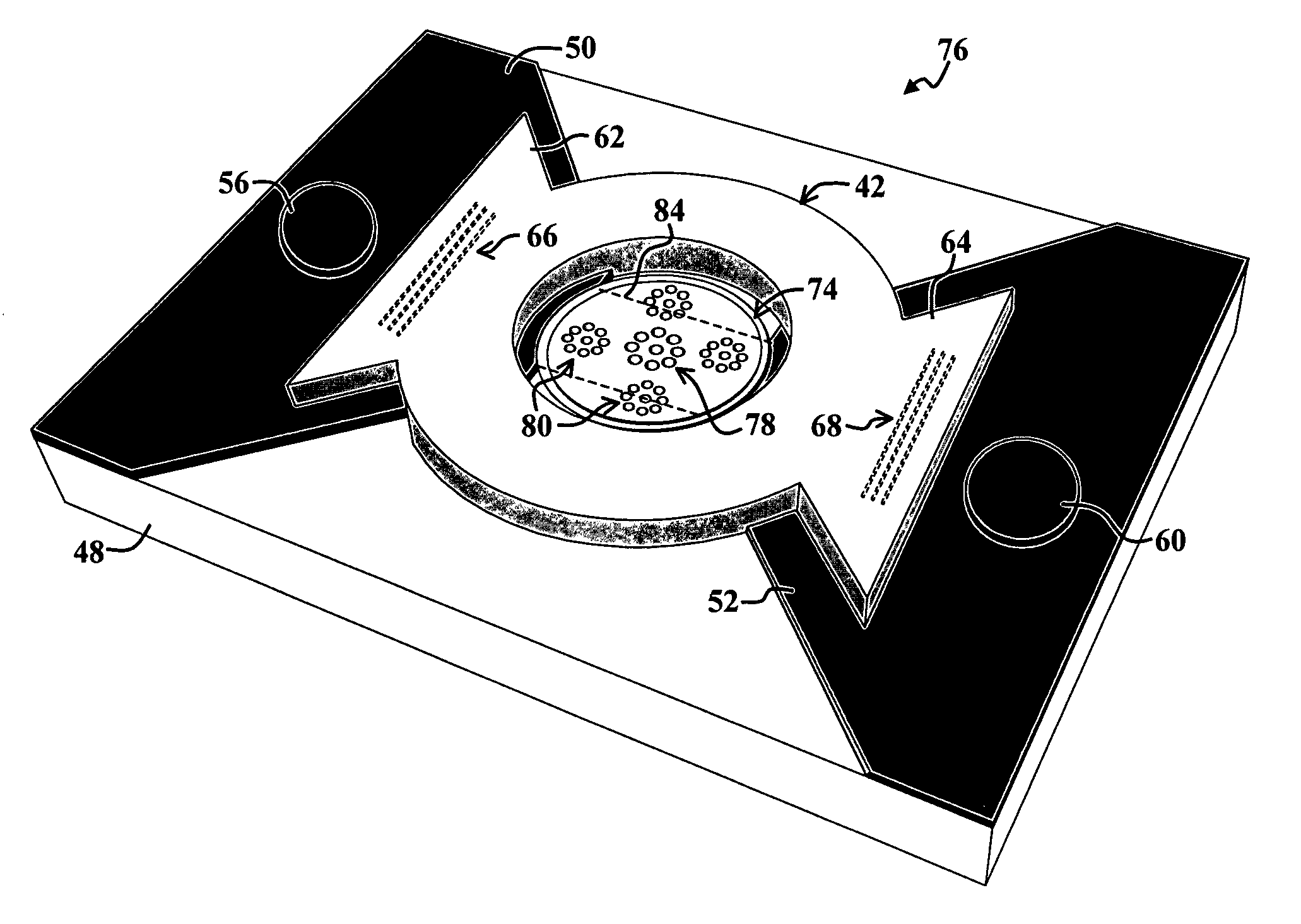

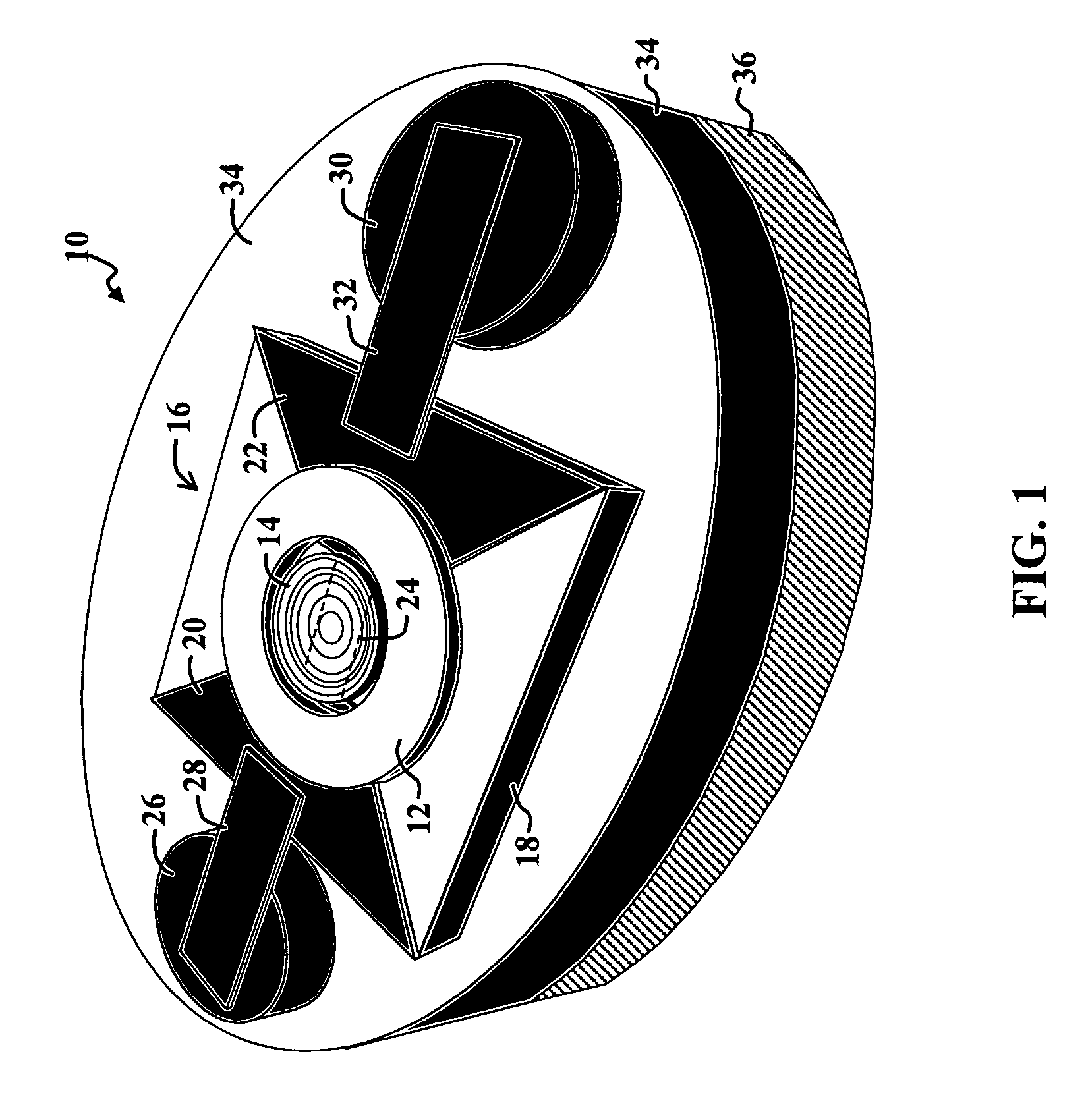

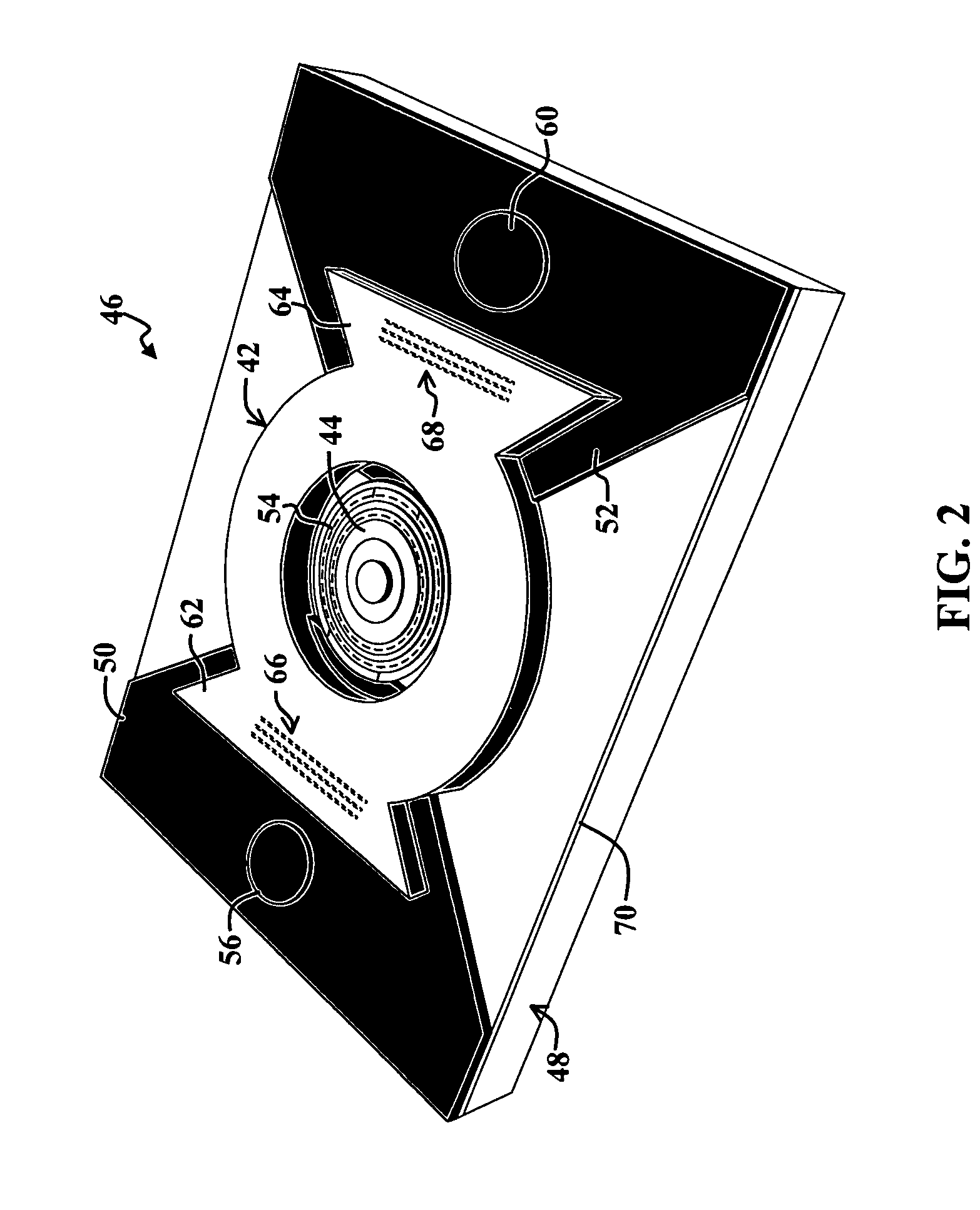

Imaging system and methodology employing reciprocal space optical design

InactiveUS6872930B2Higher Effective MagnificationExpand field of viewBeam/ray focussing/reflecting arrangementsSolid-state devicesImage systemDisplay device

An imaging system and methodology is provided to facilitate optical imaging performance. The system includes a sensor having one or more receptors and an image transfer medium to scale the sensor and receptors to an object field of view. A computer, memory, and / or display associated with the sensor provides storage and / or display of information relating to output from the receptors to produce and / or process an image, wherein a plurality of illumination sources can also be utilized in conjunction with the image transfer medium. The image tranfer medium can be configured as a k-space filter that correlates a pitch associated with the receptors to a diffraction-limited spot within the object field of view, wherein the pitch can be unit-mapped to about the size of the diffraction-limited spot within the object field of view.

