Patents

Literature

45 results about "Which solvents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

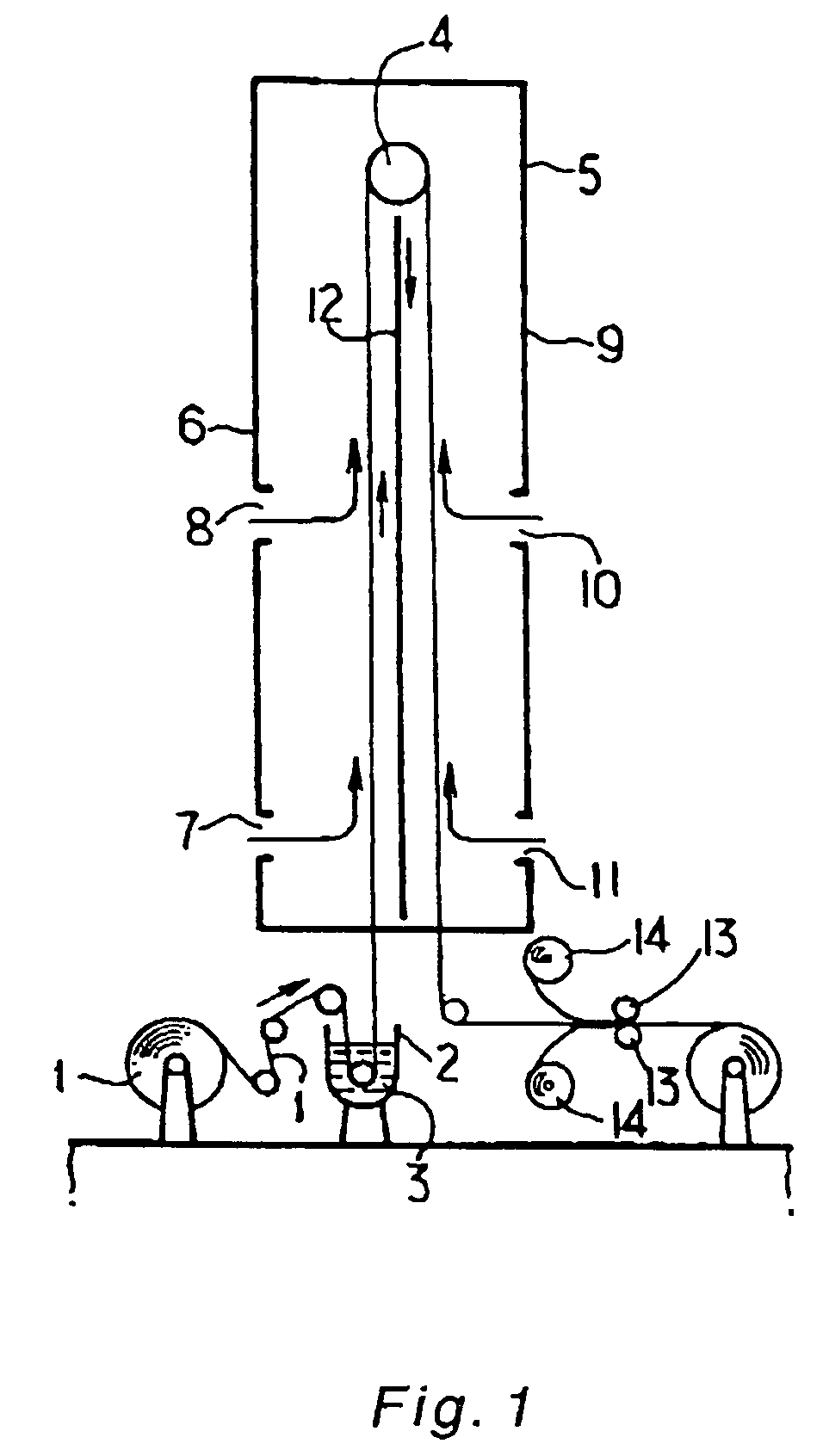

Process for manufacturing potable water and apparatus therefor

InactiveUS20140319056A1Save energy necessarySave energyWaste water treatment from quariesMembranesWater vaporPotable water

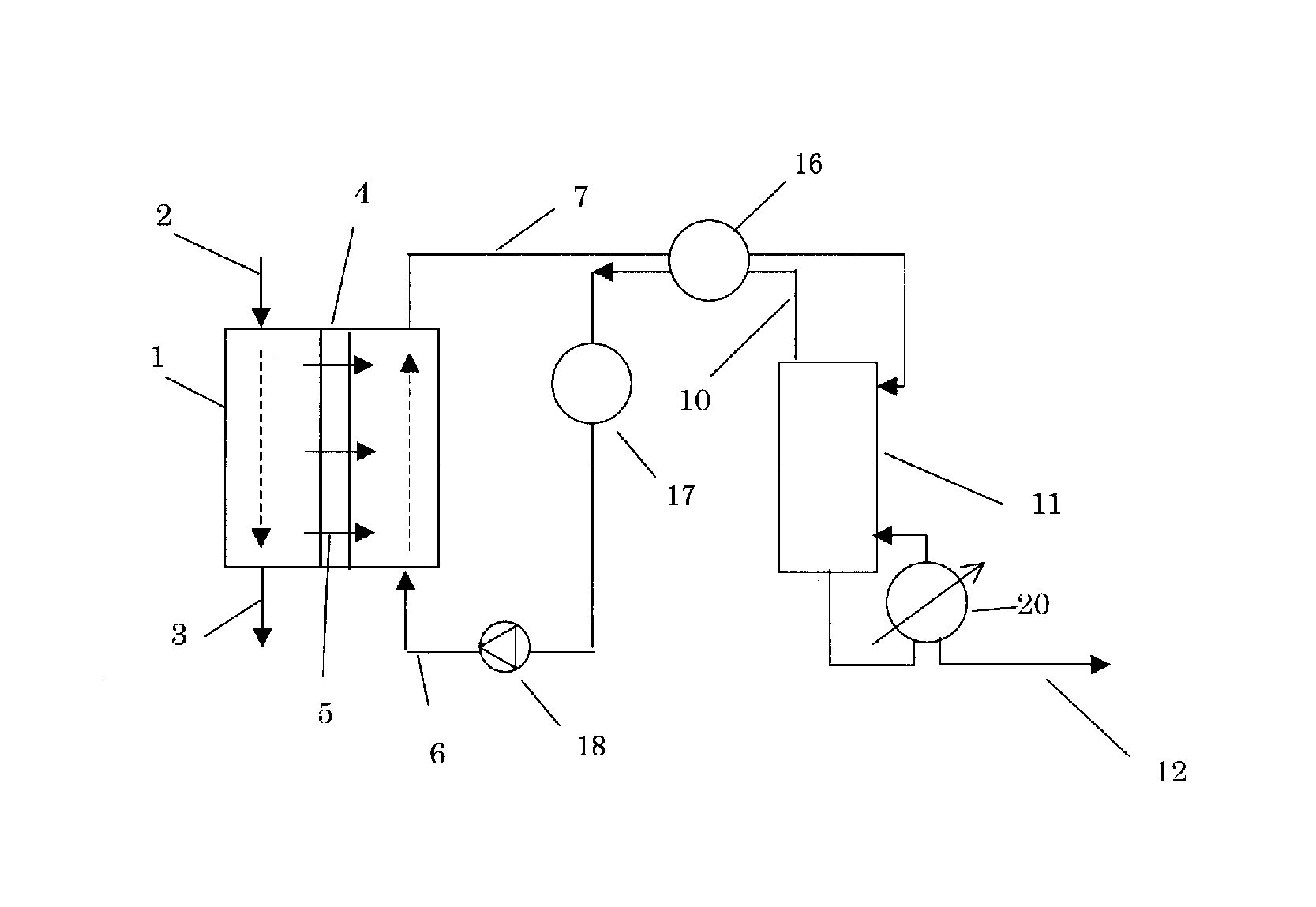

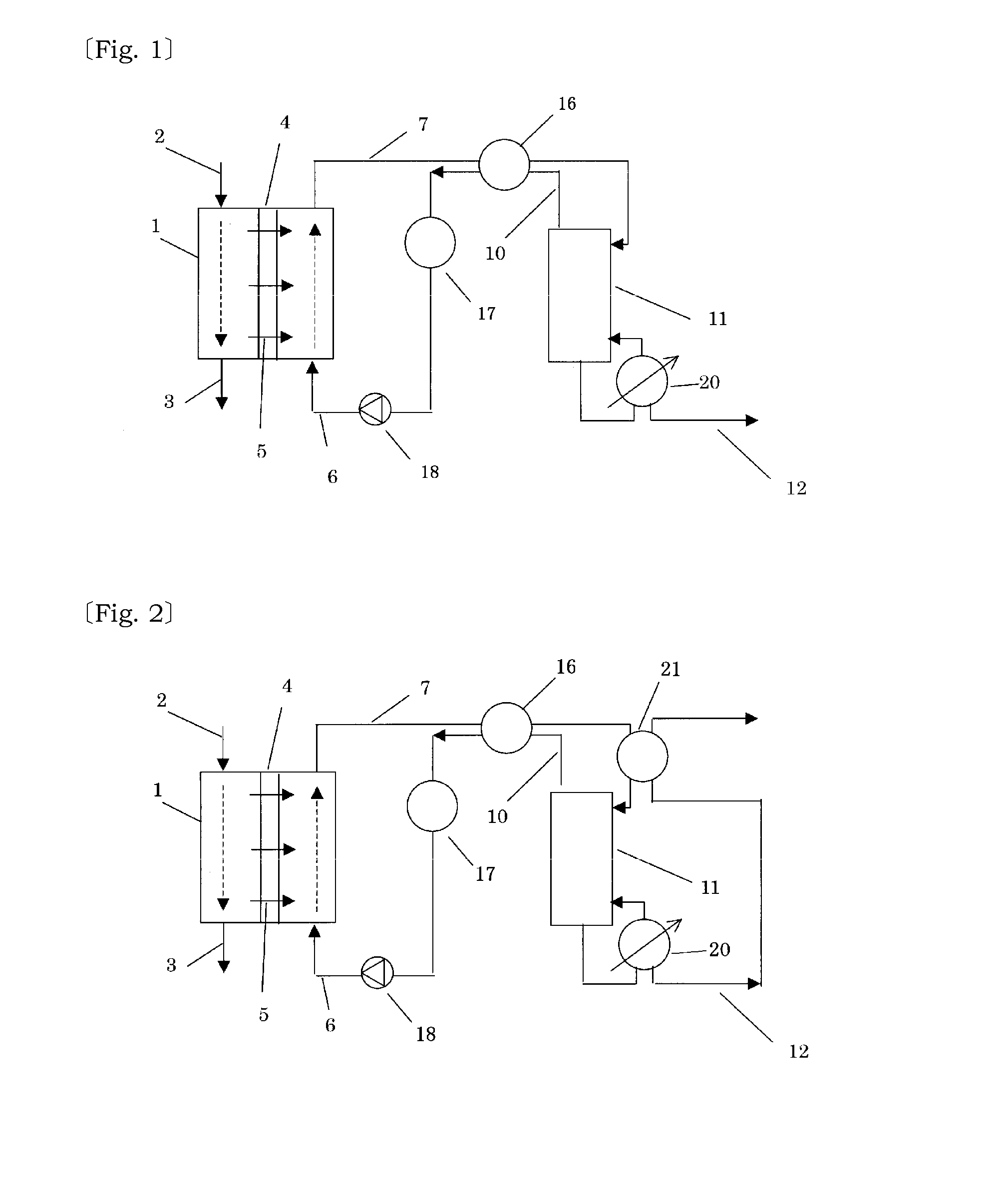

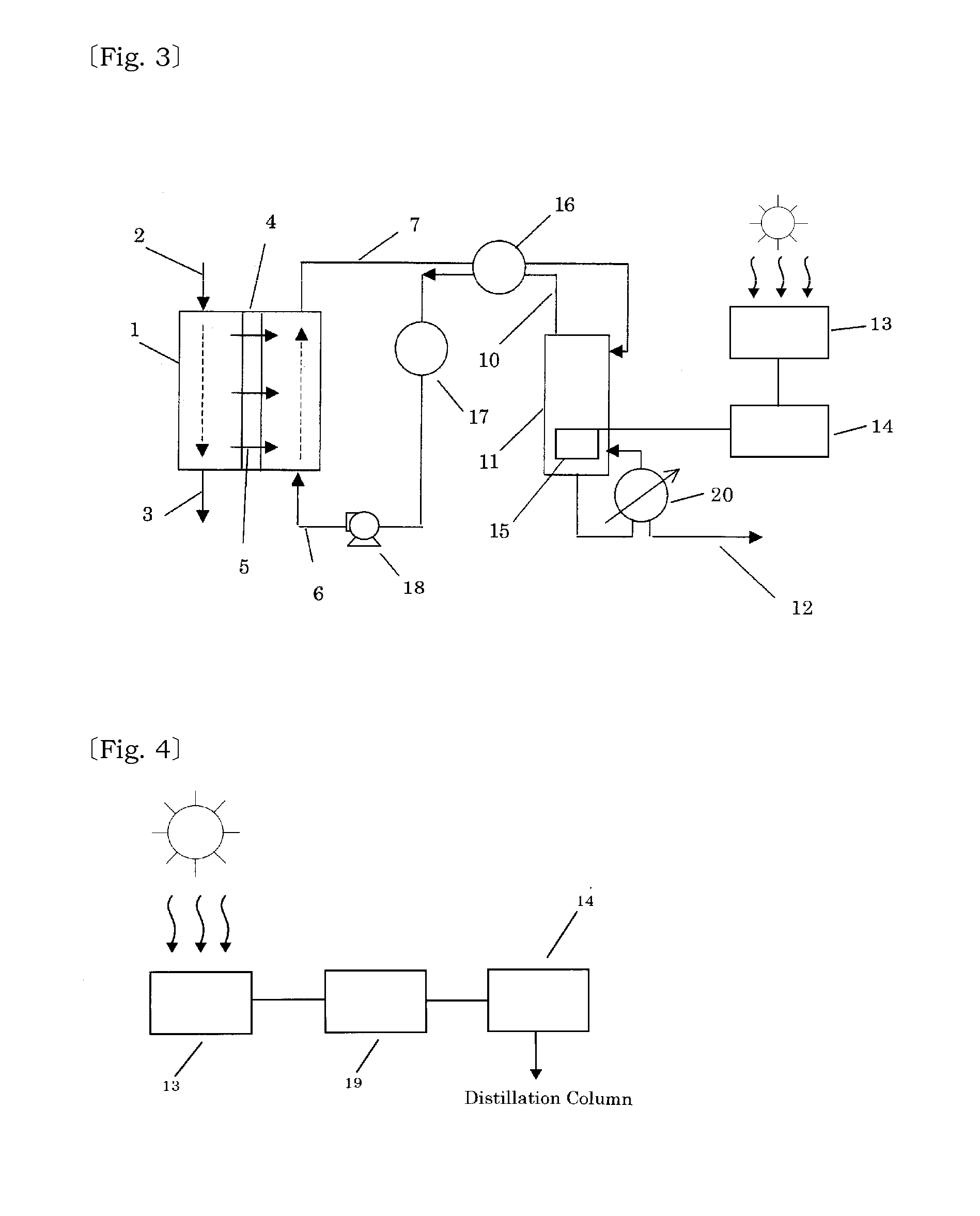

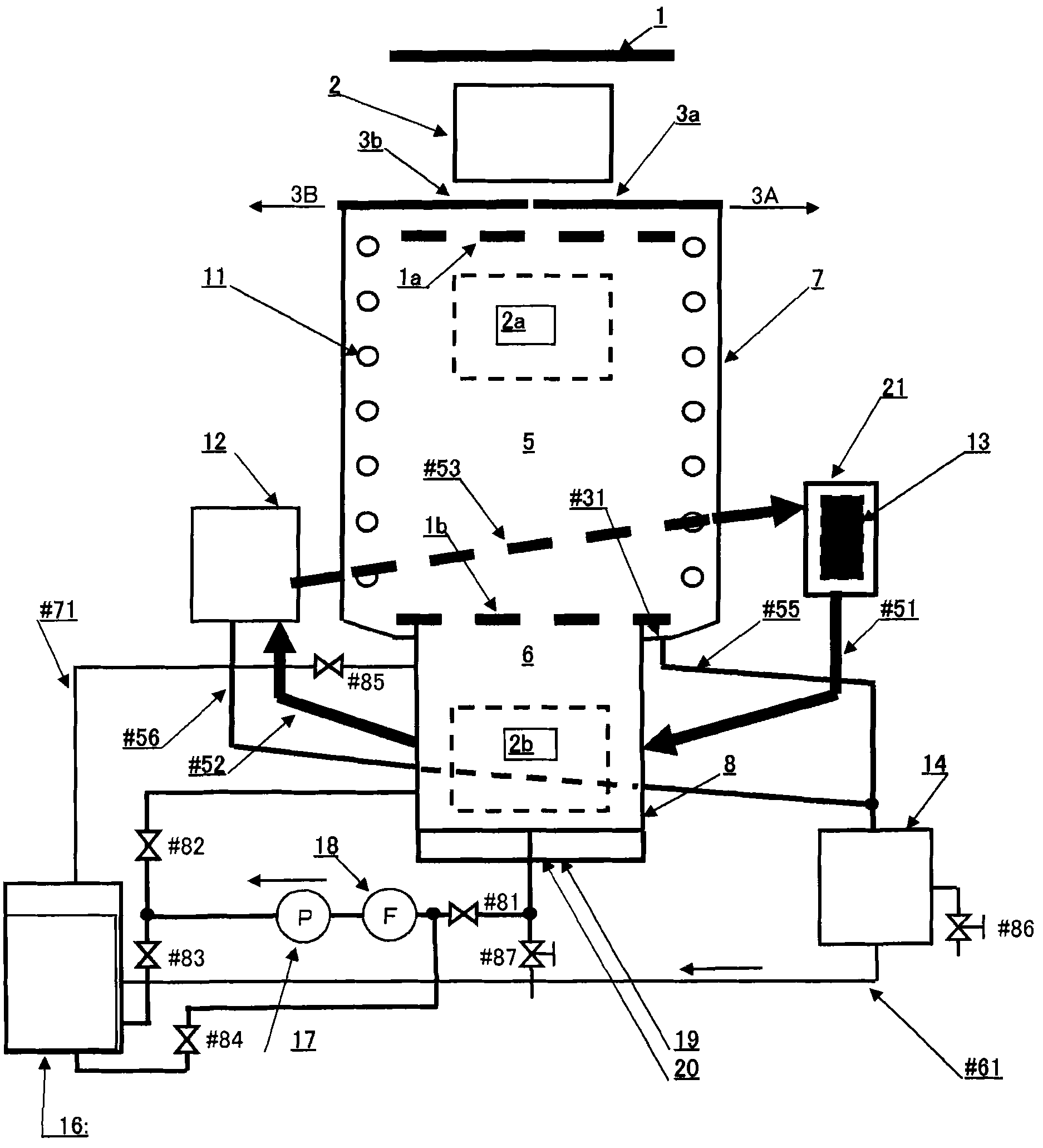

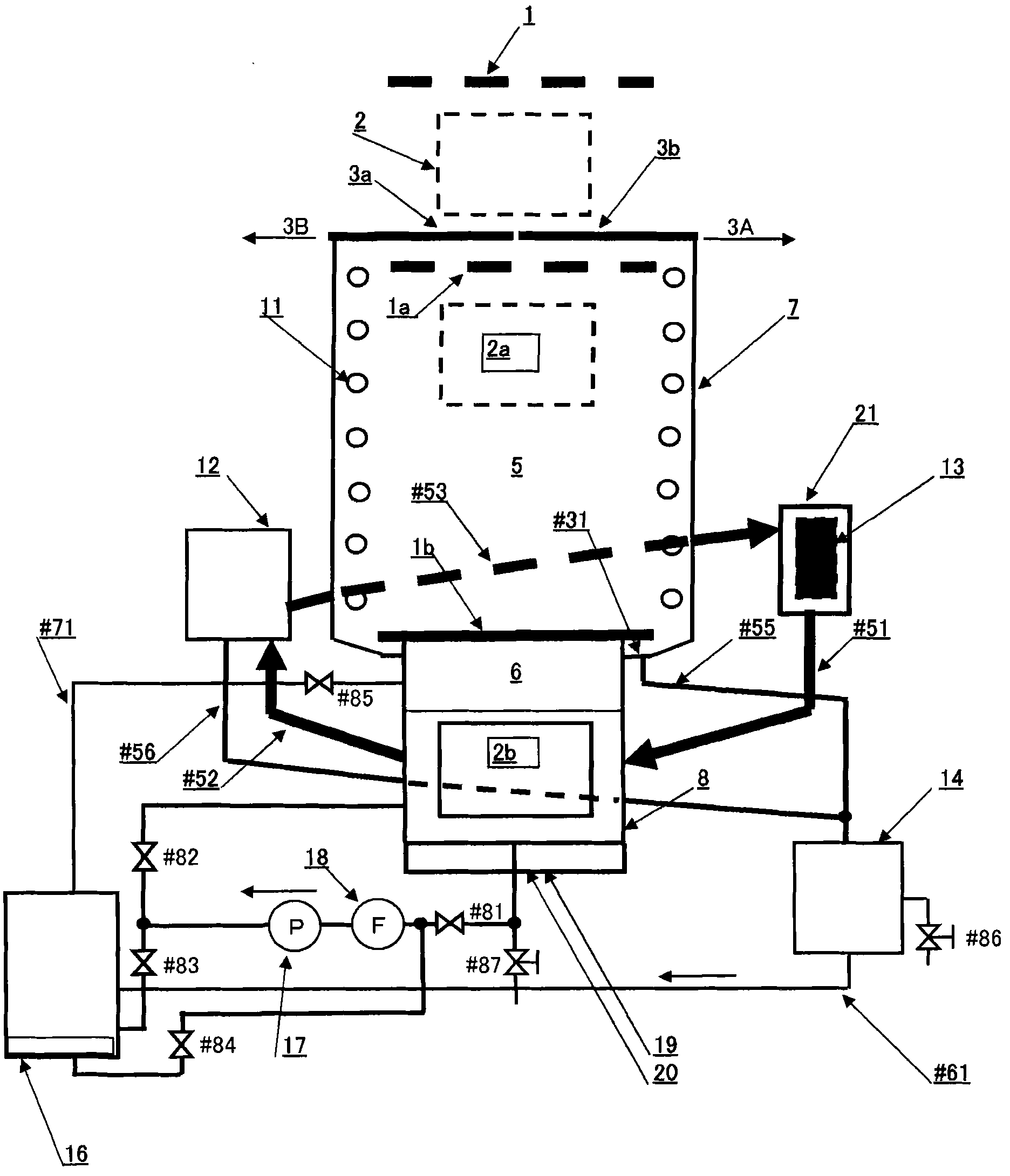

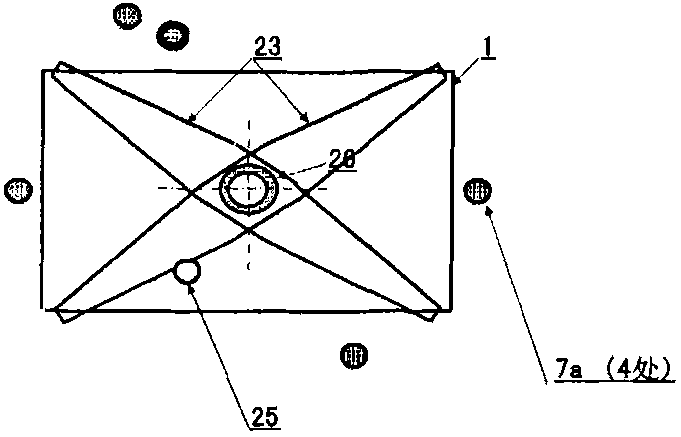

It is to provide a process for manufacturing potable water from a liquid to be treated, such as seawater by using forward osmosis membrane, wherein the solution after the separation of water from dilute draw solution diluted by the migration of water from the liquid to be treated, is stably regenerated and reutilized and an apparatus therefor, and the process and apparatus are a process for manufacturing potable water which comprises, a forward osmosis step wherein a liquid of which solvent is water is allowed to contact with a draw solution produced by dissolving a prescribed amount of a volatile material in water through a semi-permeable membrane, and water in said liquid is allowed to migrate to said draw solution through said semi-permeable membrane, a distillation step wherein a dilute draw solution having been diluted with water which was produced in said step is adjusted to a prescribed temperature, and then is delivered to a distillation column where gas comprising the volatile material and water vapor is discharged from the top of the column and potable water is discharged from the bottom of the column, and a cooling • regeneration step wherein said draw solution is regenerated by cooling said gas and an apparatus therefor.

Owner:JFEENG CORP

Macroporous gel, its preparing and its use

A macroporous gel is disclosed which is obtainable by a) polymerizing an aqueous solution of one or more water-soluble monomers selected from the group consisting of: N-substituted and non-substituted (meth)acrylamides; N-alkyl substituted N-vinylamides; hydroxyalkyl (meth)acrylates; vinylacetate; alkylethers of vinyl alcohol; ringsubstituted styrene derivatives; vinyl monomers; (meth)acrylic acid and salts thereof; silicic acid; and monomers capable of forming polymers via polycondensation, under freezing at a temperature below the solvent crystallization point, at which solvent in the system is partially frozen with the dissolved substances concentrated in the non-frozen fraction of solvent to the formation of a cryogel, and b1) modifying the cryogel by introducing a member selected from the group consisting of ligands, charged groups, dyes and hydrophobic groups thereinto (i) in one or more steps by methods known per se subsequent to thawing of the cryogel or (ii), when appropriate, by using appropriately substituted monomers in the polymerization reaction; or b2) carrying out the polymerization in the presence of a filler, or; b3) carrying out the polymerization in the presence of a filler and, after thawing of the cryogel, modifying the cryogel as set forth under b1) above. A method for its preparation is also disclosed as is also some uses thereof.