Owner:PIXEL MATCHED HLDG

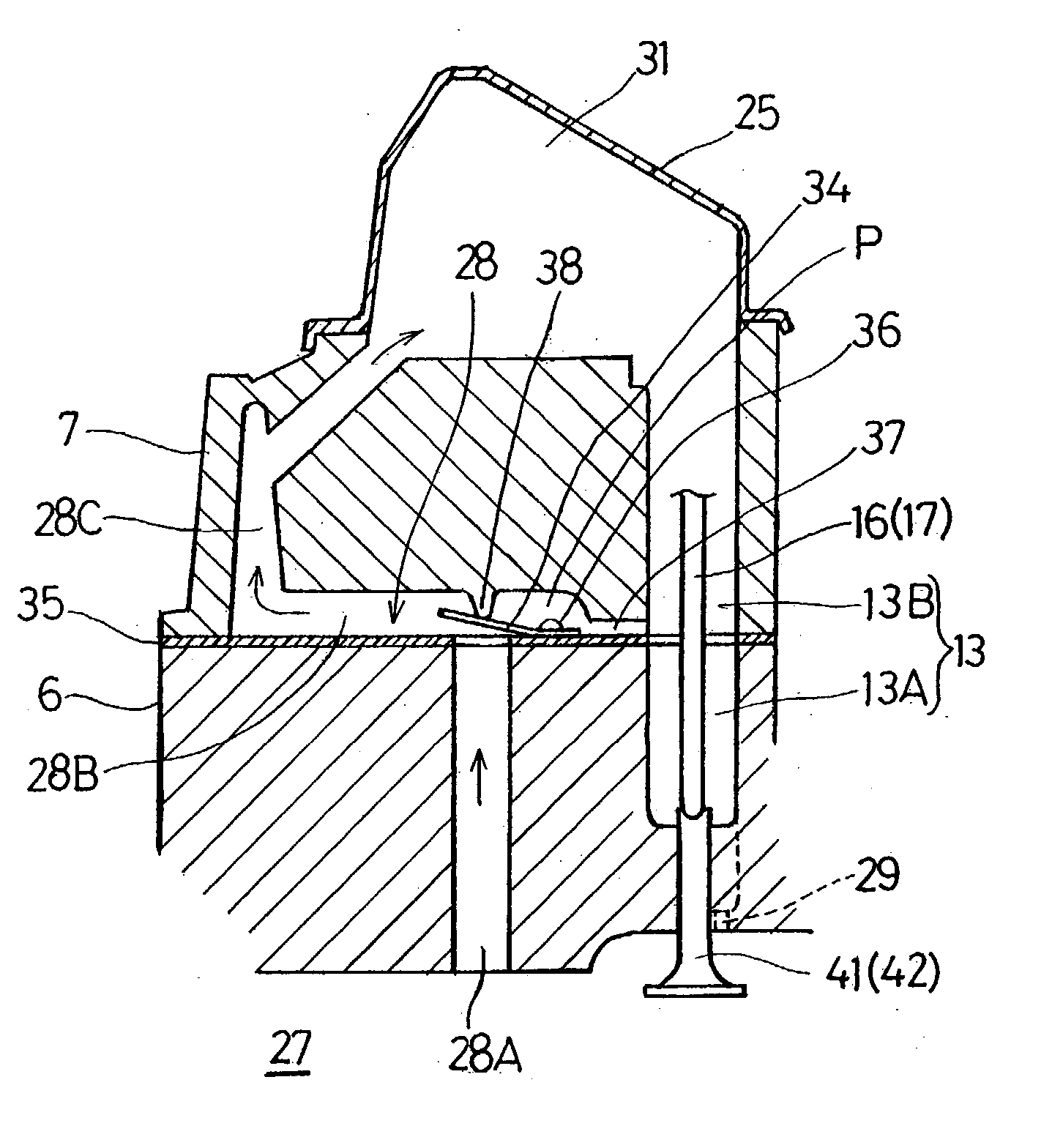

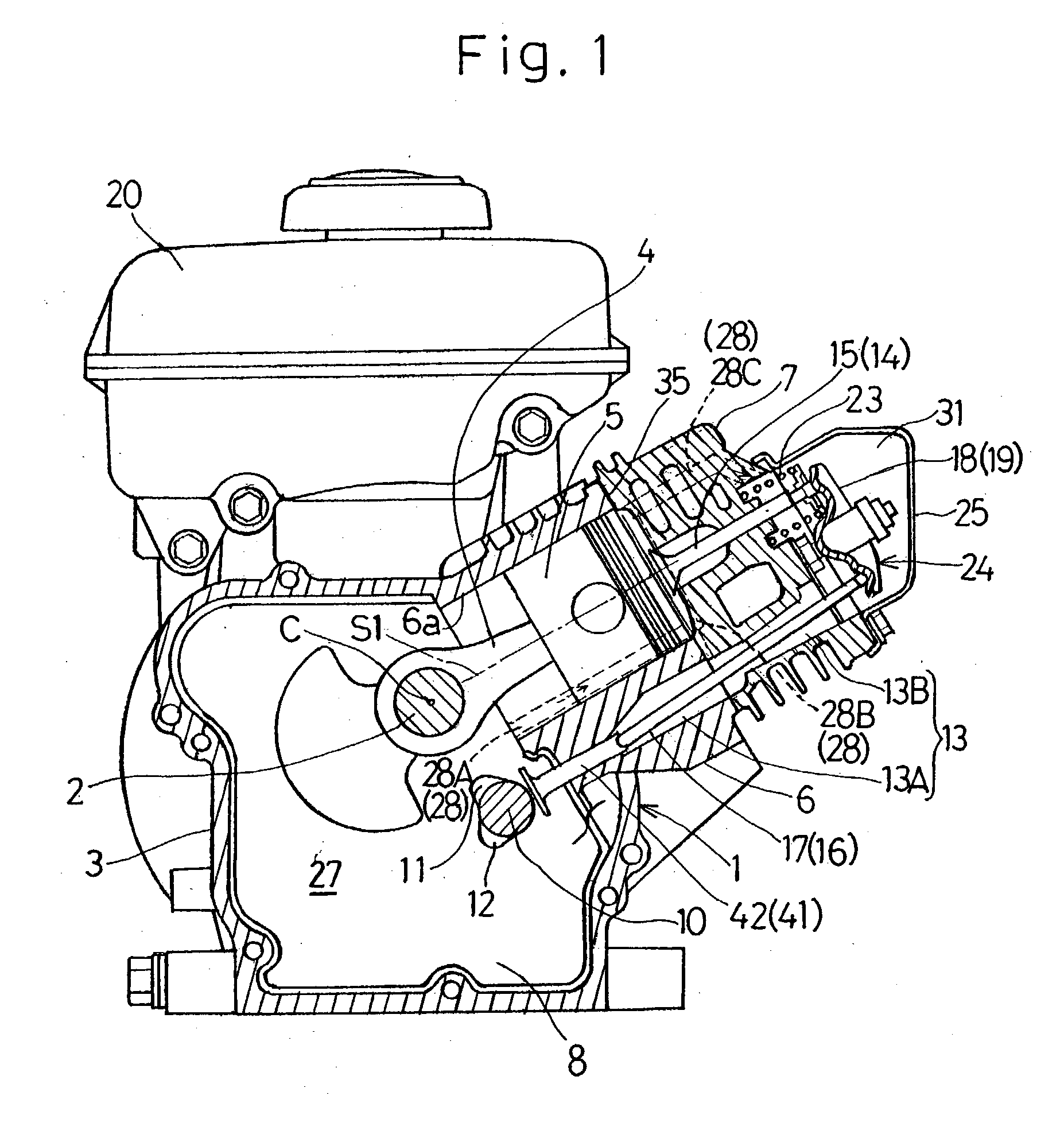

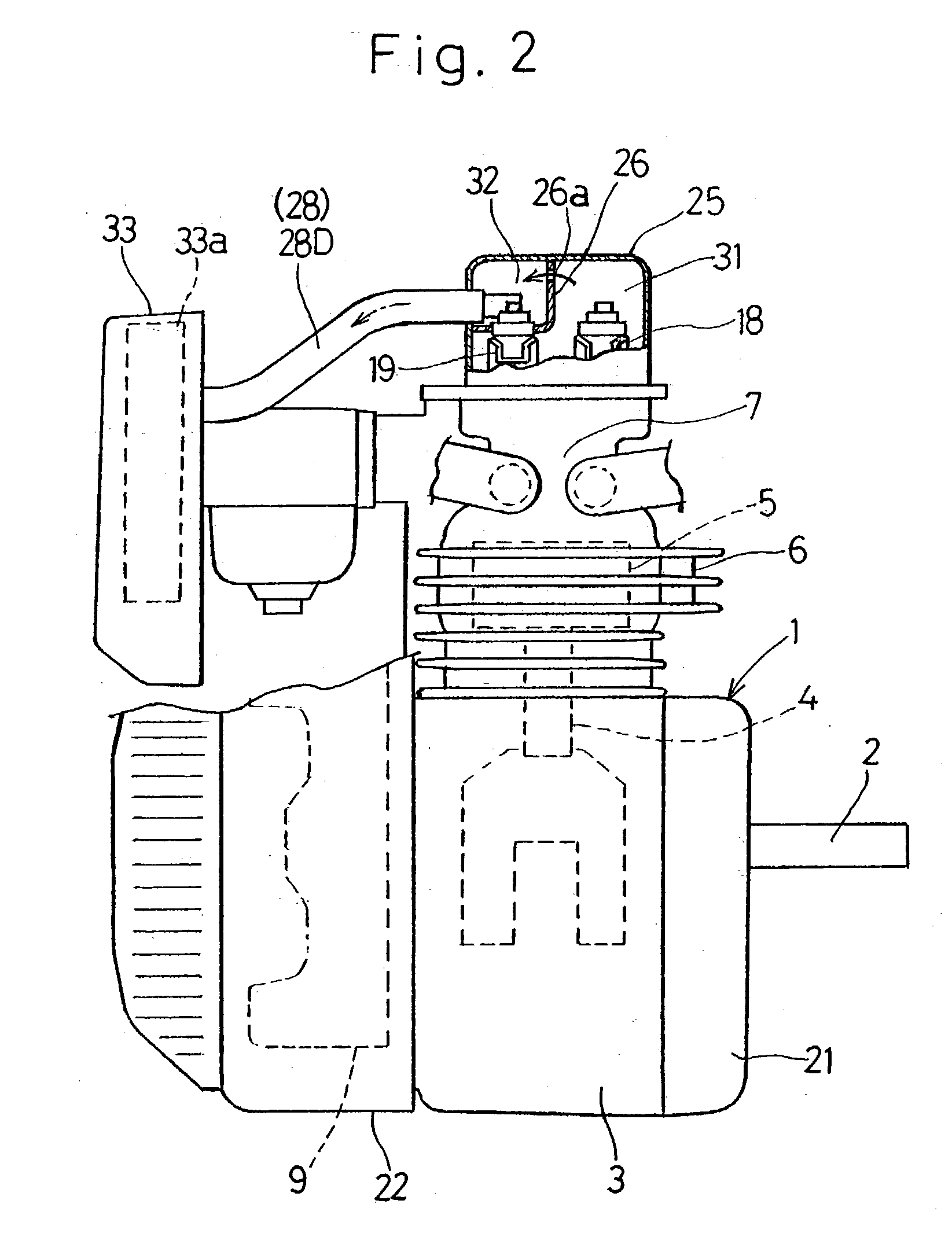

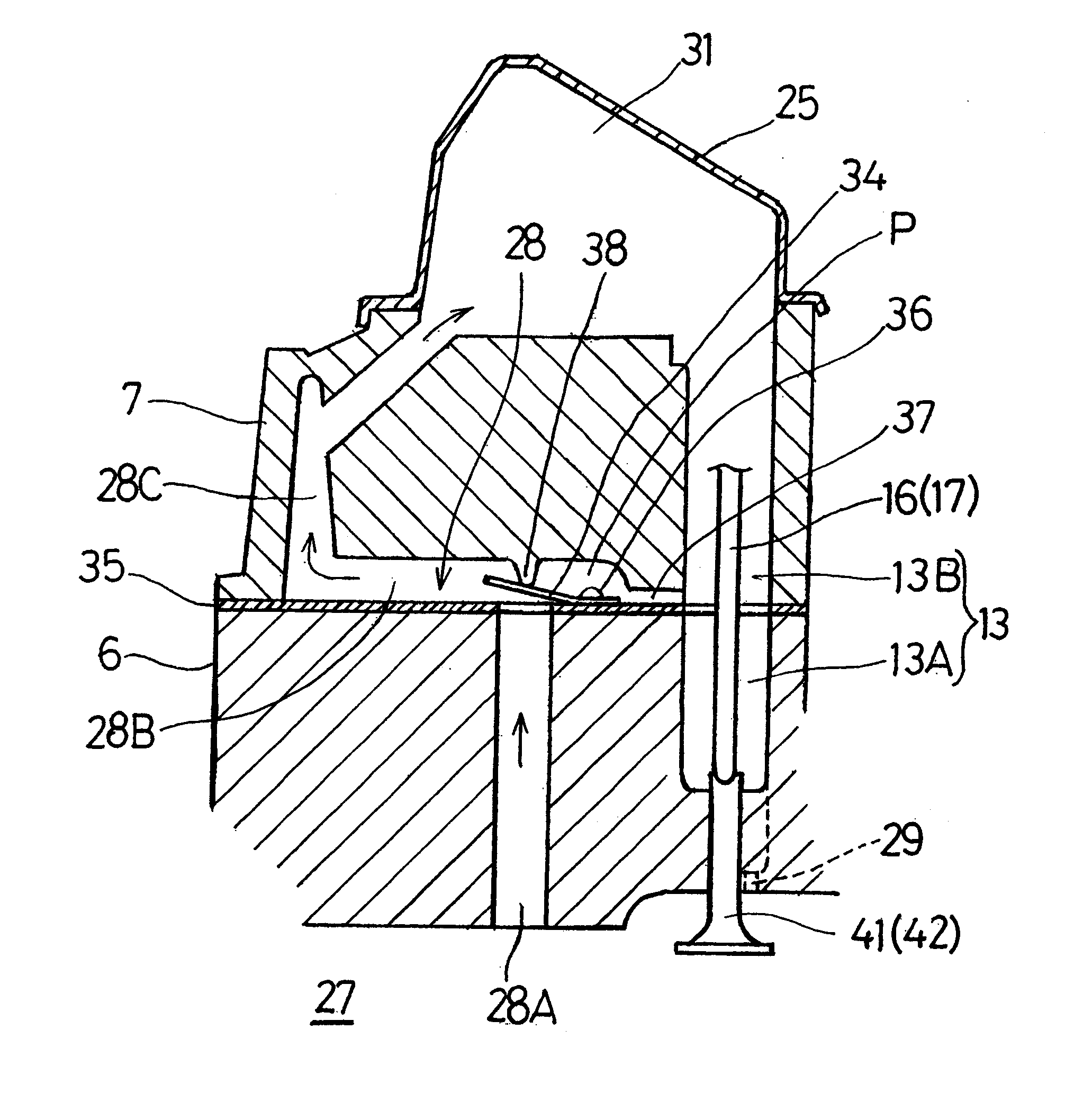

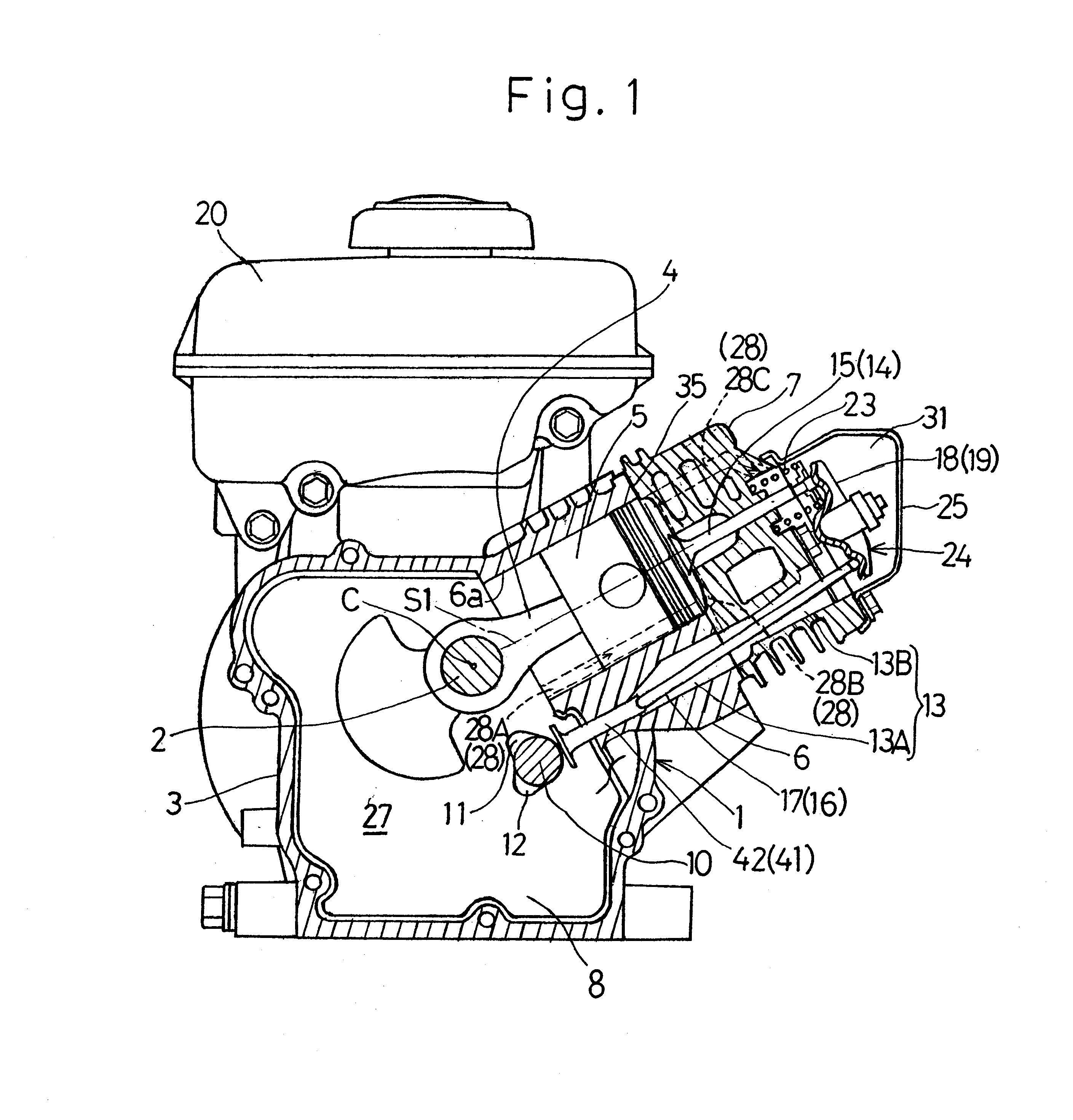

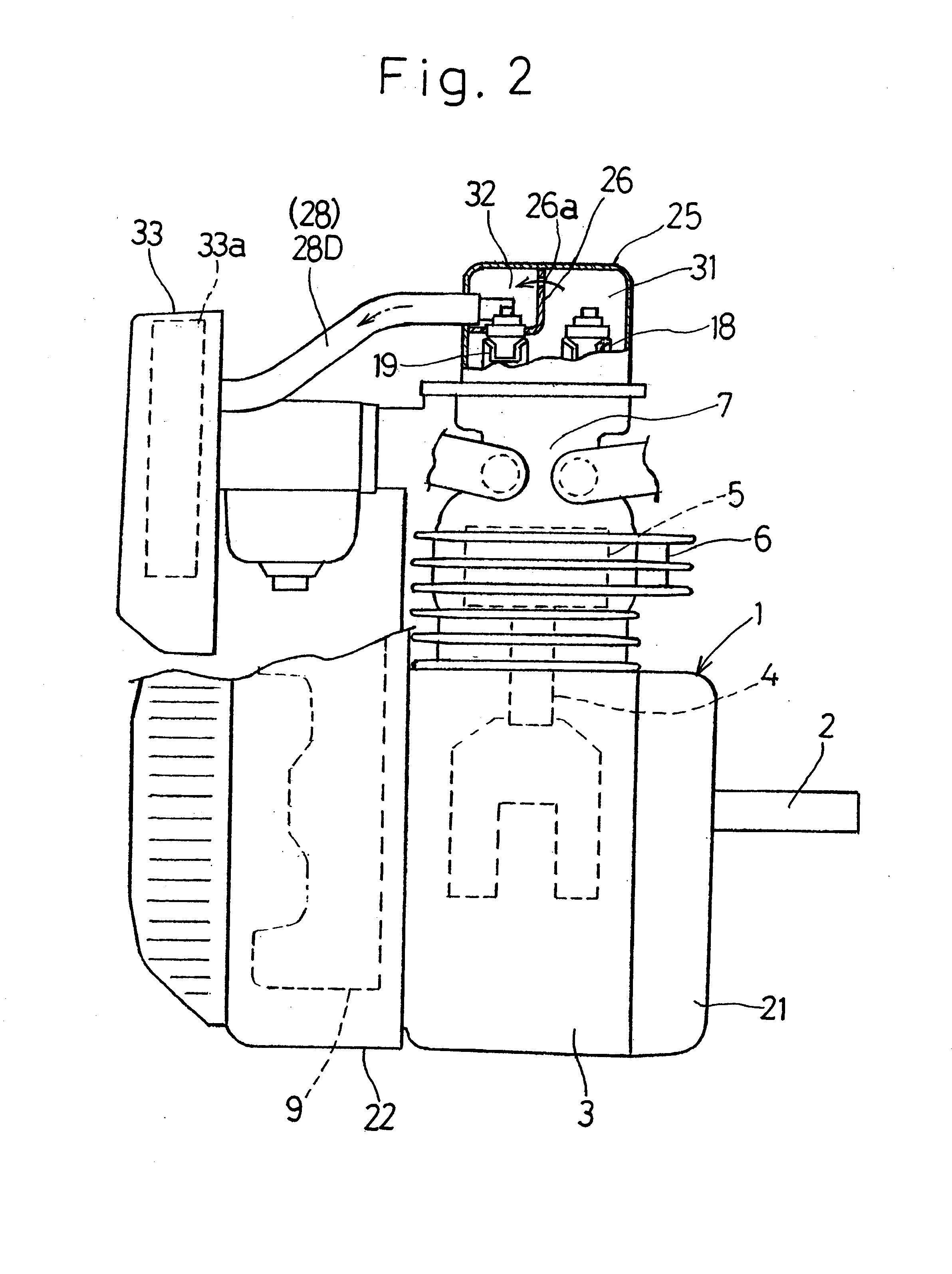

Breathing device for internal combustion engine

InactiveUS20030150437A1Low costSmall sizeEngine sealsInternal combustion piston enginesCombustionEngineering

To provide a breathing device for an internal combustion engine, wherein the structure around the check valve is simplified so that the engine as a whole can be manufactured compact, the breathing device includes a check valve (34) for fluid connecting, a crank chamber (27) and a rocker arm chamber (31) in the combustion engine. The check valve (34) is disposed in a head gasket (35) that is interposed between a cylinder block (6) and a cylinder head (7). The check valve (34) is in the form of a reed valve separate from the head gasket (35) and is supported by the head gasket (35) by means of a rivet (36).

Owner:KAWASAKI HEAVY IND LTD

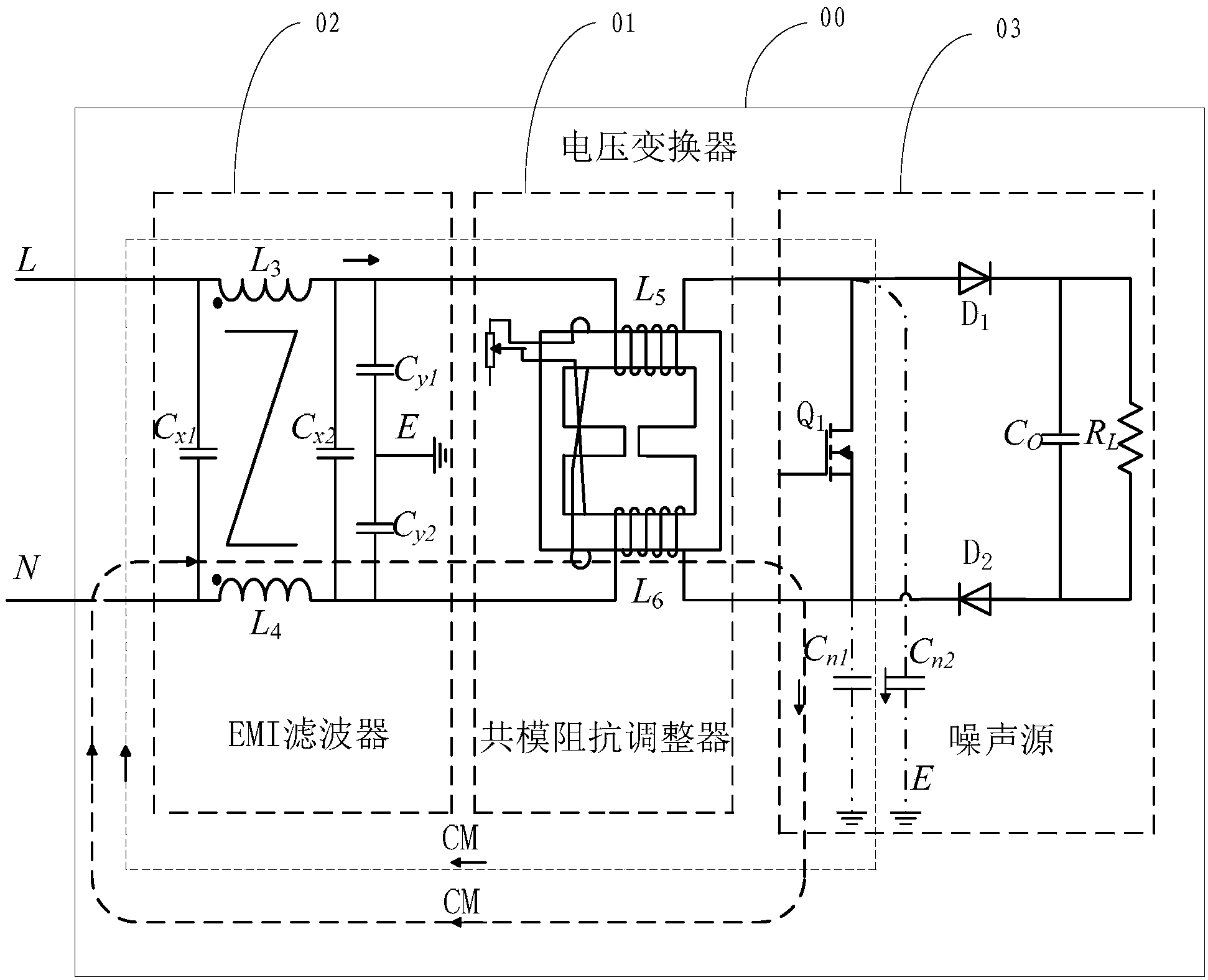

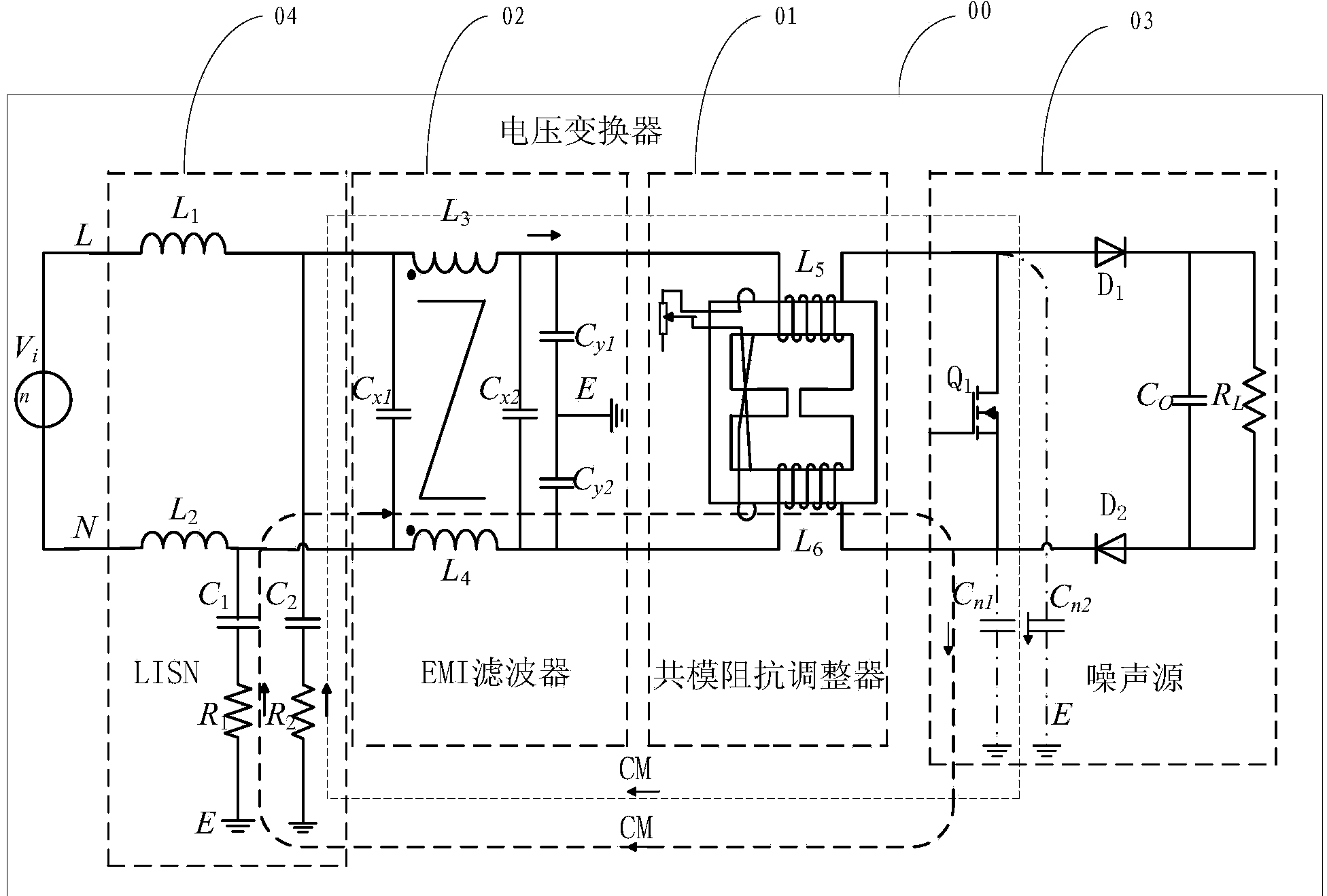

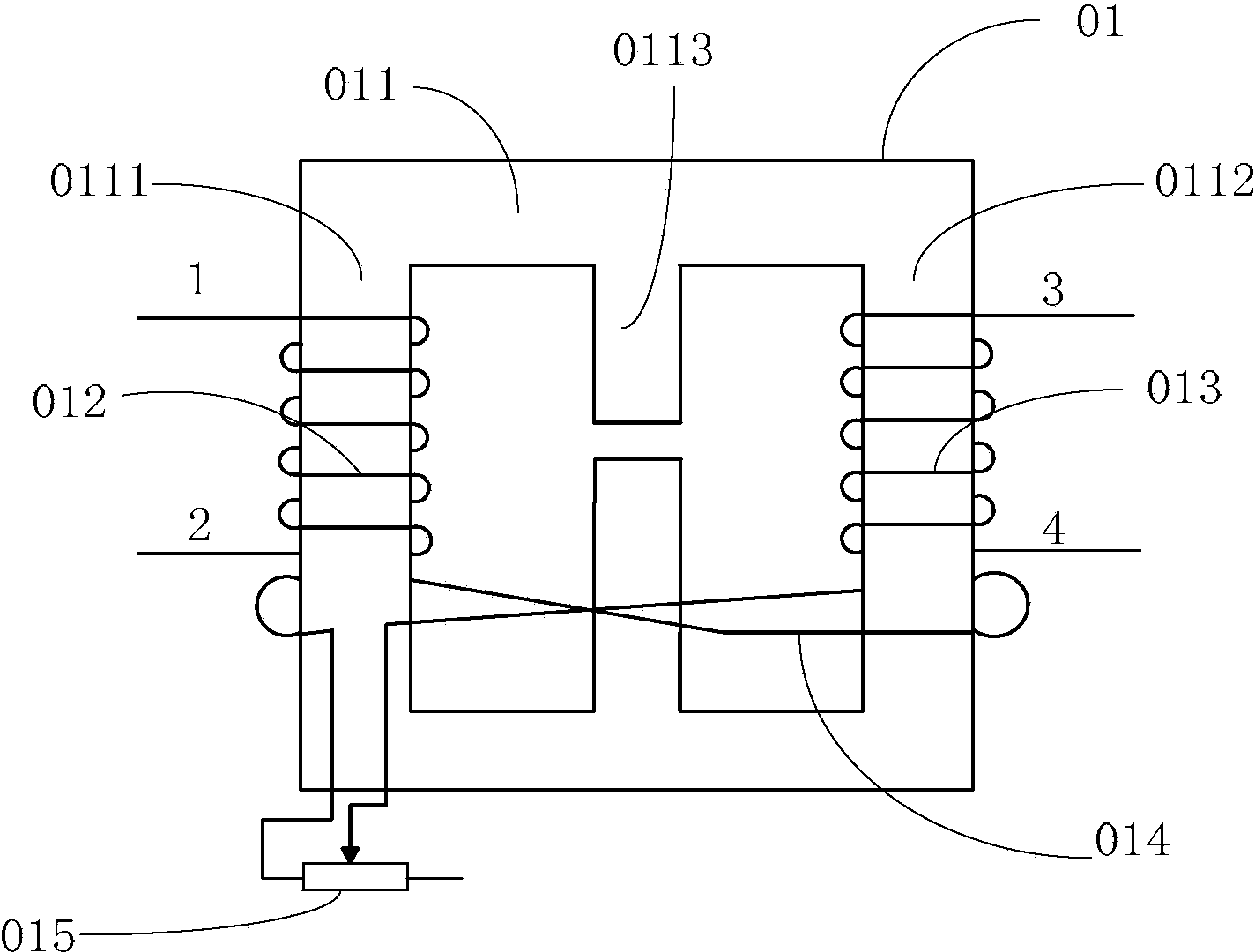

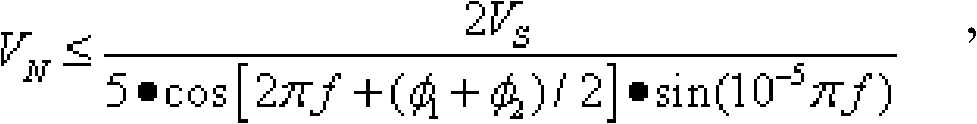

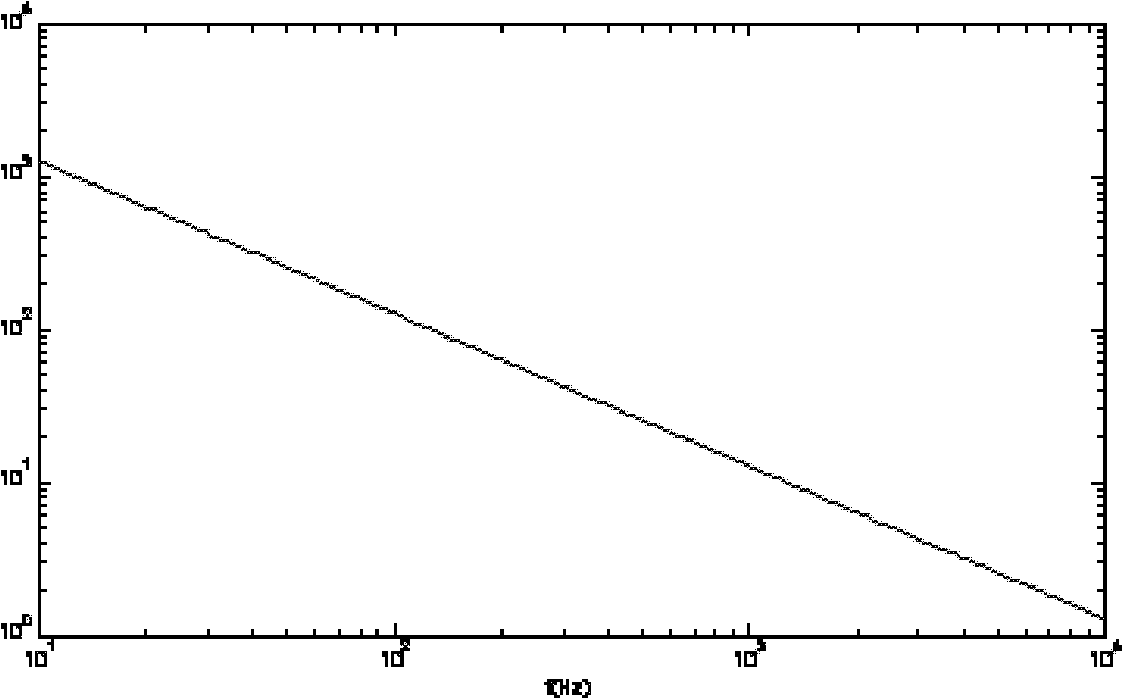

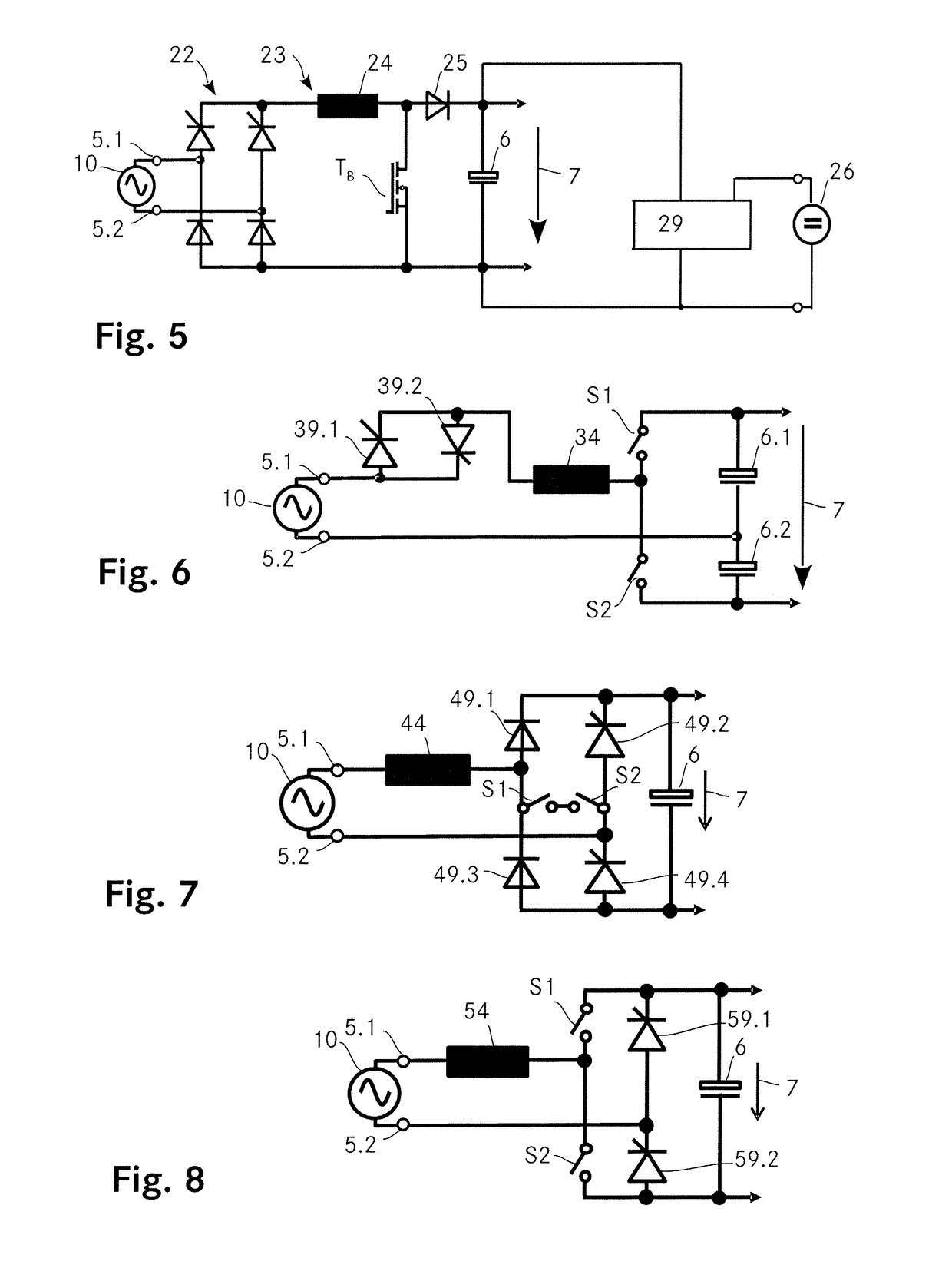

Voltage converter and common-mode noise impedance adjusting method

ActiveCN103457454AReduce Design ConstraintsReduce volumeTransformers/inductances casingsDc-dc conversionVoltage converterEngineering

The invention provides a voltage converter and a common-mode noise impedance adjusting method and relates to the field of circuits. The common-mode impedance value of a noise source and the impedance value of an EMI filter are made to reach a mismatch state, therefore, the limit to the design of the EMI filter is reduced, and the EMI filter is made to be smaller in size and higher in use efficiency. The method includes the steps that the impedance value of the common-mode noise source is adjusted through adjustment of a balance impedance value in a balancing winding on the voltage converter so as to enable the impedance value of the common-mode noise source and the impedance value of the EMI filter to reach the mismatch state. The voltage converter and the common-mode noise impedance adjusting method are used for enabling the impedance value of the common-mode noise source and the impedance value of the EMI filter to reach the mismatch state.

Owner:HUAWEI TECH CO LTD +1

Breathing device for internal combustion engine

InactiveUS6659094B2Low costSmall sizeEngine sealsNon-fuel substance addition to fuelCombustionEngineering

To provide a breathing device for an internal combustion engine, wherein the structure around the check valve is simplified so that the engine as a whole can be manufactured compact, the breathing device includes a check valve (34) for fluid connecting, a crank chamber (27) and a rocker arm chamber (31) in the combustion engine. The check valve (34) is disposed in a head gasket (35) that is interposed between a cylinder block (6) and a cylinder head (7). The check valve (34) is in the form of a reed valve separate from the head gasket (35) and is supported by the head gasket (35) by means of a rivet (36).

Owner:KAWASAKI HEAVY IND LTD

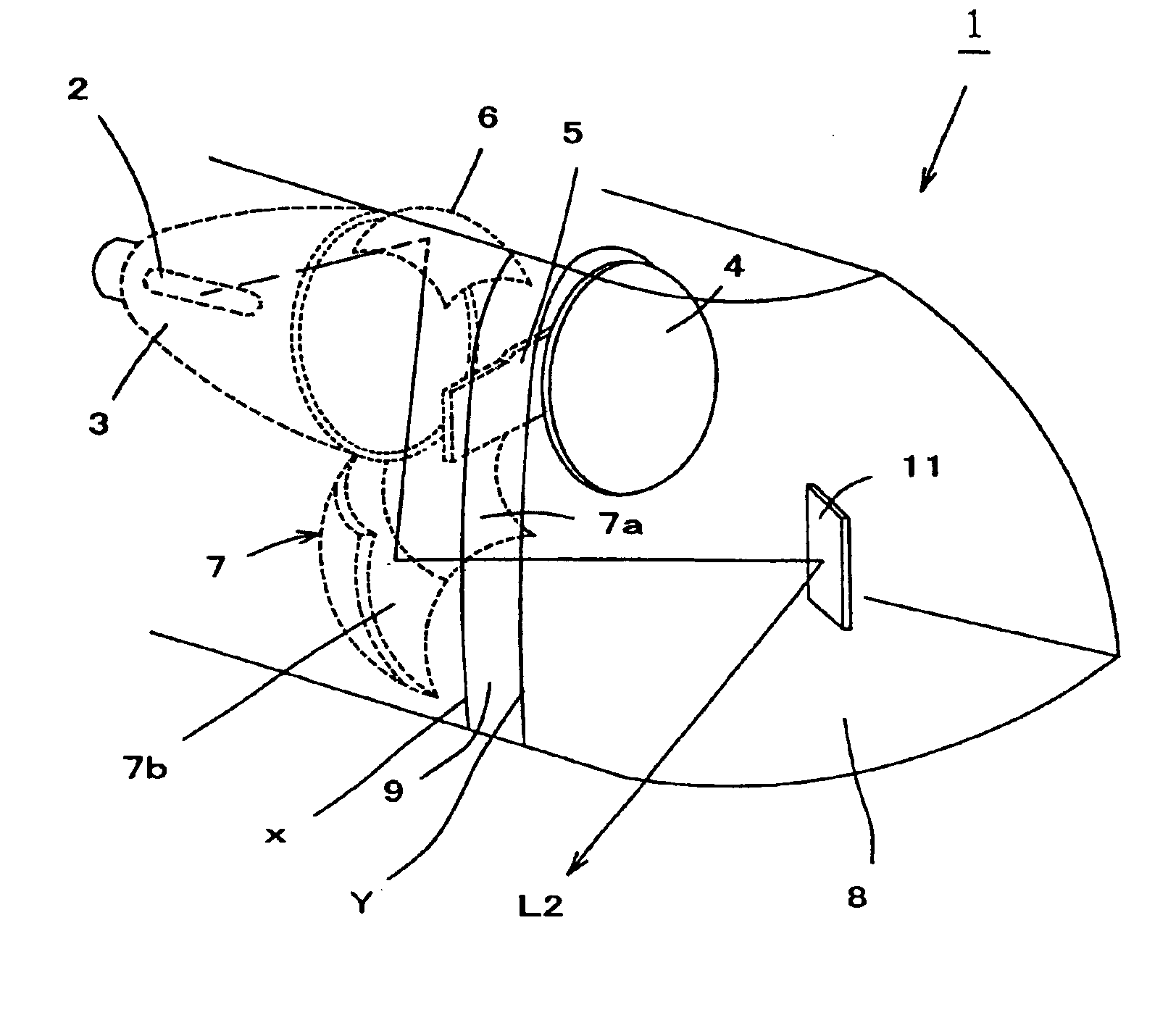

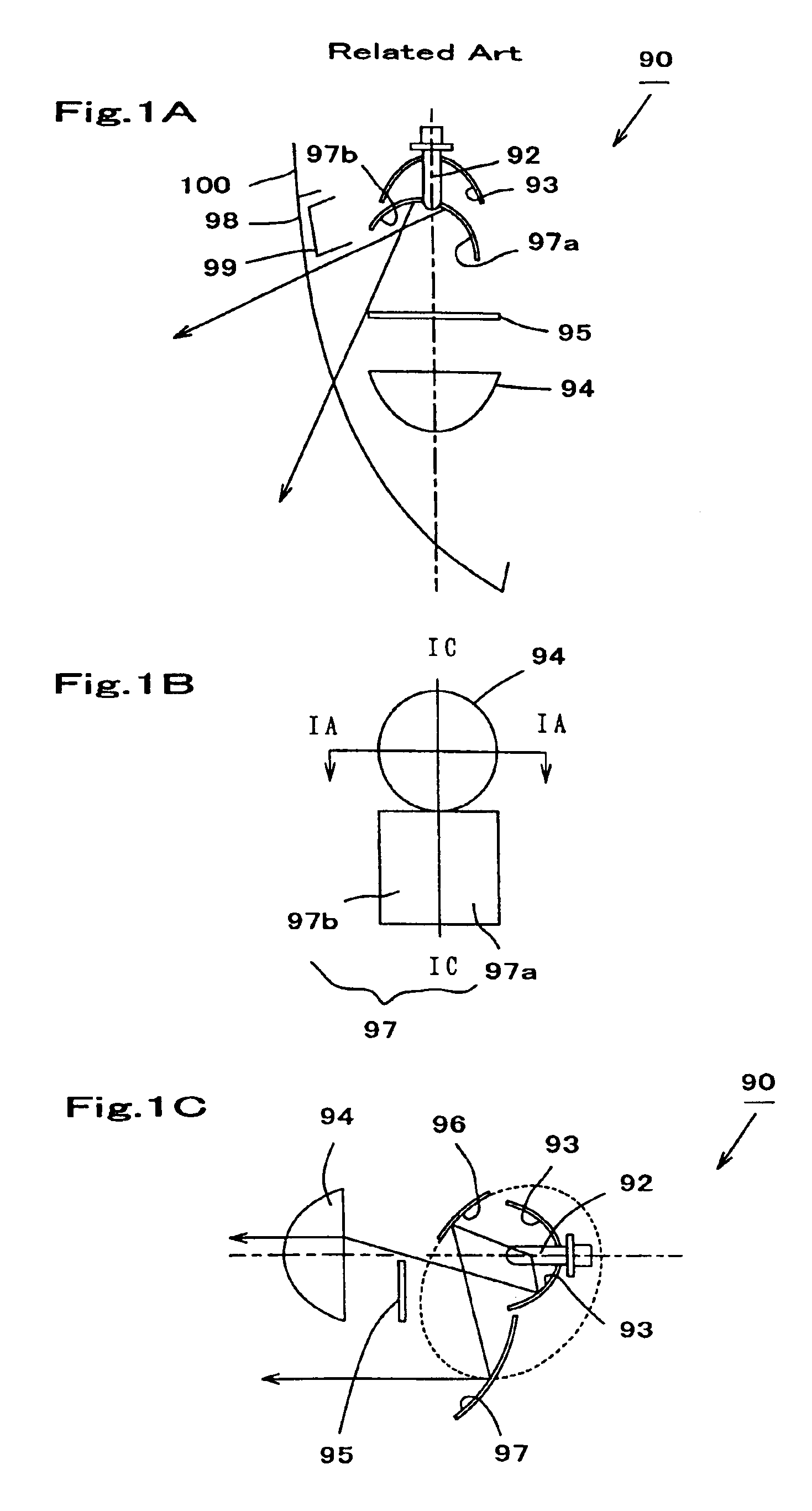

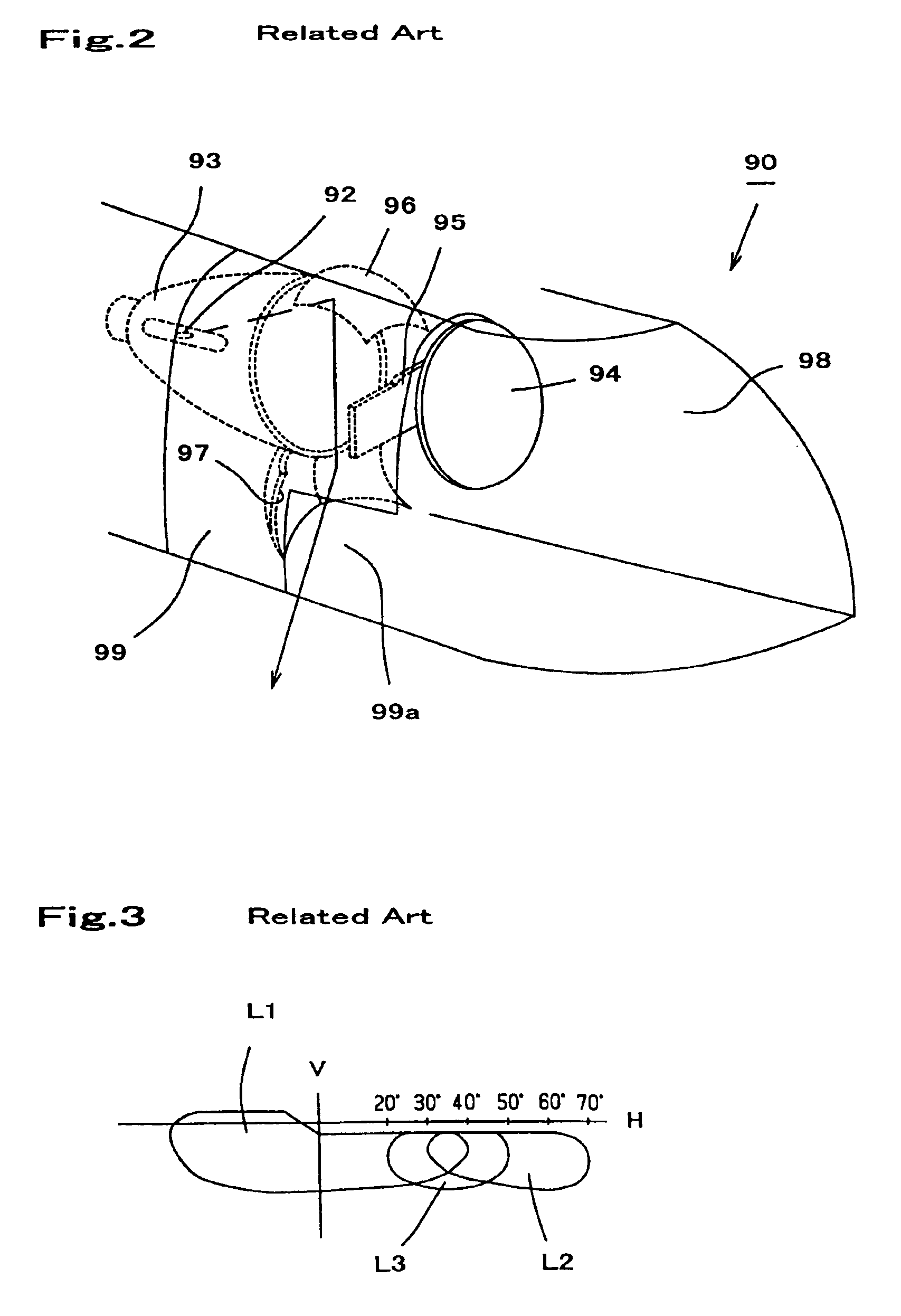

Vehicle lamp and method

InactiveUS6921188B2Easy constructionReduce Design ConstraintsVehicle headlampsPoint-like light sourceDistribution characteristicOptoelectronics

A vehicle lamp emitting light to a lateral direction can include a simple construction to reduce design limitations, and can achieve desired light distribution characteristics by controlling the direction and intensity of light illuminated in a range covering the front and the side of the vehicle. The vehicle lamp preferably includes: a second reflecting surface for reflecting incident light from a light source to a predetermined direction; a third reflecting surface, arranged forward of the light source and backward of a projection lens and out of a main optical path, for reflecting light from the second reflecting surface toward front; and a fourth reflecting surface, arranged forward of the third reflecting surface and out of the main optical path, for reflecting light from the third reflecting surface to a lateral direction relative at least to a region of light emitted from the projection lens along the main optical path.

Owner:STANLEY ELECTRIC CO LTD

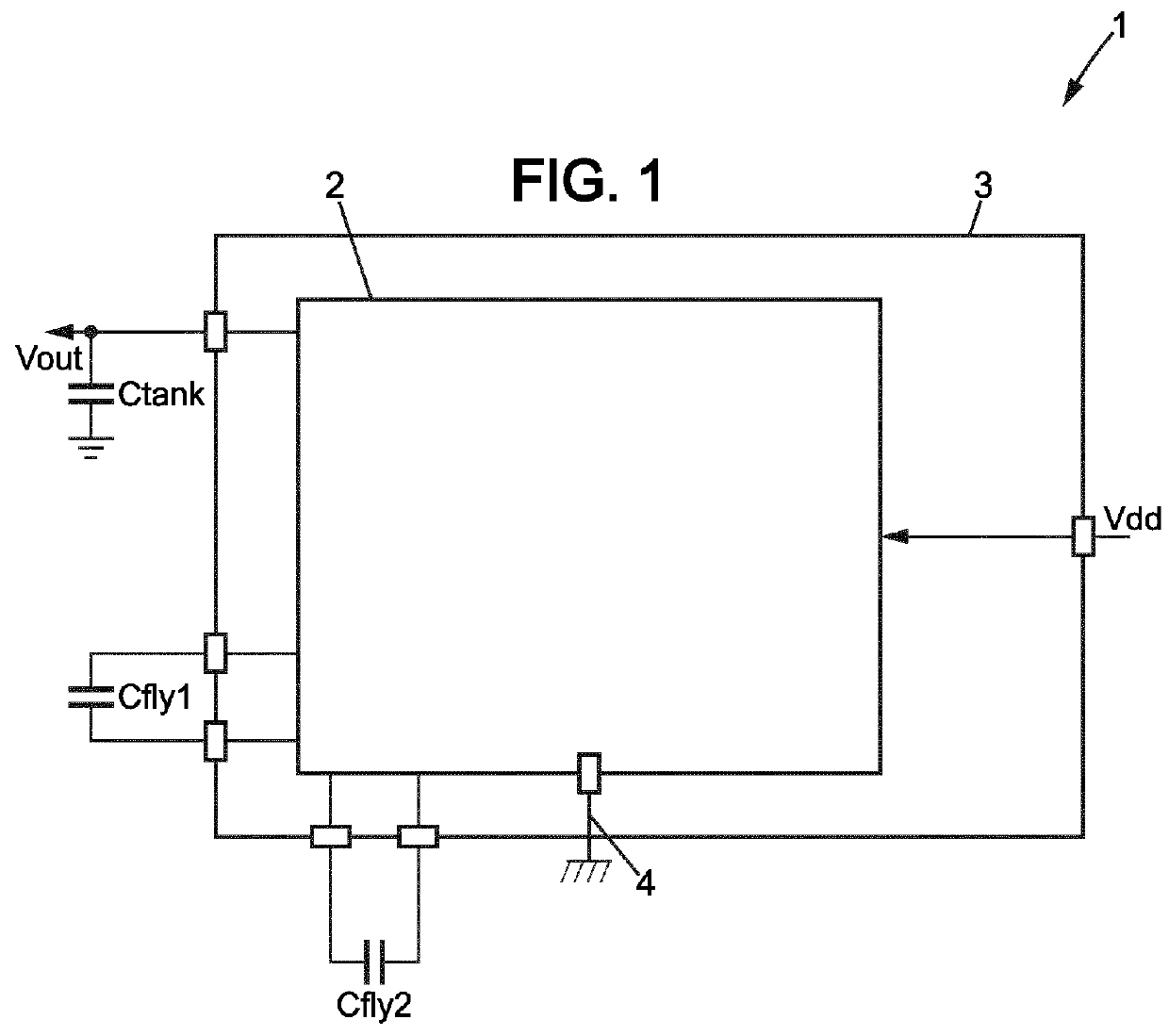

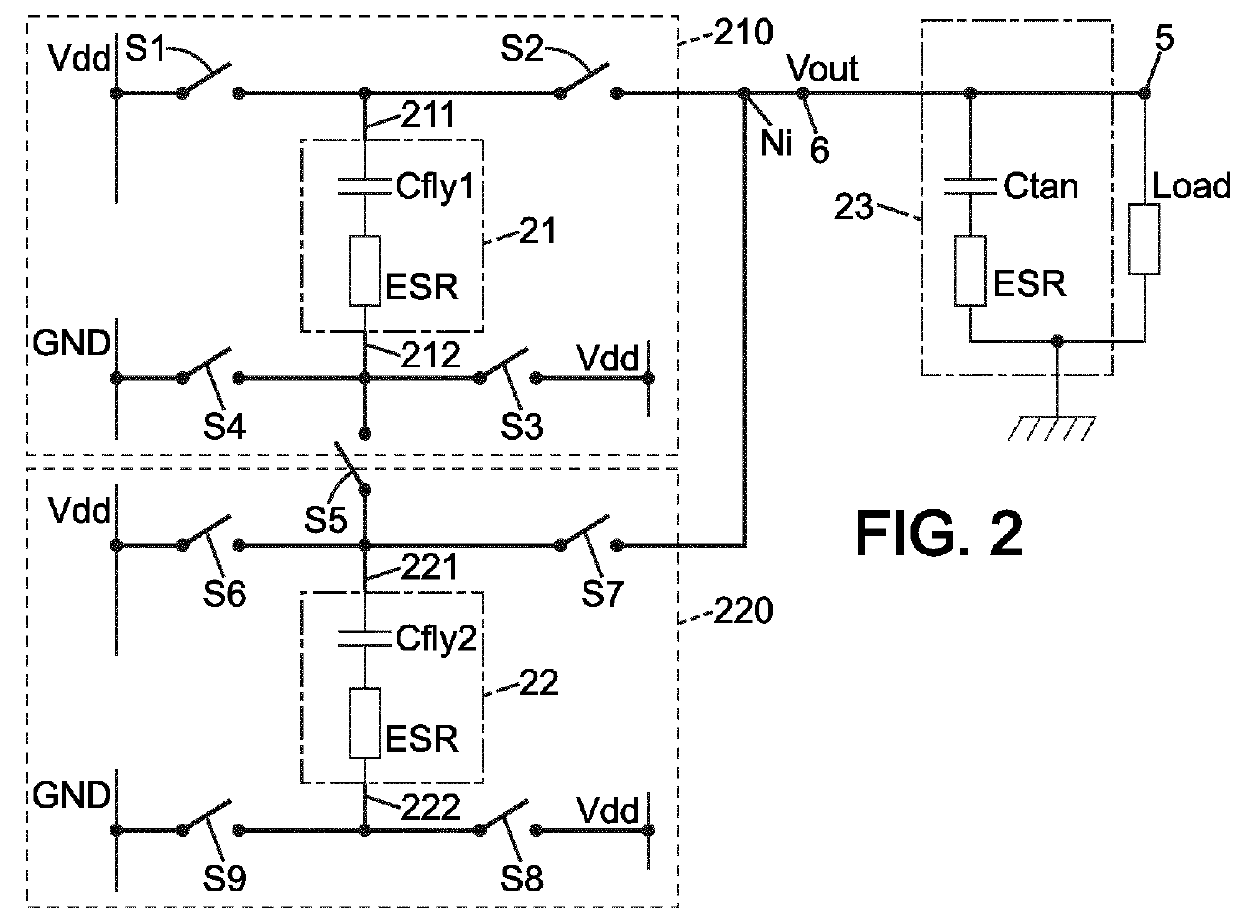

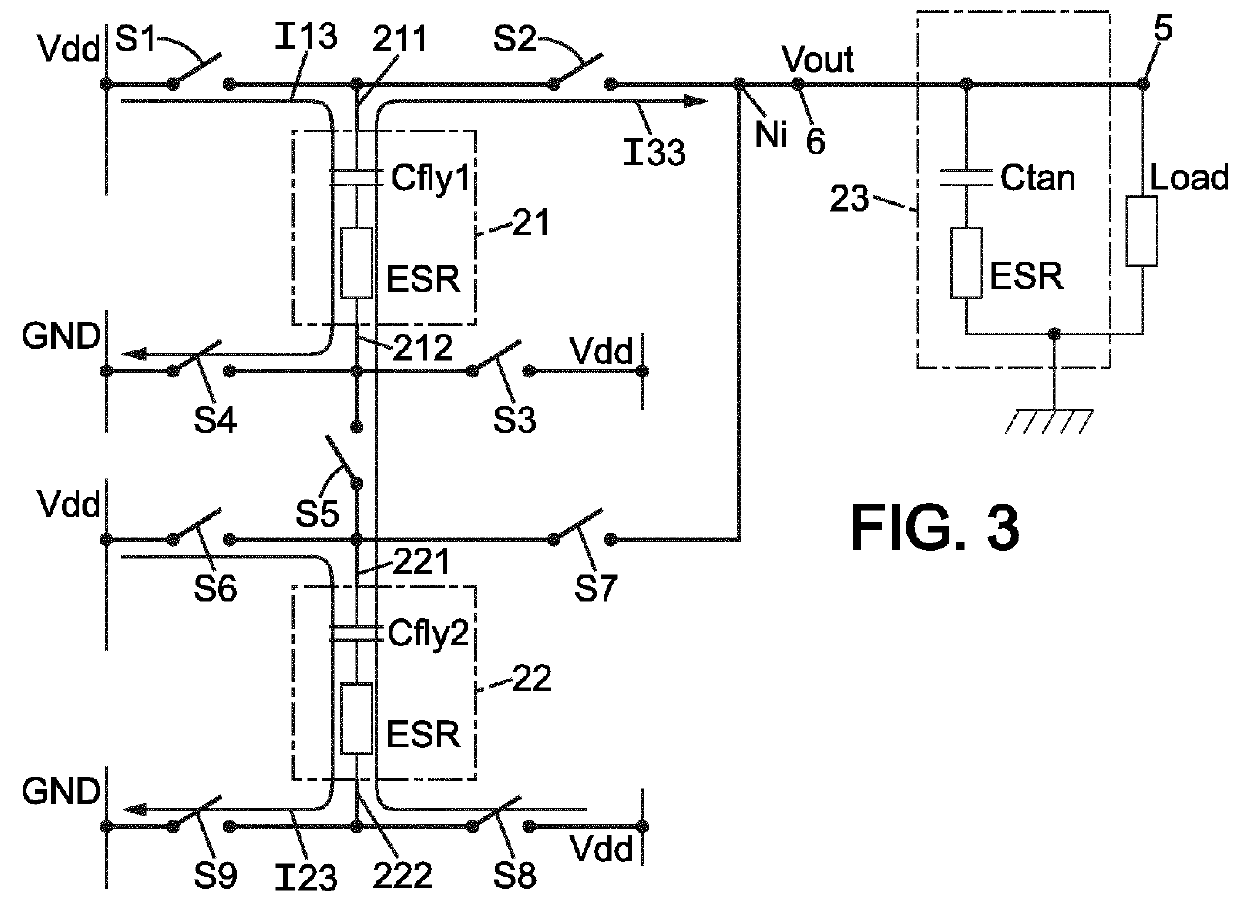

Charge pump circuit

InactiveUS20140307493A1Less surface areaLower internal resistanceEfficient power electronics conversionAc-dc conversionCharge and dischargeFlying capacitor

There is described a charge pump circuit (1) circuit comprising an input terminal, an output terminal (5) connected to an intermediate node (Ni), a ground terminal (4), a first fly capacitor module (21) with a first fly capacitor (Cfly1) having a first pin (211) and a second pin (212) and connected to the intermediate node (Ni); and a second fly capacitor module (22) with a first fly capacitor (Cfly2) having a first pin (221) and a second pin (222) and connected to the intermediate node (Ni); wherein each being adapted to successively charge and discharge a the first fly capacitor and the second fly capacitor, respectively, wherein the second pin (212) of the first fly capacitor module (21) is connected to the first pin (221) of the second fly capacitor module (22) by a direct connection.