Owner:PROTISTA BIOTECH AB

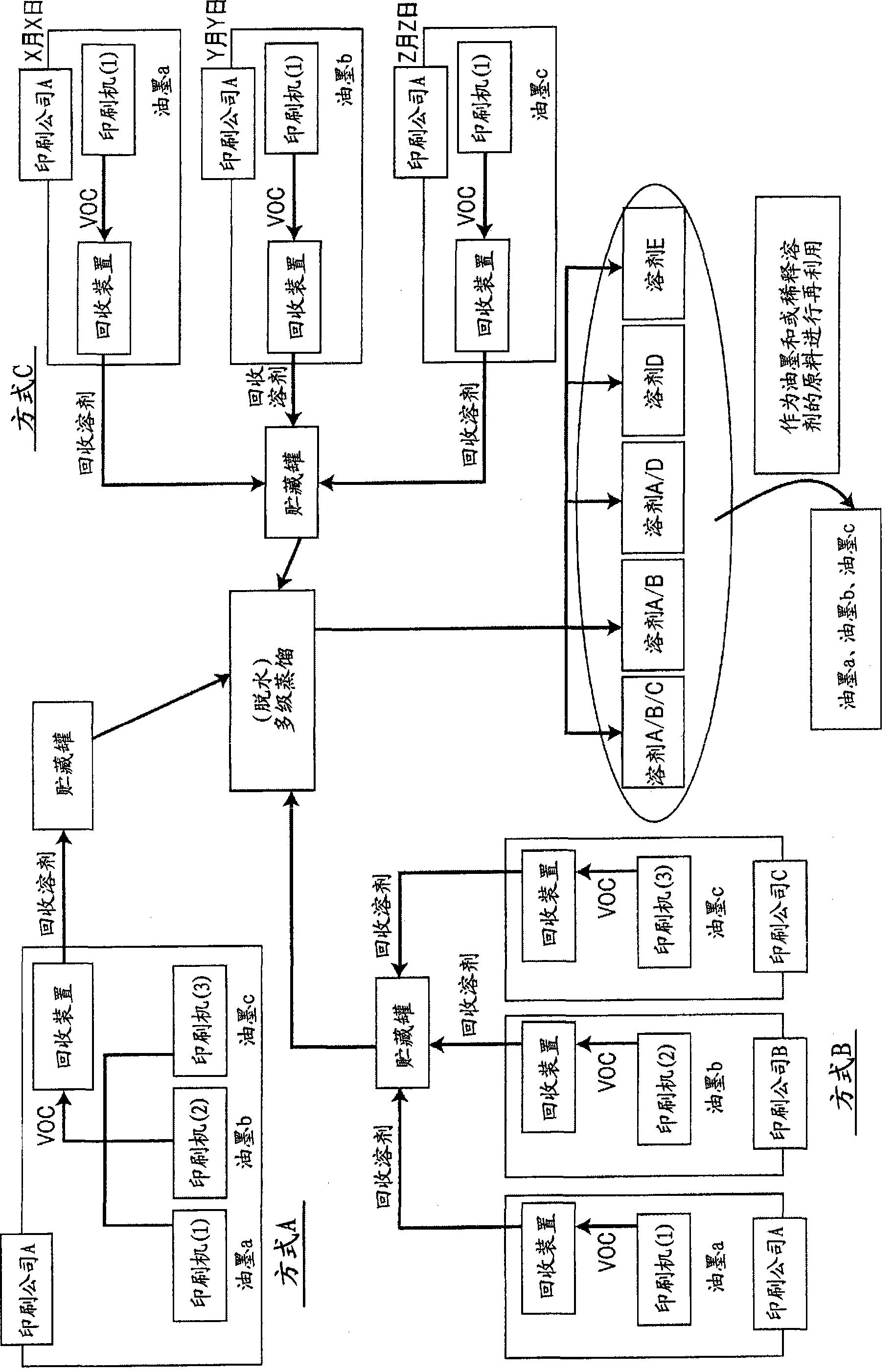

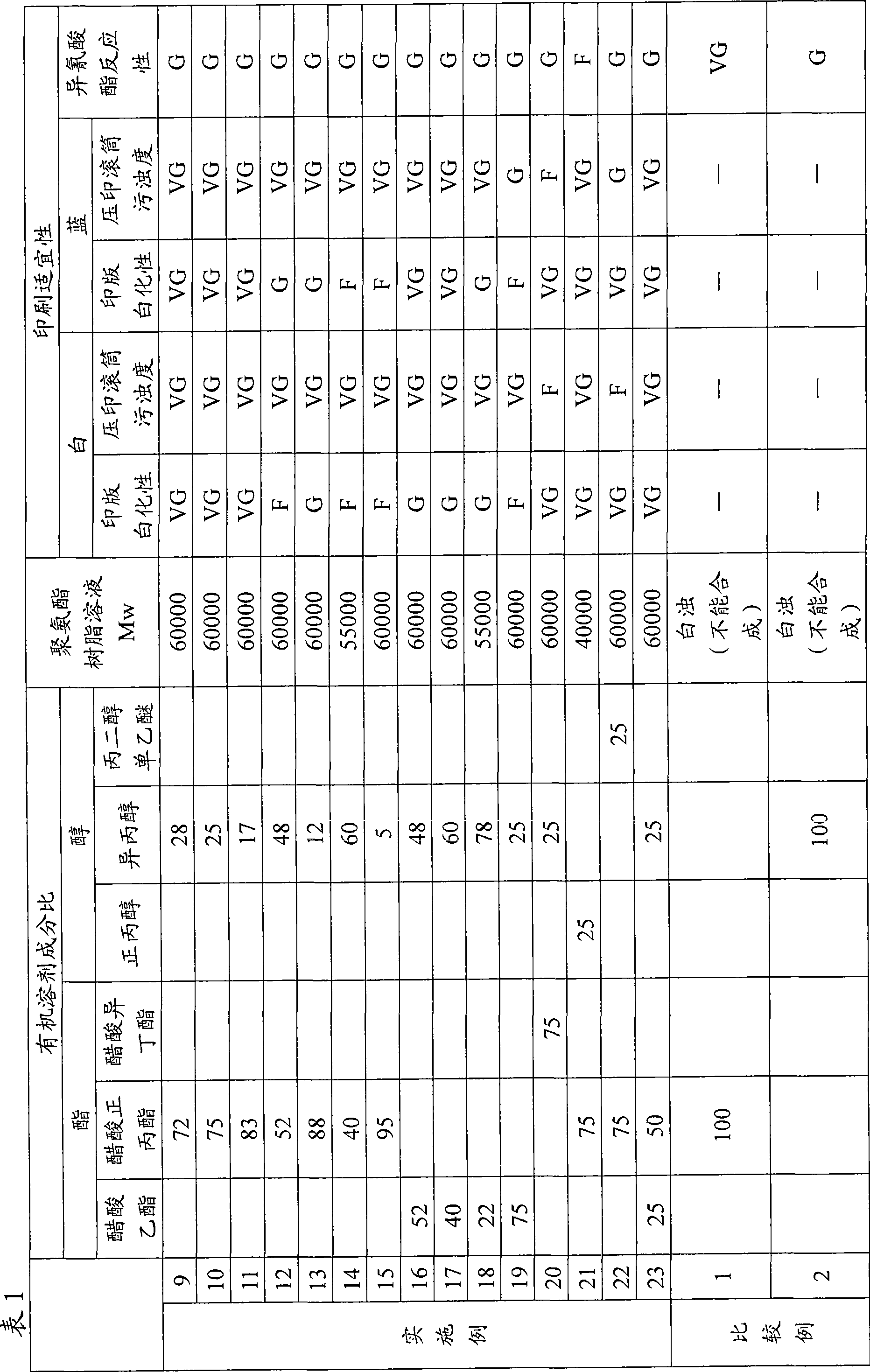

Printing ink composition of solvent recovery/reuse type, diluent solvent, and method of reusing recovered solvent

A method of solvent recovery / reuse in printing or coating with a printing ink composition containing solvents which comprises: a step in which solvents which have volatilized are recovered with a solvent recovery apparatus; a step in which the solvents obtained are separated by multistage distillation into single solvents and / or two or more azeotropic compositions; and a step in which the solvents recovered are reused as a raw printing ink material and / or a raw material for a diluent solvent.

Owner:TOYO INK SC HOLD CO LTD

Single crystal thin film of organic semiconductor compound and method for producing the same

Disclosed is a method for producing a single crystal thin film of an organic semiconductor compound, which comprises a step for forming a liquid film (9) on a substrate (2) by coating the substrate (2) with an organic solvent having a dielectric constant of not less than 4.5 in which solvent an organic semiconductor compound can be dissolved, a step for supplying and dissolving the organic semiconductor compound into the liquid film (9), and a step for crystallizing the organic semiconductor compound in the organic solvent.

Owner:FUJIFILM CORP +1

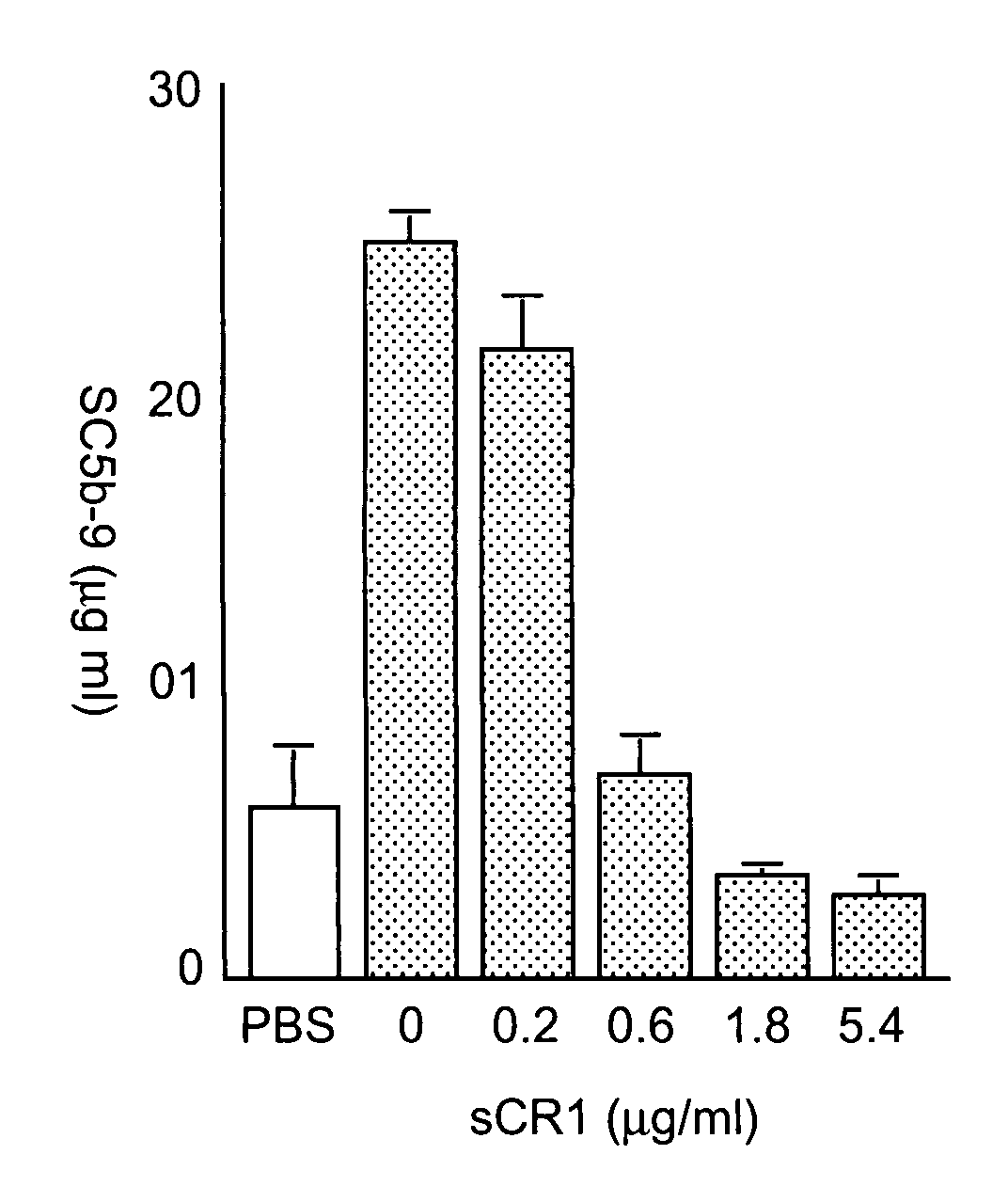

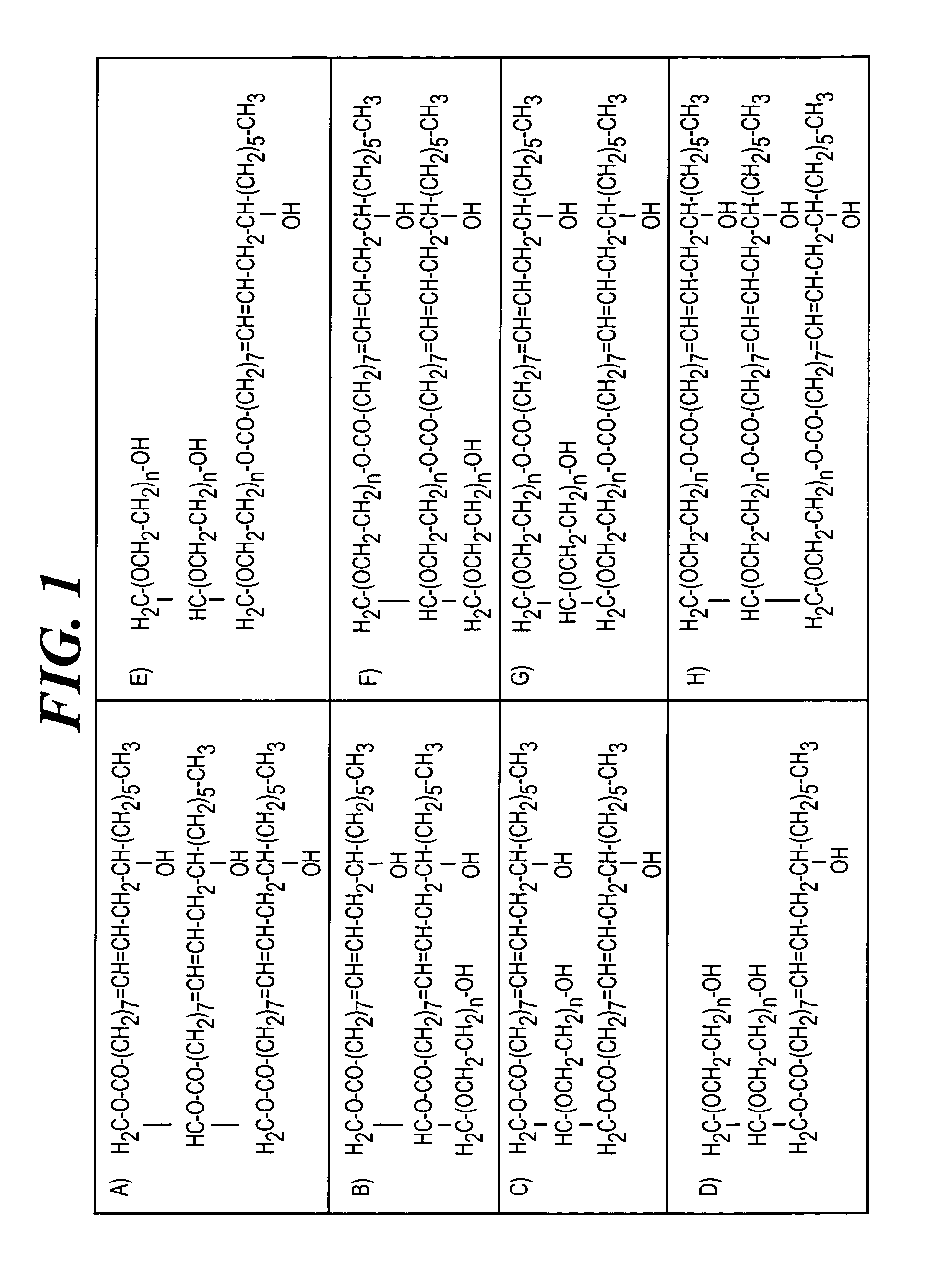

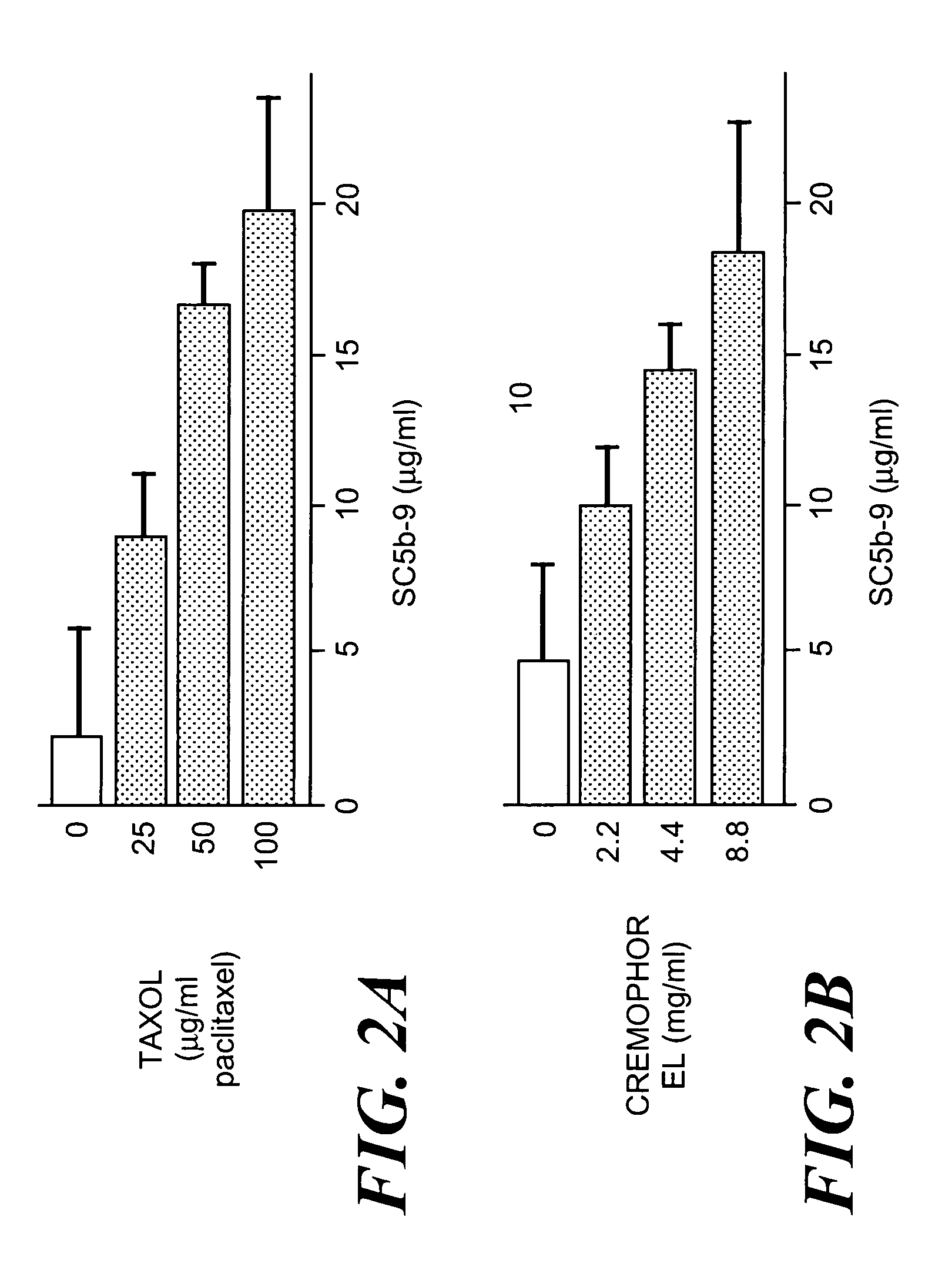

Method of inhibiting side effects of pharmaceutical compositions containing amphiphilic vehicles or drug carrier molecules

A method is provided for inhibiting or preventing toxicity and other unwanted effects (a) caused by solvents for pharmaceuticals which solvents or emulsifier which contain amphiphilic molecules such as polyethoxylated oils or a derivative thereof, or (b) caused by a drug in a vehicle containing amphiphilic molecules such as phopholipids or derivative thereof, emptying a complement inhibitor. Drug compositions containing amphiphilic molecules, or derivatives thereof and a complement inhibitor, and pharmaceutical compositions including a drug, solvent or carrier containing amphiphilic molecules or derivatives thereof, and a complement inhibitor are also provided.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