Owner:OPTIS CIRCUIT TECH LLC

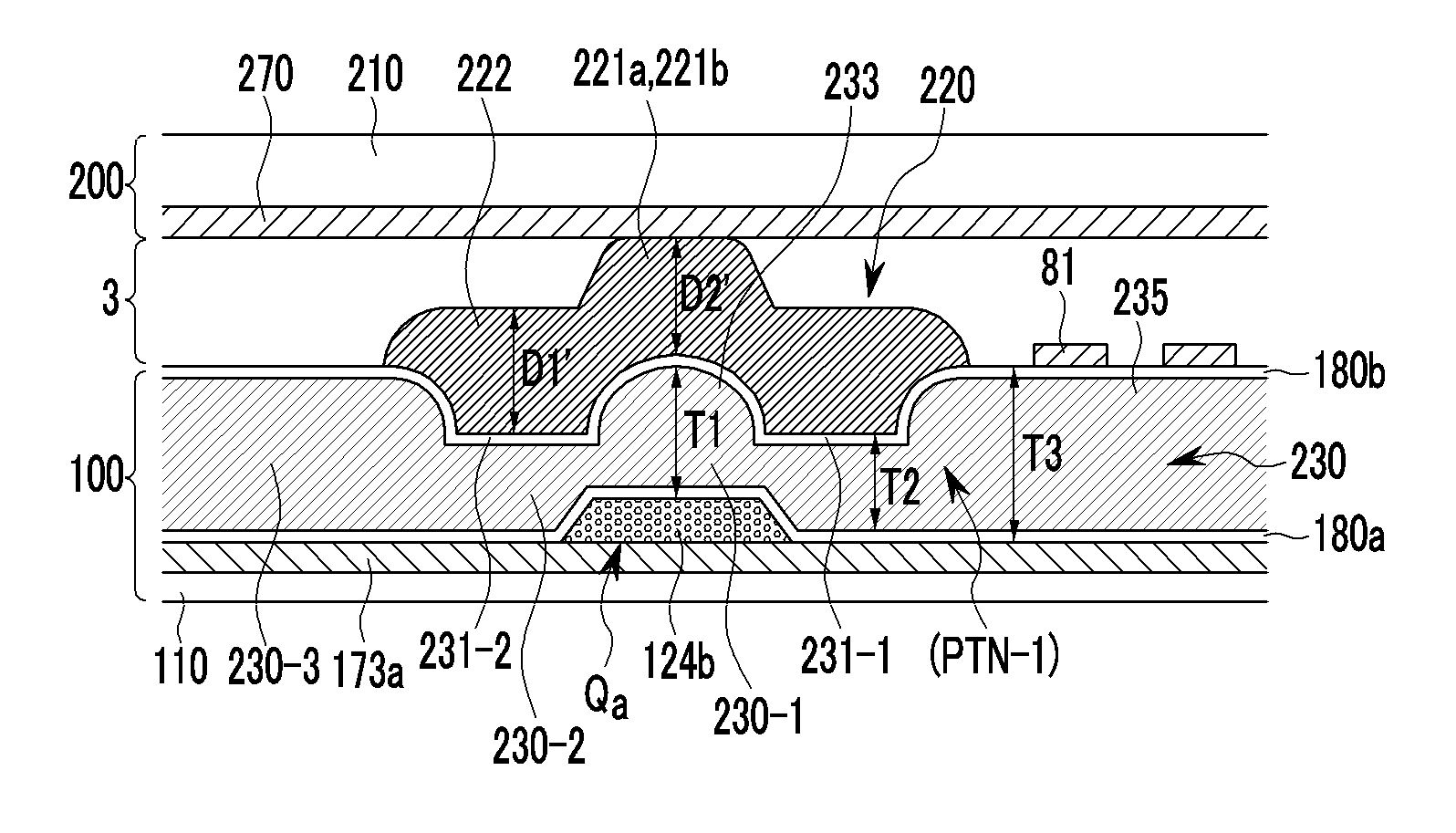

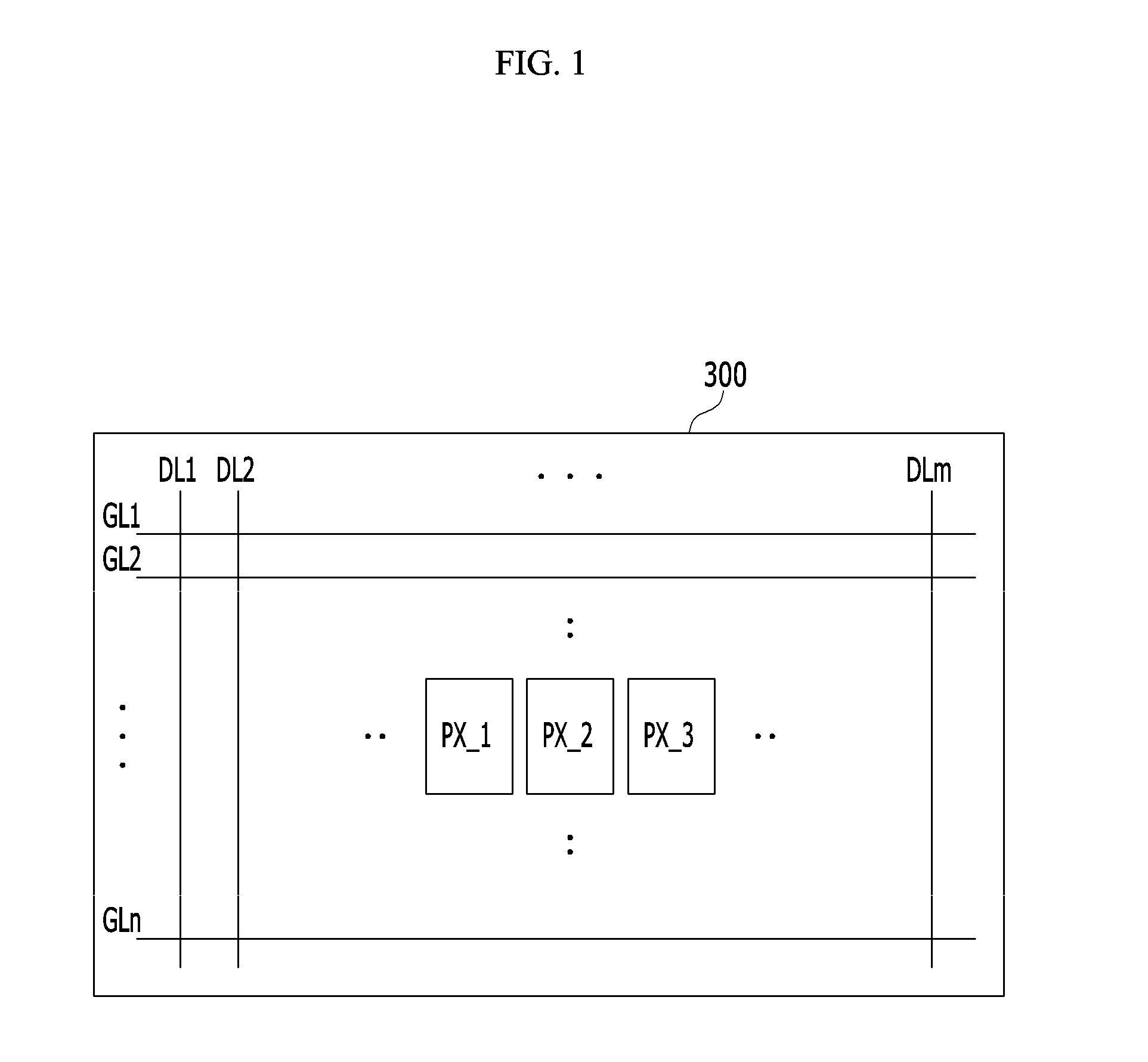

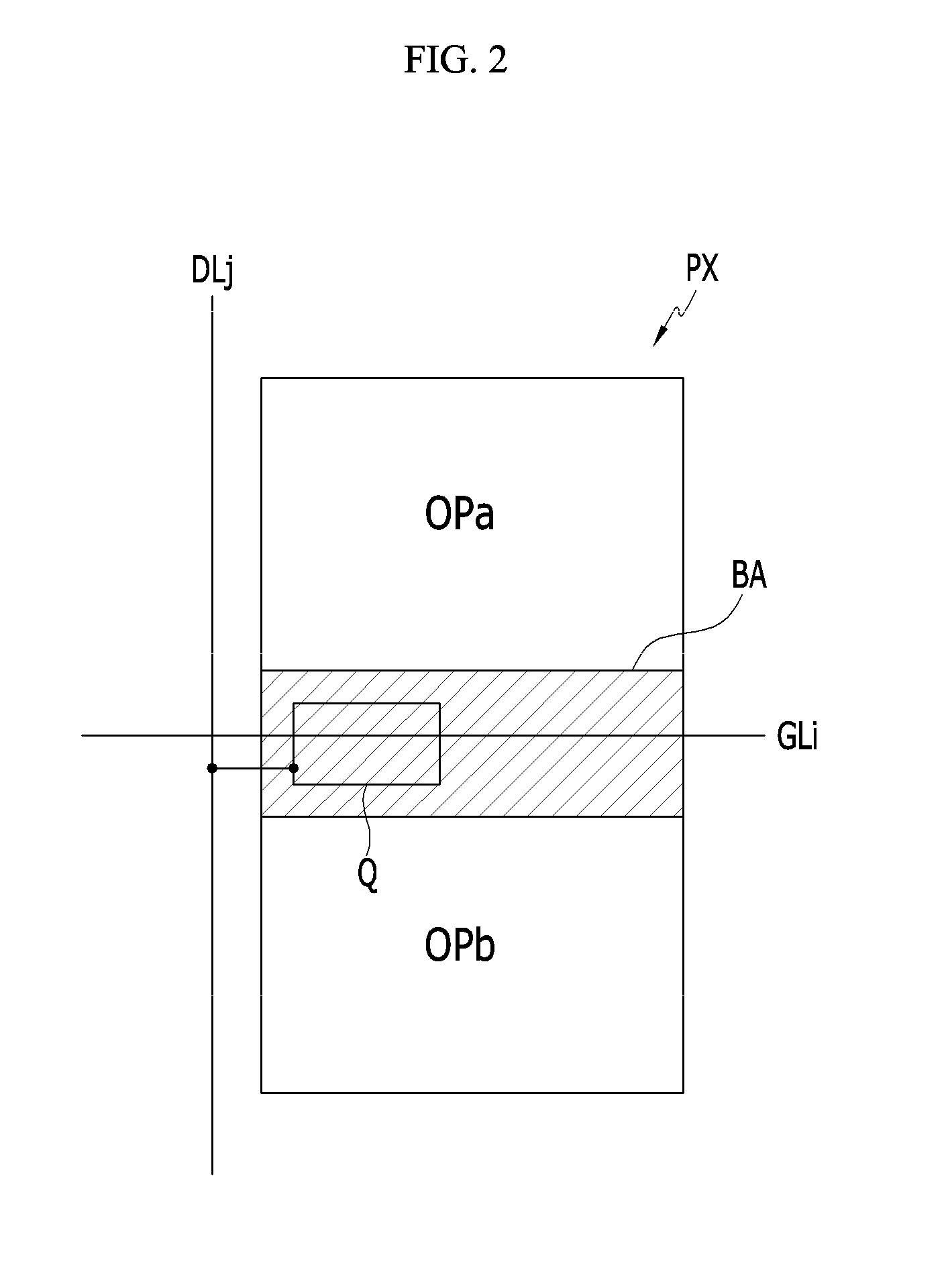

Liquid crystal display and manufacturing method of the same

ActiveUS20160231617A1Prevent overdevelopmentStability of material be improveNon-linear opticsLiquid-crystal displayLiquid crystal

A liquid crystal display includes a first substrate including a light transmitting area and a light blocking area, a gate conductor configured to transfer gate signals and a data conductor configured to transfer data voltages, the gate conductor and the data conductor disposed on the first substrate, a color filter disposed on the gate conductor, a black column spacer disposed on the color filter and corresponding to the light blocking area, a second substrate facing the first substrate, and a liquid crystal layer disposed between the first substrate and the second substrate, in which in the light blocking area, the color filter includes a step, the black column spacer overlaps the color filter including the step, and the black column spacer includes spacers having the same thickness.

Owner:SAMSUNG DISPLAY CO LTD

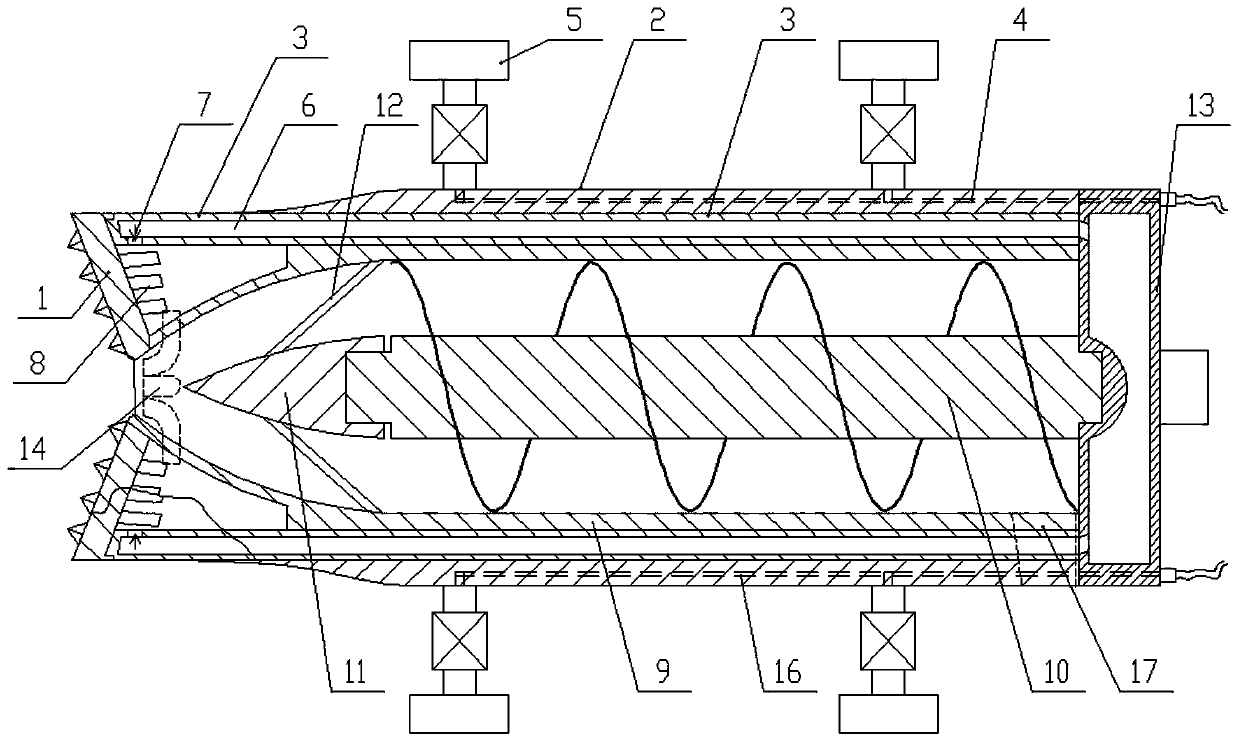

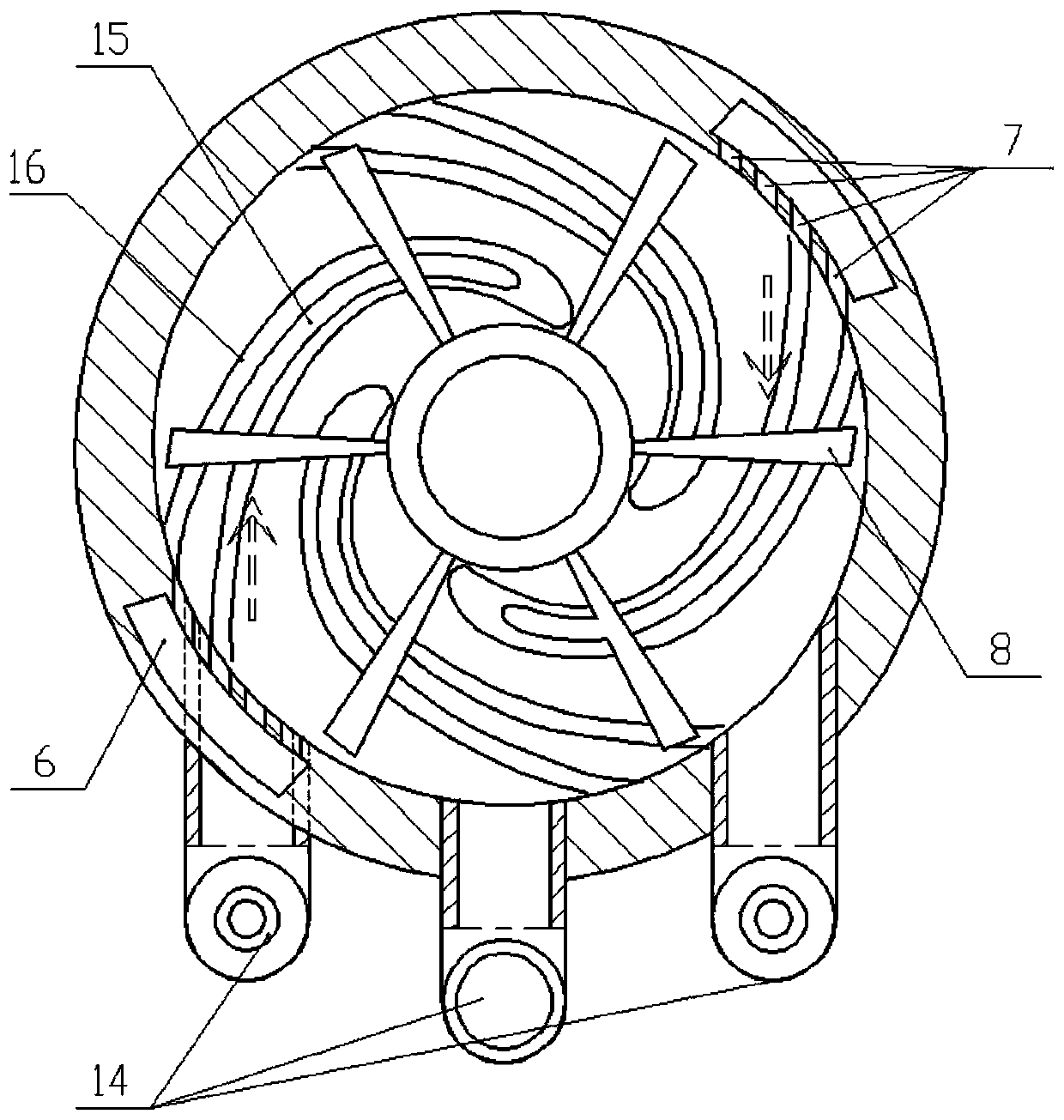

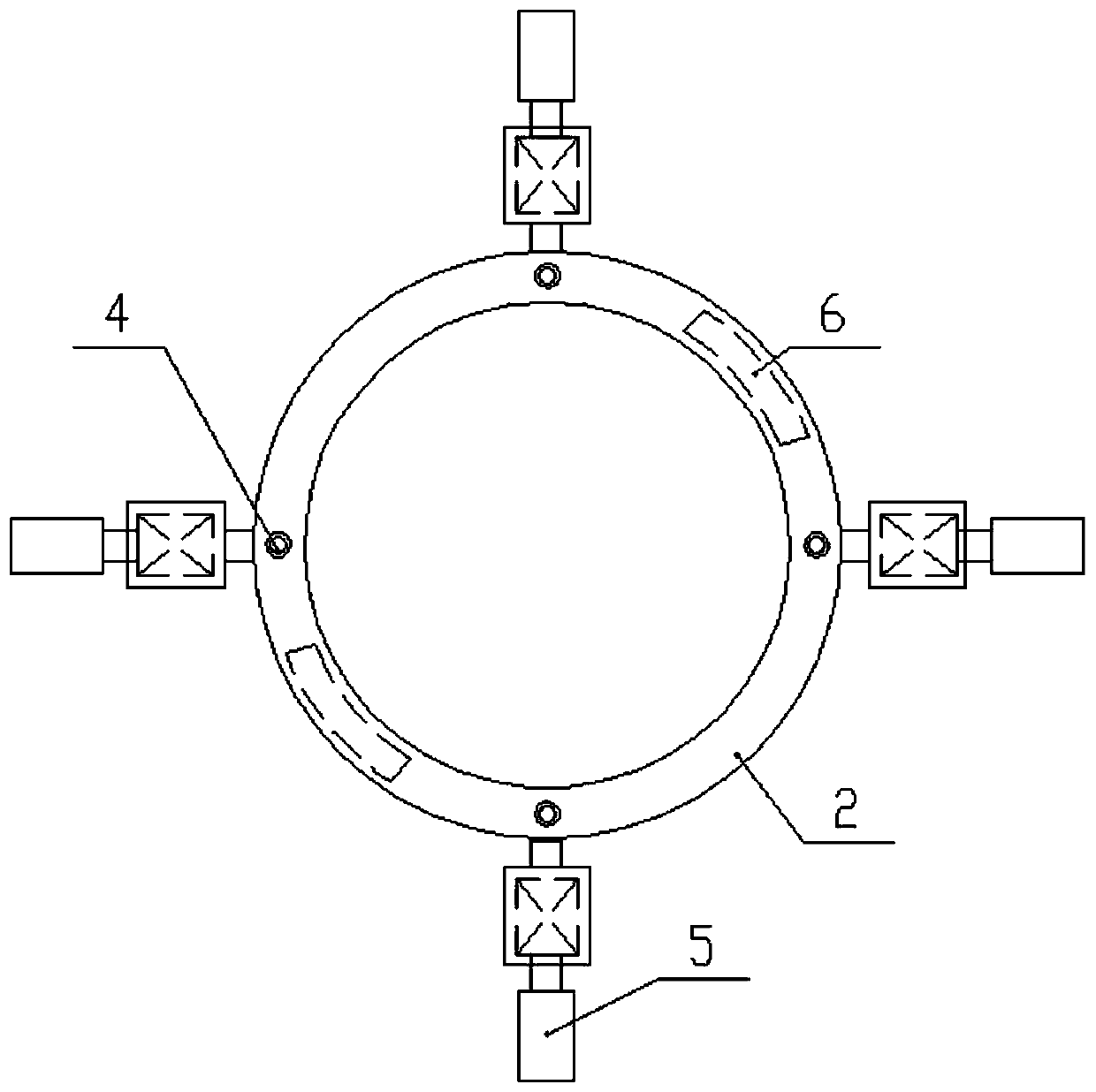

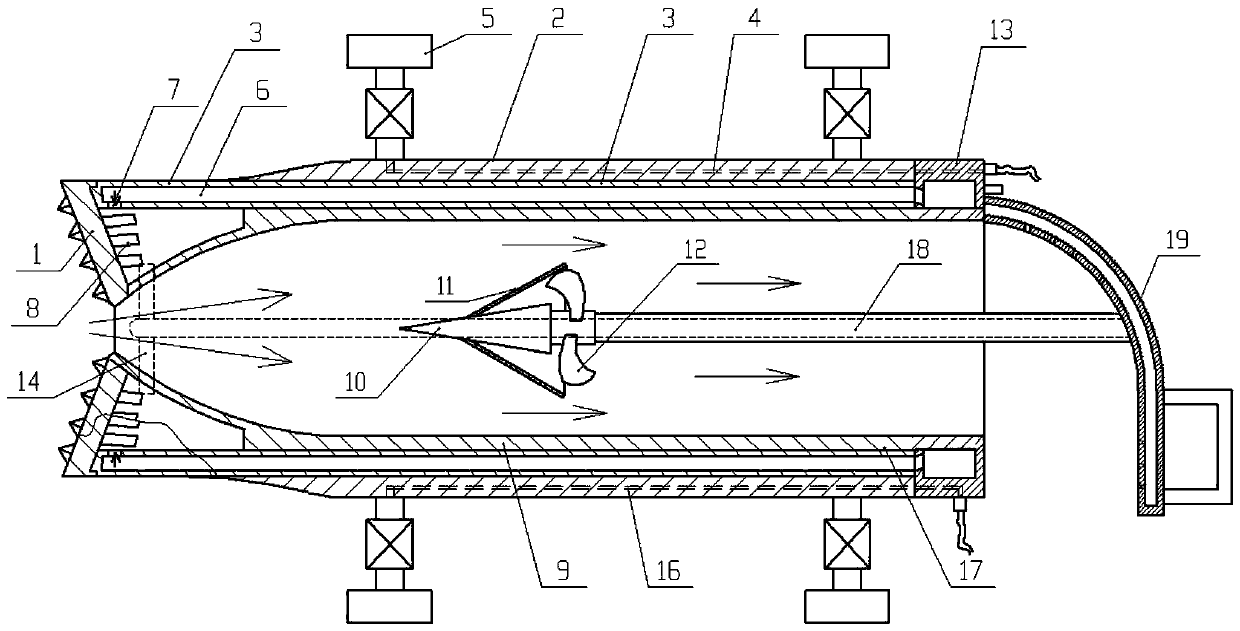

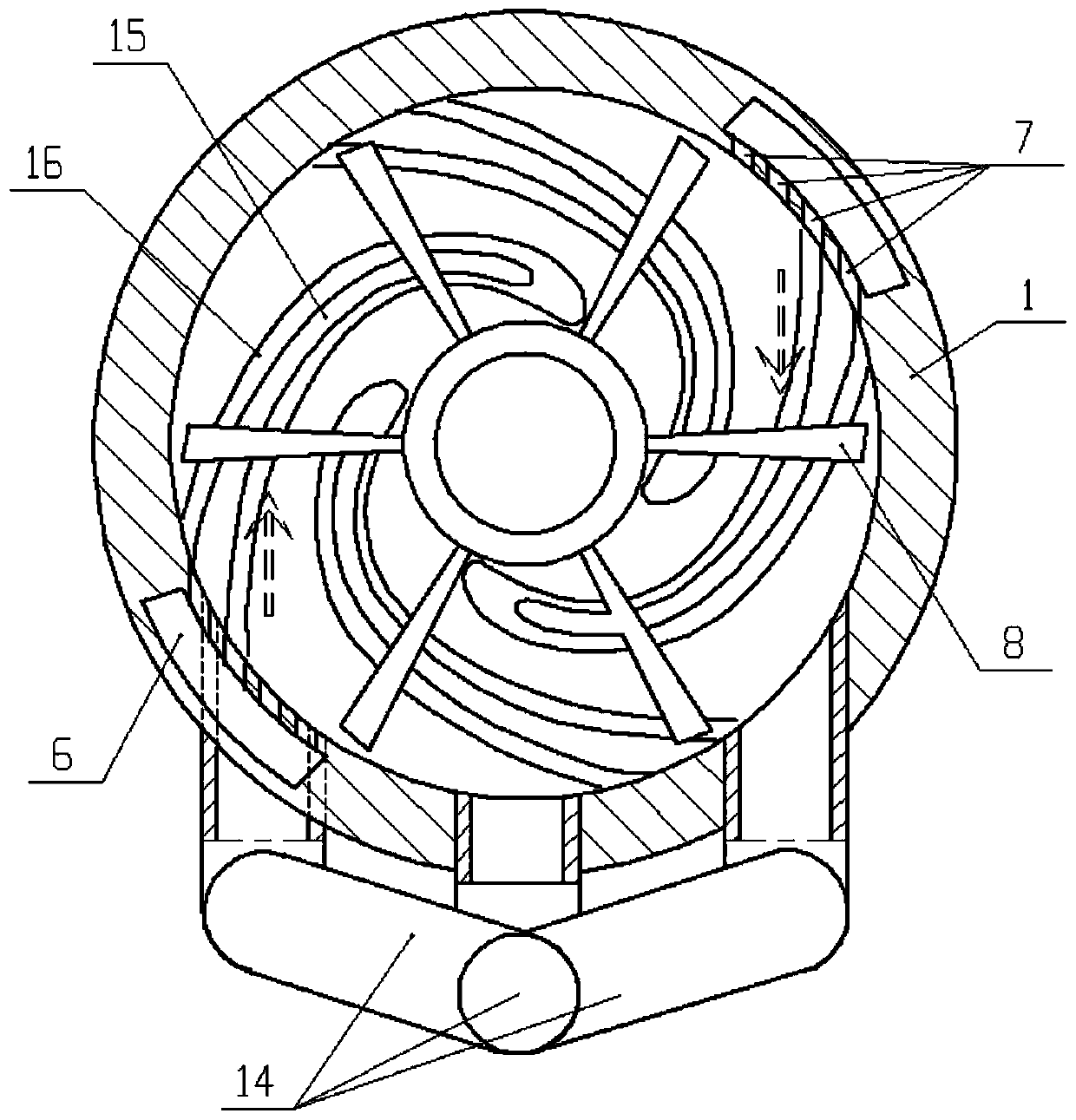

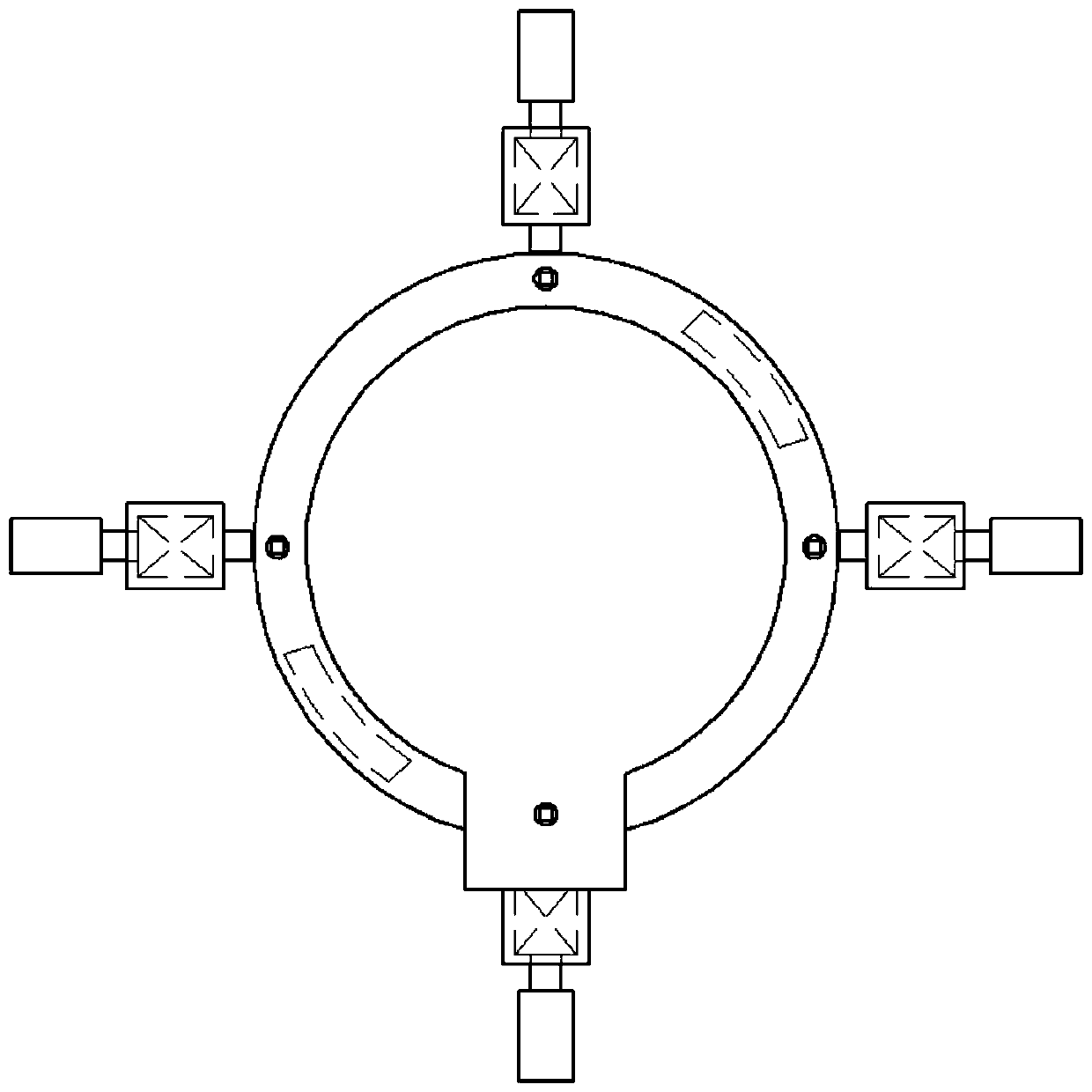

Pipeline dredging and guiding device for water conservancy construction

The invention discloses a pipeline dredging and guiding device for water conservancy construction. The pipeline dredging and guiding device comprises a rotating head, an outer cylinder, an inner cylinder, a core assembly and a rear end cover, wherein the rotating head comprises a conical shell-shaped main body, cutter teeth are arranged on the inner side wall of the main body, blades are arrangedon the outer side wall of the main body, and the blades are gradually shortened from the large end to the small end of the main body; an outlet of a water outlet pipeline is arranged by facing a cutting face of the rotating head; jet holes for ejecting water flow are formed nearby the bottoms of water injection cavities of the inner cylinder, and the water flow ejected from the jet holes just impacts the blades to drive the rotating head to perform rotary cutting; a mandrel is connected with a bullet structure through a connecting rod fixed on the inner wall of a core tube to be fixed in the core tube in a suspended manner, the rear end of a rotating shaft is mounted on the rear end cover, and a hollow cavity of the rear end cover is communicated with the water injection cavities of the inner cylinder; a discharge port penetrating through the inner cylinder and the outer cylinder is formed in the lower side wall, close to the rear end cover, of the core tube. The device is high in dredging capacity and quite high in dredging efficiency.