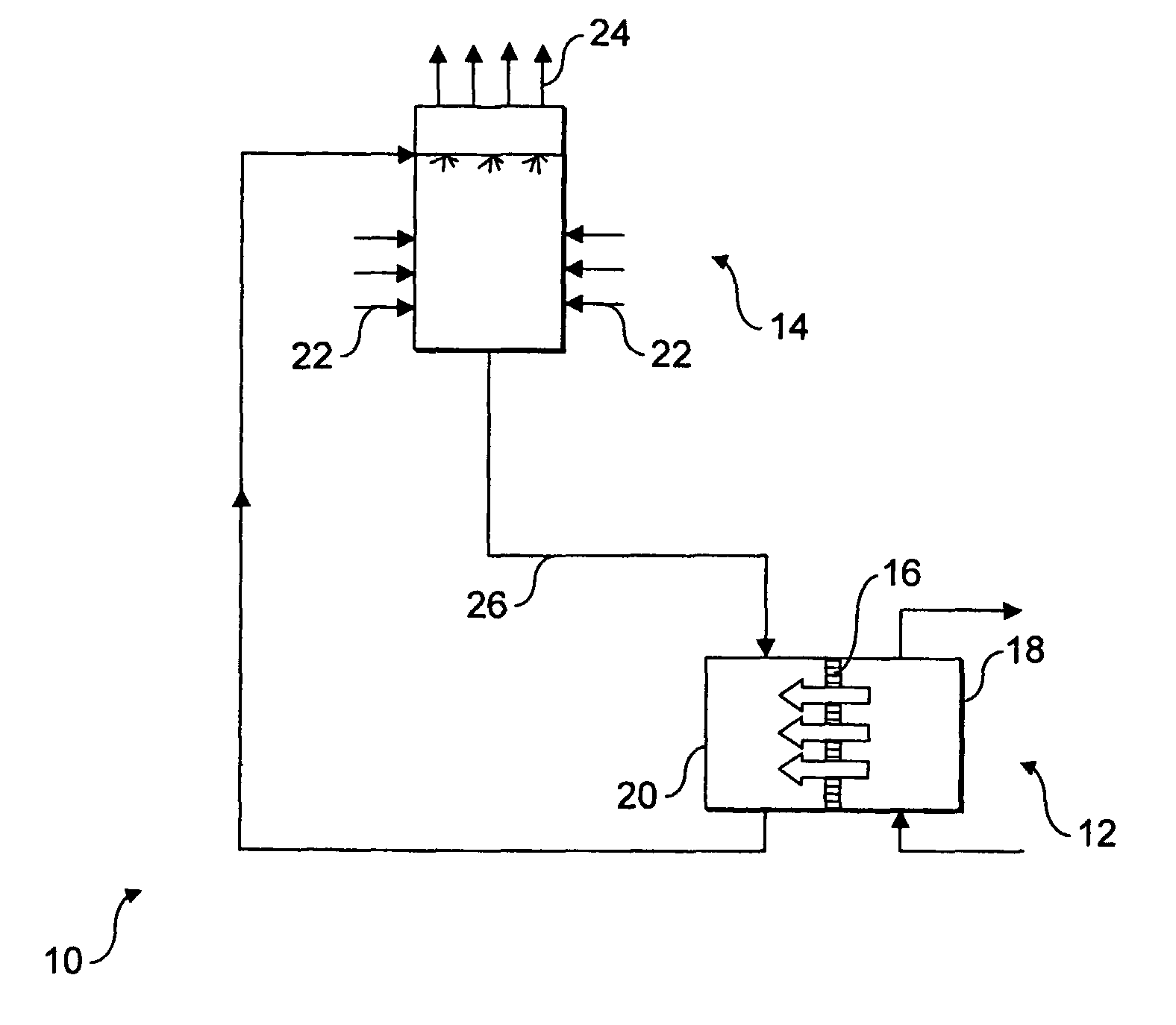

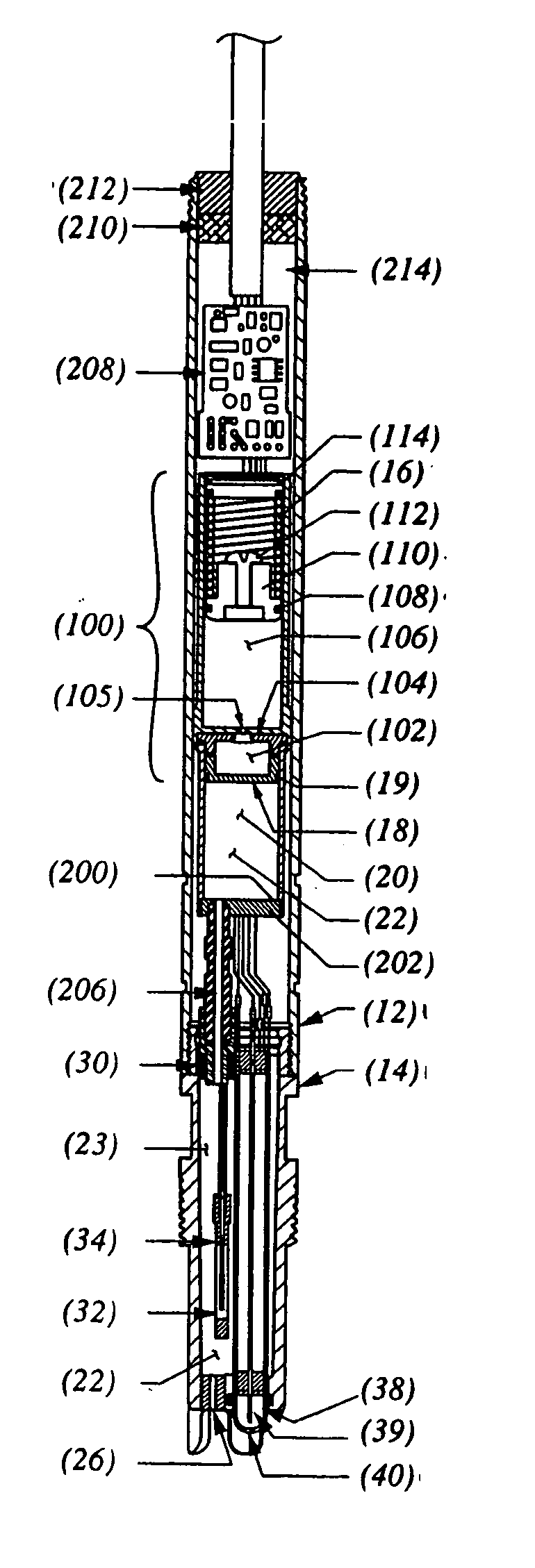

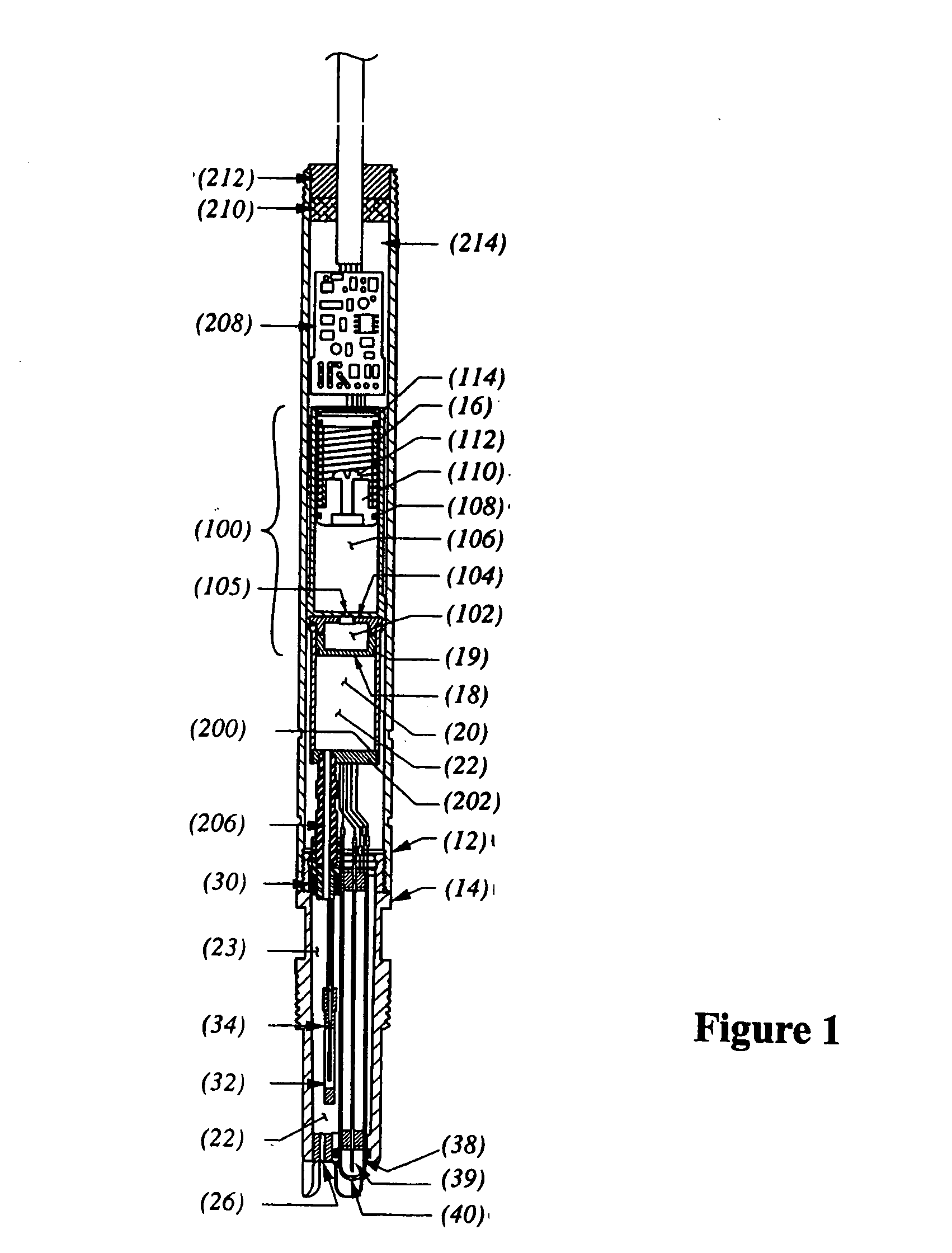

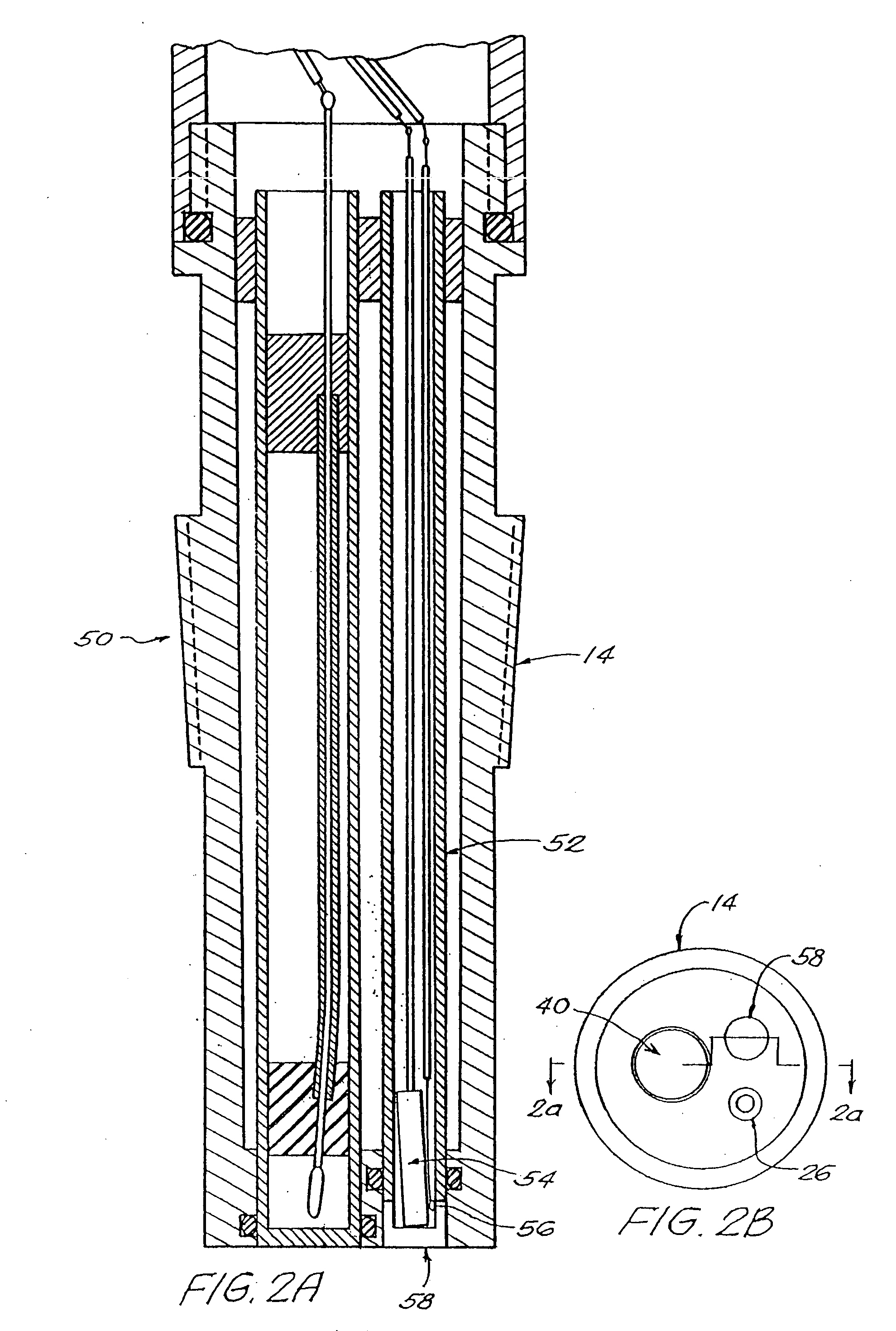

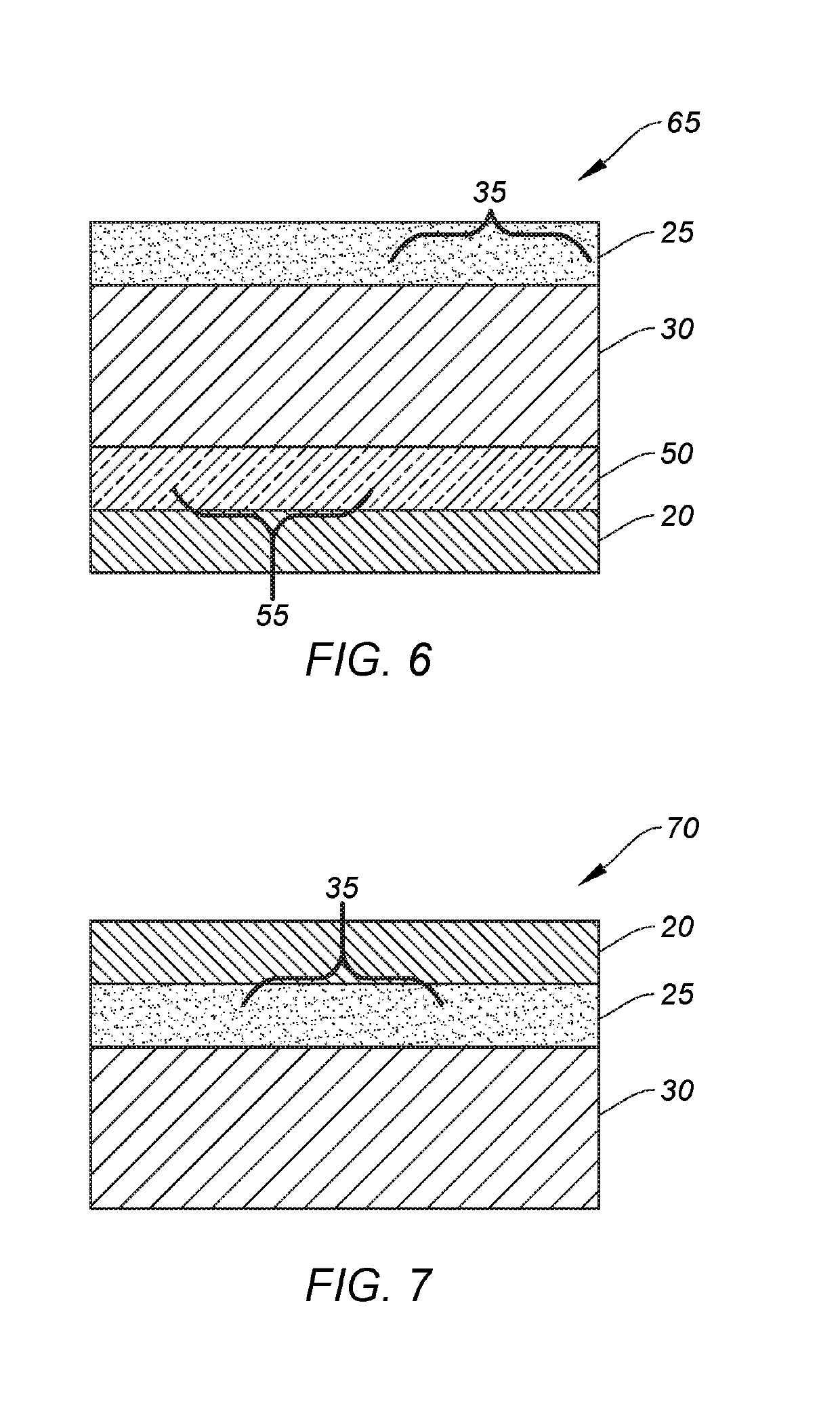

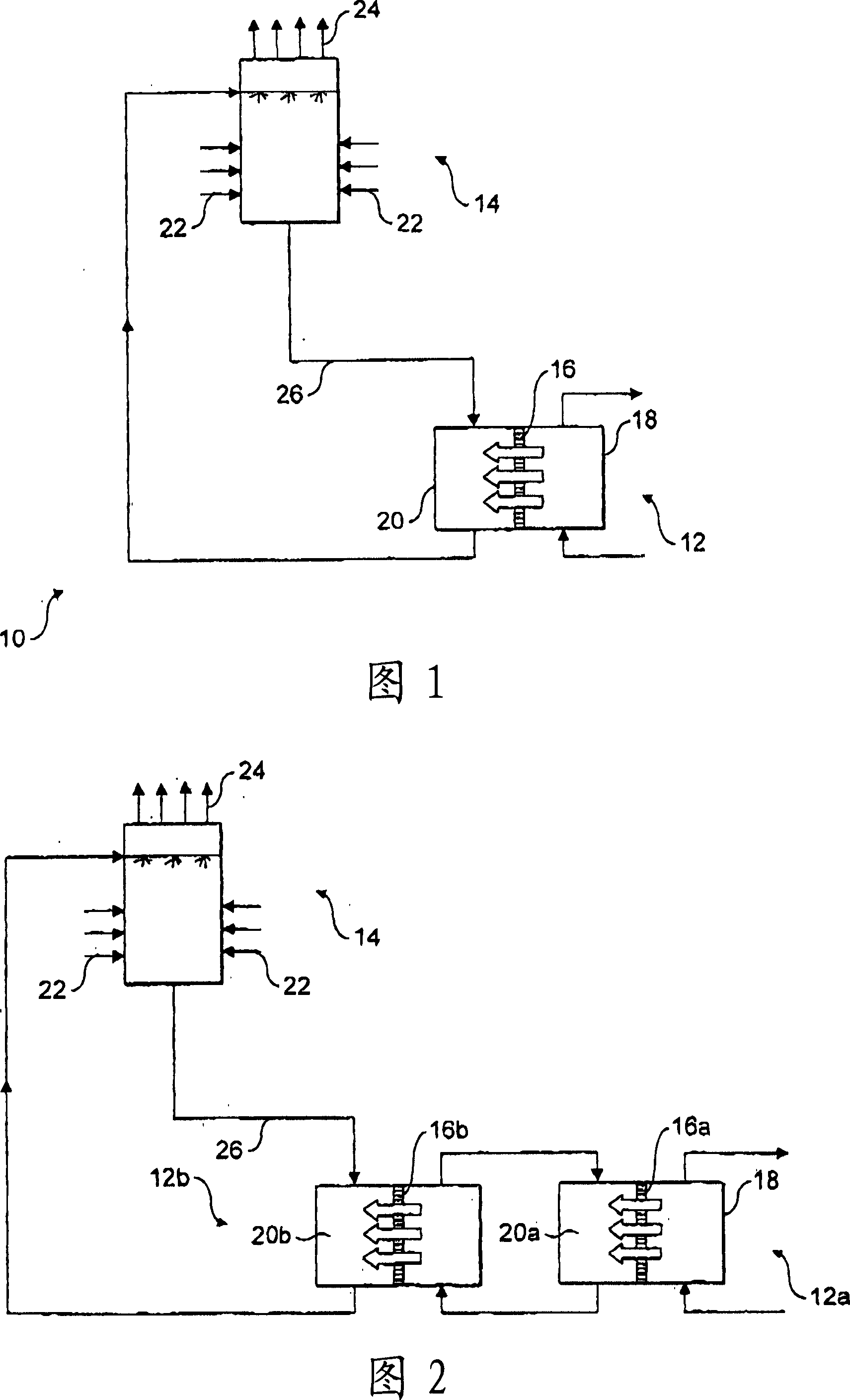

Cooling apparatus

ActiveUS7823396B2Reduce power consumptionImprove heat transfer efficiencySemi-permeable membranesEfficient regulation technologiesEvaporationPermselective membrane

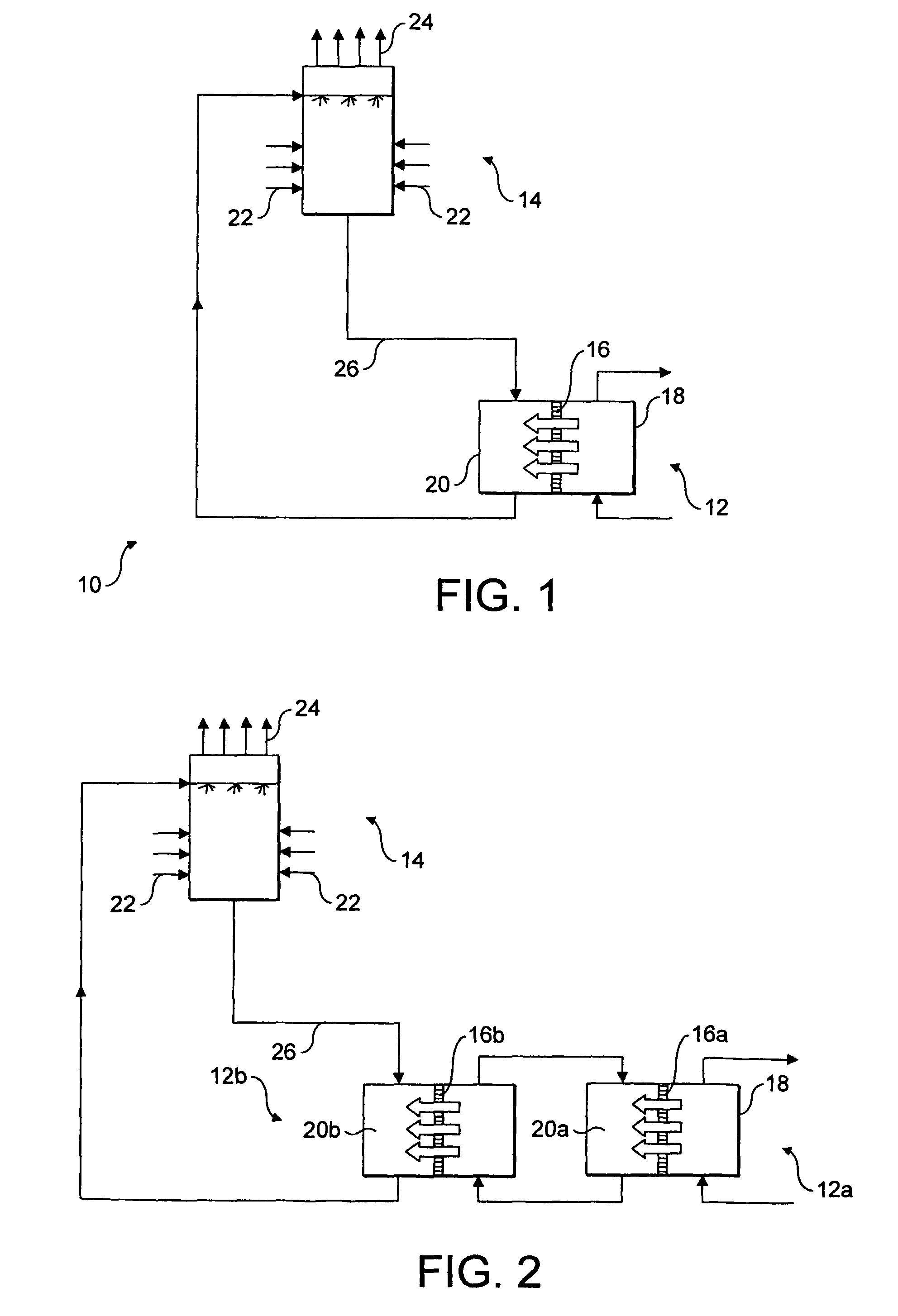

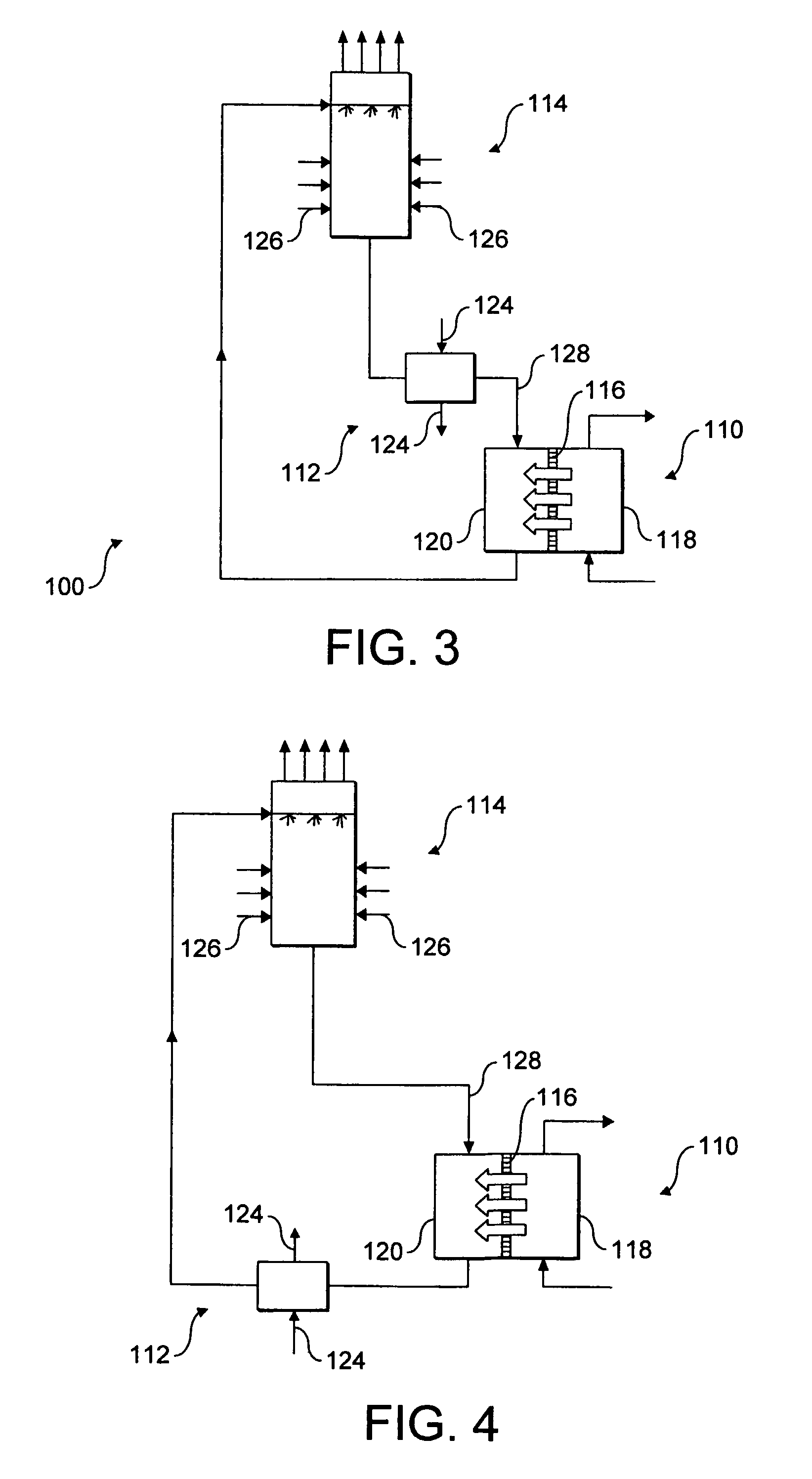

A process for introducing a solution into an evaporative cooling apparatus (14), said process comprising a) positioning a selectively permeable membrane (16) between a first solution (18) and a second solution (20) having a higher solute concentration than the first solution (18), such that the solvent from the first solution (18) flows across the selectively permeable membrane (16) to dilute the second solution (20), b) introducing the second solution into an evaporative cooling apparatus (14) in which solvent is removed from the second solution (20) by evaporation, and c) recycling the second solution (20) from step b) to step a) to draw solvent from the first solution (18).

Owner:UNIVERSITY OF SURREY

Water dispersible resin, two-component thermosetting resin composition, and method of producing the same

InactiveUS20090234074A1High viscosityDisadvantage is causedPolyurea/polyurethane coatingsPolymer scienceSolution polymerization

The water dispersible resin of the present invention is contained in a base component of a two-component thermosetting resin composition. The water dispersible resin is prepared by dispersing a solvent resin in water, which solvent resin is obtained by solution polymerization, carried out in two or more stages, of a monomer mixture containing a polyfunctional monomer, an acid group-containing monomer, and a hydroxyl group-containing monomer, the polyfunctional monomer having a plurality of vinyl groups in its single molecule. The monomer mixture contains the polyfunctional monomer by not less than 0.1% by weight but not more than 3% by weight, and the water dispersible resin thus obtained has an acid value of solid content of not less than 10 mgKOH / g but not more than 45 mgKOH / g, a hydroxyl value of solid content of not less than 50 but not more than 200, and a viscosity of not less than 50 mPa·s but not more than 10,000 mPa·s when a nonvolatile content is 45% by weight. This makes it possible to provide a two-component thermosetting resin composition, which is easily dealt with, formed into a coating film having an excellent appearance, and further, has an excellent pot life.