Owner:李建岗 +3

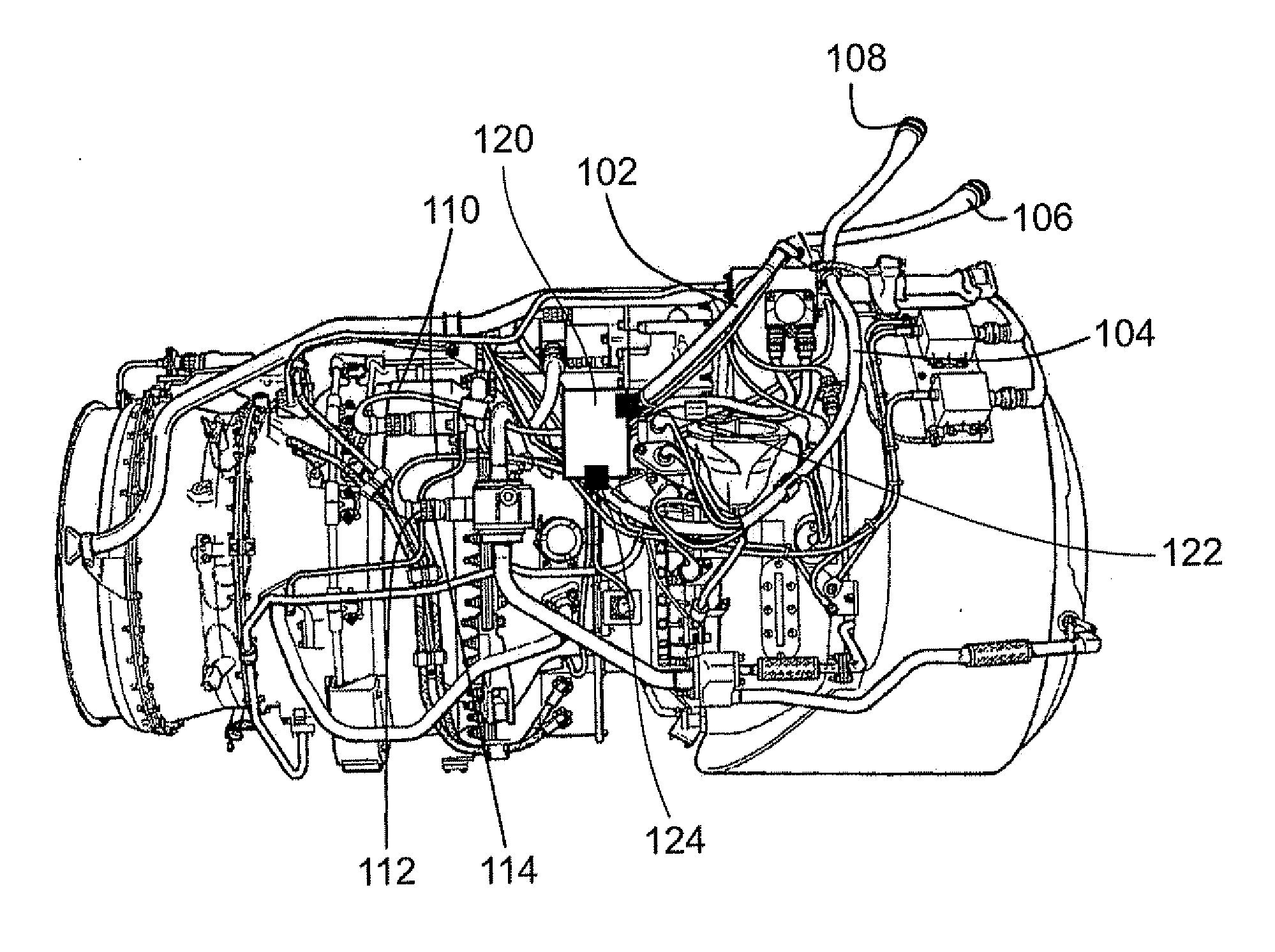

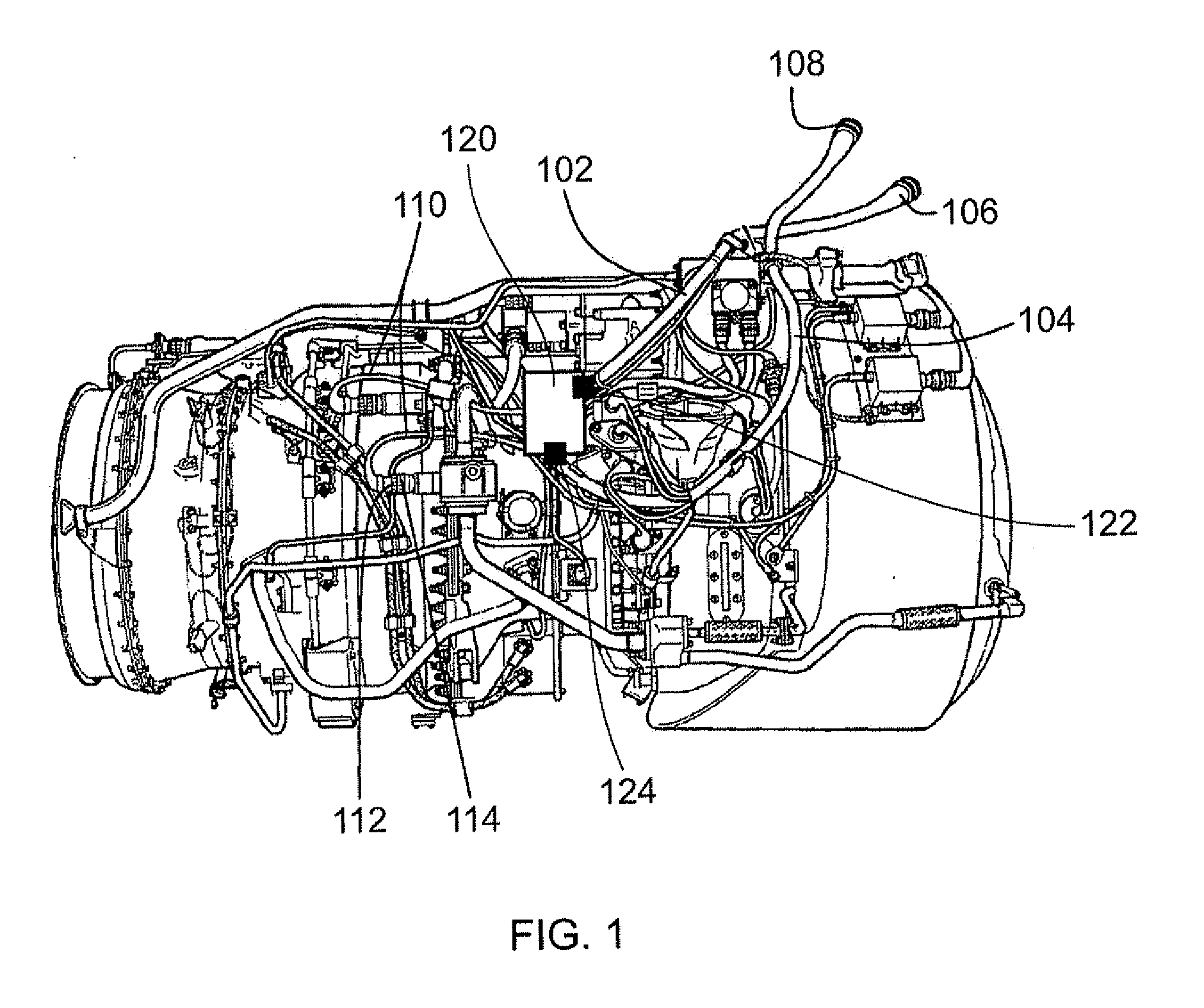

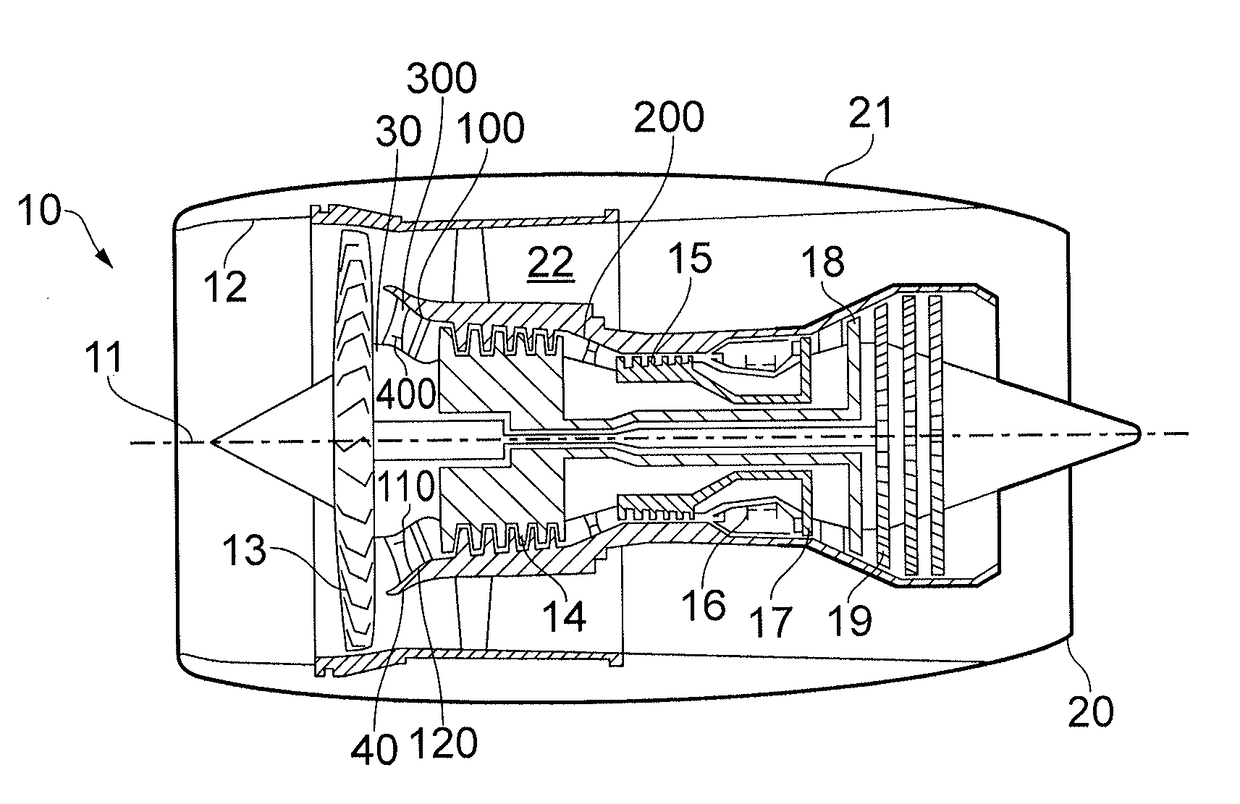

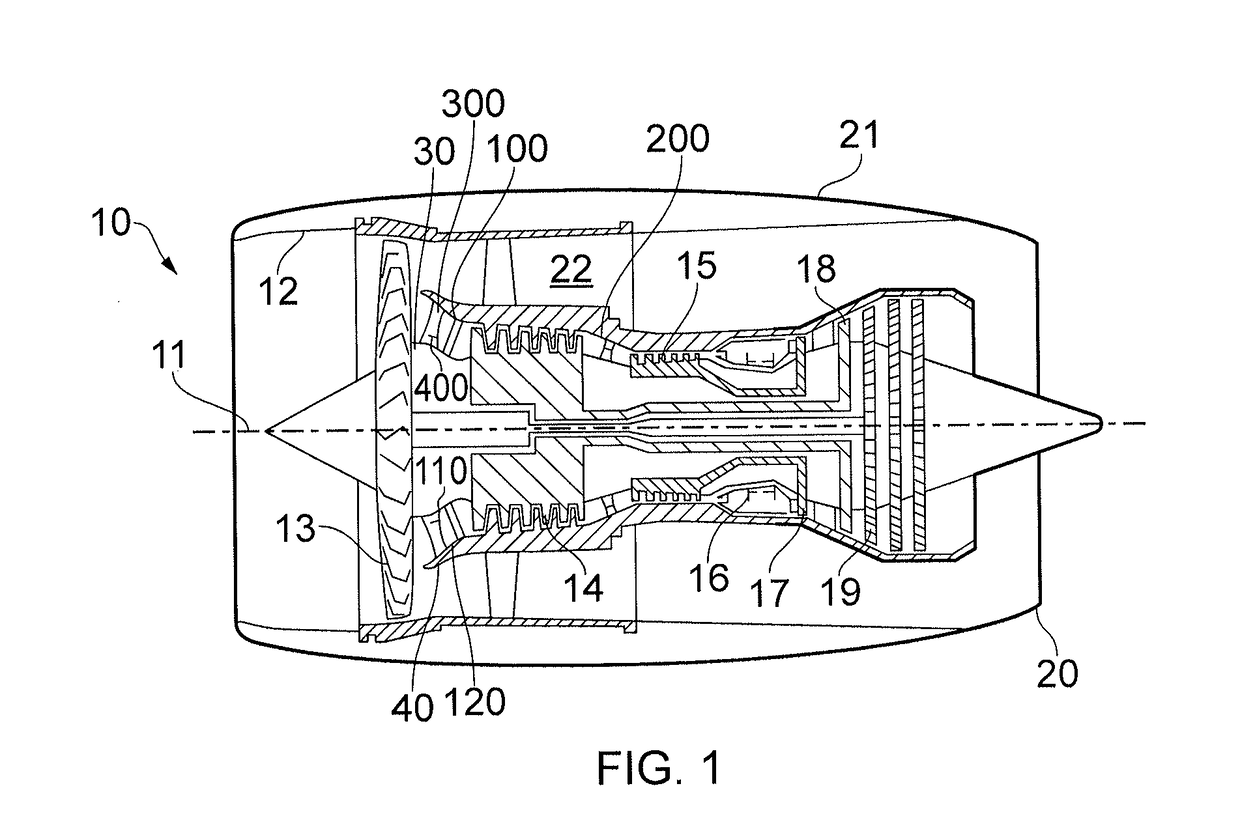

Electronic unit mounting

ActiveUS20130160461A1Reduce the amount requiredProlong lifeMachine supportsTurbine/propulsion fuel flow conduitsElectricityElectrical conductor

An electrical assembly 600 comprising an electrical raft 200 and an electronic unit 300 is provided to a gas turbine engine 10. The electrical raft 200 has electrical conductors 252 embedded in a rigid material 220, which may be a rigid composite material. The electrical conductors 252 are in electrical contact with the electronic unit 300. When the electronic unit 300 is installed, at least a part 310 of it forms a part of a gas-washed surface of the engine 10. The electronic unit 300 is then easily accessible from the engine 10, and potentially complex and / or heavy access doors / panels may not be required.

Owner:ROLLS ROYCE PLC

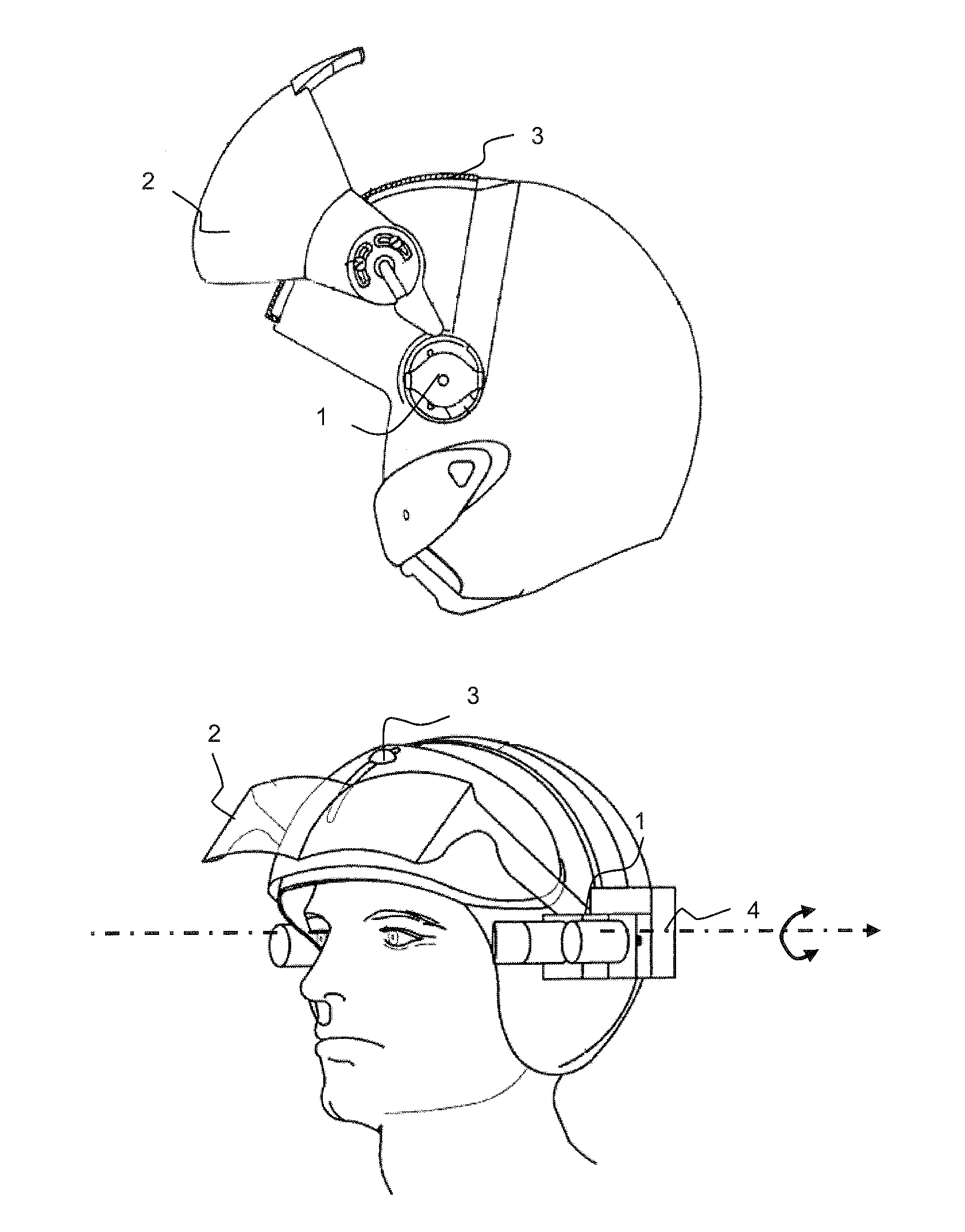

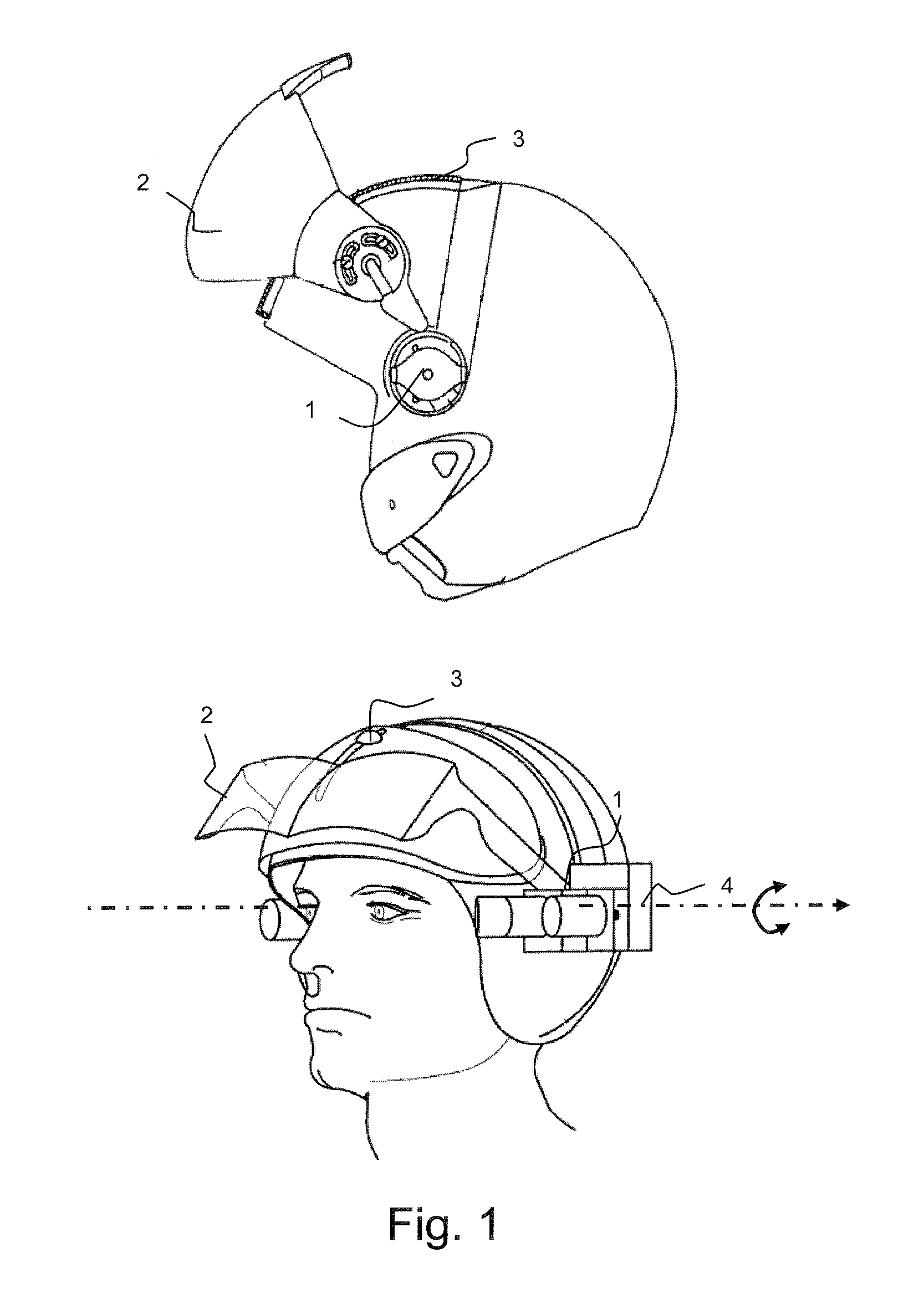

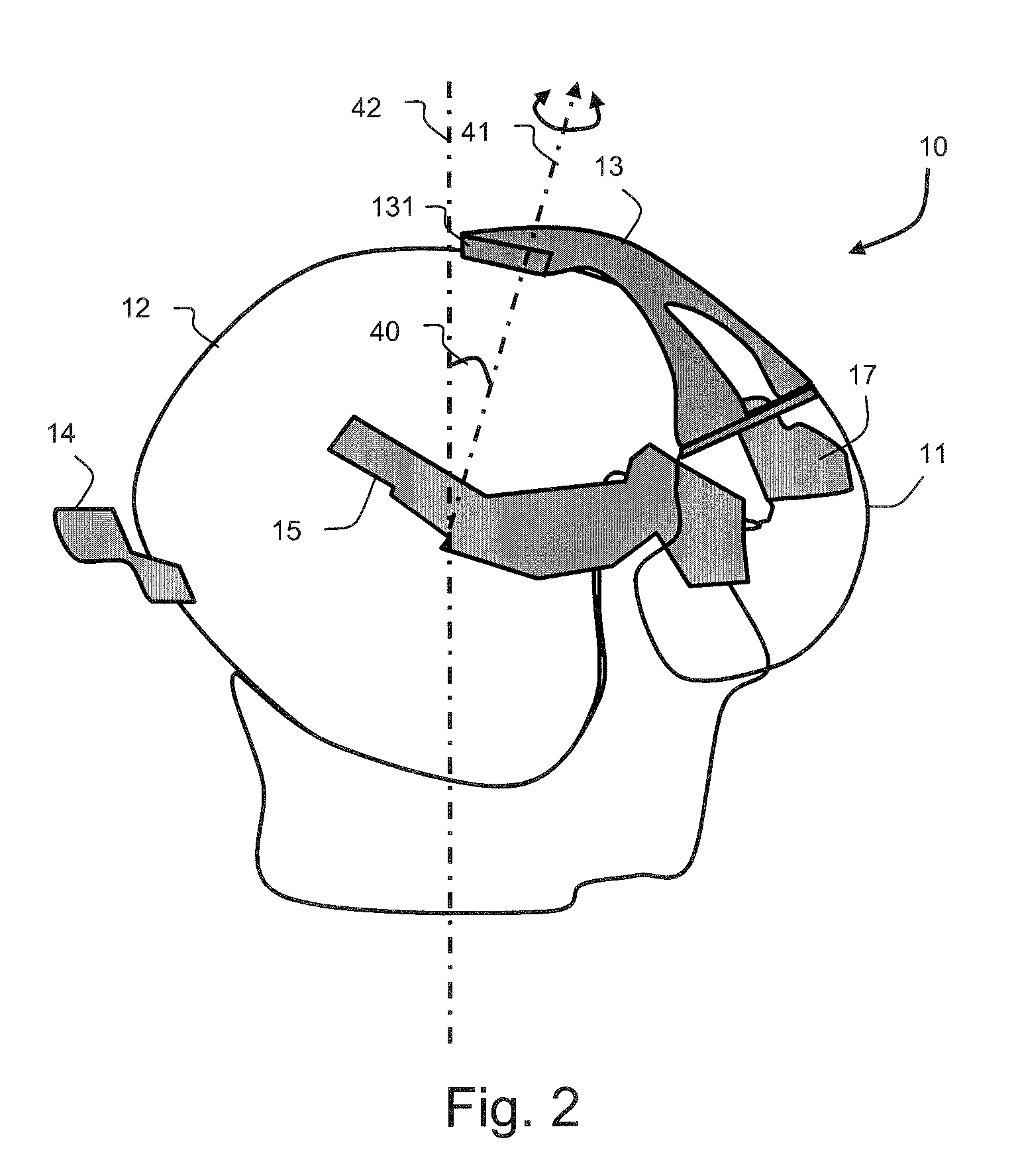

Helmet comprising a movable visor with a vertical axis of rotation

InactiveUS20100132085A1Reduce decreaseProtect the headHelmetsHelmet coversEngineeringMechanical engineering

The invention relates to a helmet comprising at least one movable visor and a shell to protect the head of the wearer, characterized in that the visor is attached to a support connected to the outer surface of the shell by a rotary mechanism making it possible to move the visor around the shell, the rotary mechanism consisting of a single mechanical connection positioned substantially at the top of the shell.The invention is designed particularly for the military aviation field and also applies to helmets comprising several visors.