Owner:NIPPON PAINT CO LTD

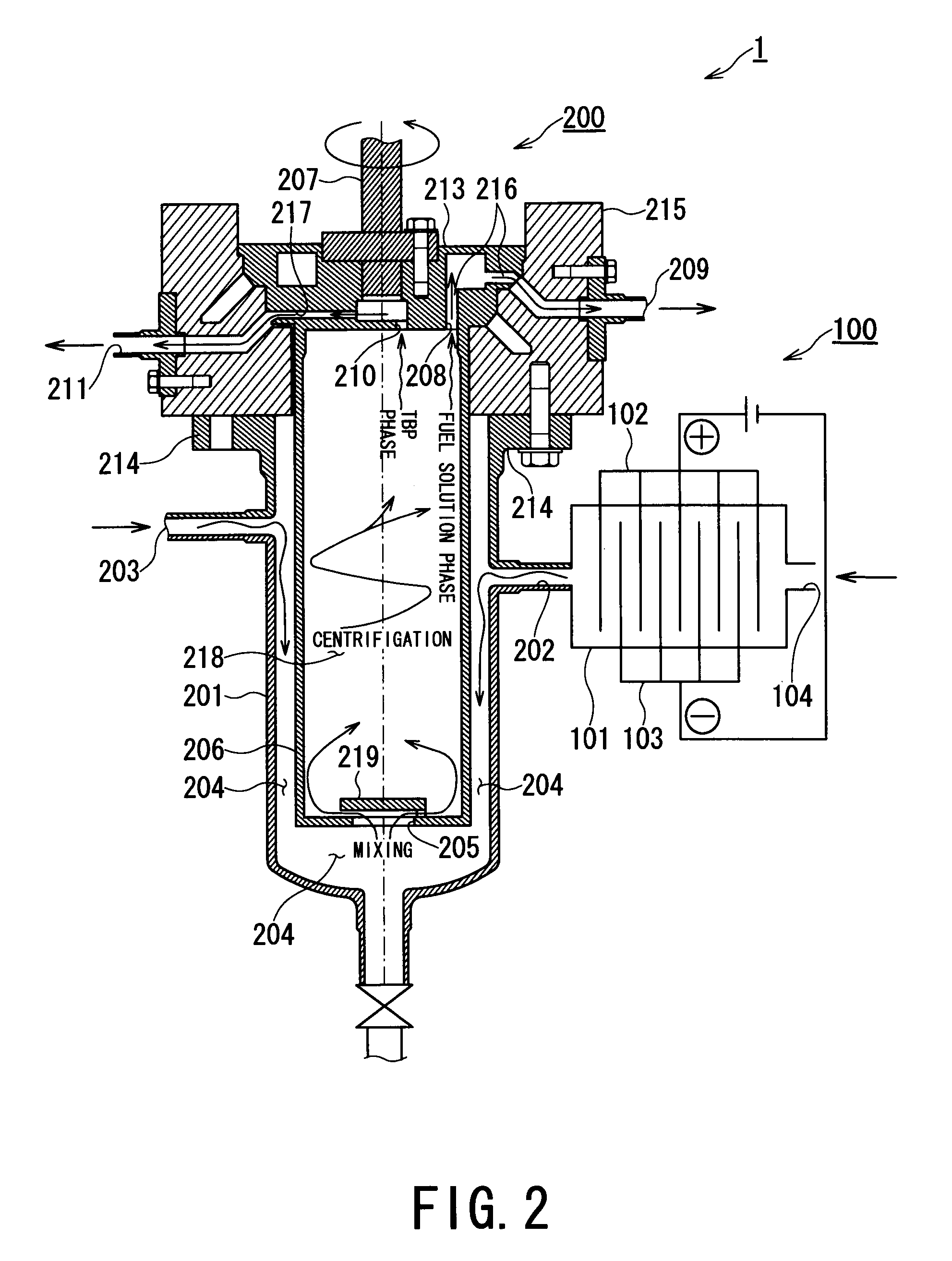

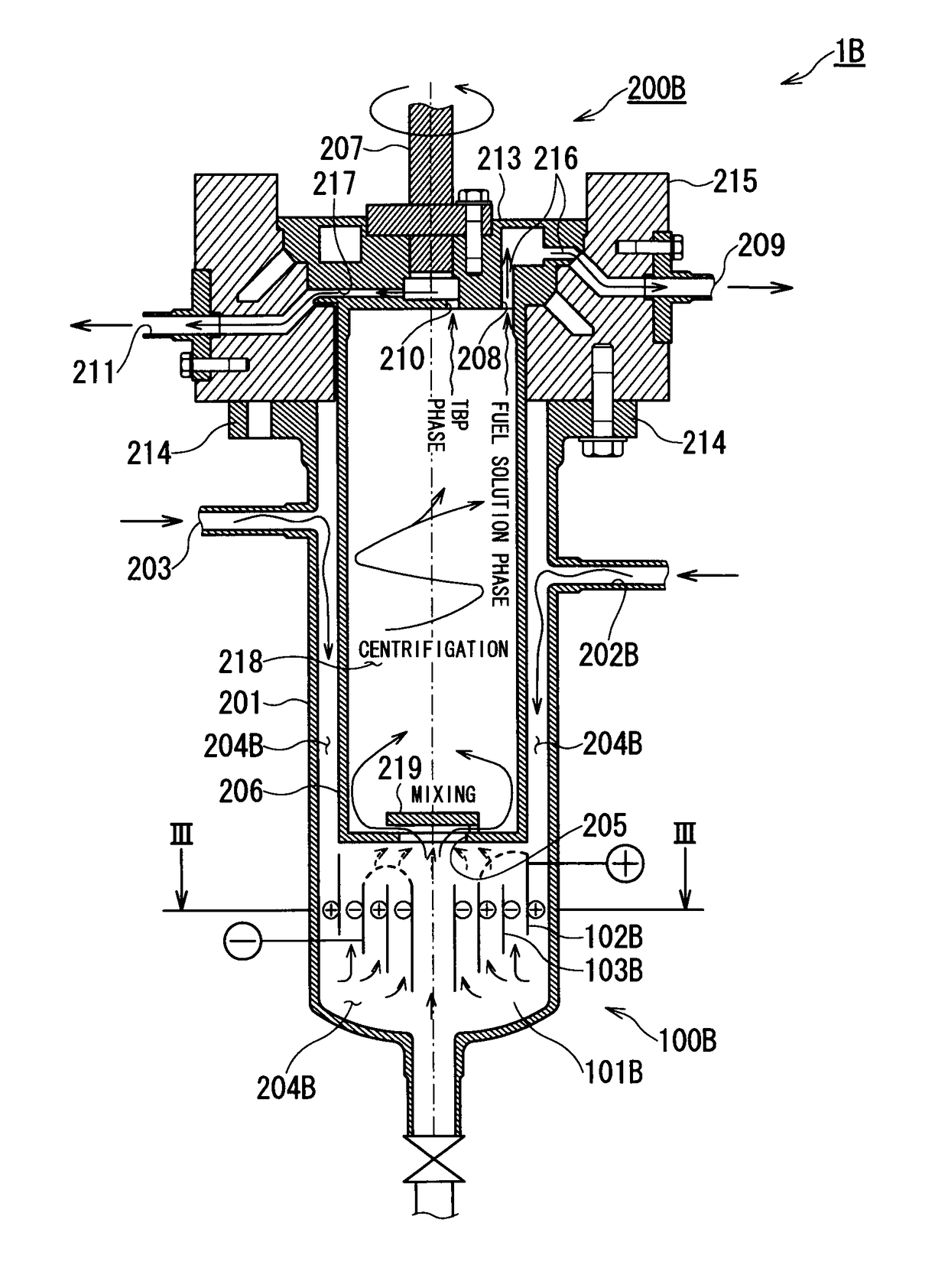

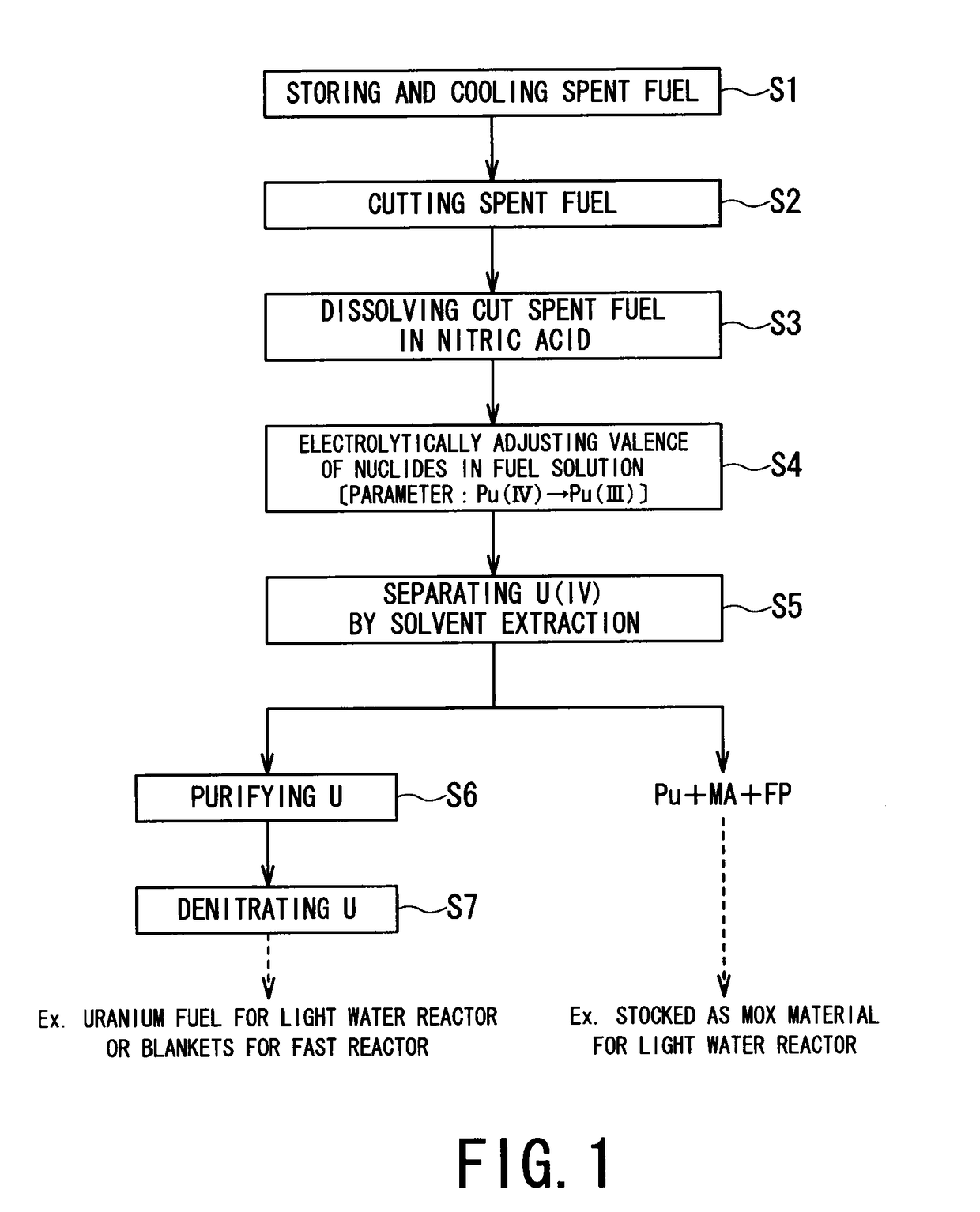

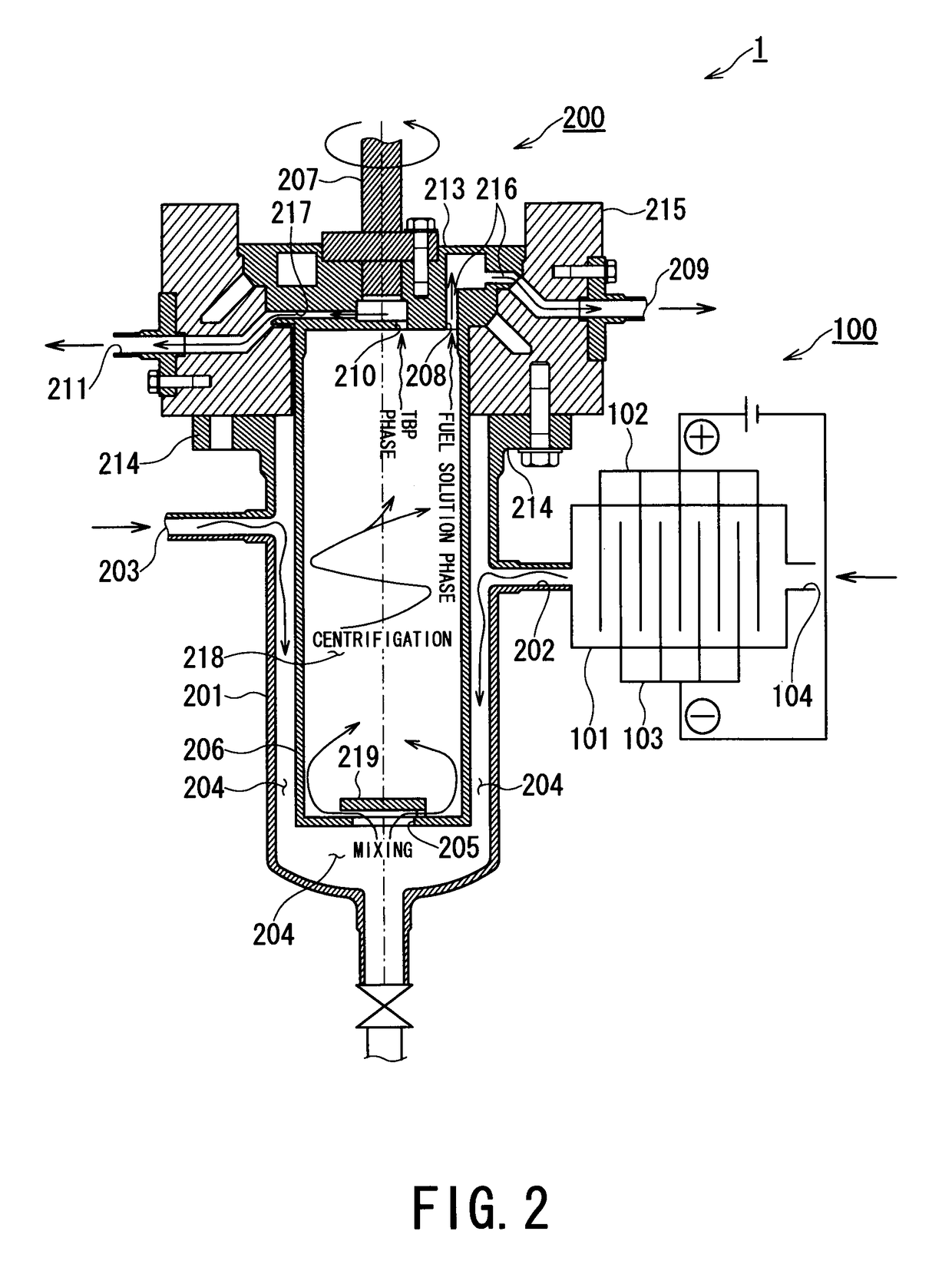

Method for reprocessing spent nuclear fuel and centrifugal extractor therefor

ActiveUS20100038249A1Isolation difficultRecovery difficultPhotography auxillary processesElectrolysis componentsElectrolysisEngineering

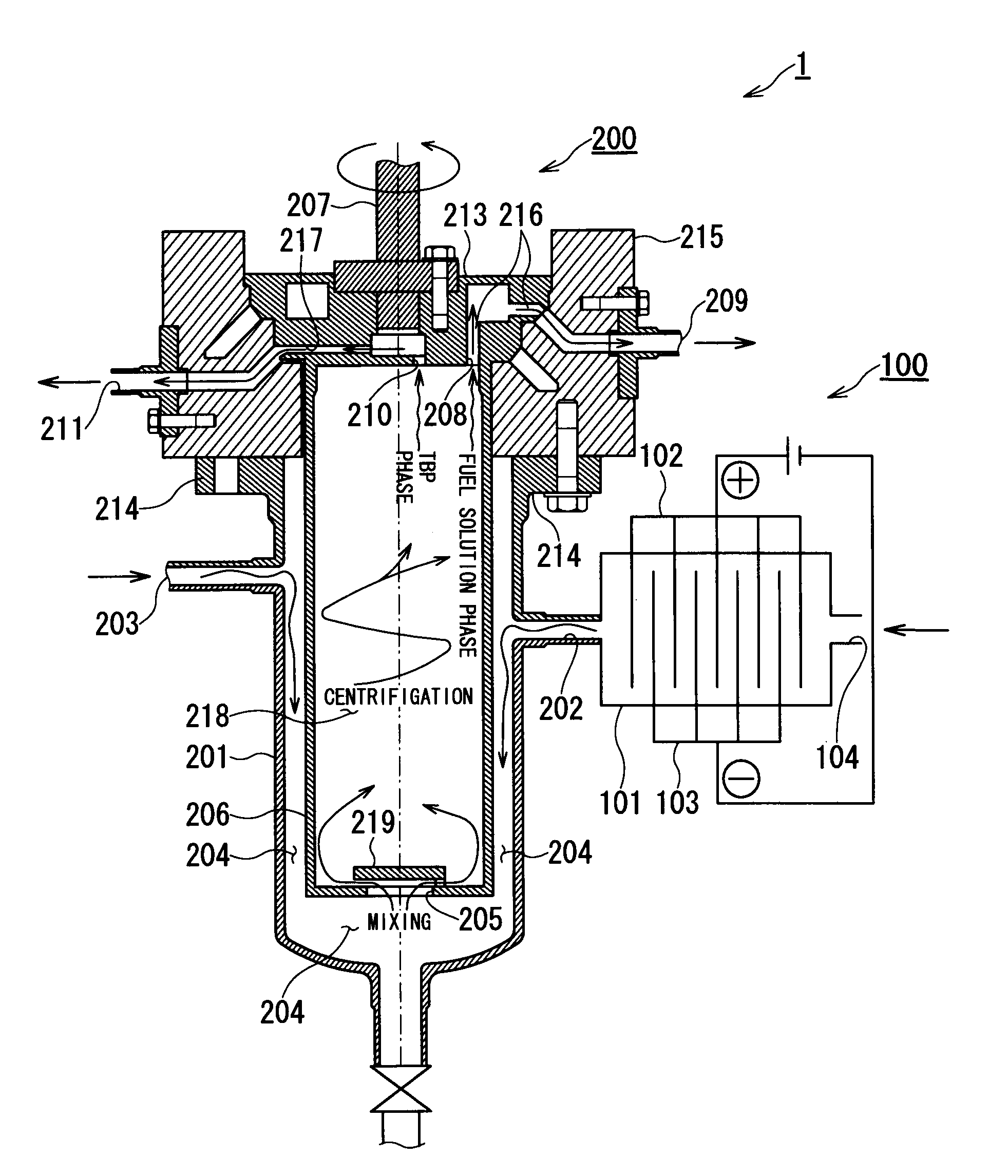

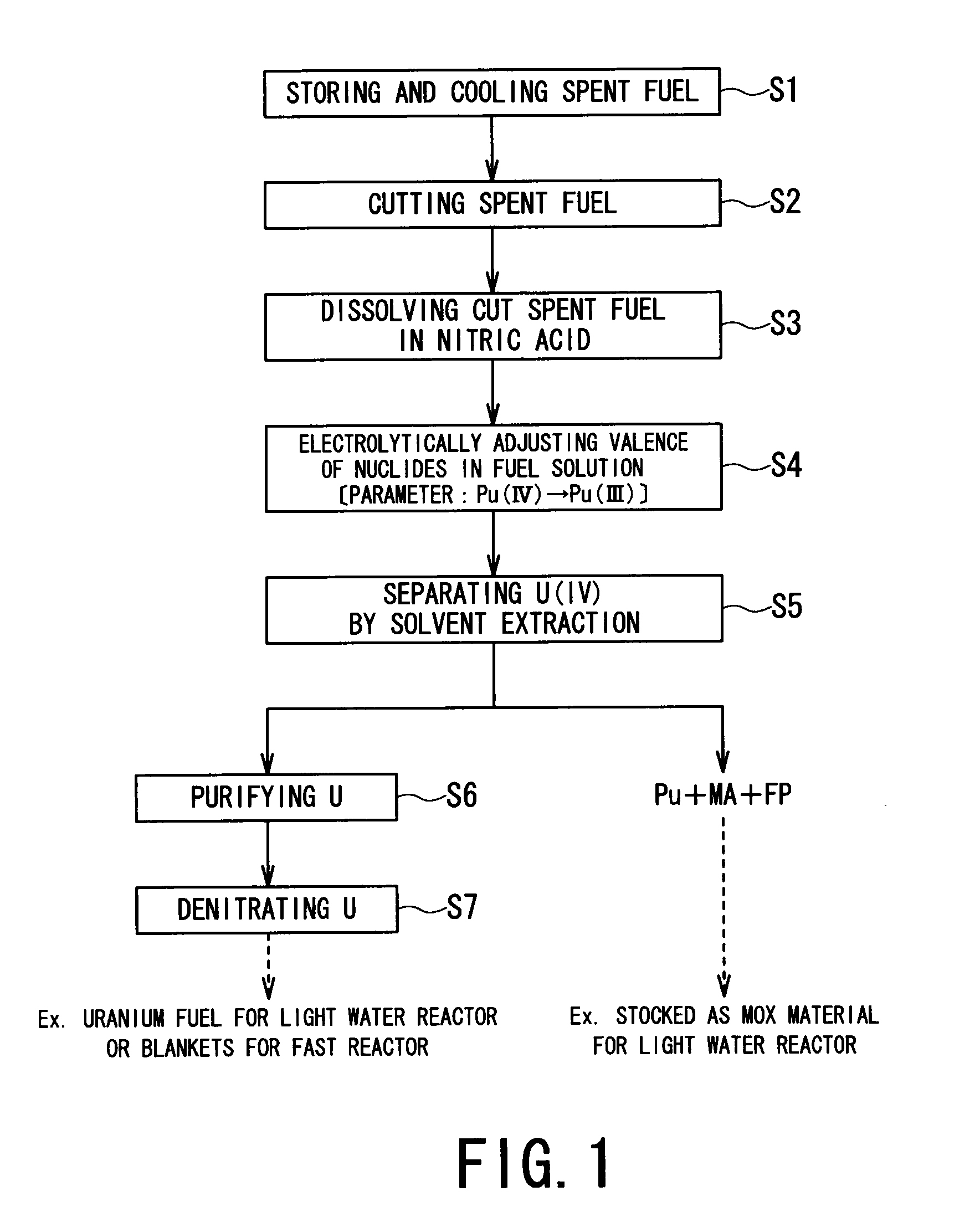

A spent nuclear fuel is reprocessed by dissolving a spent nuclear fuel in an aqueous nitric acid solution and separating and recovering nuclides contained in the resulting fuel solution by solvent extraction. A spent nuclear fuel reprocessing method includes: an electrolytic valence adjustment step in which nuclides contained in the fuel solution is electrolytically reduced without removing fission products or minor actinides until valence of plutonium is at a level at which solvent extraction efficiency is low by using the valence of plutonium contained in the fuel solution as a parameter; and a nuclide separation step in which, by using an extraction solvent which extracts uranium contained in the fuel solution, uranium is distributed from the fuel solution subjected to the electrolytic valence adjustment step to the extraction solvent.

Owner:KK TOSHIBA

Use of an osmotic pump to create a flowing reference junction for ionic-activity sensors

InactiveUS20060249386A1Reduce volumeMade smallMaterial electrochemical variablesSemipermeable membraneOsmotic pump

In an ionic-activity sensor, an osmotic pump drives a reference-cell electrolyte to flow through an interface with the solution to be measured. This minimizes contamination of the reference cell by that solution. The driving force results from expansion of an electrolytic-agent reservoir into which solvent from a solvent reservoir diffuses through a semi-permeable membrane. The electrolytic-agent reservoir contains an electrolytic-agent solution in which a quantity of undissolved is disposed to keep the electrolytic-agent solution saturated as solvent diffuses into it.

Owner:INVENSYS SYST INC

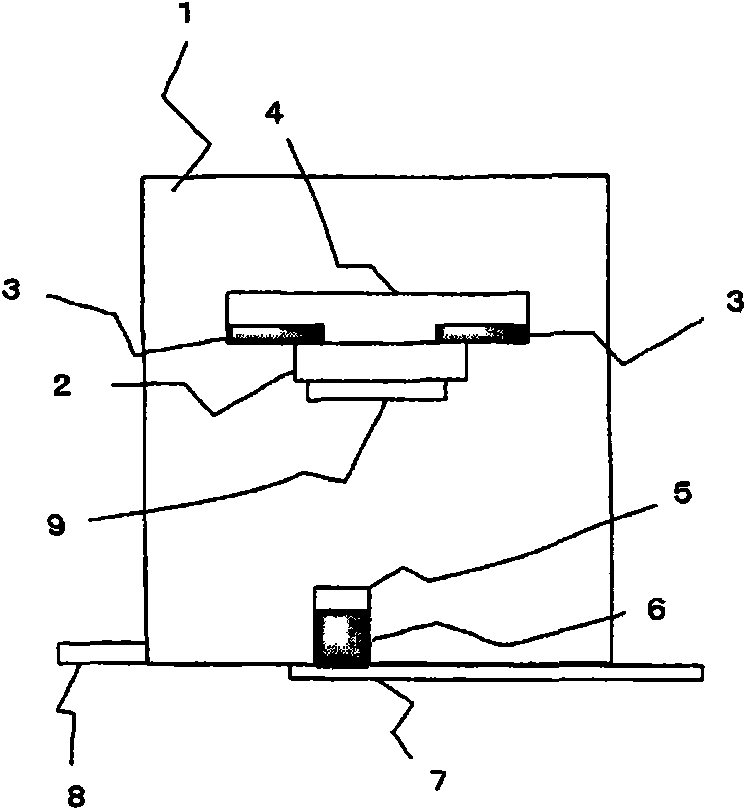

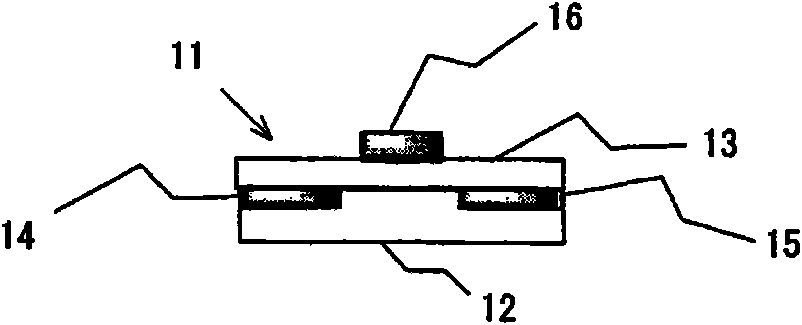

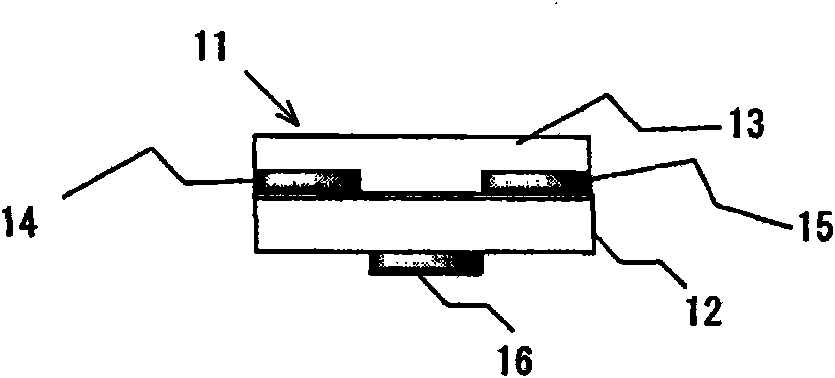

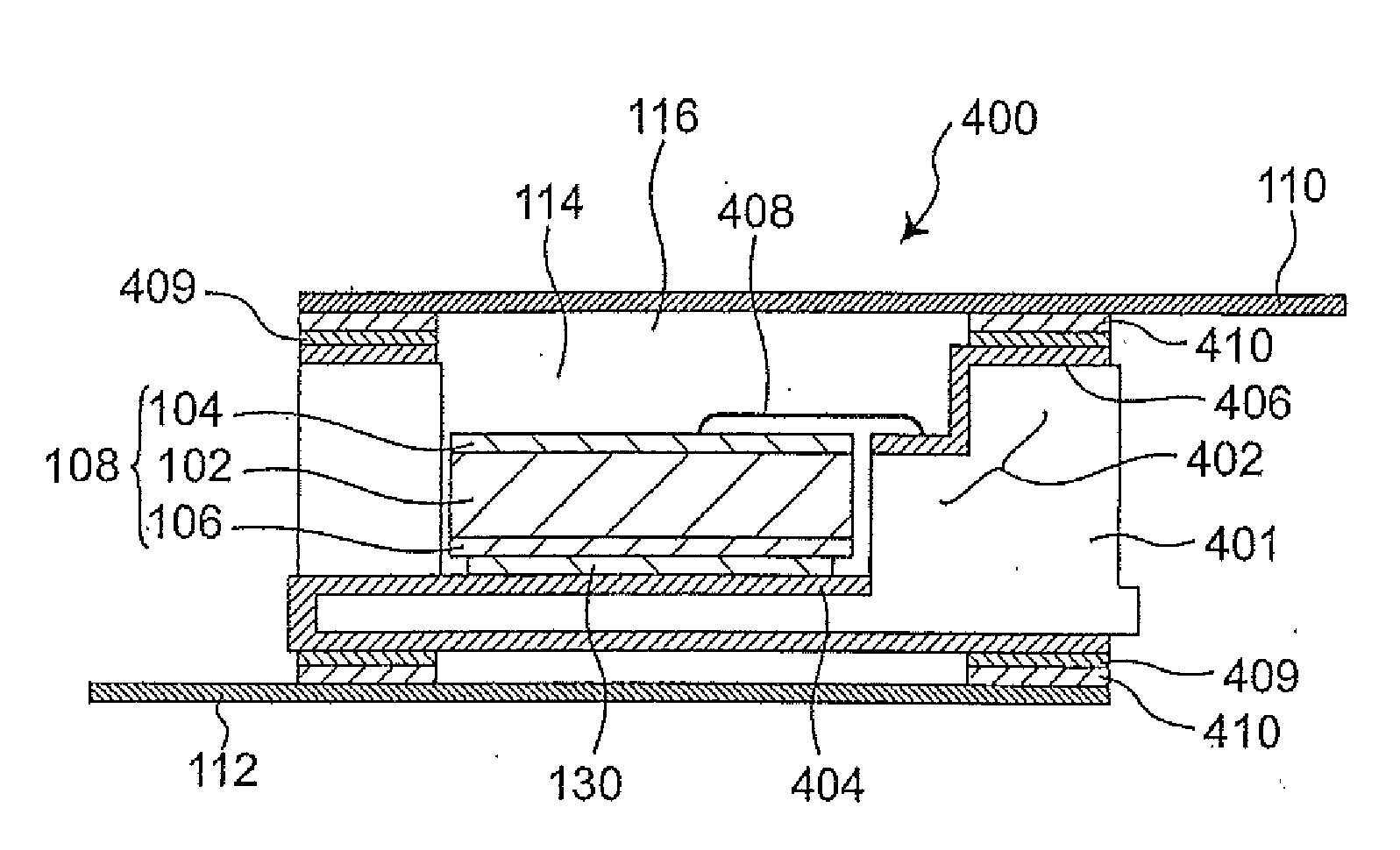

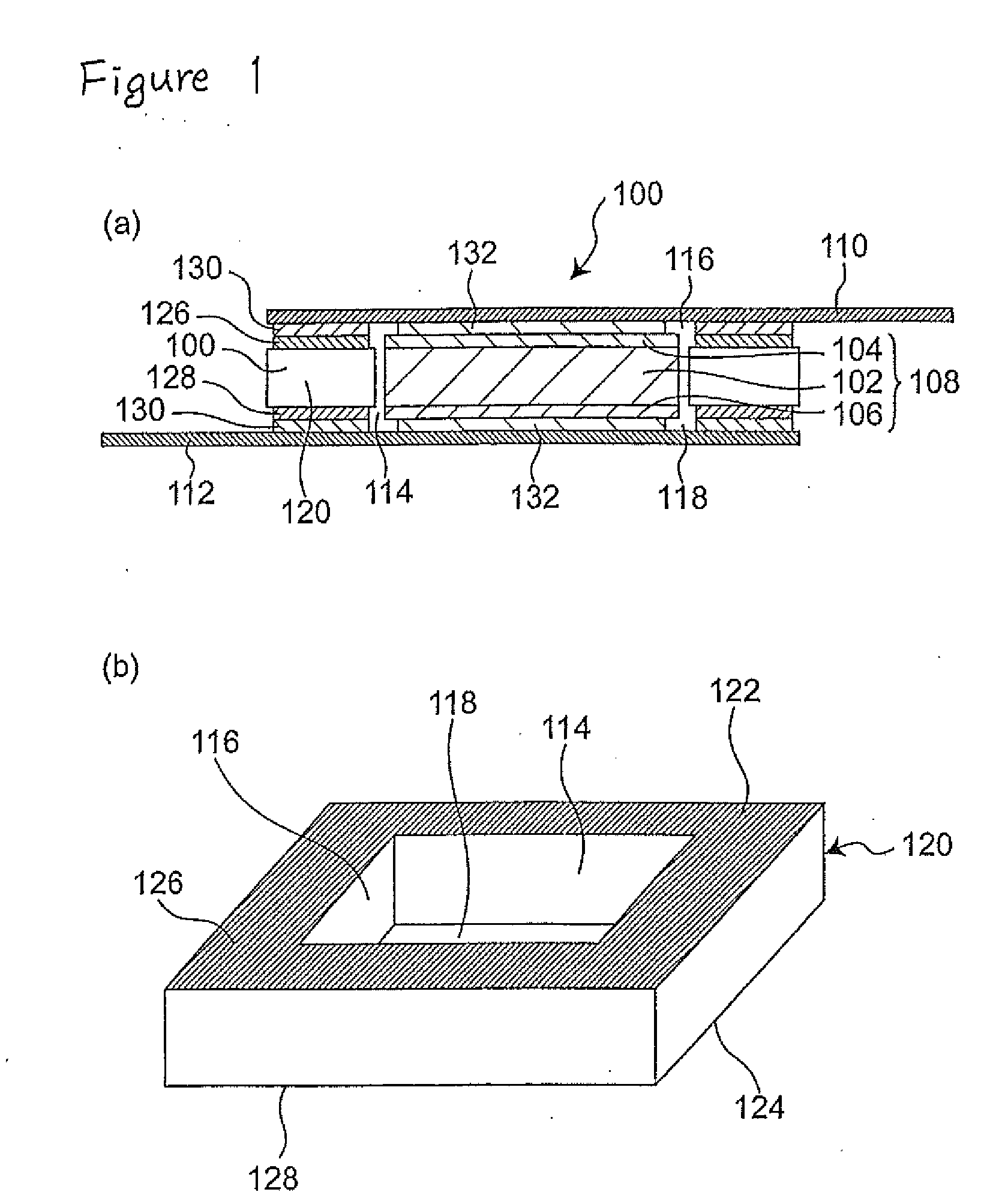

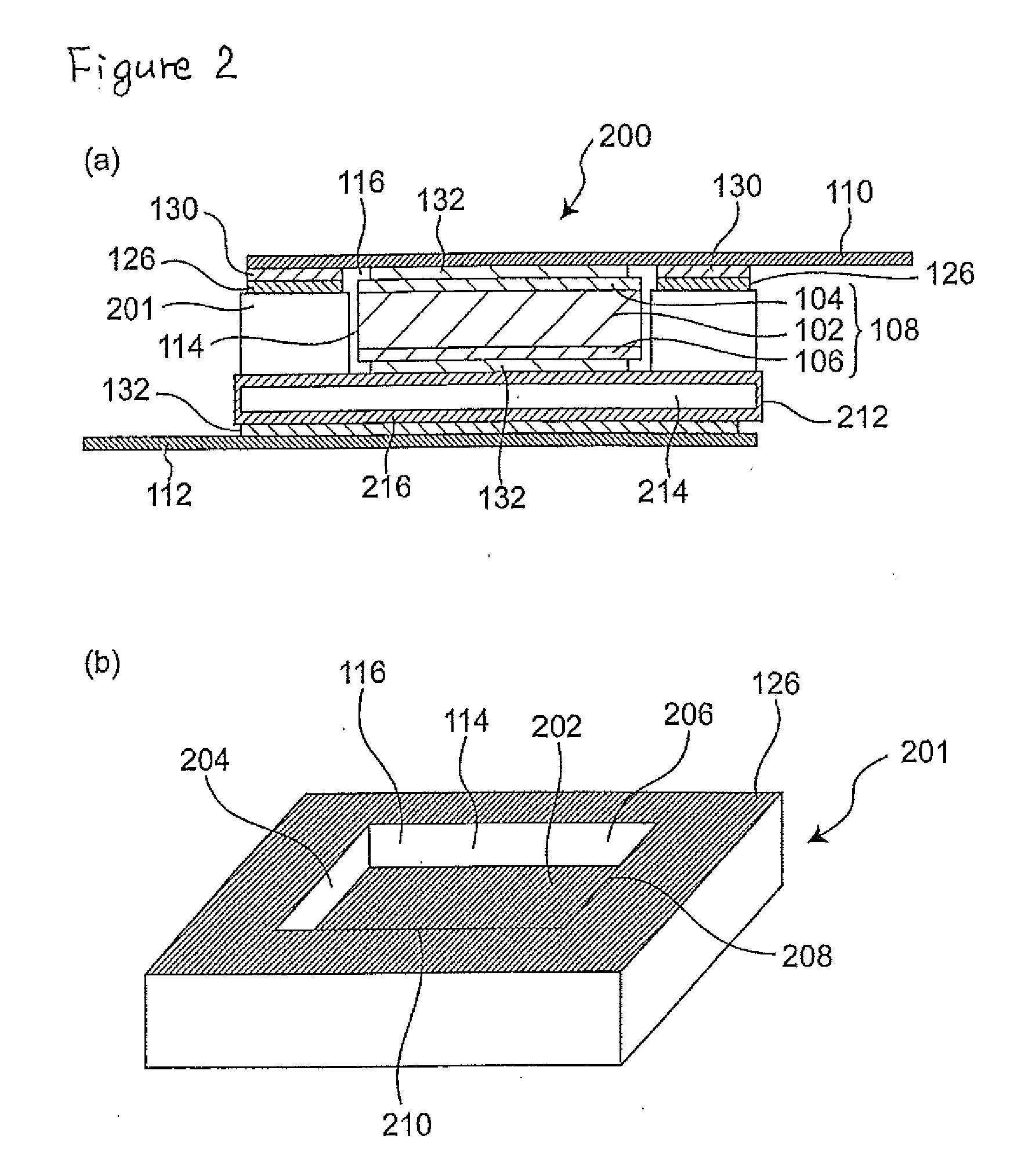

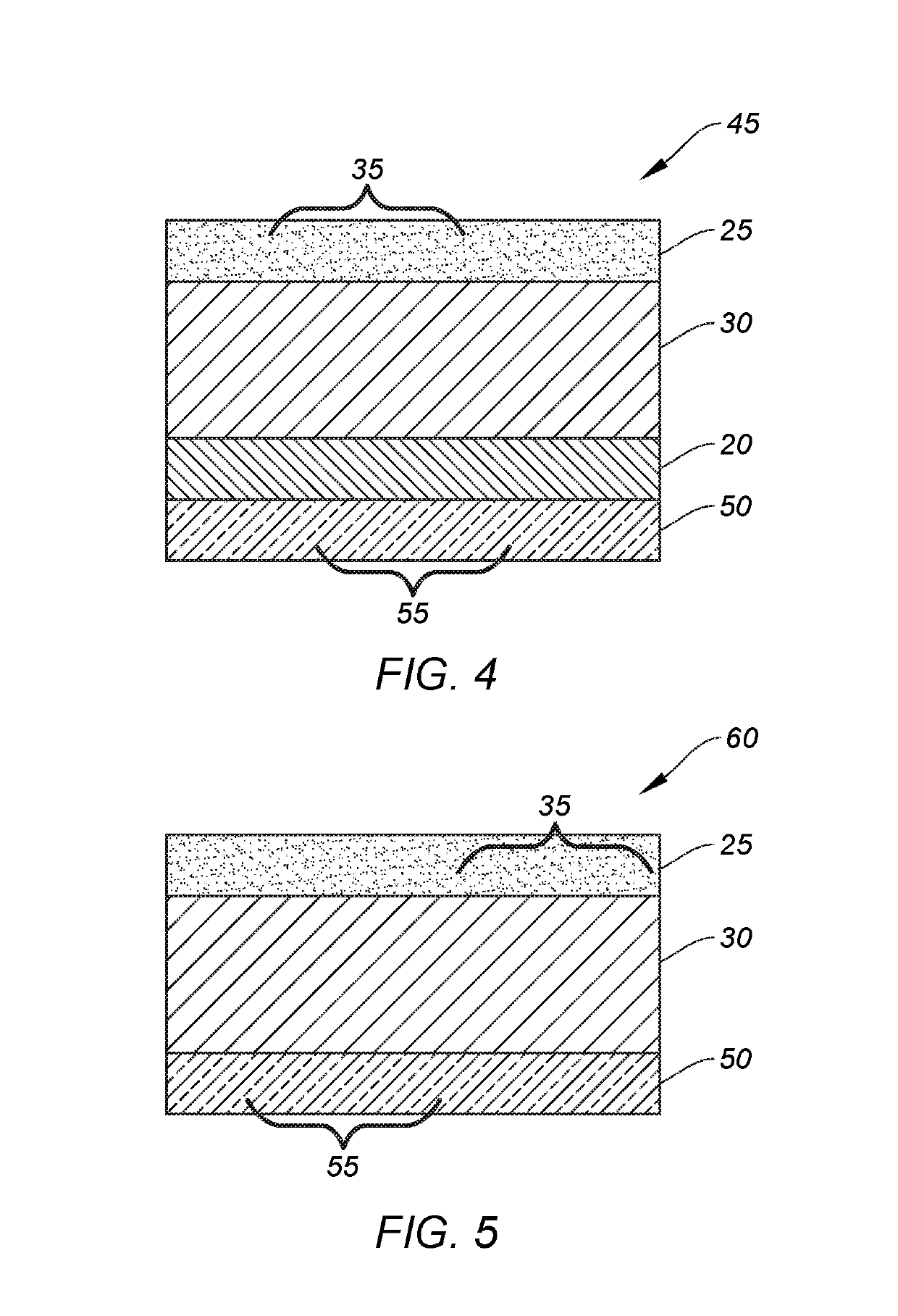

PTC Device

InactiveUS20110170221A1Prevent oxidationLower resistancePositive temperature coefficient thermistorsArrangements responsive to excess currentWhich solventsPolymer

There is provided a PTC device wherein its PTC element functions appropriately even when the PTC device is used in an environment in which solvent is present. The PTC device includes (1) a polymer PTC component including a polymer PTC element and a first and a second metal electrodes disposed on both sides of the main surface thereof; (2) a lead connected to at least one of the metal electrodes of the polymer PTC component; and (3) a ceramic package having an open-ended space for accommodating the polymer PTC component, said open-ended space having at least one opening that defines the open-ended space. The lead closes said opening in order to isolate the polymer PTC component disposed in said open-ended space from the environment surrounding the ceramic package.

Owner:LITTELFUSE JAPAN GK

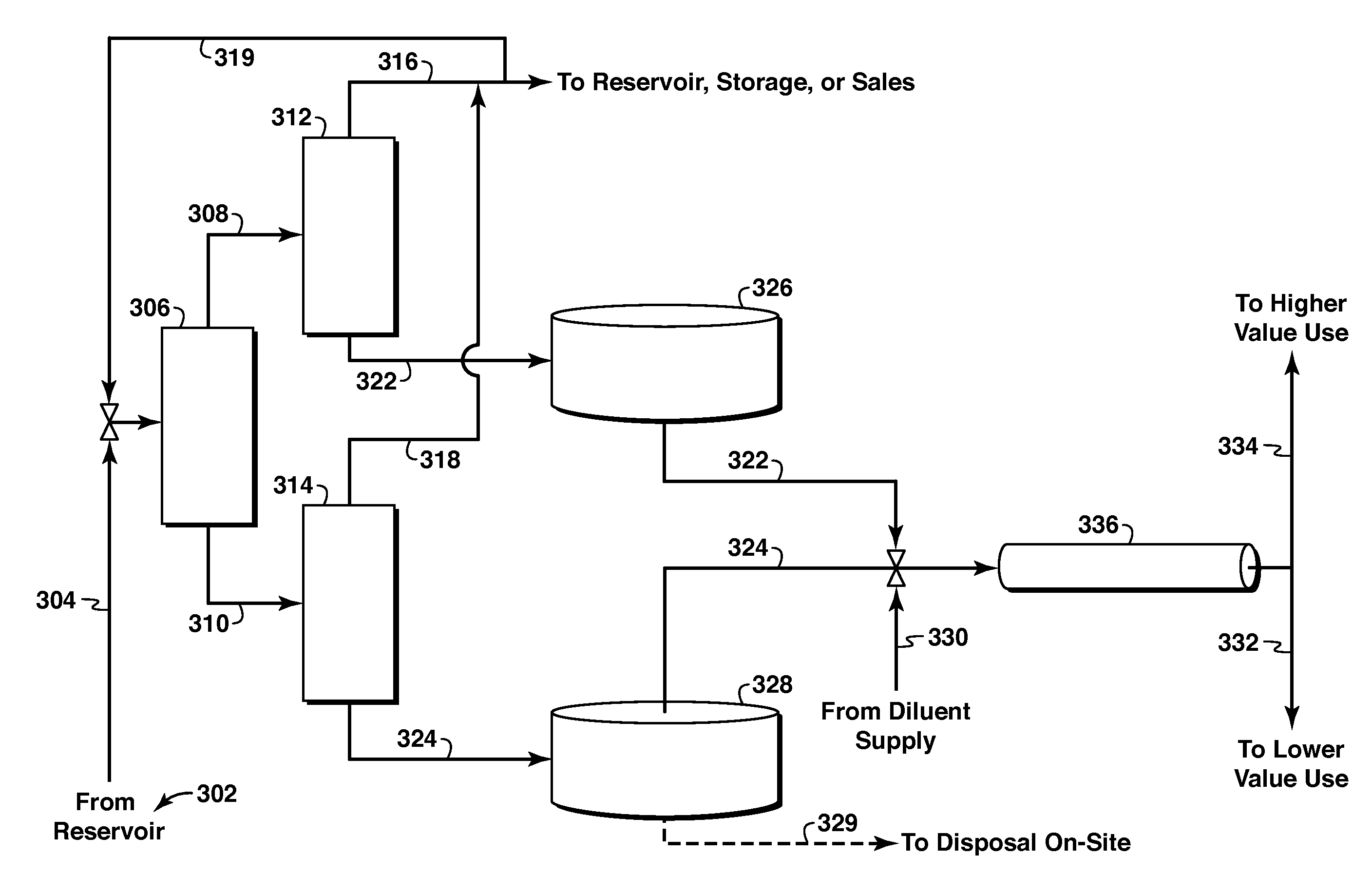

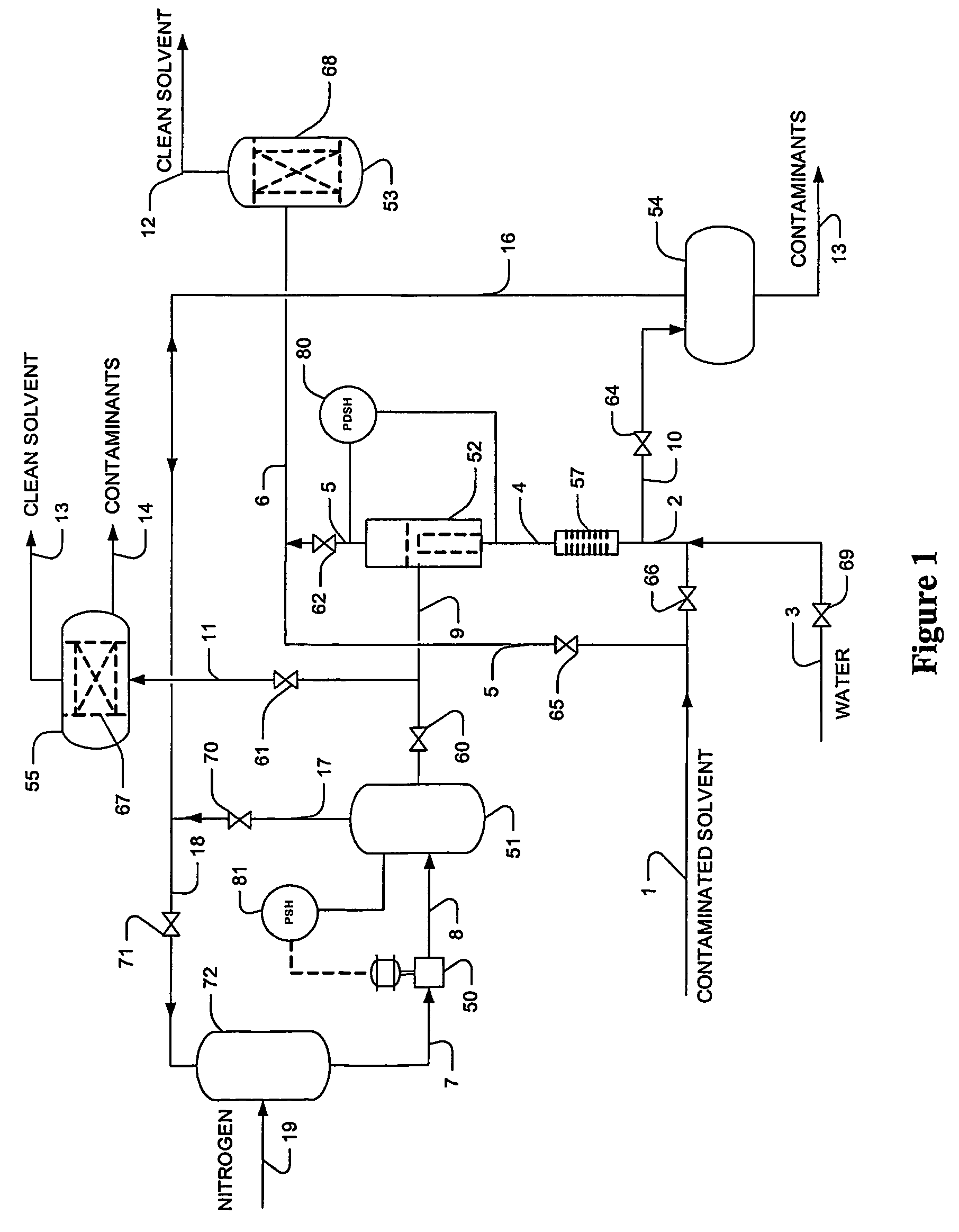

Solvent separation in a solvent-dominated recovery process

Owner:EXXONMOBIL UPSTREAM RES CO

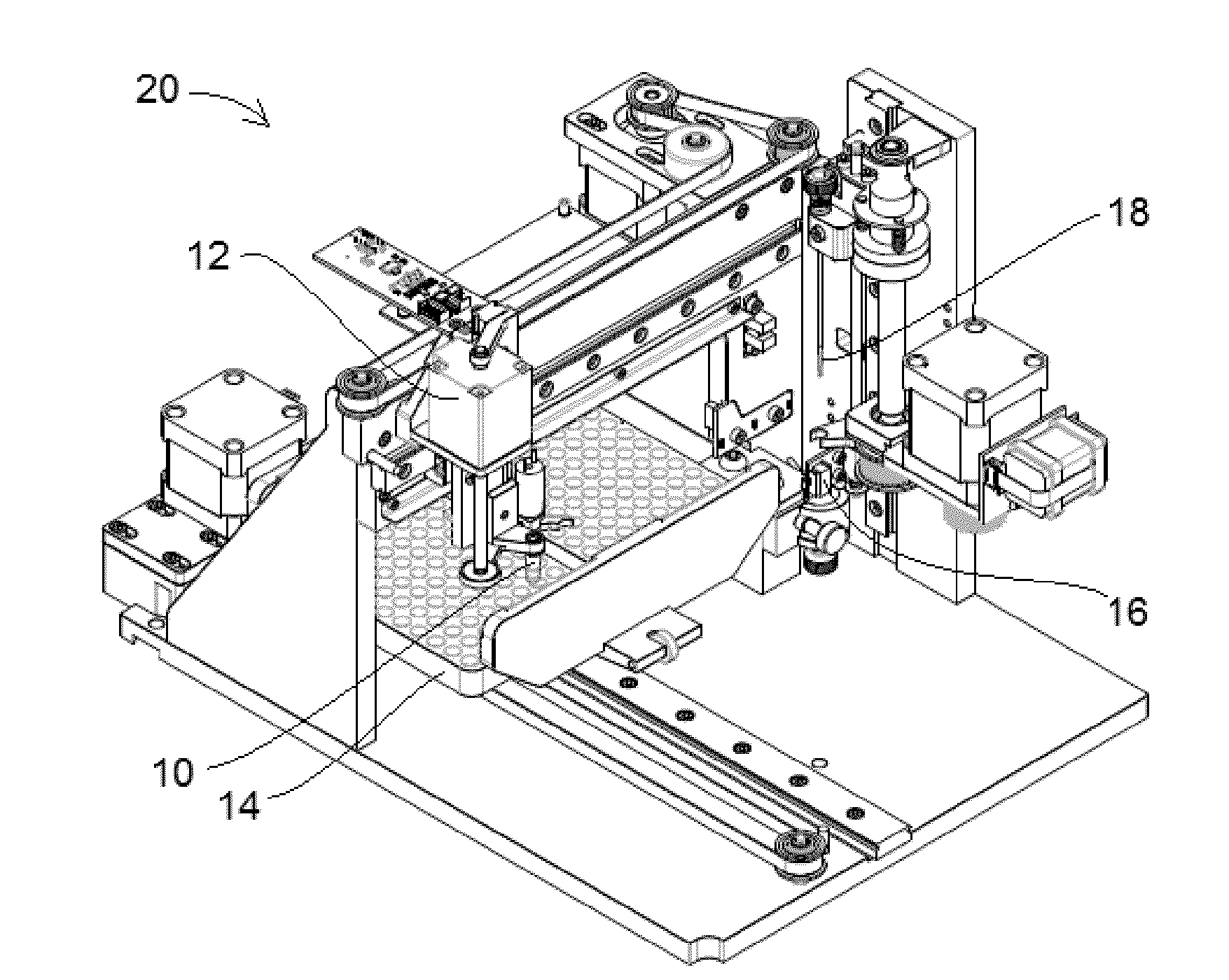

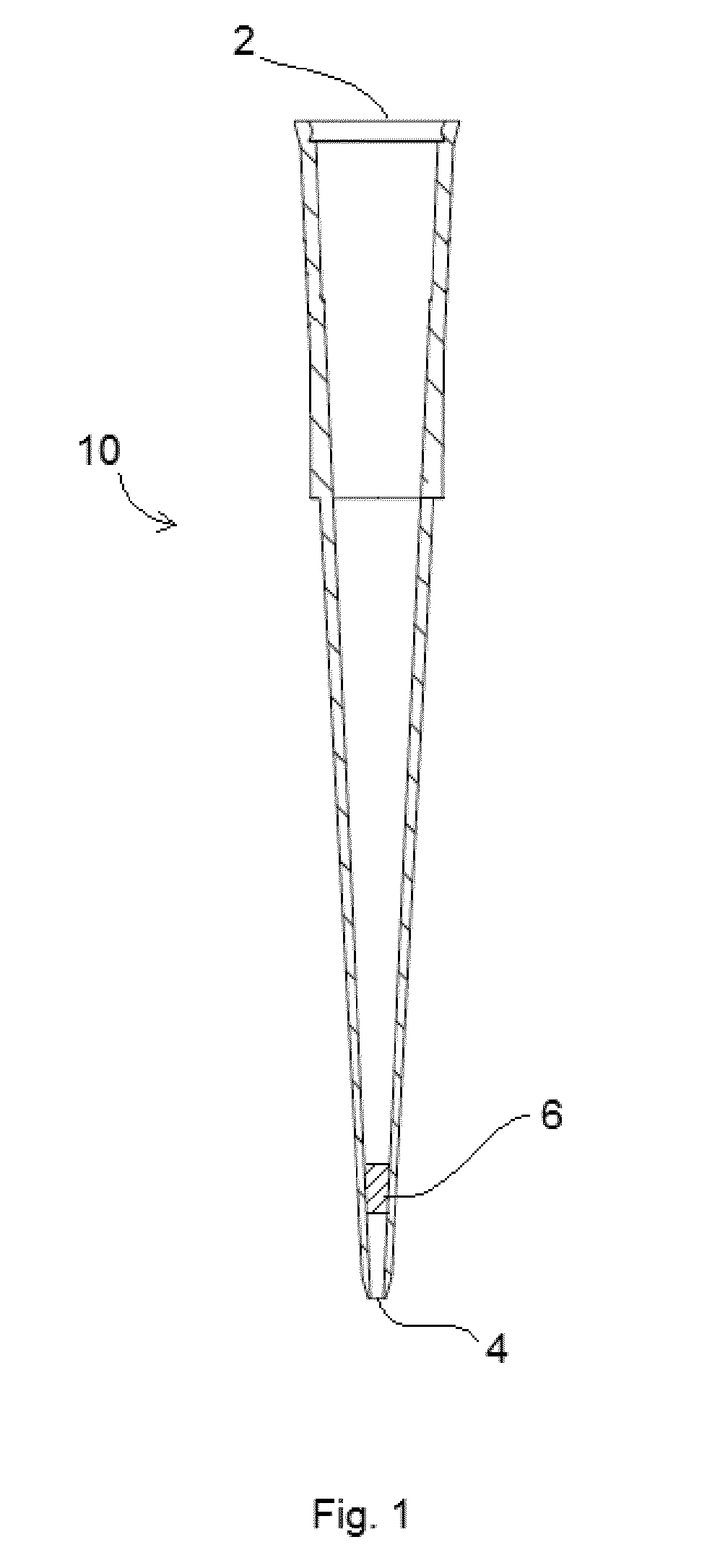

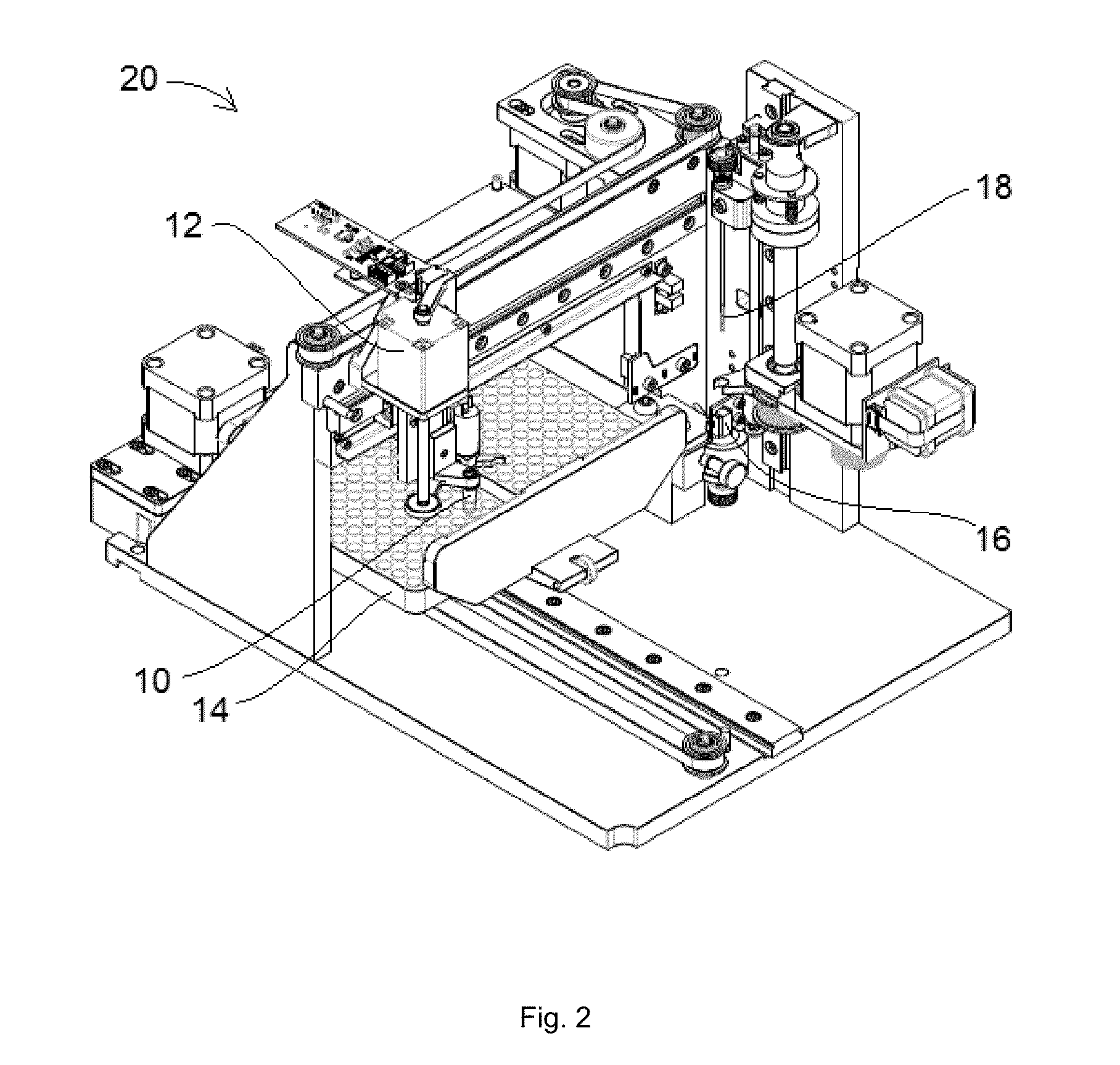

Automated system for handling components of a chromatographic system

ActiveUS20140338430A1Perform determination quickly and reliably and accuratelyComponent separationRobotic systemsSorbent

An automated system for handling components of a chromatographic system, comprising: one or more trap columns each having sorbent material therein; a robotic system for moving a trap column from a storage position to an operating position where the trap column is connected in a liquid pathway along which solvent is flowed in operation to a liquid chromatography (LC) column; and an optical sensor for sensing one or more parameters of the trap column. Sensed parameters can include: a presence or absence of a trap column in the operating position, a position or orientation of the trap column, a fluid level in the trap column, the presence and position of a sorbent material in the trap column, the condition of the trap column and / or whether the trap column is new or used.