Owner:THALES SA

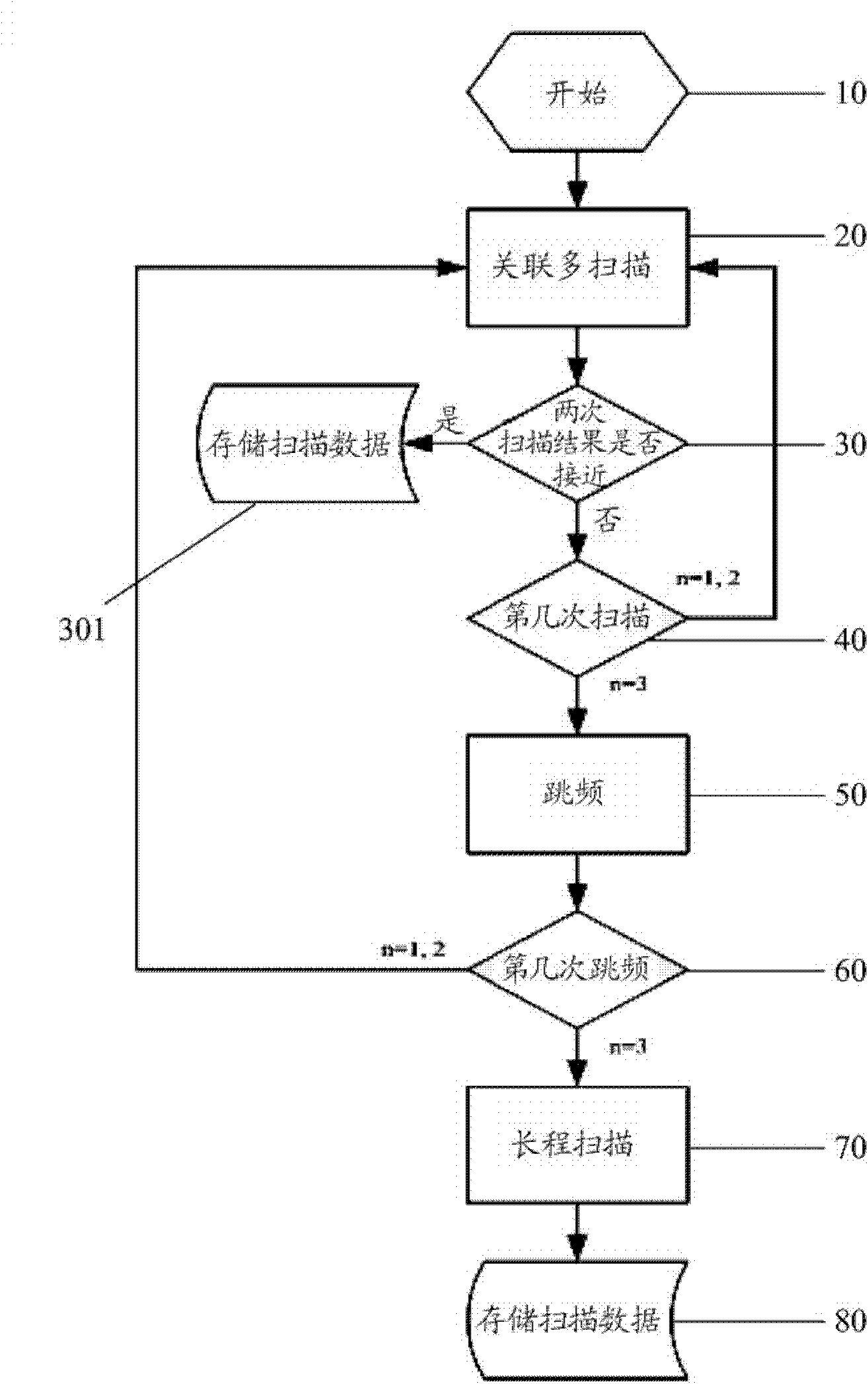

Noise filtering method for capacitive touch panel

ActiveCN102760015AReduce Design ConstraintsReduce module costInput/output processes for data processingTouch panelBackground noise

A noise filtering method for a capacitive touch panel comprises the steps of: carrying out scanning on one channel for more than one time, comparing scanned results and judging background noise by means of empty scanning.

Owner:ORISE TECHNOLOGY CO LTD

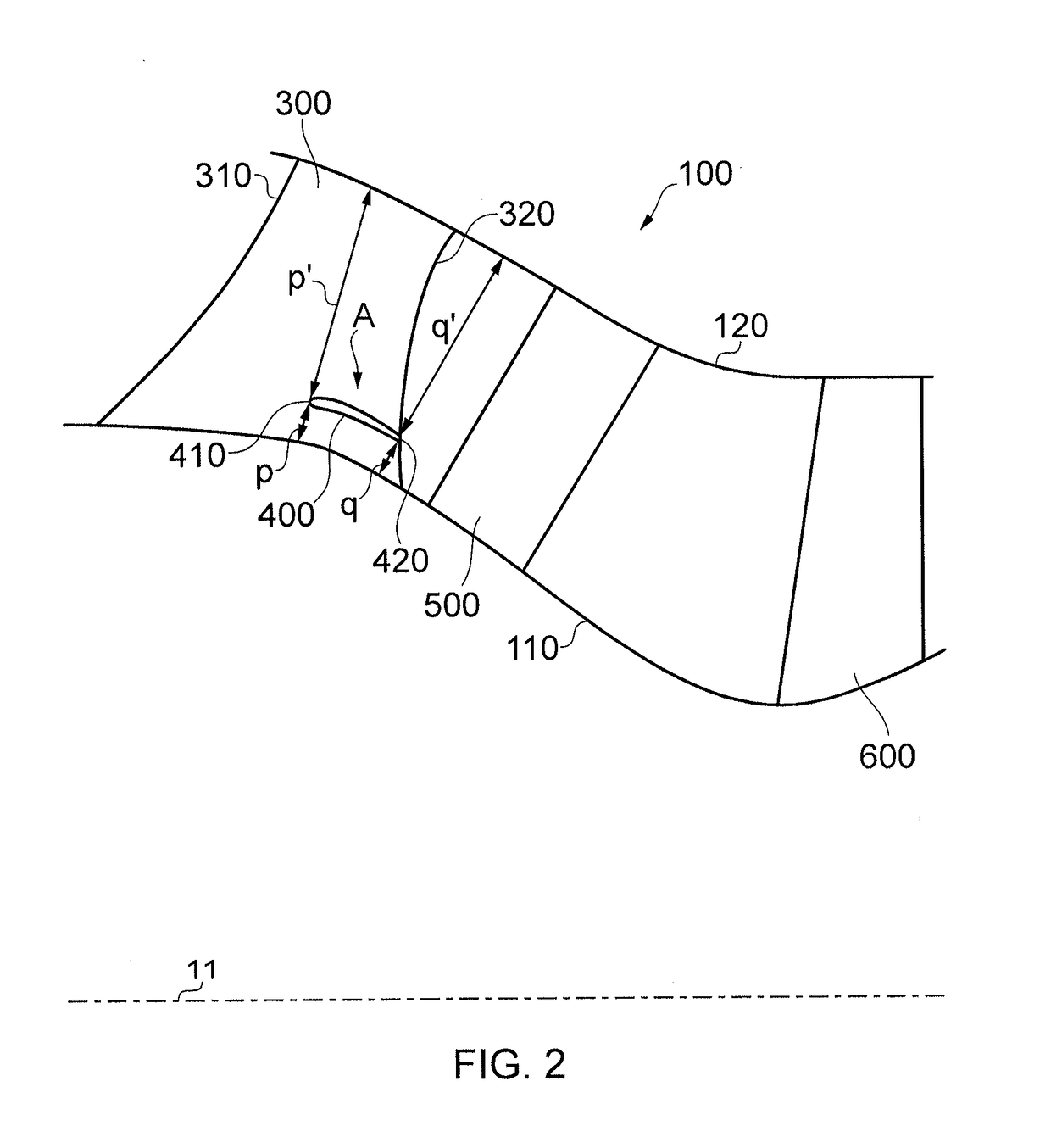

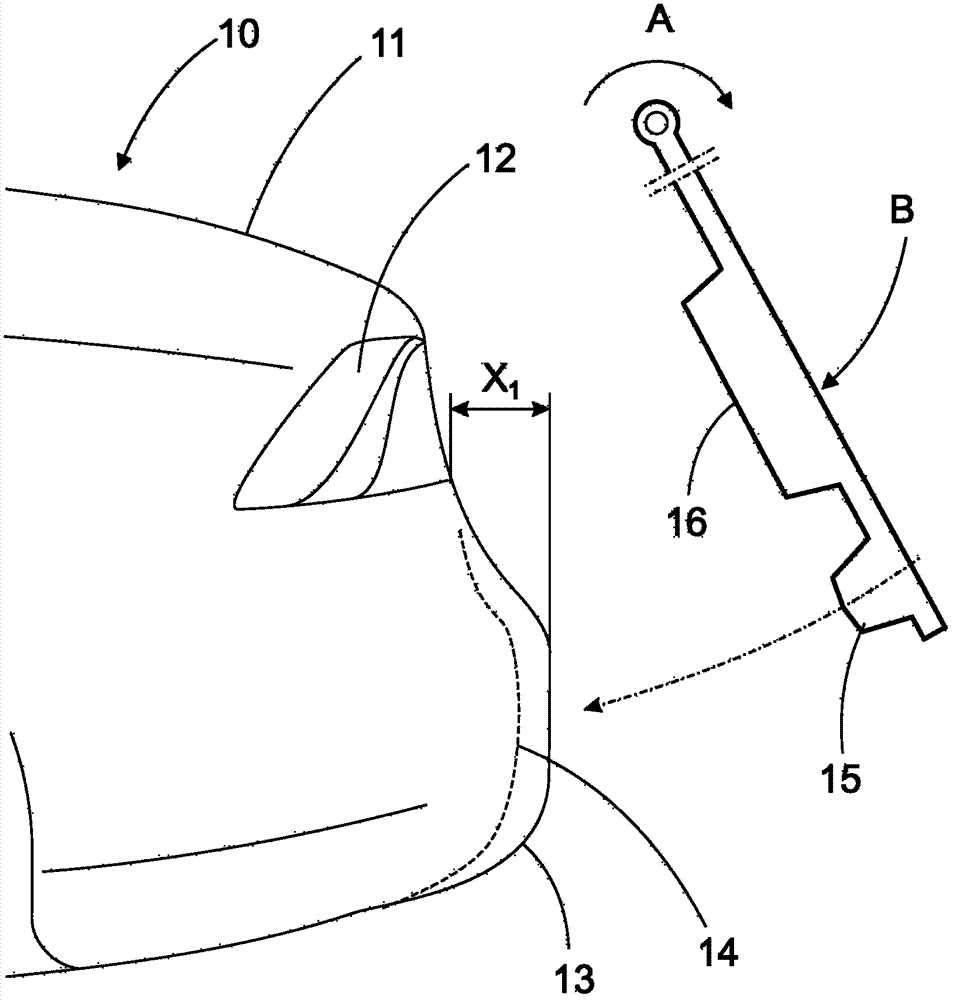

Gas turbine engine vane splitter

InactiveUS20170184053A1Reduce Design ConstraintsHigh trafficEngine manufacturePump componentsTurbineGas turbines

A gas turbine engine duct turns radially inwardly in the downstream direction. The duct includes a plurality of radially extending stator vanes. A generally circumferentially extending splitter vane is provided between two circumferentially neighbouring stator vanes. The splitter vane improves the flow near to the radially inner wall of the duct. This can allow greater design freedom in the duct geometry.

Owner:ROLLS ROYCE PLC

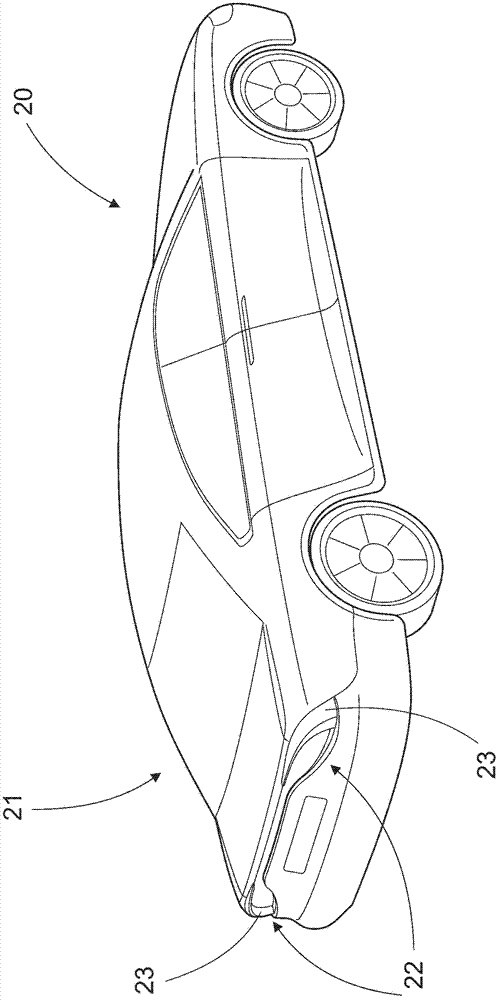

Vehicle light unit and vehicle

InactiveCN102734730AReduce Design ConstraintsReduce offsetPoint-like light sourceProtective devices for lightingEngineeringMotorized vehicle

The invention relates to a vehicle light unit and a vehicle. The invention relates to the light unit on an automotive vehicle, which light unit makes up an assembly adapted for attachment to the vehicle. The light unit comprises a translucent body attached to the assembly, said translucent body having a outer surface defining a light emitting area, an inner surface facing the vehicle, and side surfaces connecting the outer and inner surfaces. At least one mounting section is provided for a light source arranged to transmit light into said translucent body, and attachment means for attaching a support or housing to a side surface or a rear surface of said translucent body. The translucent body forms a wave guide arranged to direct and disperse light from at least one light source through said translucent body so as to provide illumination through the light emitting area; and which body comprises a shock absorbing elastic material.

Owner:VOLVO CAR CORP

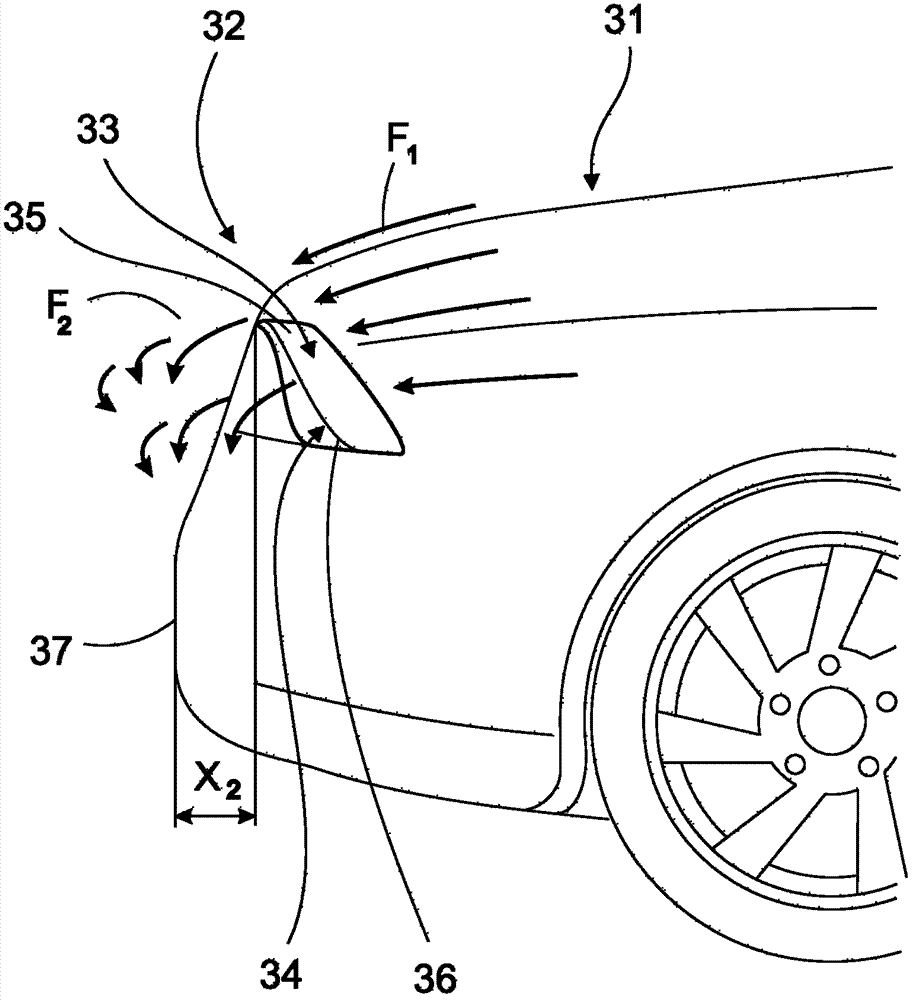

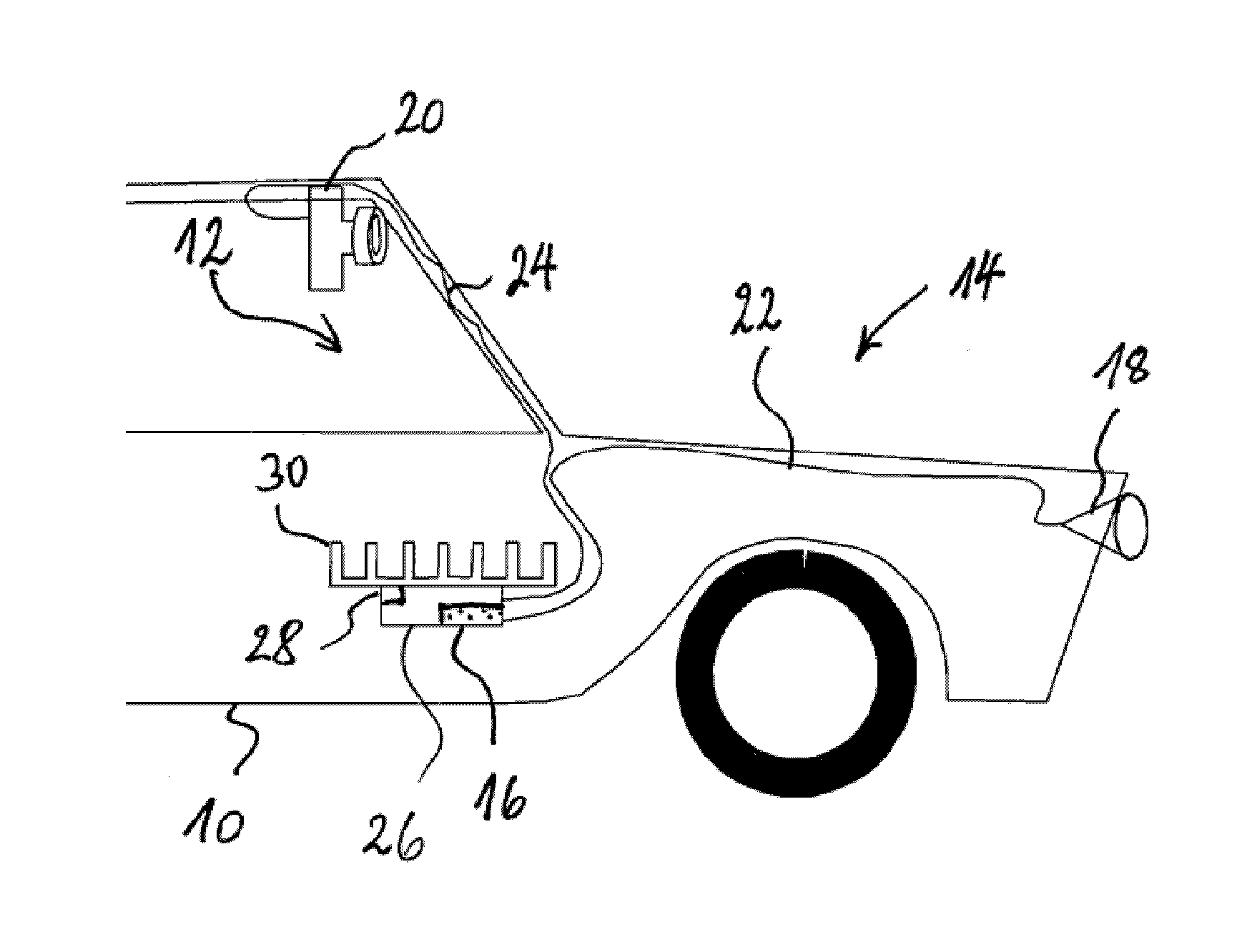

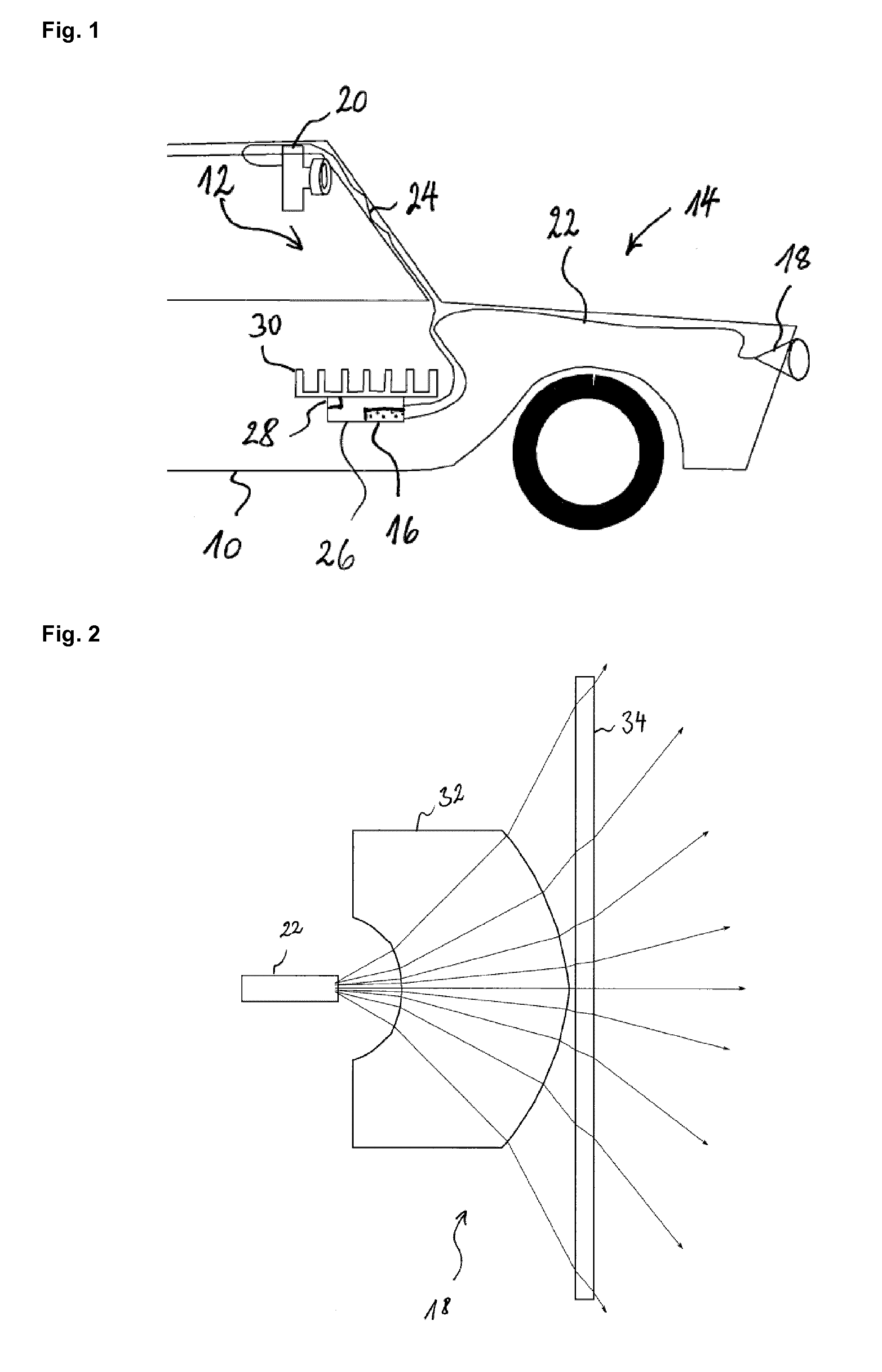

Driver assistance system comprising an optical detector with active scene illumination

ActiveUS20150168555A1Efficient Power ConversionReduces implanted lifetime of deviceOptical rangefindersOptical signallingDriver/operatorTime of flight

A driver assistance system (12) comprises an optical detector (14) with active scene illumination. The optical detector includes at least one of a stereoscopic imager, a time-of-flight imager, a structured-light imager and a night vision system. The optical detector includes a light source (16) for converting electrical energy into light, projection optics (18) for illuminating a scene with light generated by the light source and one or more optical sensors (20) for detecting light returned from the scene in response to the scene being illuminated. The light source is thermally connected to a heat sink (30) for evacuating heat produced by the light source and the projection optics are optically connected to the light source with one or more optical fibers (22) for transport of light generated by the light source to the projection optics.

Owner:IEE INT ELECTRONICS & ENG SA

Scrap chute mechanism

The invention aims to provide a scrap chute mechanism which can smoothly discharge materials under a condition that the height of a lower mould is small so as to reduce limit on design of the mould. The scrap chute mechanism comprises a scrap chute and an air cylinder, wherein the scrap chute is arranged on a lower mould body through a hinge; the air cylinder is vertically arranged at the lower part of the scrap chute; the end of a piston rod of the air cylinder is movably connected with or pushes against the bottom of the scrap chute. When the mechanism works, the piston rod of the air cylinder reciprocates vertically and constantly under the action of air, and the piston rod can jack the scrap chute up when moving upwards; the scrap chute can only rotate around the hinge because the scrap chute is limited by the hinge under the scrap chute; the angle of the scrap chute is increased in the rotating process, and scrap can be smoothly discharged. The scrap chute mechanism has a simple structure and can discharge smoothly under a condition that the angle of the scrap chute is small, therefore the design limit of the mould is reduced, and the reliability of automatic production is improved.

Owner:CHERY AUTOMOBILE CO LTD

PTC Device

InactiveUS20110170221A1Prevent oxidationLower resistancePositive temperature coefficient thermistorsArrangements responsive to excess currentWhich solventsPolymer

There is provided a PTC device wherein its PTC element functions appropriately even when the PTC device is used in an environment in which solvent is present. The PTC device includes (1) a polymer PTC component including a polymer PTC element and a first and a second metal electrodes disposed on both sides of the main surface thereof; (2) a lead connected to at least one of the metal electrodes of the polymer PTC component; and (3) a ceramic package having an open-ended space for accommodating the polymer PTC component, said open-ended space having at least one opening that defines the open-ended space. The lead closes said opening in order to isolate the polymer PTC component disposed in said open-ended space from the environment surrounding the ceramic package.