Owner:PROXEON BIOSYST

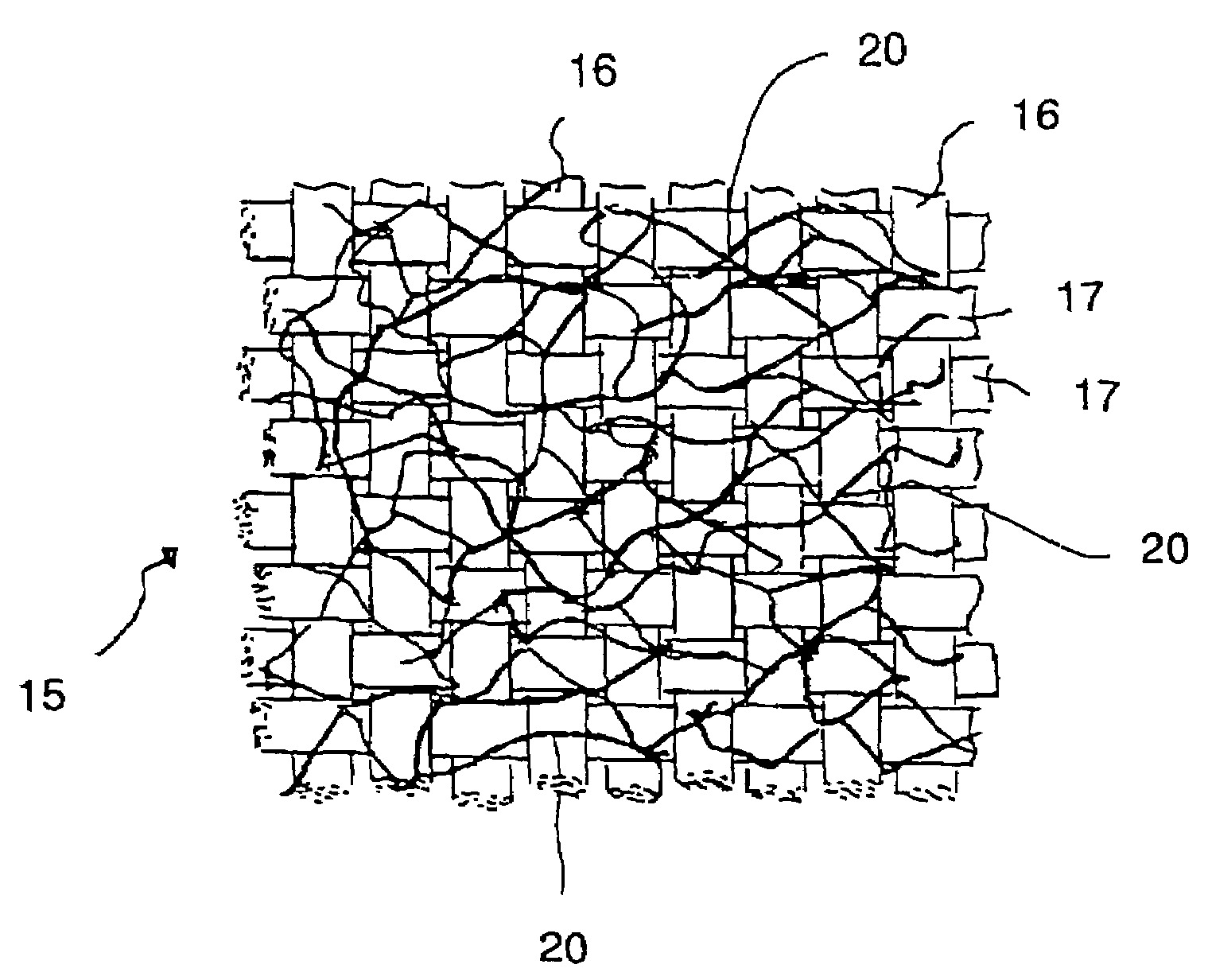

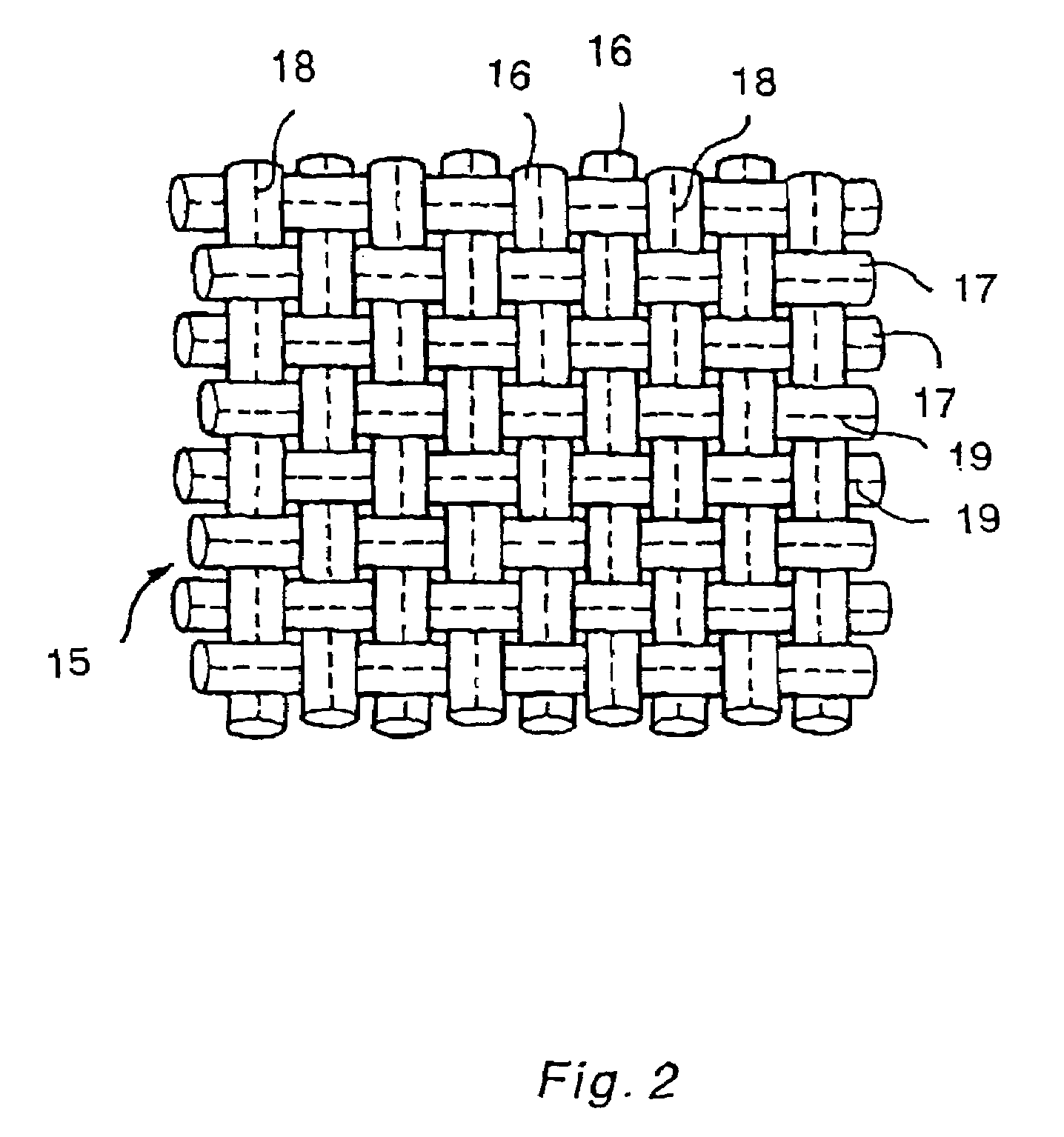

Cloth prepreg and wet process for manufacturing the same

A wet process for manufacturing a cloth prepreg with a uniform fiber distribution and large cover factor comprises impregnating a woven fabric with a diluted resin and drying, which fabric has a number of crossing points of warp and weft in the range of 2,000 to 70,000 / m2, which process further comprises at least one of the steps (A) and (B), namely(A) a step of distributing a line-shaped binder on the fabric to fix the yarn flatness prior to impregnating the fabric with a resin diluted with a solvent, at least 80% of which solvent is a nonsolvent of the binder and,(B) a step of calendering the woven fabric after drying.

Owner:TORAY IND INC

Industrial method for producing natural capsicine

ActiveCN101161635ASubstantially dissolveGood oil solubilityCarboxylic acid amide separation/purificationOrganic solventCapsaicin

The present invention relates to an industrial method for producing natural capsaicin, which includes the following procedures that: firstly extraction and separation, in which solvent A is used at first and mixed with the raw material under adequate agitation, then the mixture is extracted with solvent B as the extractant, the extract of solvent A is condensed, and the temperature of the liquid phase is lowered to obtain a thick jelly for later usage; secondly separation and crystallization, the thick jelly is dissolved with a heated lipid through adequate mixing, the mixture is cooled down and allowed for standing for crystallization, and the capsaicin crystal is obtained, thirdly rinsing and drying, the plant oil containing the capsaicin crystal is filtrated to obtain the crystal of capsaicin, which is rinsed with solvent B adequately to eliminate the plant oil, and the obtained crystal undergoes decompressed vaporization to eliminate the solvent to obtain the natural capsaicin crystal, in which the content of total alkali is more than percent. The present invention has much shortened technical process, decreased categories of organic solvent to be used, low fabrication cost and capability of environmental protection.

Owner:CHENGUANG BIOTECH GRP CO LTD

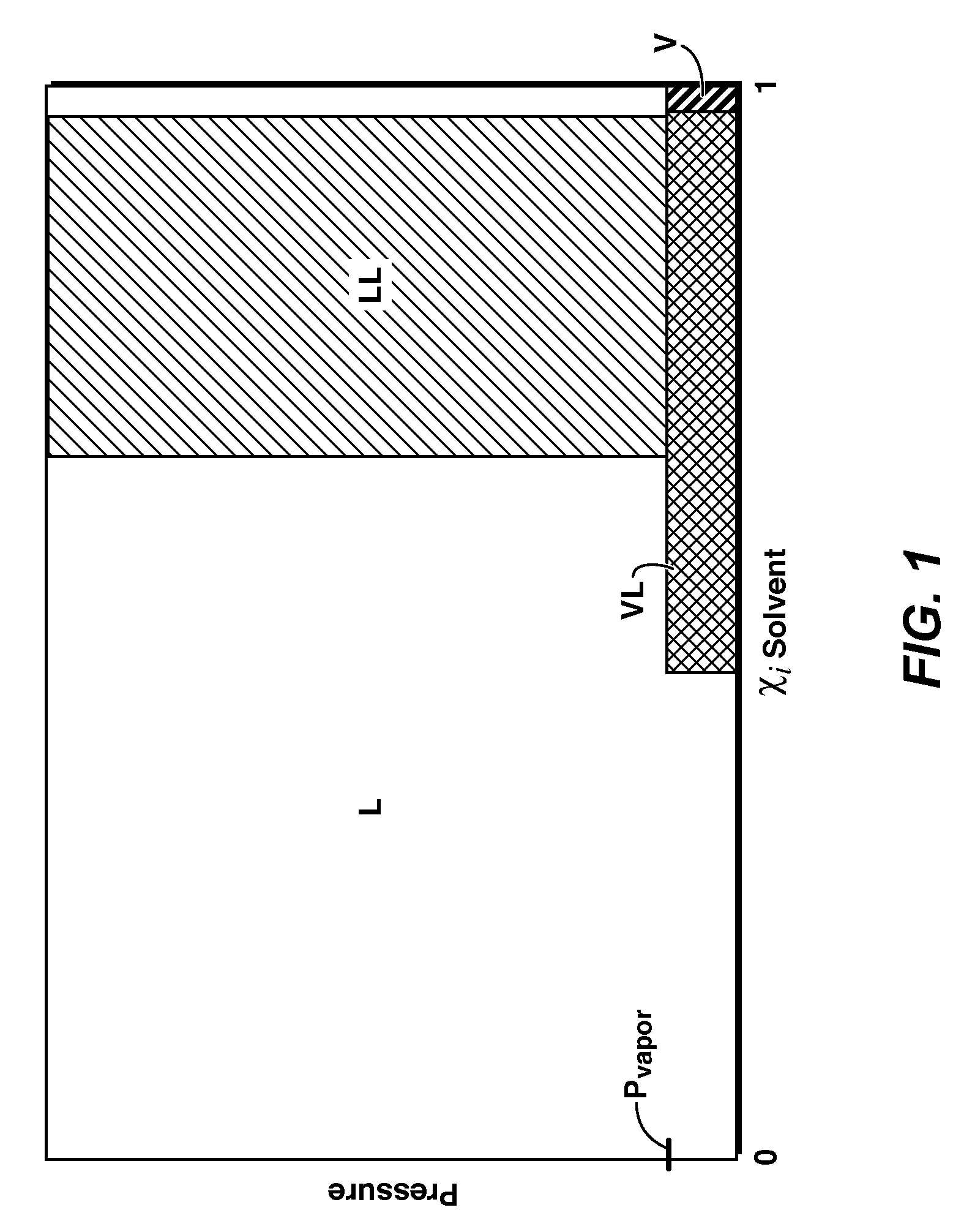

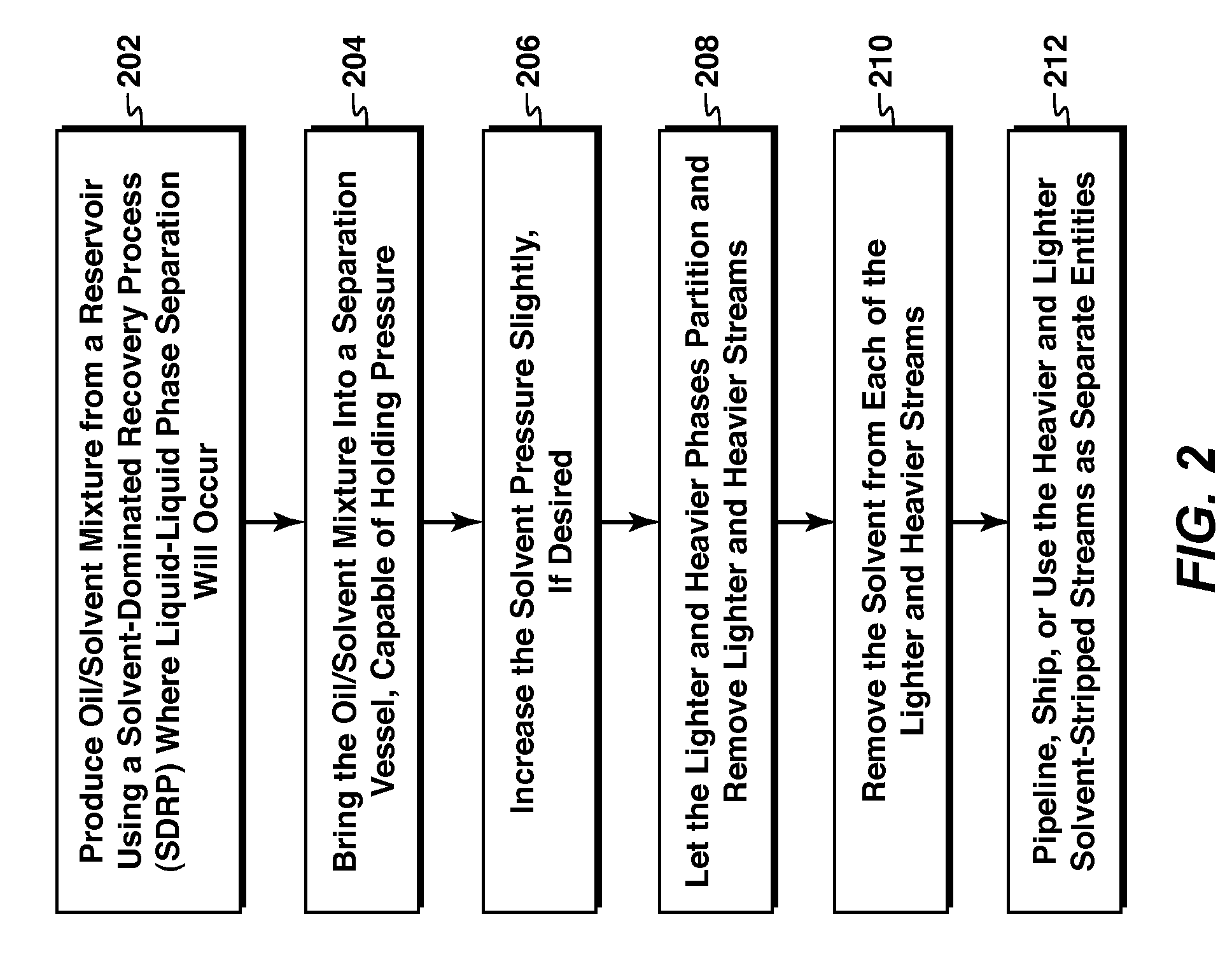

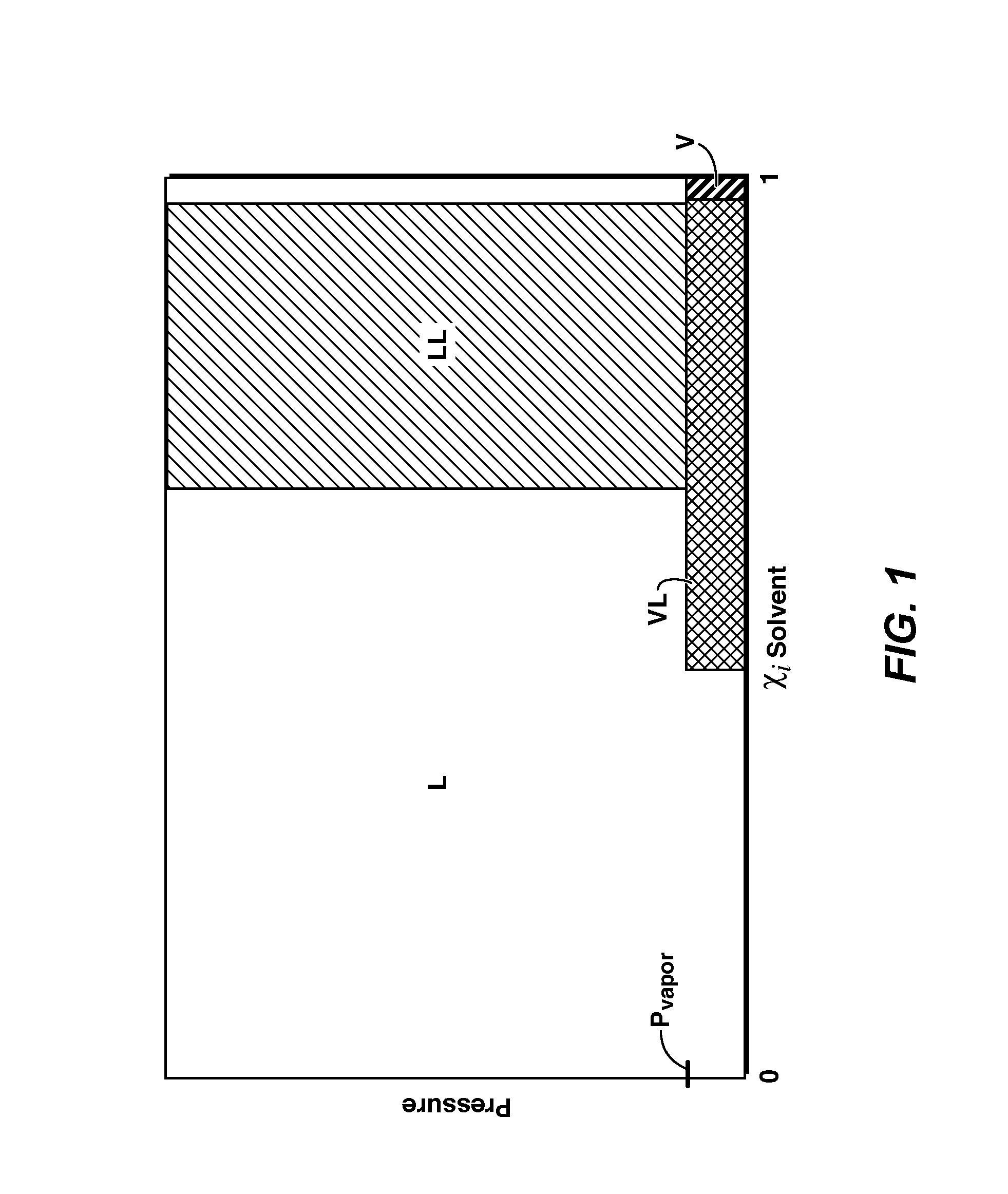

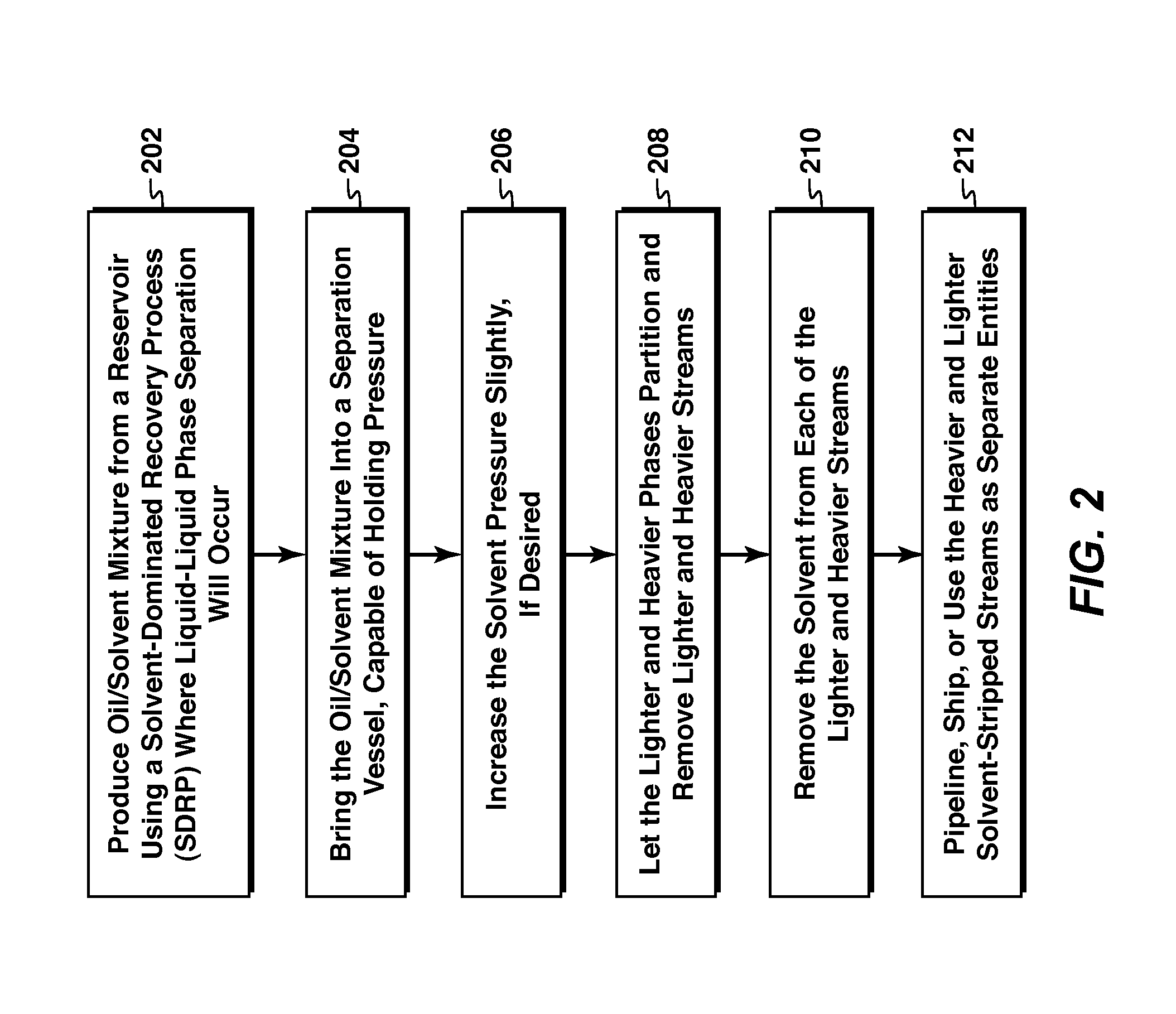

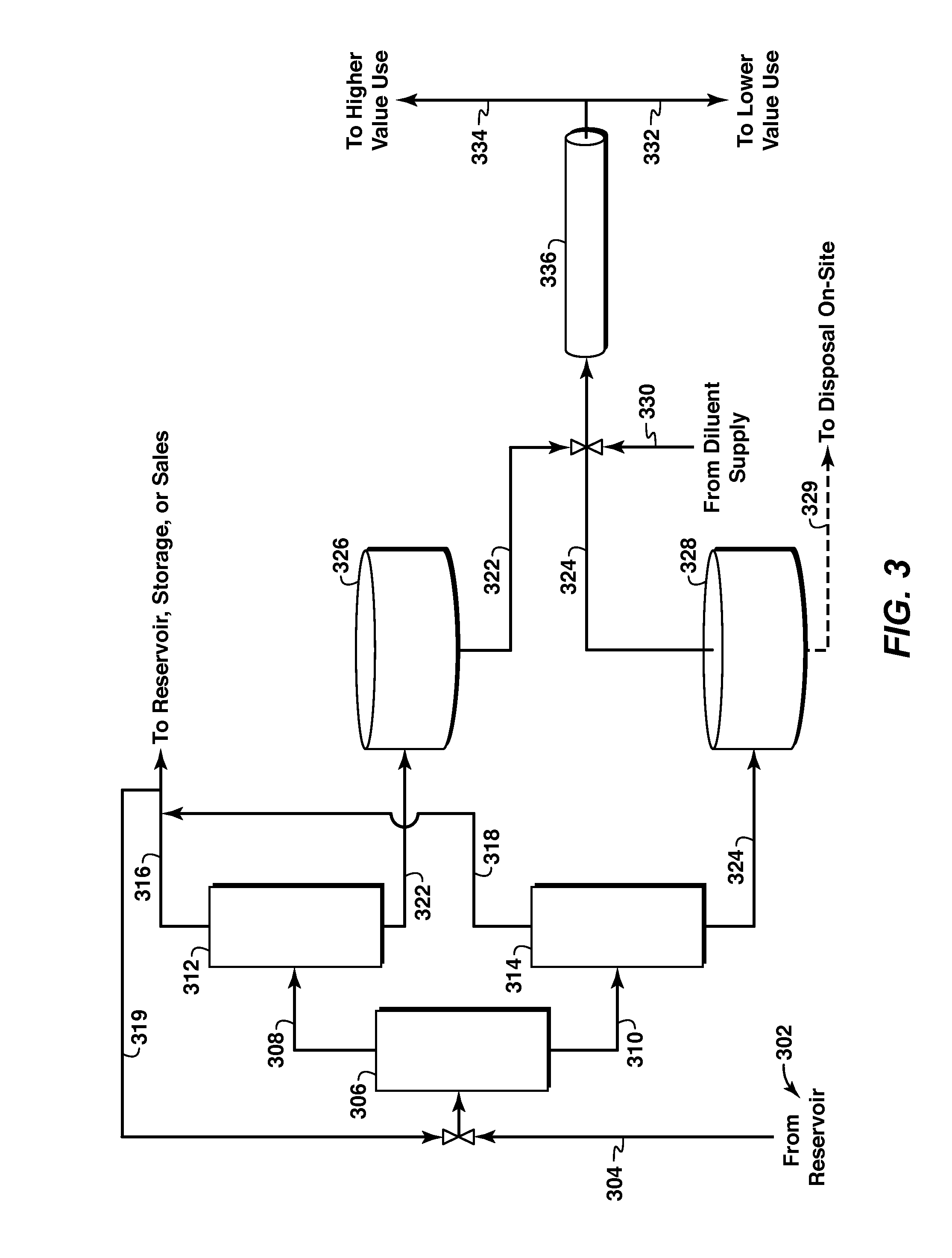

Solvent Separation In A Solvent-Dominated Recovery Process

In solvent-dominated recovery processes for recovering In situ oil, including bitumen, the produced fluid stream includes oil and solvent. The solvent is preferably recovered and reinjected into the reservoir. In previously described methods, solvent is removed from the oil / solvent mixture. In the present method, the oil / solvent mixture is first separated into a heavier stream and a lighter stream from which solvent is independently removed.