Owner:LITTELFUSE JAPAN GK

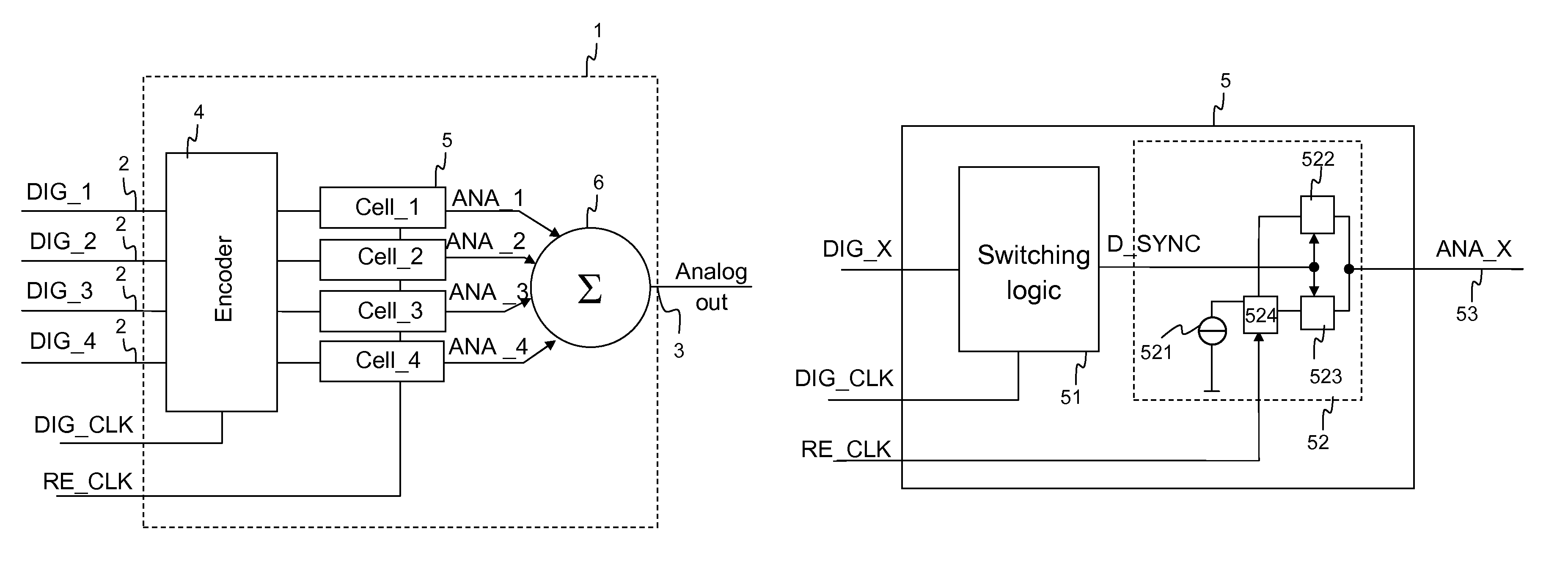

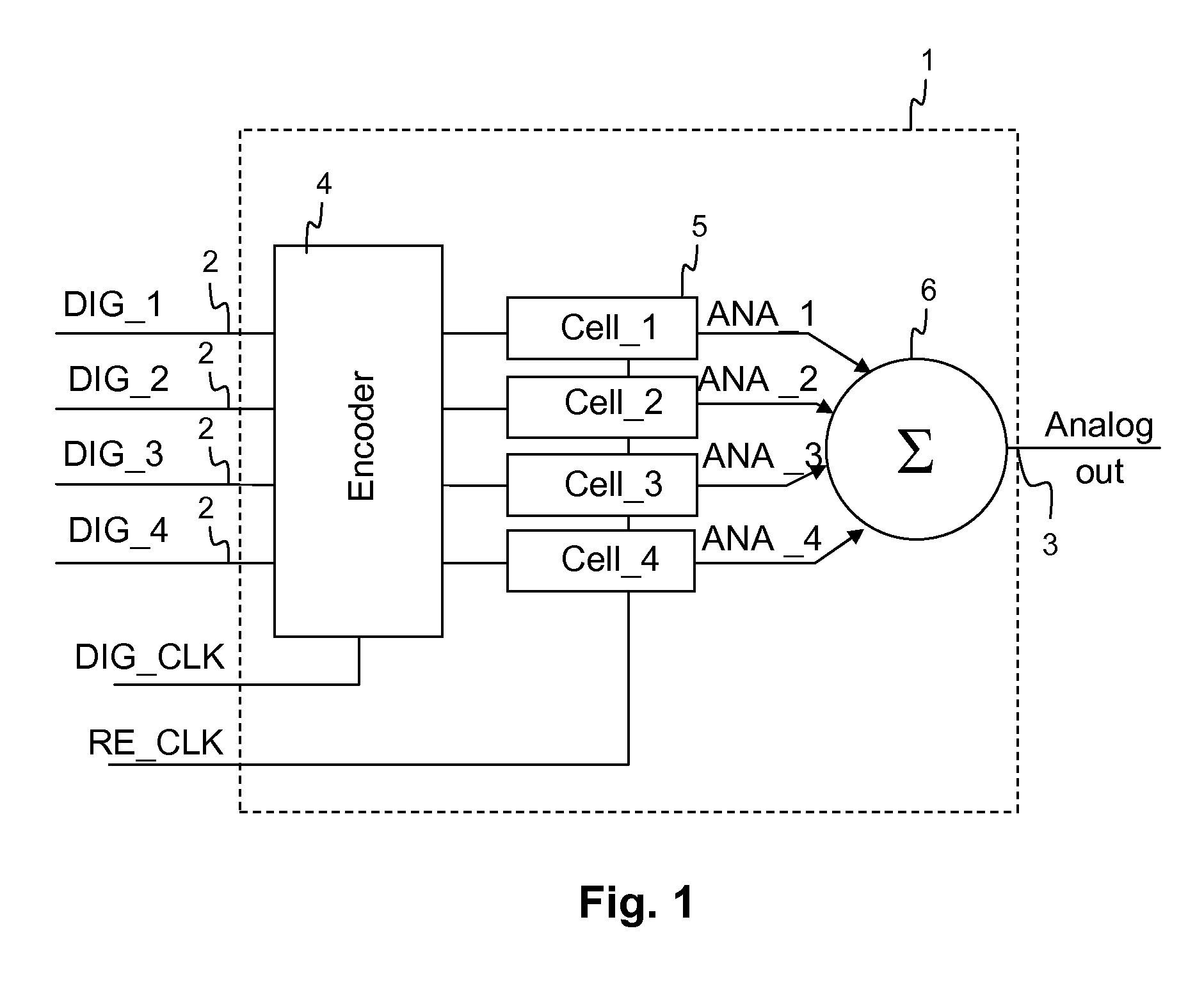

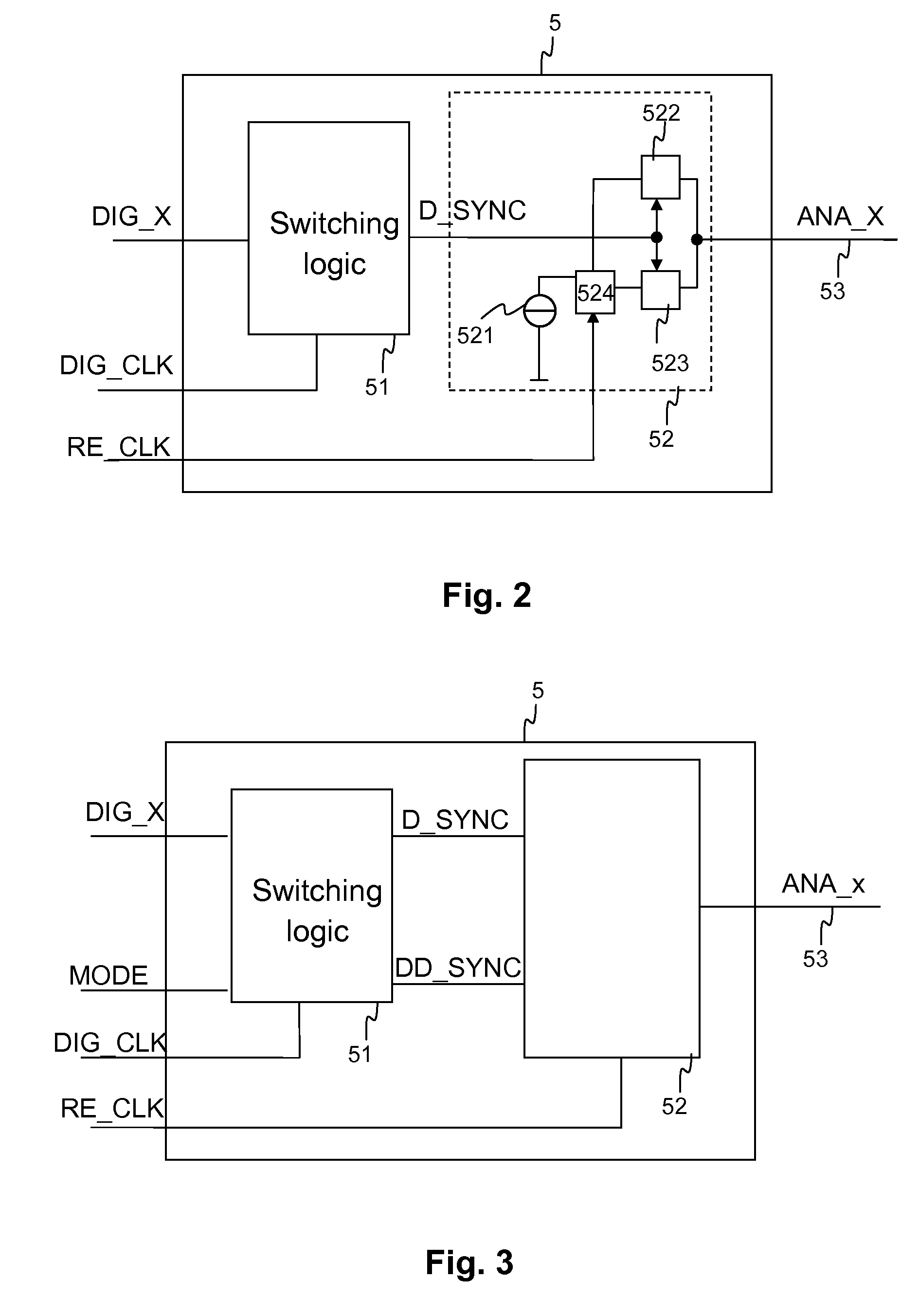

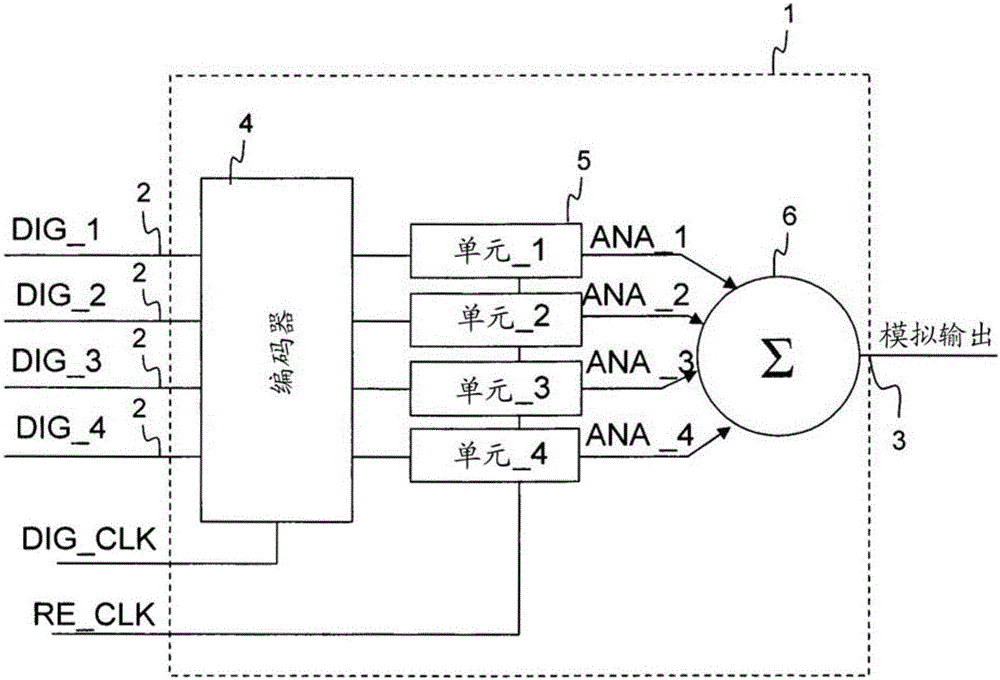

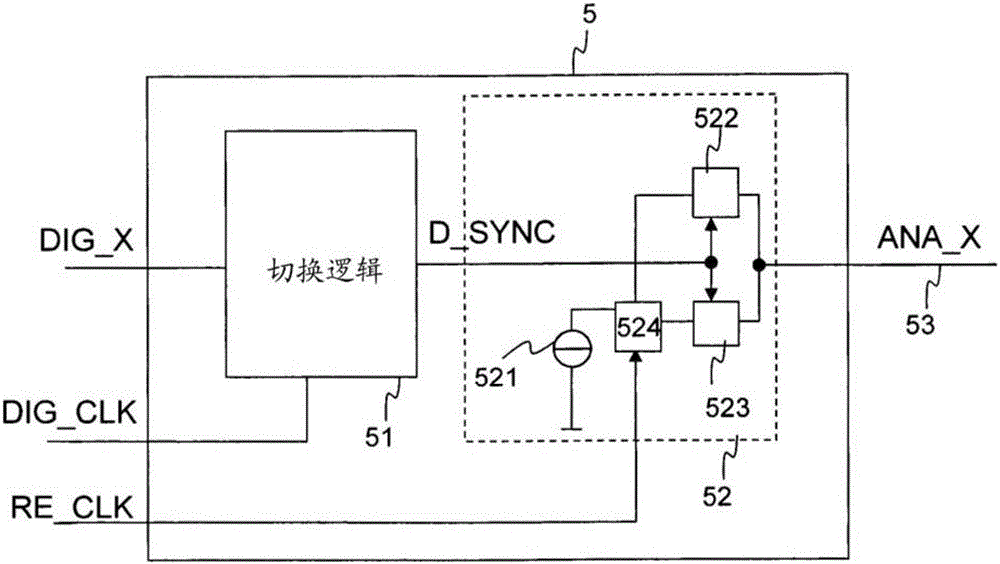

Digital-to-analog converter with local interleaving and resampling

ActiveUS9350377B1Reduce Design ConstraintsEliminates timing glitchElectric signal transmission systemsDigital-analogue convertorsDigital analog converterAnalog signal

The invention relates to a digital to analog converter and a method for a digital to analog conversion, wherein the digital to analog converter comprises at least one analog output cell configured to selectively generate a partial analog signal in response to a partial digital input signal. The analog output cell comprises an analog output switching unit that comprises a current source connected in series to a first node of a retiming switch and a first switch element as well as a second switching element, both connected with respect to first nodes in parallel to a second node of the retiming switch and a switching logic configured to regulate the transmission of said partial analog signal to an analog cell output.