Owner:EXXONMOBIL UPSTREAM RES CO

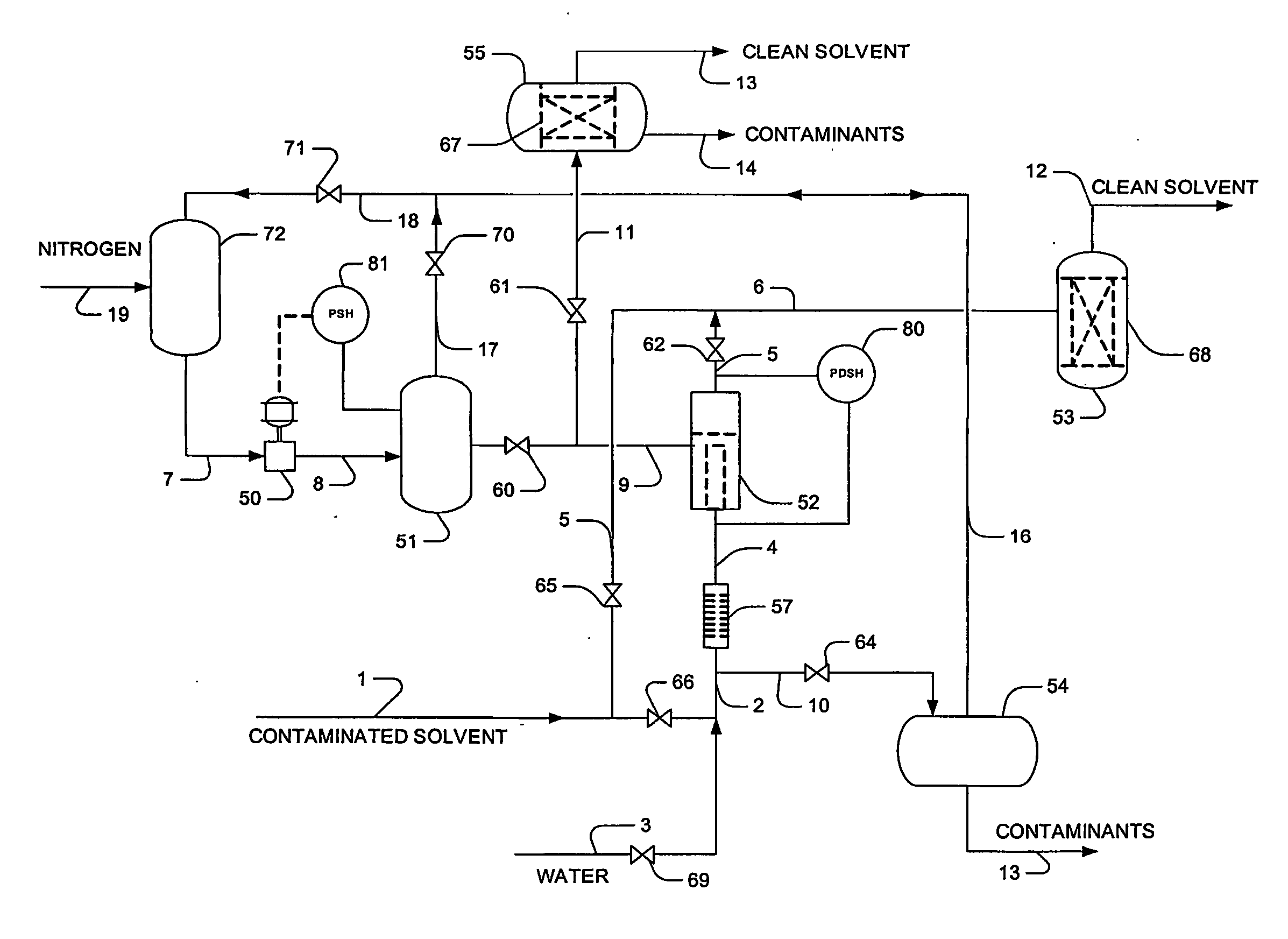

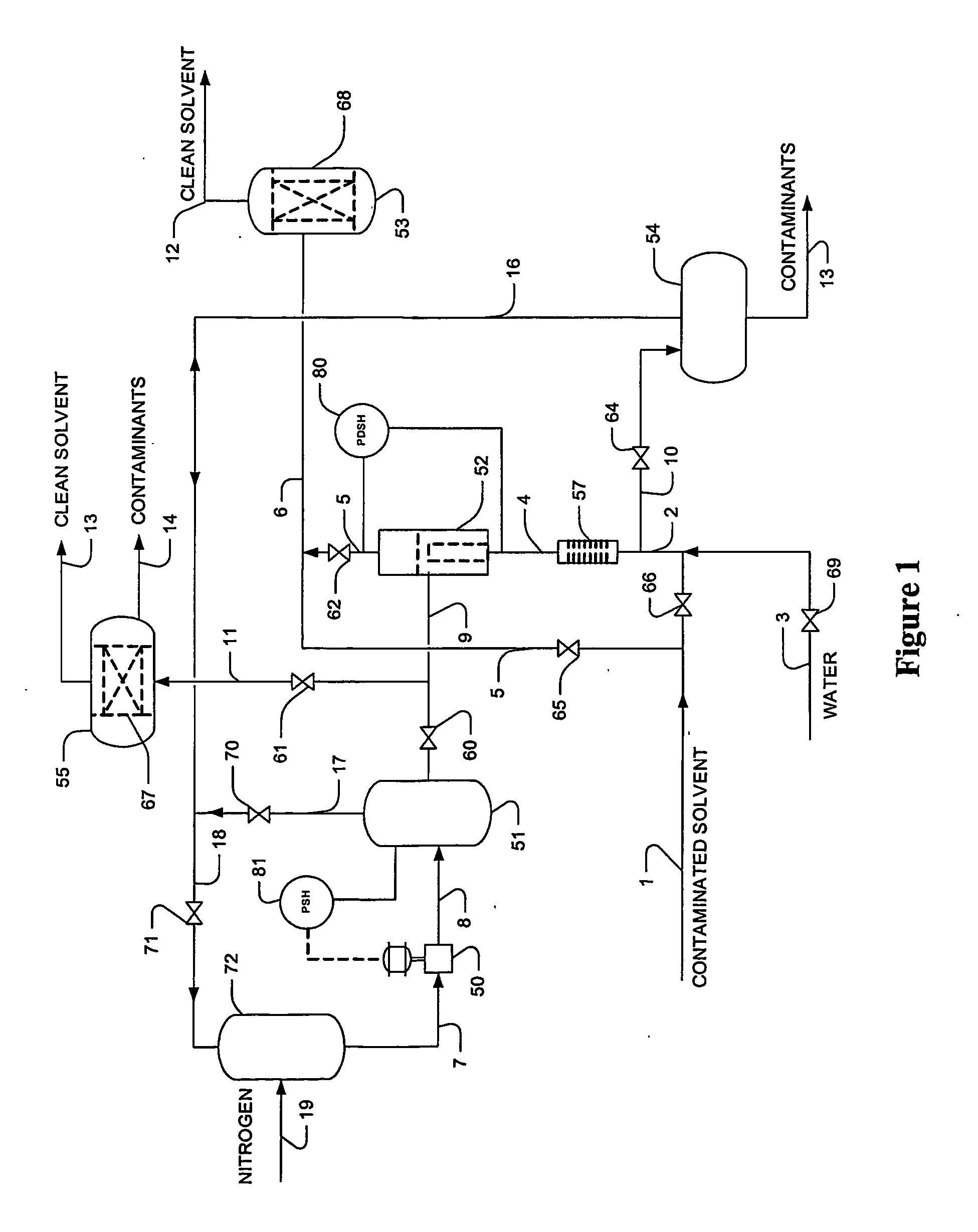

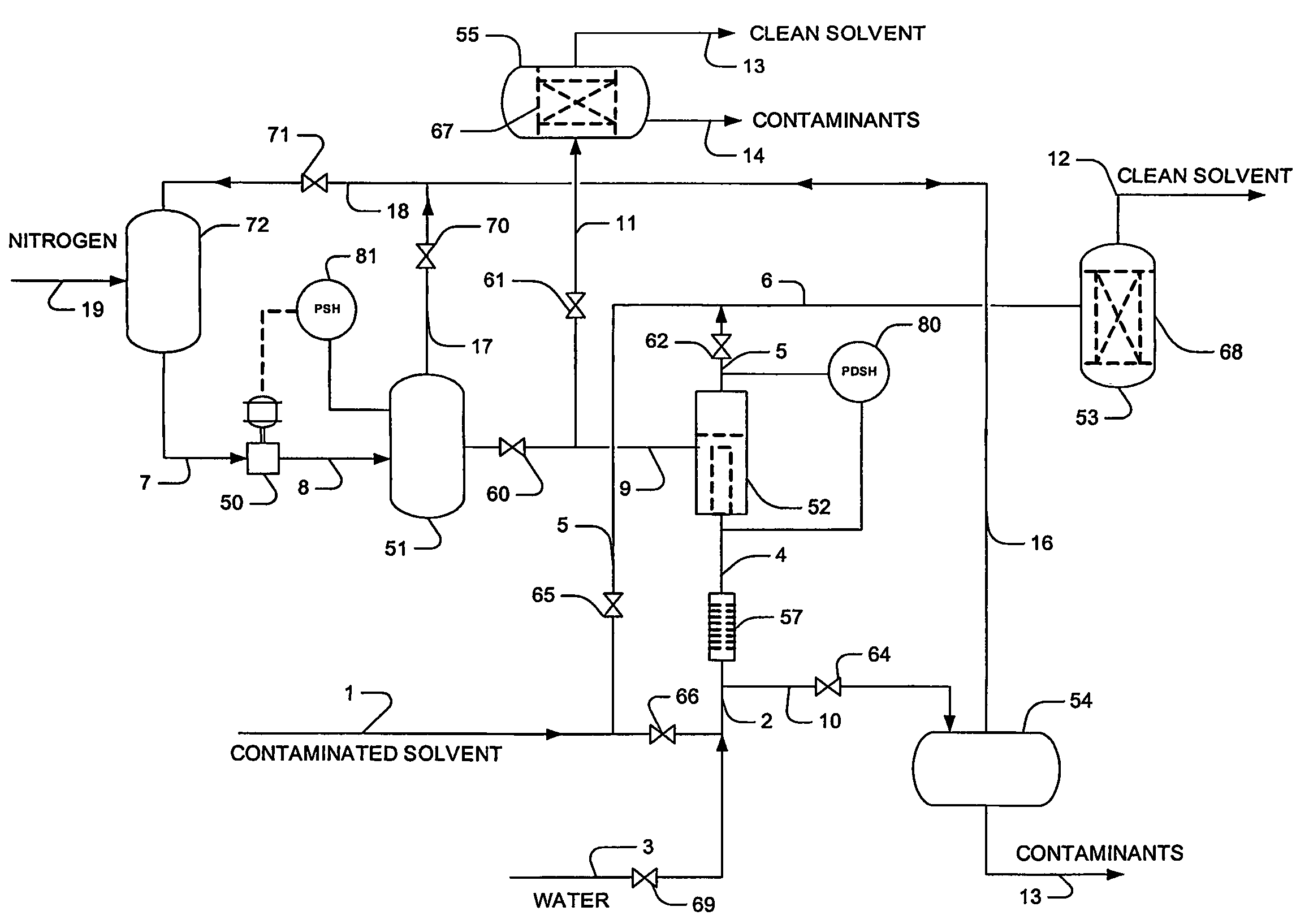

Solvent Filtration System And Methods

InactiveUS20070267353A1Displacement minimizationDispersed particle filtrationWater/sewage treatmentParticulatesFiltration

A filter system has a first filter from which solvent is recovered in a cleaning cycle using a rinse fluid in forward flow, and from which particulates are removed using flush gas in reverse flow. At least part of the solvent and the flush gas are recycled to the system and in still further preferred aspects, filtration of the solvent continues during the cleaning cycle via a bypass circuit through which the solvent is routed to a second filter.

Owner:FLUOR TECH CORP

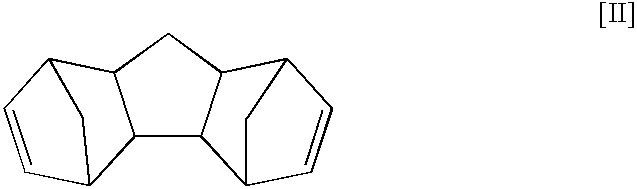

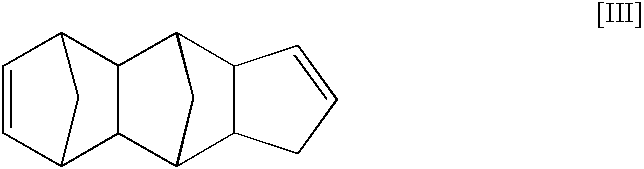

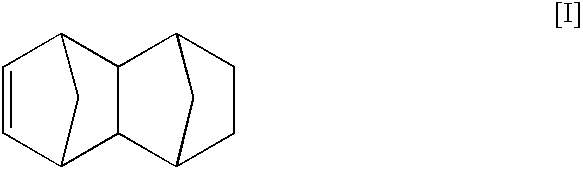

Tetracyclododecene compositions and process for producing the same

InactiveUS6512152B1Easily decomposed into CPDHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsCross-linkVitrification

The present invention is drawn to a tetracyclododecene composition having a regulated cyclopentadiene trimer content, whereby addition polymerization with the aid of a Ziegler catalyst can be carried out while preventing gelation caused by a cross-linking reaction. A tetracyclododecene composition regulated with respect to the content of a specific ingredient having a molecular weight of 188 is disclosed, whereby polymers having high glass transition temperatures can be obtained through various polymerizations. Further, the present invention is drawn to a method for producing tetracyclododecene in the presence of an aliphatic solvent having a boiling point close to that of norbornene, which solvent is effective in inhibiting the recovered norbornene from solidifying. Preferred for obtaining high purity tetracyclododecene by removing the methyltetrahydroindene contained in dicyclopentadiene feedstock is a continuous process comprising a combination of reaction, distillation, and recovery / circulation, and so forth.

Owner:NIPPON PETROCHEMICAL CO LTD

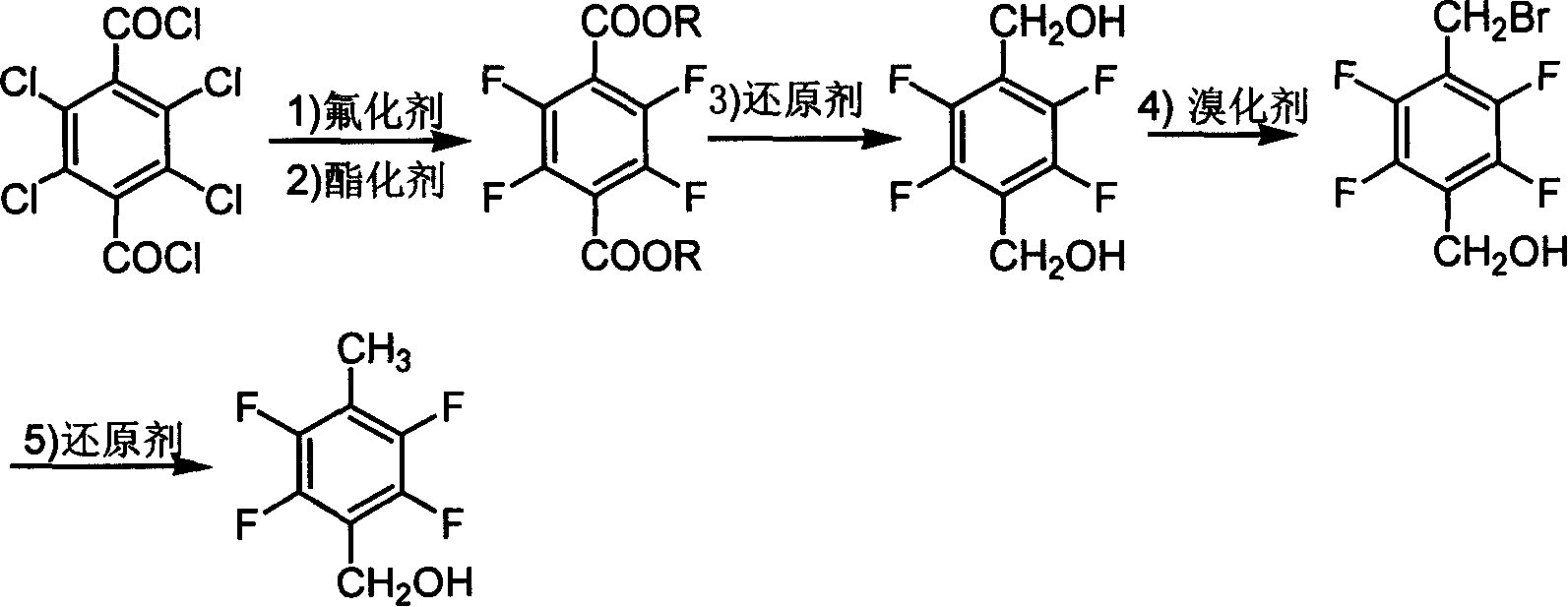

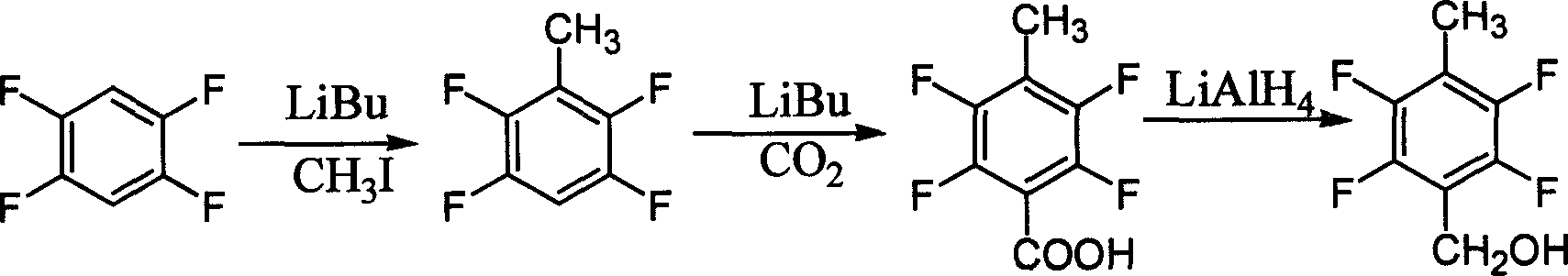

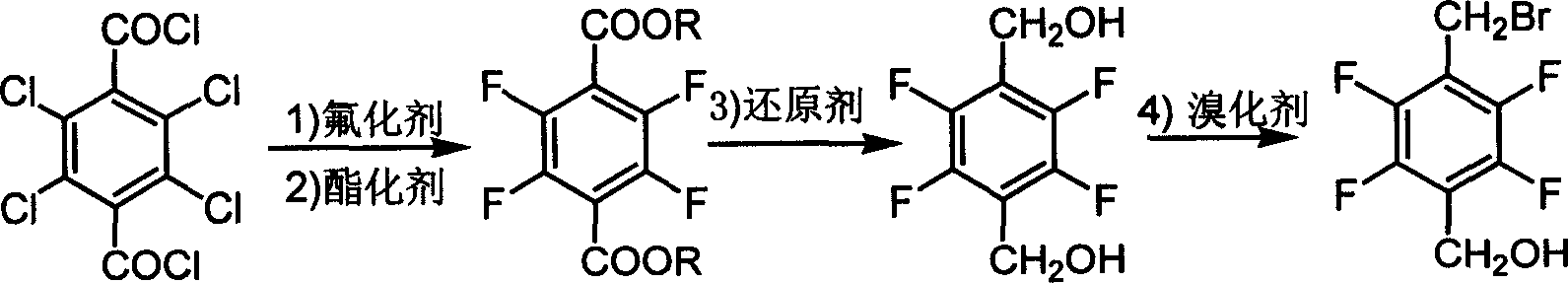

Process for preparing 2, 3, 5, 6-tetrafluoro-p-xylyl alcohol

InactiveCN1204104CConvenient sourceLow priceOrganic compound preparationHydroxy compound preparationSulfolanePotassium fluoride

The invention discloses a preparation method of 2,3,5,6-tetrafluoro-p-methylbenzyl alcohol, which belongs to the preparation technology of 2,3,5,6-tetrafluoro-p-methylbenzyl alcohol. The method is prepared by taking 2,3,5,6-tetrachloroterephthaloyl chloride as a raw material through fluorination, esterification, reduction, bromination and reduction. The fluorinating agent of the fluorination reaction is potassium fluoride, etc., the solvent is sulfolane, etc., the catalyst is calixarene, etc., and the reaction temperature is 40°C-230°C. Esterification The esterification agent is aliphatic alcohol or aromatic alcohol, and the reaction temperature is 20°C to 120°C. Reduction reaction of ester The reducing agent is sodium borohydride, etc., the solvent is sulfolane, etc., and the reaction temperature is -10°C to 60°C. The bromination agent for the bromination reaction is HBr acid, the solvent is dichloromethane, and the reaction temperature is 30°C to 160°C. The reducing agent of the bromide reduction reaction is magnesium powder, etc., the solvent is fatty alcohol, water, chloride, etc., and the reaction temperature is -10°C to 50°C. The invention has the advantages of simple process, low production cost, high product yield and purity, and is suitable for industrialized production.

Owner:TIANJIN UNIV

Solvent filtration system and methods

InactiveUS7785480B2Displacement minimizationDispersed particle filtrationWater/sewage treatmentParticulatesFiltration

A filter system has a first filter from which solvent is recovered in a cleaning cycle using a rinse fluid in forward flow, and from which particulates are removed using flush gas in reverse flow. At least part of the solvent and the flush gas are recycled to the system, and in still further preferred aspects, filtration of the solvent continues during the cleaning cycle via a bypass circuit through which the solvent is routed to a second filter.