Owner:ROHDE & SCHWARZ GMBH & CO KG

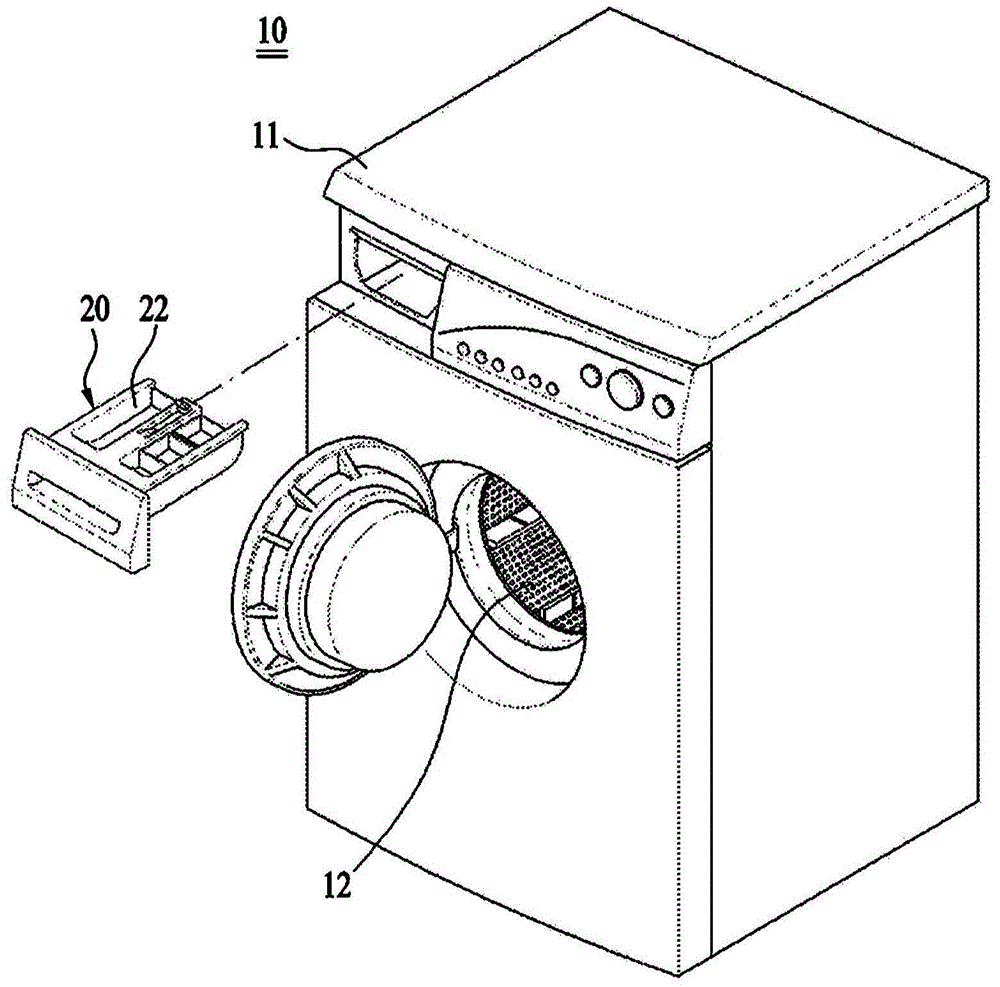

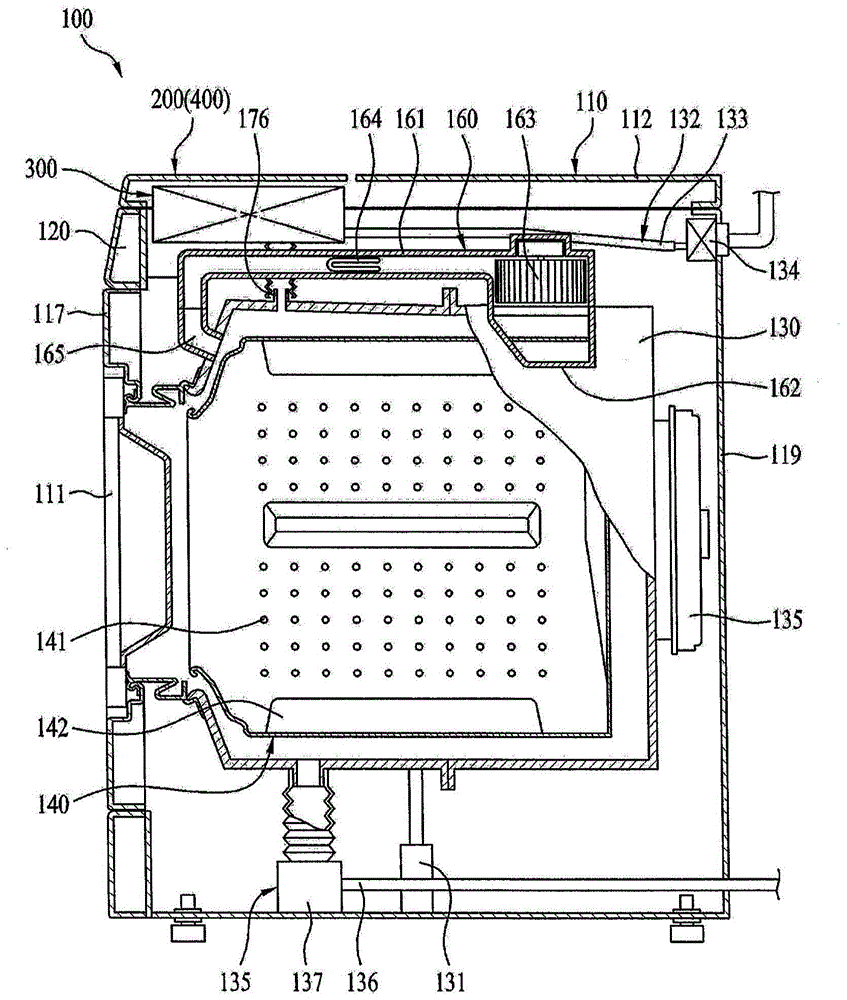

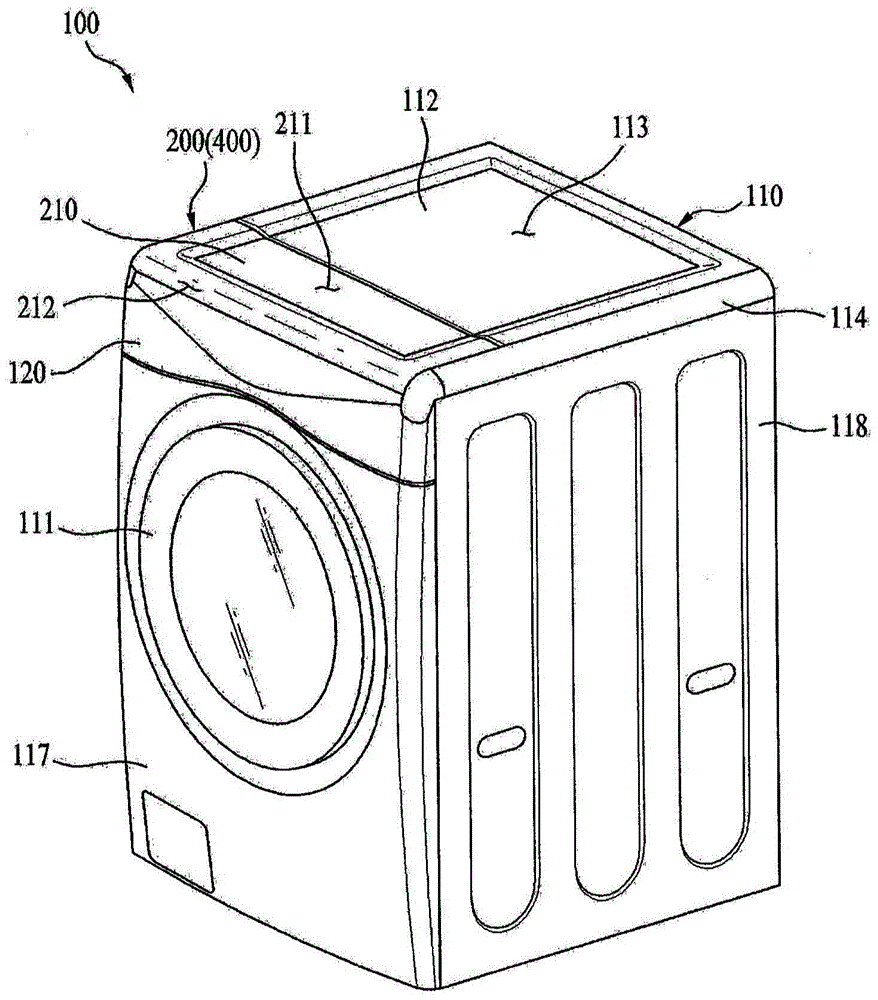

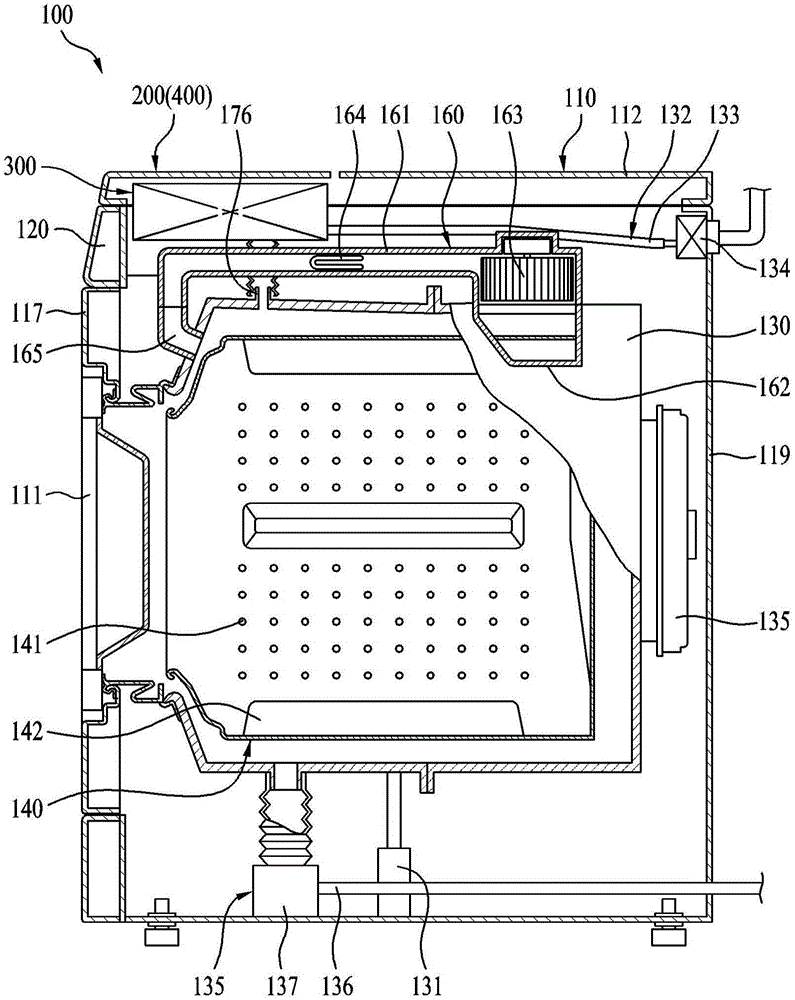

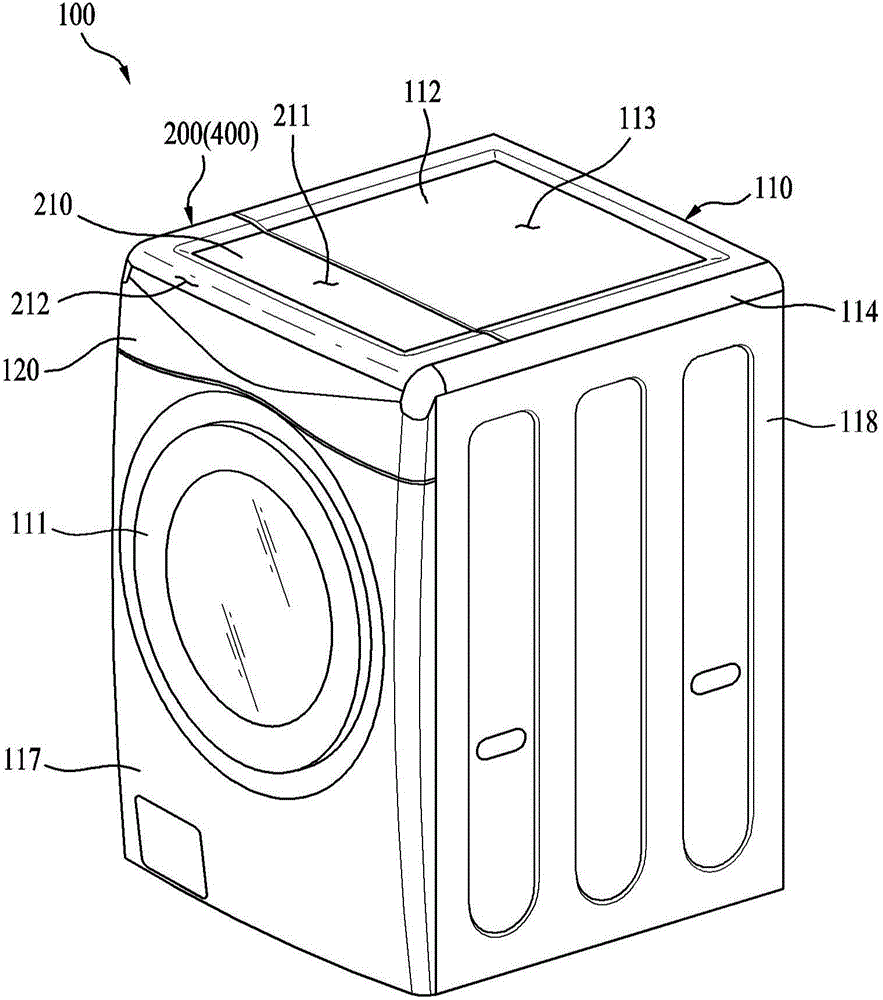

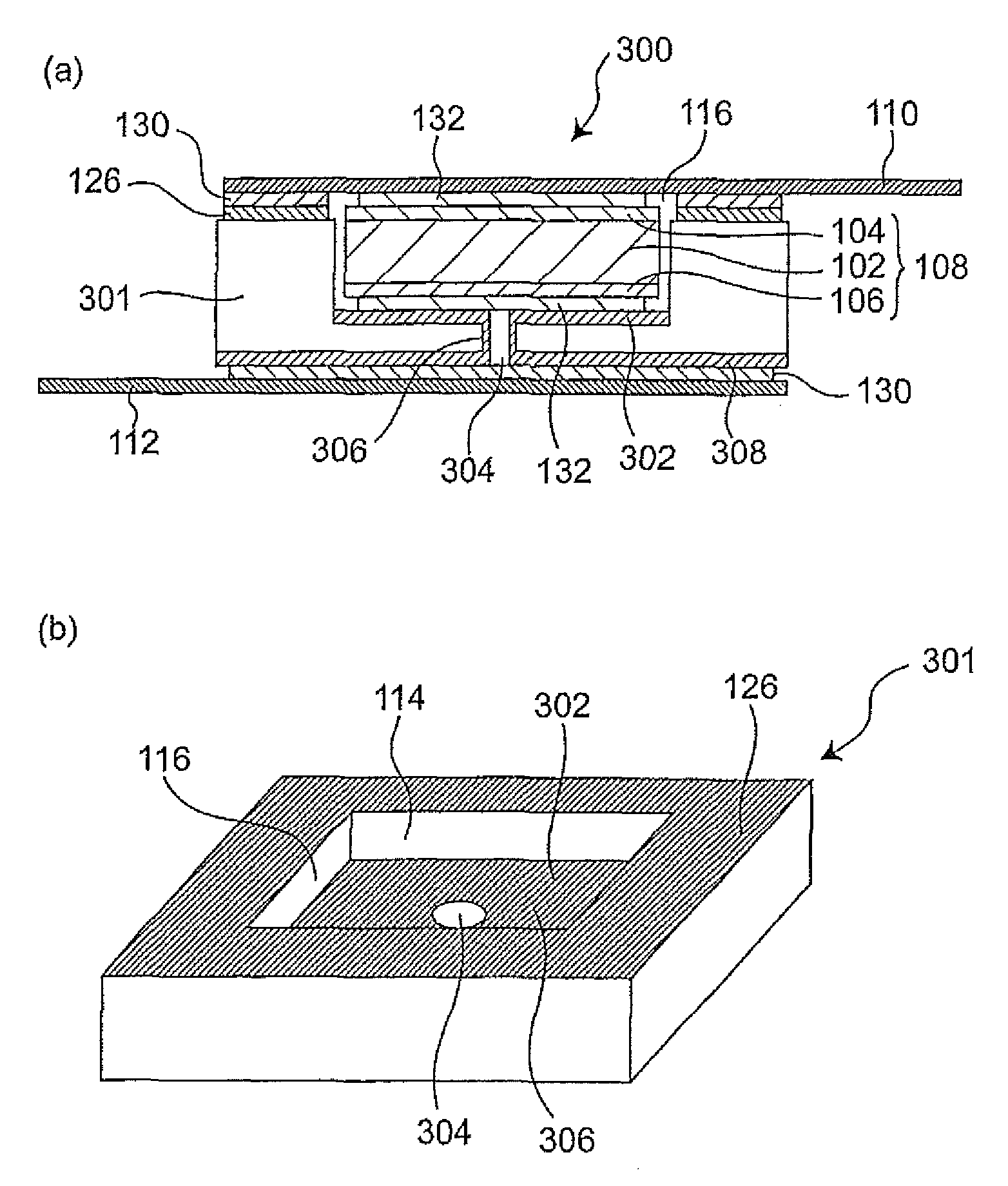

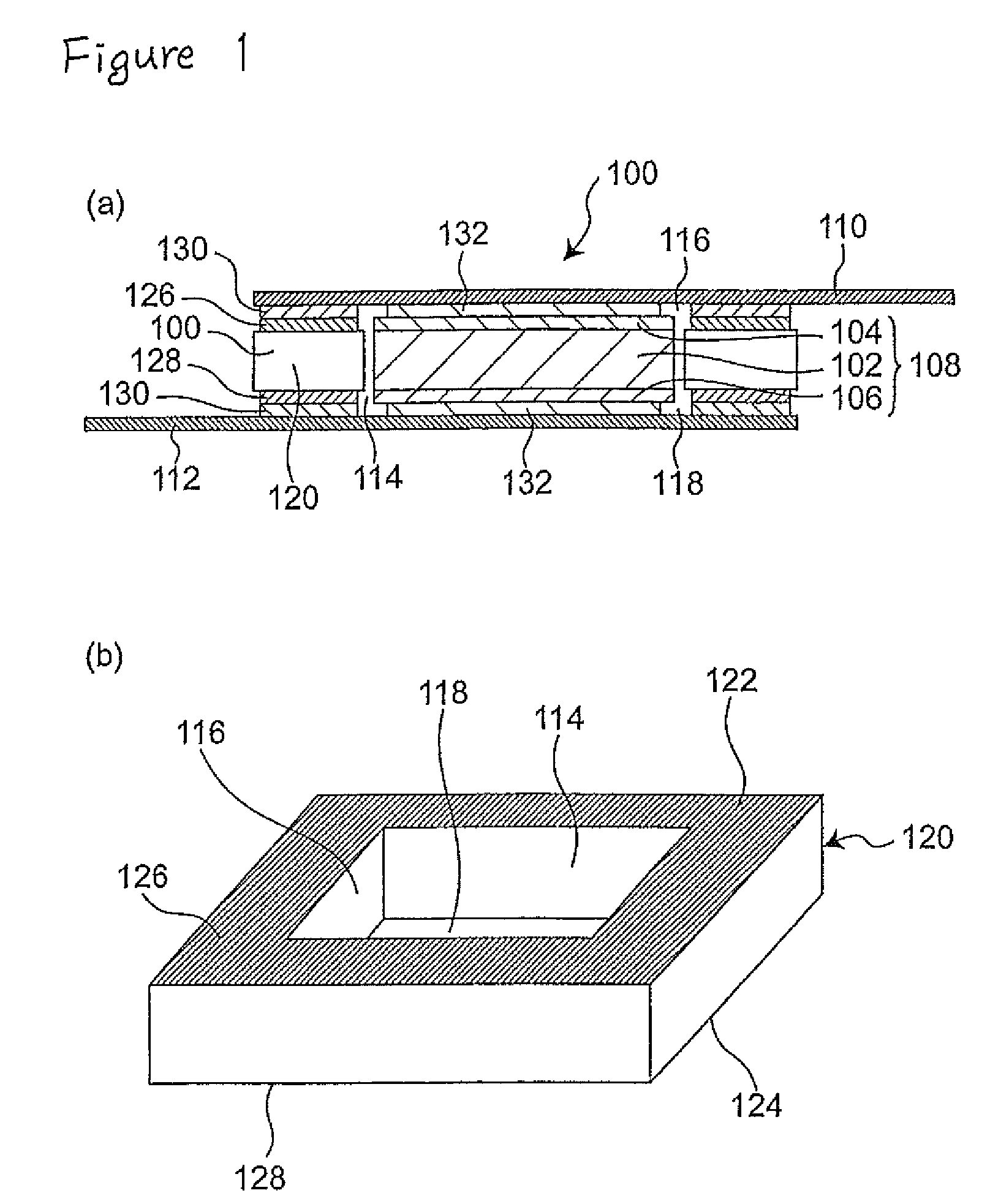

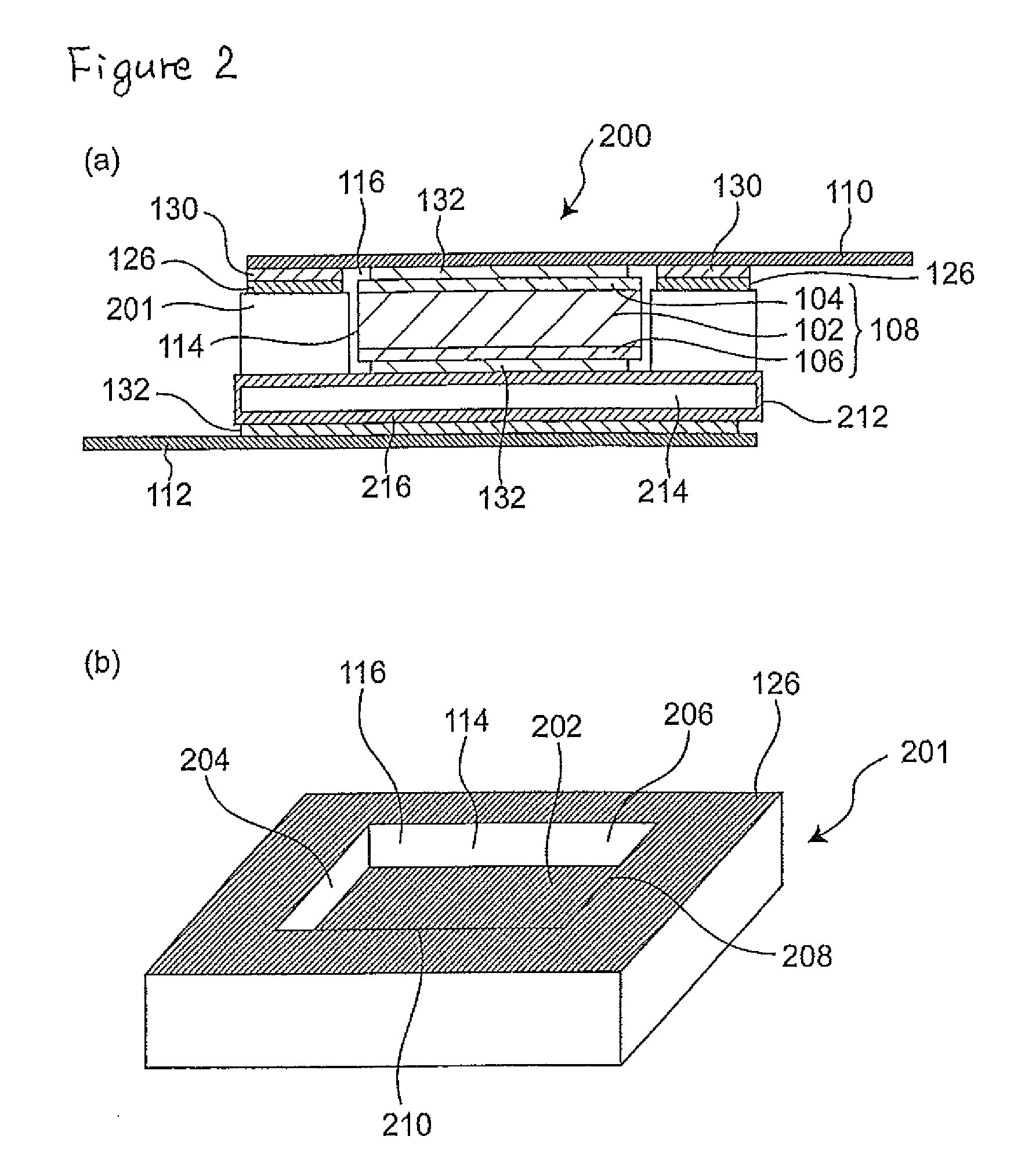

Washing machine

ActiveCN104674498AConvenient and easy to put inReduce Design ConstraintsOther washing machinesWashing machine with receptaclesMechanical engineering

Disclosed is a washing machine (100) comprising: a cabinet (110) including an upper cover (112) forming a rear portion of the upper surface of the cabinet (110); a tub (130) provided within the cabinet (110); a rotatable drum (140) provided within the tub (130); a detergent dispenser (300) located above the front portion of the tub (130) and exposed to the exterior of the washing machine; and a detergent dispenser cover (200, 400) opening and closing the upper surface of the detergent dispenser (300) exposed by the upper cover (112) and formed in front of the upper cover (112).

Owner:LG ELECTRONICS INC

Efficient exploding foil initiator and process for making same

InactiveUS7938065B2Improve protectionEase of mass productionIncandescent ignitionBlasting cartridgesEngineeringActuator

An actuator assembly that includes, in one example embodiment, a substrate with a bridge coupled between a first electrode and a second electrode on the substrate. A lithographically disposed flyer is positioned in proximity to the bridge. In a more specific embodiment, the actuator assembly further includes a lithographically disposed barrel that partially surrounds the flyer. A fireset is coupled to pins that extend through the substrate to the first electrode and the second electrode. The flyer further includes a three-dimensional surface adapted to flatten during flight. The flyer may be concave, convex, or may star shaped, may have perforations therein, or may exhibit another shape or other features.

Owner:DESAI AMISH

Washing machine

ActiveCN104674513AReduce Design ConstraintsOptimize locationOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

Disclosed is a washing machine (100) comprising: a cabinet (110) including an upper cover (112) forming a rear portion of the upper surface of the cabinet (110); a tub (130) provided within the cabinet (110); a rotatable drum (140) provided within the tub (130); a detergent dispenser (300) located above the front portion of the tub (130) and exposed to the exterior of the washing machine; and a detergent dispenser cover (200, 400) opening and closing the upper surface of the detergent dispenser (300) exposed by the upper cover (112) and formed in front of the upper cover (112).

Owner:LG ELECTRONICS INC

Digital-to-analog converter with local interleaving and resampling

ActiveCN106341134AEliminate Duty Cycle IssuesReduce Design ConstraintsDigital-analogue convertorsPhysical parameters compensation/preventionDigital analog converterAnalog signal

The invention relates to a digital to analog converter and a method for a digital to analog conversion, wherein the digital to analog converter comprises at least one analog output cell configured to selectively generate a partial analog signal in response to a partial digital input signal. The analog output cell comprises an analog output switching unit that comprises a current source connected in series to a first node of a retiming switch and a first switch element as well as a second switching element, both connected with respect to first nodes in parallel to a second node of the retiming switch and a switching logic configured to regulate the transmission of said partial analog signal to an analog cell output.

Owner:ROHDE & SCHWARZ GMBH & CO KG

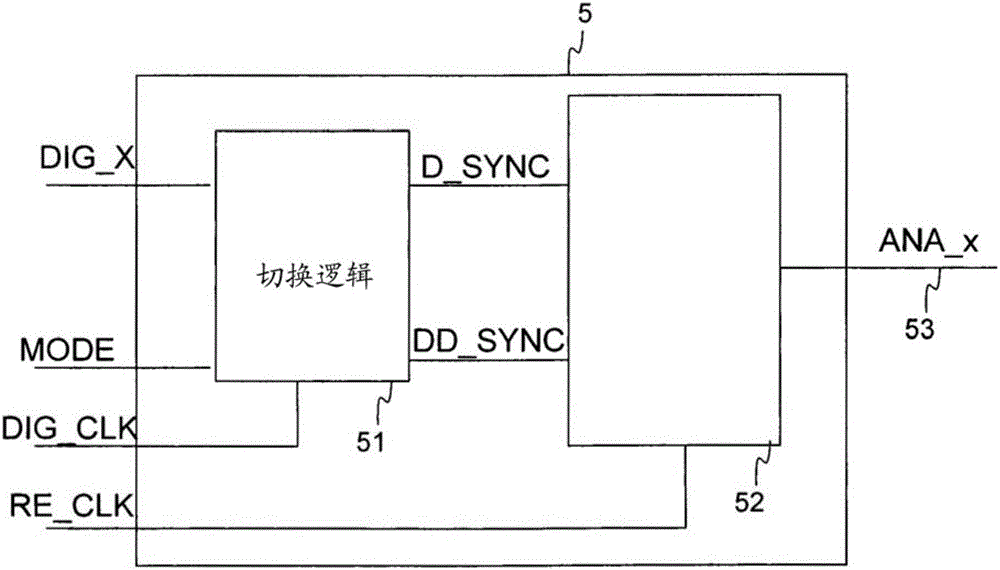

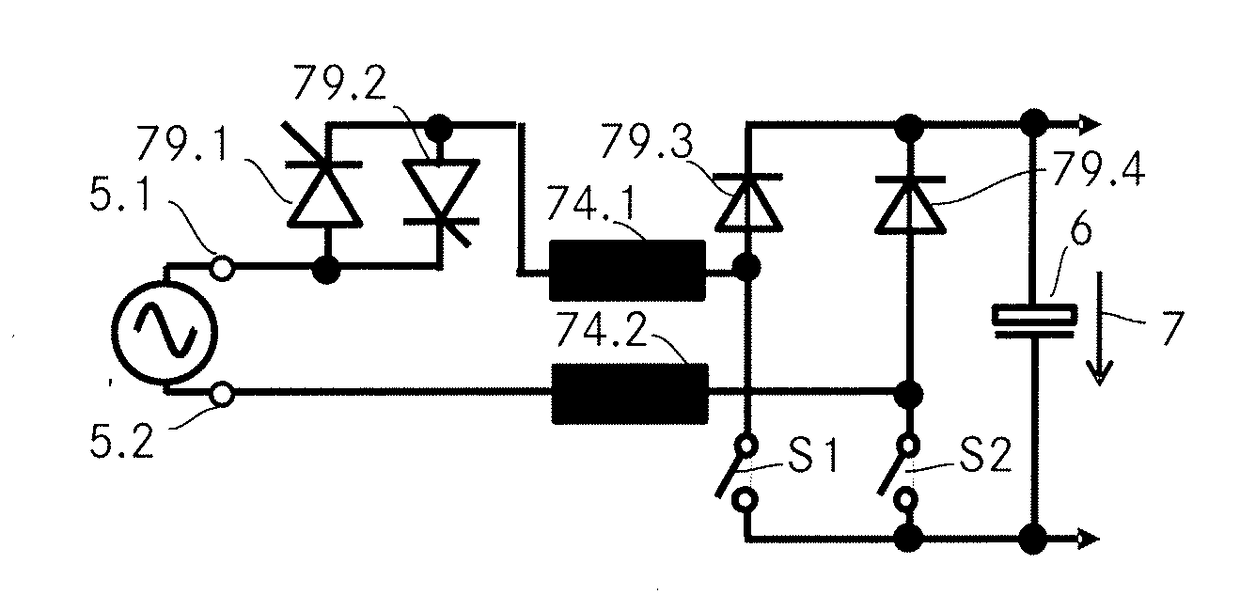

Resistorless precharging

ActiveUS20180083528A1Simple designReduce Design ConstraintsThyristorAc-dc conversion without reversalConvertersCharge current

A boost PFC converter includes a rectifier, a converter and an output stage comprising an output capacitor where the DC output voltage is provided across the output capacitor. The rectifier includes four rectifying elements connected in a full bridge configuration where the upper two of these four rectifying elements are thyristors and where the lower two are diodes. In that the thyristors are controlled such as to be open for only a part of each half period of the input voltage, the amount of current per half period that is passed to the output capacitor is controllable and can be made very small. Accordingly, the charge current for precharging the output capacitor can be controllably limited such that a bulky precharge resistor is not required anymore to avoid high inrush currents.

Owner:DELTA ELECTRONICS (THAILAND) PUBLIC CO LTD

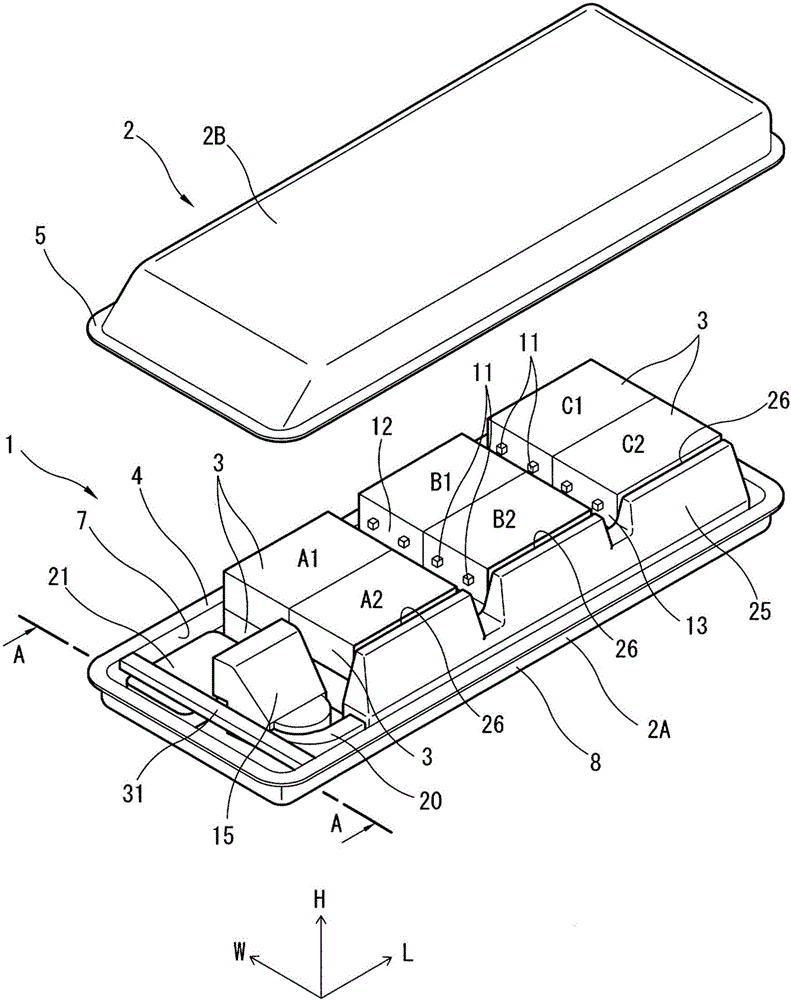

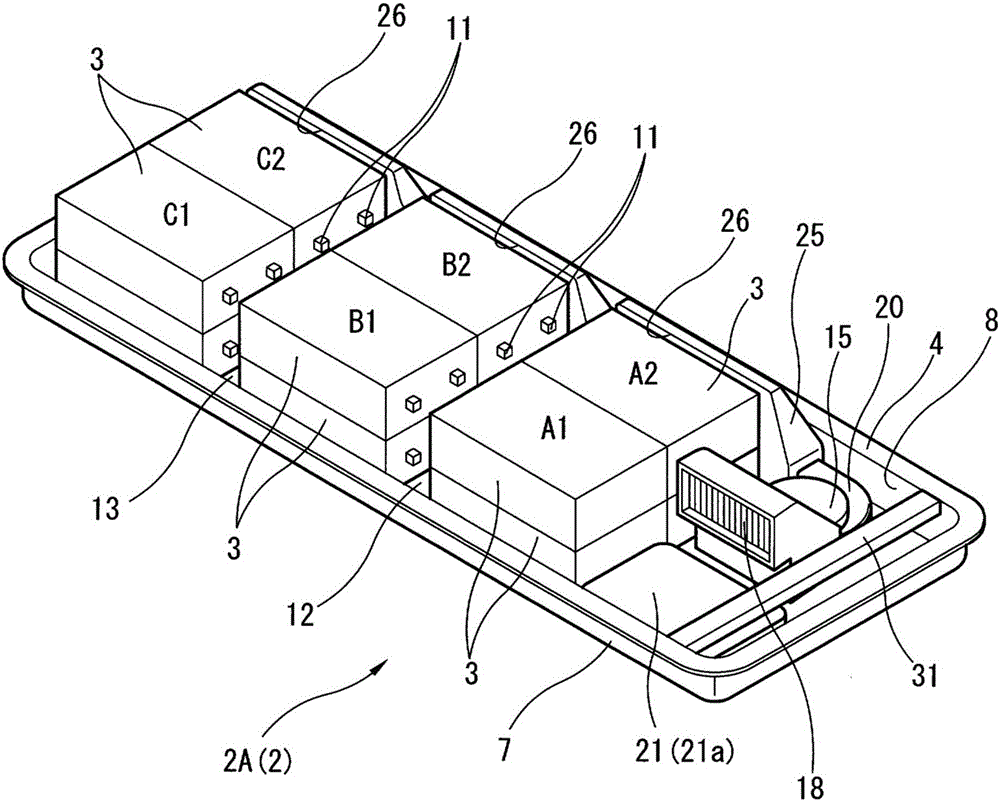

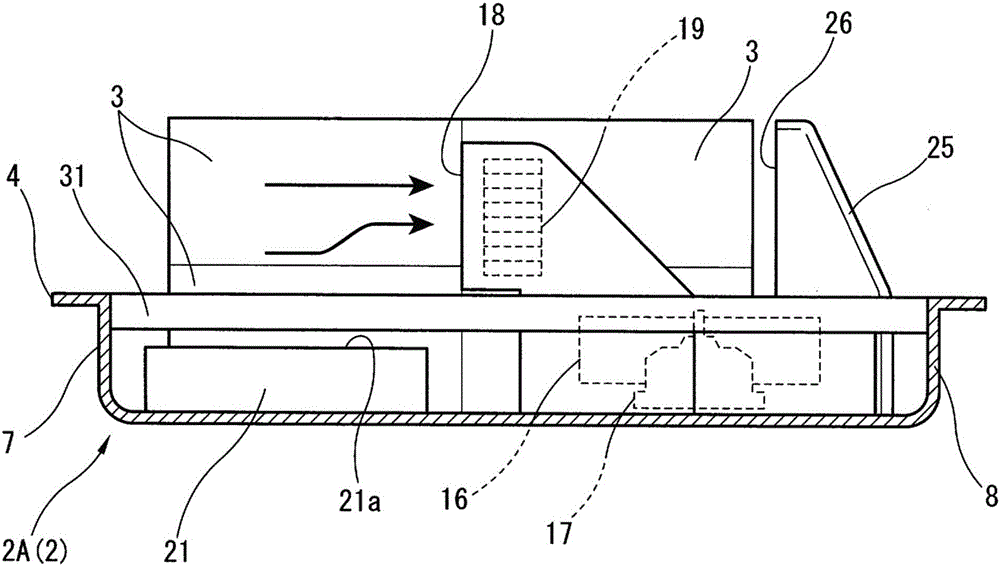

Battery pack for vehicle

ActiveCN106169629AIncreased Design FreedomReduce Design ConstraintsLarge-sized flat cells/batteriesFinal product manufactureCooling UnitsEngineering

Provided is a battery pack for a vehicle including an approximately rectangular pack case, a plurality of flat box-shaped battery modules, a cooling unit, and a junction box for storing a relay, in which: the plurality of battery modules is piled up flat in the pack case so that a terminal provided on a short side of each battery module is directed in a longitudinal direction of the pack case; the cooling unit is disposed at one end of the pack case in the longitudinal direction and configured to send and circulate cooling air in the pack case along an outer periphery of the pack case; and the junction box is disposed in a most downstream side of the circulating cooling air beside the cooling unit in a width direction of the pack case.

Owner:ENVISION AESC JAPAN LTD

PTC device

InactiveUS8421583B2Resistance of the PTC component can be maintained lowPrevent oxidationCurrent responsive resistorsEmergency protective arrangements for automatic disconnectionPolymer scienceEngineering

There is provided a PTC device wherein its PTC element functions appropriately even when the PTC device is used in an environment in which solvent is present. The PTC device includes: (1) a polymer PTC component including a polymer PTC element and a first and a second metal electrodes disposed on both sides of the main surface thereof; (2) a lead connected to at least one of the metal electrodes of the polymer PTC component; and (3) a ceramic package having an open-ended space for accommodating the polymer PTC component, said open-ended space having at least one opening that defines the open-ended space. The lead closes said opening in order to isolate the polymer PTC component disposed in said open-ended space from the environment surrounding the ceramic package.

Owner:LITTELFUSE JAPAN GK

Pipeline dredging and flow guiding tool for water conservancy construction

InactiveCN109894437ASolve the problem of chip removalReduce volumeHollow article cleaningImpellerWater flow

The invention discloses a pipeline dredging and flow guiding tool for water conservancy construction. The pipeline dredging and flow guiding tool for water conservancy construction comprises a rotating head, an outer cylinder, an inner cylinder, a core body part and a back end cover; the rotating head comprises a conical shell-shaped body, the inner side wall of the body is provided with cutter teeth, the outer side wall of the body is provided with blades, and the length of the blades is gradually decreased from the large end of the body to the small end of the body; water outlet pipelines are arranged in a backward extending mode in the length direction of a core cylinder; the portion nearby the cavity bottom of a water injection cavity of the inner cylinder is provided with jetting holes used for jetting out water flow, and the water flow jetted out from the jetting holes exactly impacts the blades to drive the rotating head to conduct rotating cutting; and a conical thrust cone iscoaxially installed in the core cylinder in a hung mode, the cone tip of the thrust cone faces the small end port of the body, and an impeller used for enabling air to quickly flow towards a back portof the core cylinder is coaxially installed on the end face of the thrust cone. The device is high in dredging capability and extremely high in dredging efficiency.

Owner:黄虎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com