Owner:FLUOR TECH CORP

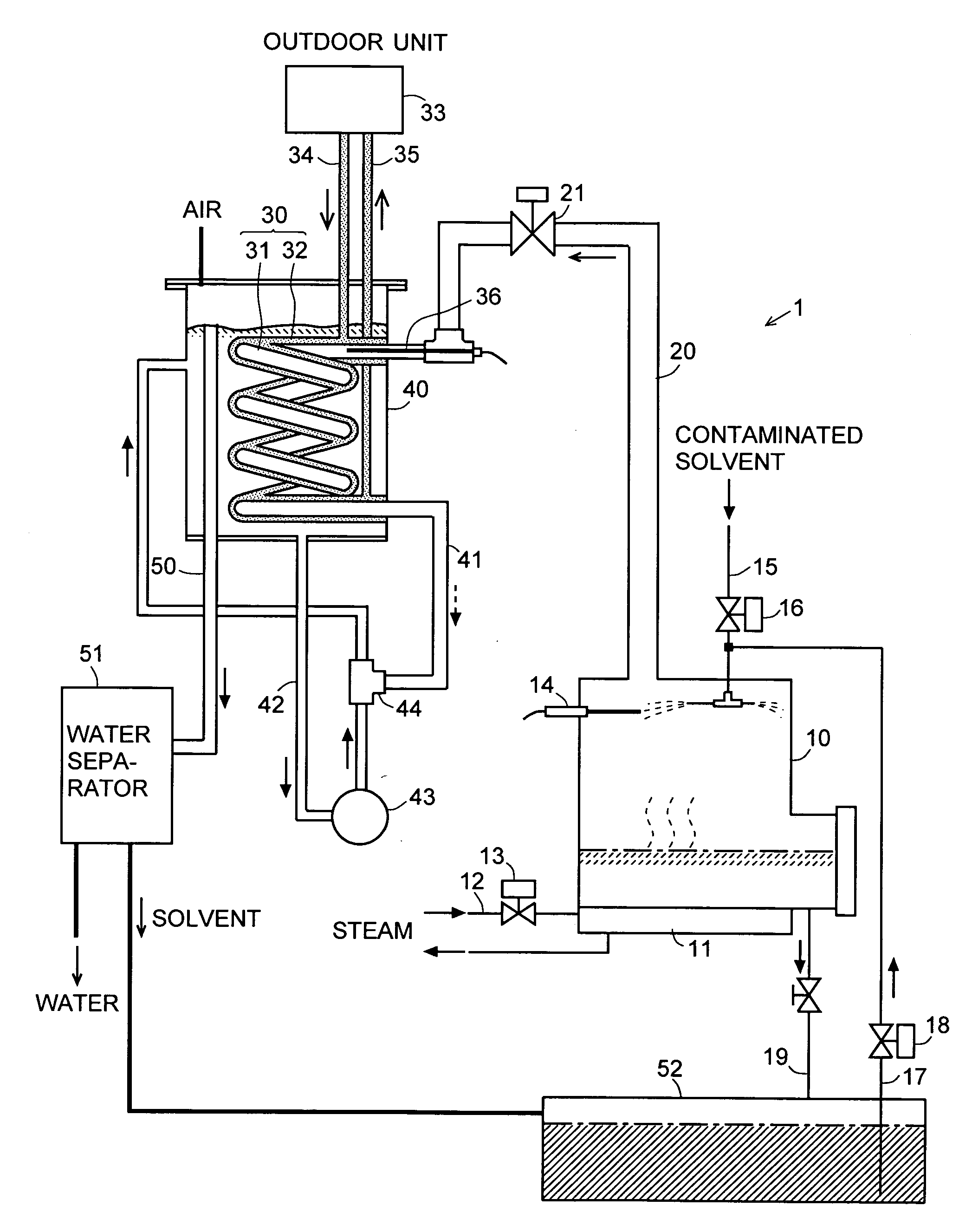

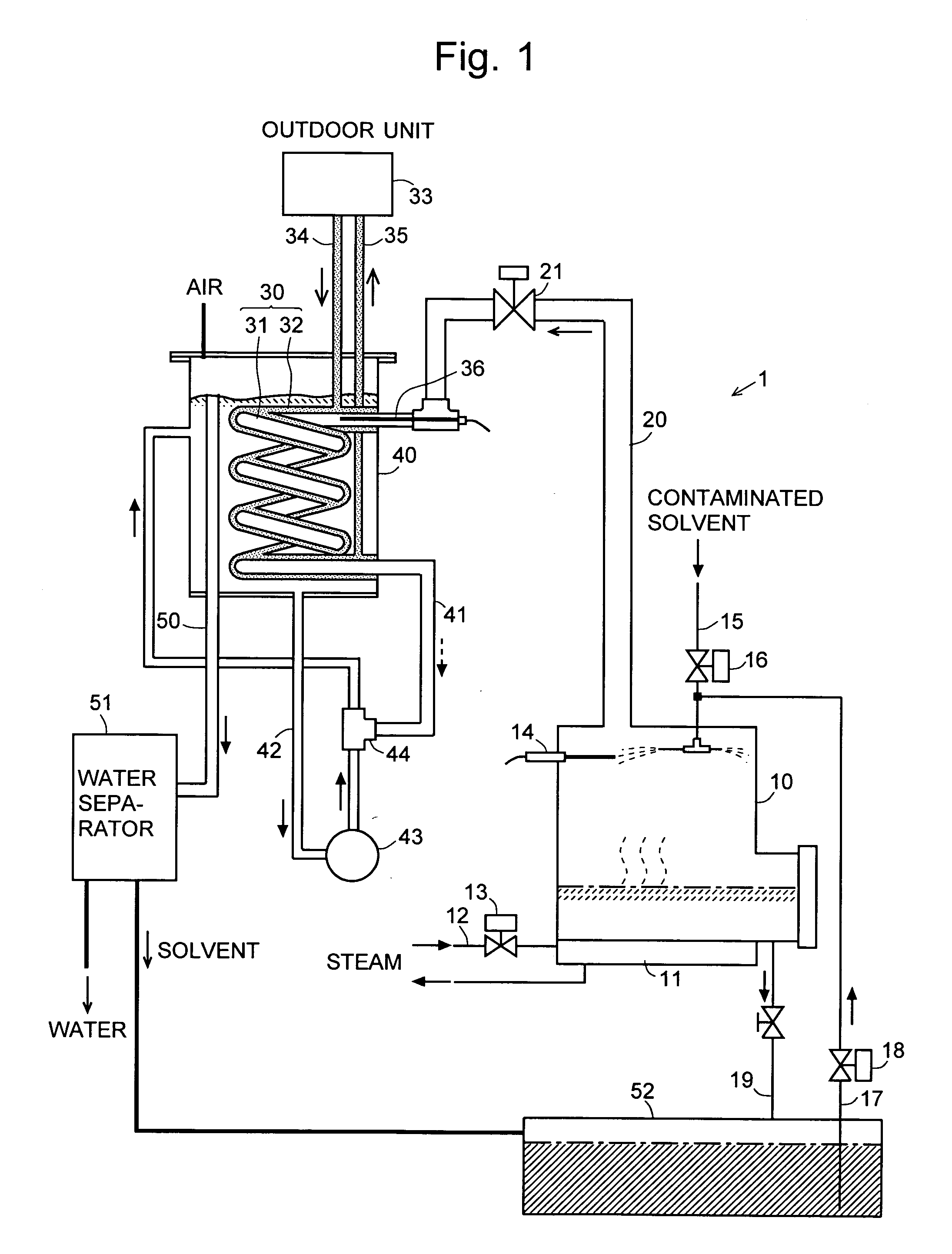

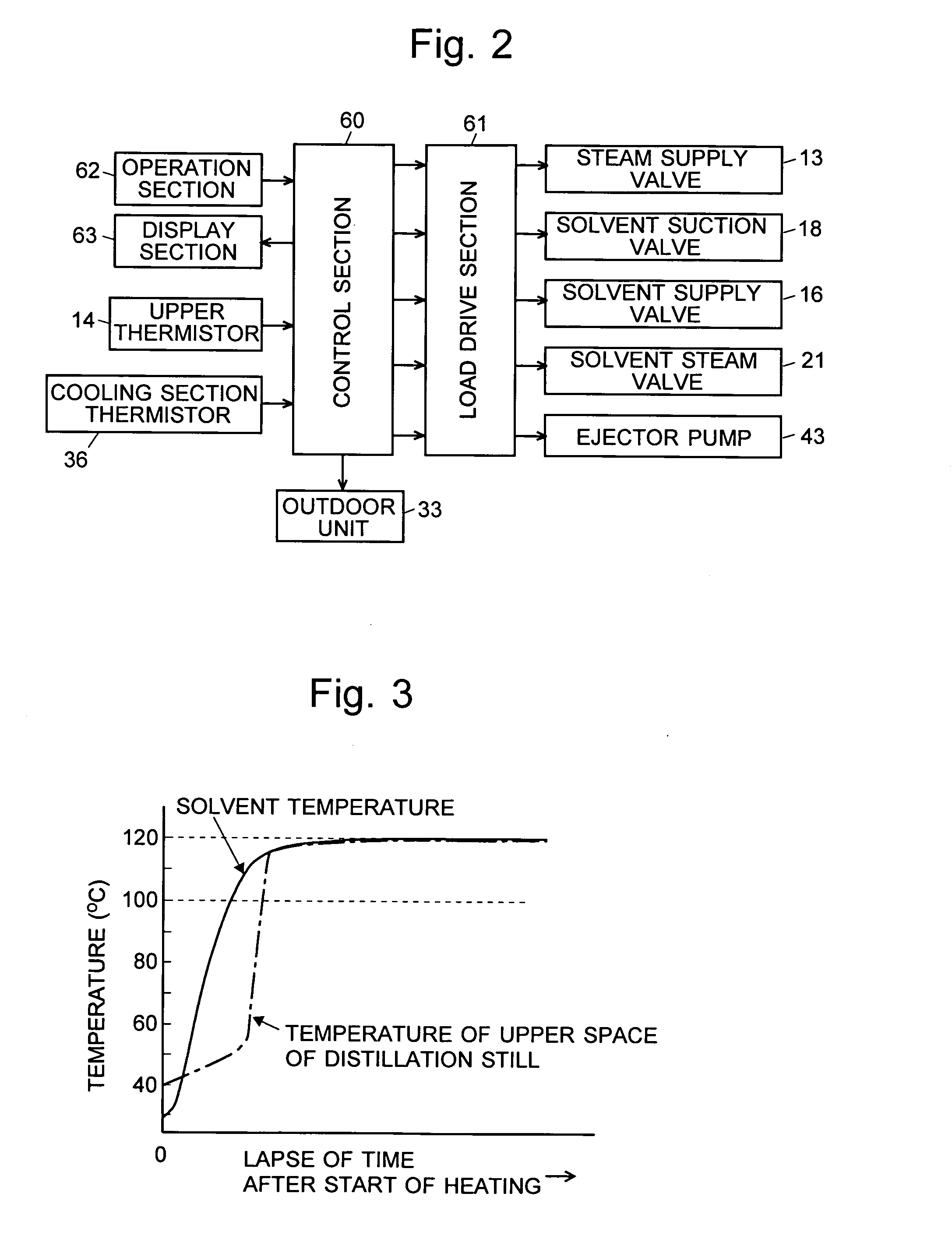

Vacuum distillation method and vacuum distillation apparatus

InactiveUS20080230370A1Reliably prevent such an abnormal foamingAvoid collisionVacuum distillation separationWater/sewage treatment by heatingSolvent vaporDouble tube

An objective of the present invention is to suppress bumping in the distillation still so as to collect a high purity solvent containing no impurities. A solvent vapor valve 21 is disposed in a solvent vapor withdrawal conduit 20 through which solvent vapor is transferred from inside the distillation still 10 to an inner pipe 31 of a double-tube structure 30 which is a heat exchange section. Also, a thermistor 14 is disposed in an upper space in the distillation still 10. After a heating chamber 11 starts heating the solvent, the start of boiling is determined by a sudden rise in temperature detected by the thermistor 14, and shortly thereafter, the solvent vapor valve 21 is closed to fill the distillation still 10 with the solvent vapor. The solvent vapor actively generated by bumping is condensed and liquefied on the cold inner surfaces of a ceiling wall and a sidewall of the distillation still 10, and concurrently, the heat of condensation is provided to the ceiling wall surface and the sidewall surface, thereby accelerating the temperature rise thereof. Bumping stops when the temperatures of the surfaces of the ceiling wall and the sidewall have reached a sufficiently high temperature, and thereafter the valve 21 is opened to transfer the solvent vapor to the double-tube structure 30 functioning as the heat exchange section.

Owner:SANYO ELECTRIC CO LTD +1

Process for regenerating a catalyst

ActiveUS20110143917A1Reduce solubilitySolubility of metal is lowMolecular sieve catalystsOther chemical processesHydrogenCobalt

A process for regenerating one or more deactivated cobalt comprising Fischer-Tropsch catalyst particle(s), comprising the steps of: (i) oxidising the catalyst particle(s) at a temperature between 20 and 400° C.; (ii) treating the catalyst particle(s) for more than 5 minutes with a solvent, which solvent comprises an amine, (iii) drying the catalyst particle(s); and (iv) optionally reducing the catalyst particle(s) with hydrogen or a hydrogen comprising gas. This process may be preceded by a step in which Fischer-Tropsch product is removed from the catalyst particle(s).

Owner:SHELL USA INC

Method for preparing hollow northylen of ultra-high relative molecular mass

InactiveCN101289765AImprove mechanical propertiesImprove extraction efficiencyHollow filament manufactureWet spinning methodsFiberPolymer science

The invention relates to a method for preparing hollow polythene fibers with superhigh relative molecular mass. The method is to extrude polythene spinning stock solution with superhigh relative molecular mass through a hollow spinning nozzle under the condition of high temperature, to make the polythene spinning stock solution enter into a precipitating bath and quenched into jel fibers, and to prepare the hollow high-strength high-modulus fibers through extraction, drying and super drawing of the prepared jel fibers. The method shortens a path by which solvent in the fibers is diffused out the jel fibers, improves the extraction efficiency, simplifies the extraction technique, eliminates uneven structure and further improves the mechanical properties of the fibers.

Owner:DONGHUA UNIV +1

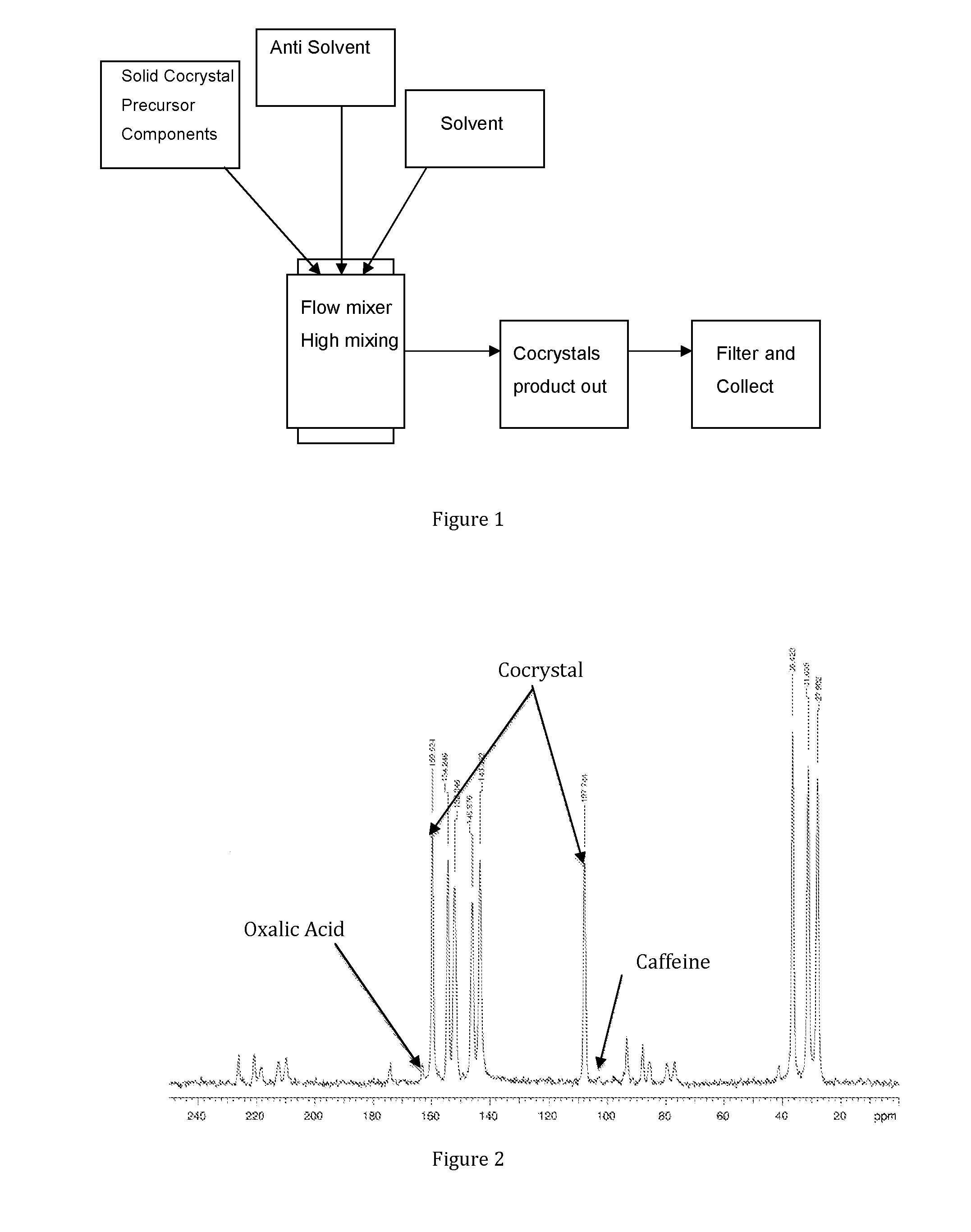

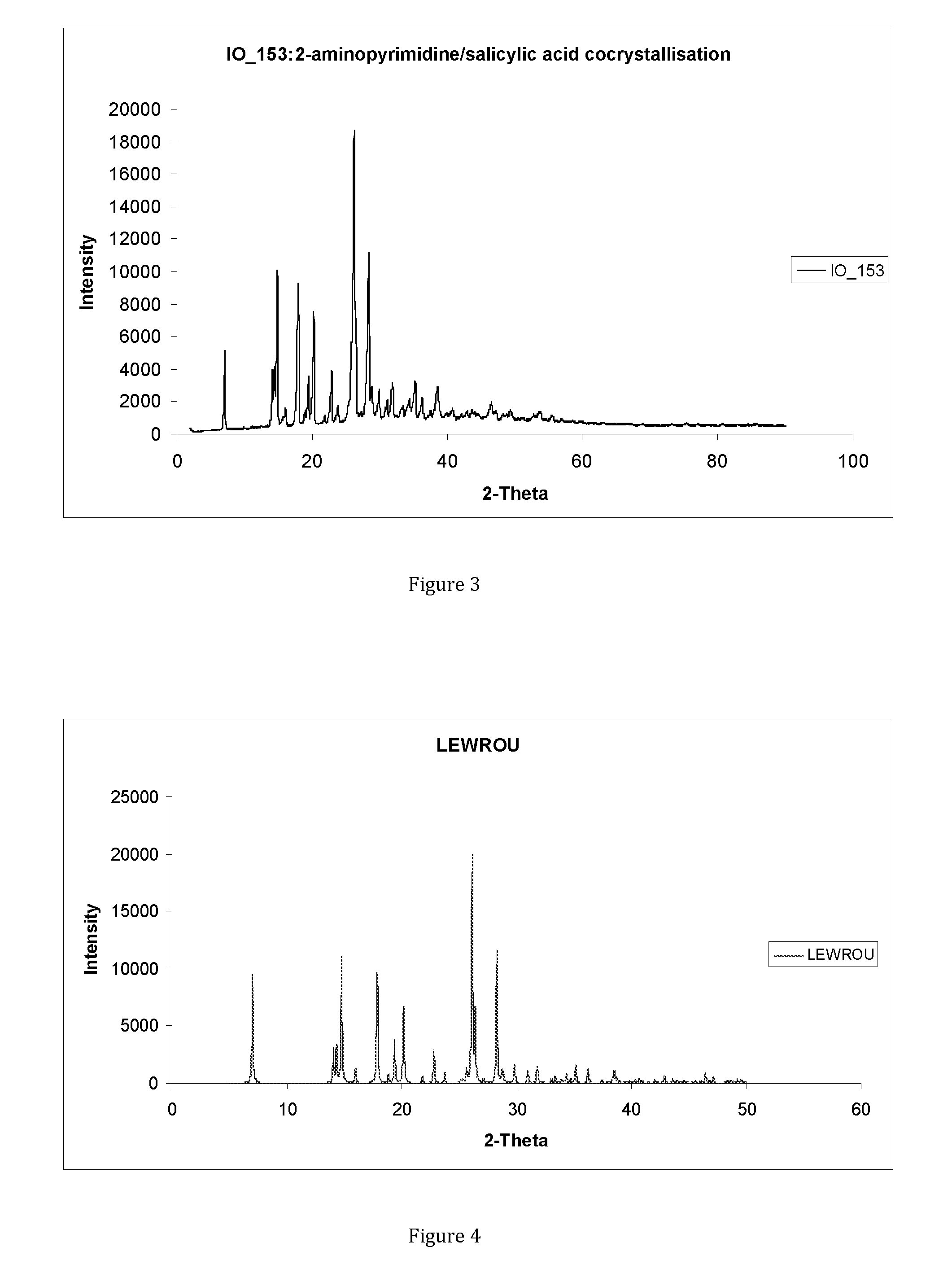

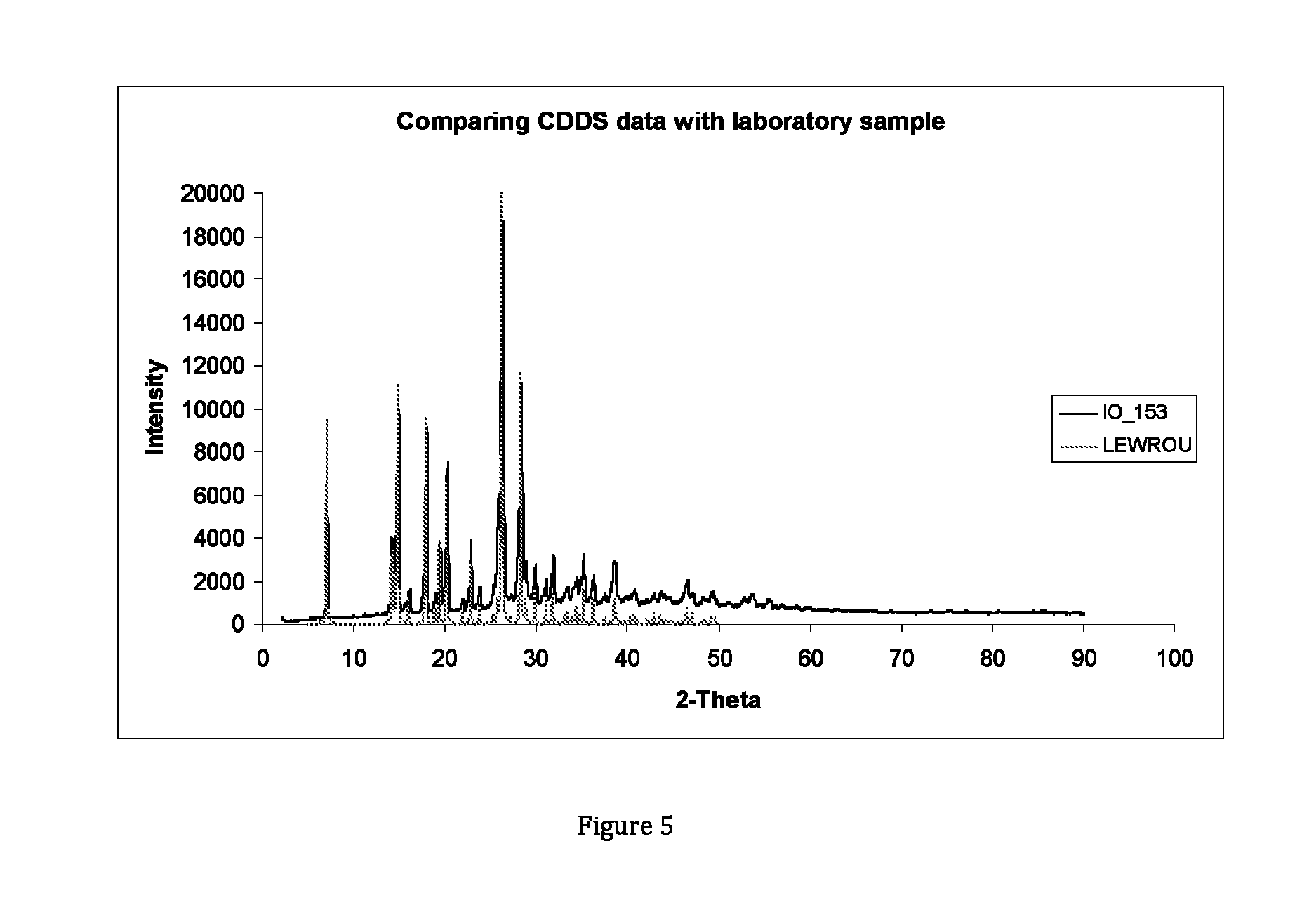

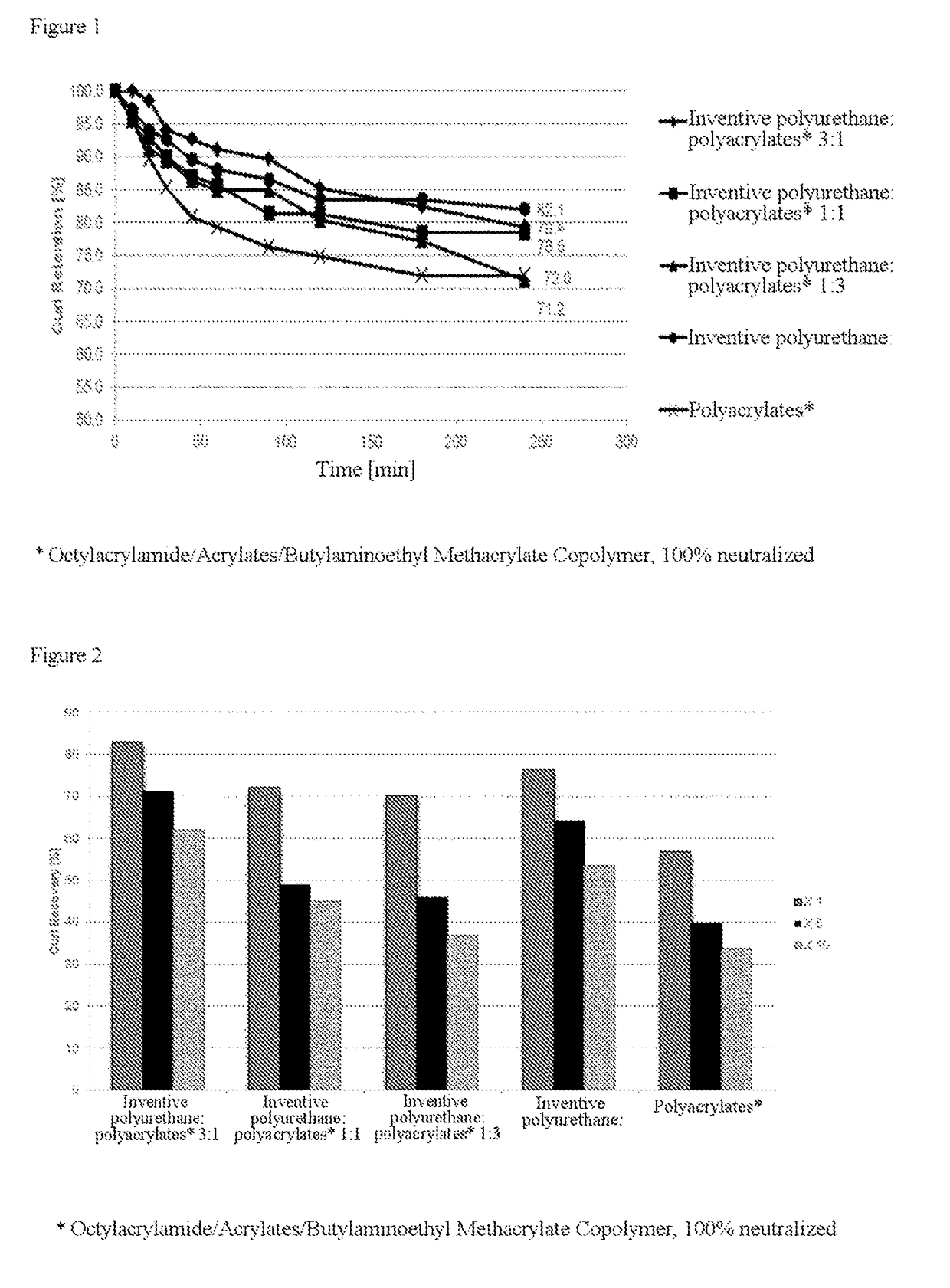

Methods for making active crystalline materials

ActiveUS9439914B2Promote quick completionSalicyclic acid active ingredientsBiocideCrystallographyLiquid medium

The present invention relates to an active crystalline material, especially an active multicomponent crystalline material such as a salt or a cocrystal, which may be made by dispersing precursor components of the active crystalline material in a liquid medium which comprises an anti-solvent, maintaining the dispersion for a period during which the active crystalline material is formed, and, during said period, exposing the dispersion to a solvent, which solvent being present in the liquid medium in a minor proportion by weight thereof.

Owner:CPI INNOVATION SERVICES LTD

Solvent systems having no flash point and methods using such solvent systems for dissolving rigid polyurethane foams

Owner:ALBEMARLE CORP

Polyurethane urea solutions for hair-styling compositions

InactiveUS20170224606A1Improve compatibilityImprove applicabilityCosmetic preparationsHair cosmeticsOrganic solventAlcohol

The invention relates to a hair-styling composition, comprising at least one propellant gas and / or a thickener, and a polyurethane urea, which has no ionic hydrophilizing groups and which is dissolved in a solvent or solvent mixture, the solvent consisting of one or more monohydroxy-functional alcohols or a solvent mixture consisting of organic solvents, which solvent mixture contains ≧50 wt. % of at least one monohydroxy-functional alcohol, with respect to the total mass of the solvent mixture. The invention further relates to the use of the hair-styling composition to shape, solidify, and / or fix hair to a method for shaping, solidifying, and / or fixing hair by using the polyurethane urea solution. The invention further relates to a method for producing a hair-styling composition, in which method the polyurethane solution is used.

Owner:COVESTRO DEUTSCHLAND AG

Silver-containing electrically-conductive compositions

ActiveUS10305022B1Improved piezoelectric responseAffects distributionPolyurea/polyurethane coatingsPiezoelectric/electrostrictive/magnetostrictive devicesYoung's modulusConductive materials

An electrically-conductive composition essentially has (a) an electrically-conductive material consisting essentially of silver nanoparticles that have a d50 of less than or equal to 60 μm and a d90 of less than or equal to 500 μm; (b) particles having a Young's modulus that is different from the Young's modulus of the (a) electrically-conductive material by at least 10%, which (b) particles have a d50 of 500 nm to 300 μm and a polydispersity coefficient of less than or equal to 3; (c) a binder material that is non-electrically-conductive; and (d) a solvent medium in an amount of less than or equal to 90 weight %, based on the total composition weight, which solvent medium is at least 50 weight % water. The weight ratio of the (b) particles to the (a) electrically-conductive material is at least 0.01:1 and up to and including 7:1.

Owner:EASTMAN KODAK CO

Method for reprocessing spent nuclear fuel and centrifugal extractor therefor

ActiveUS9666315B2Isolation difficultRecovery difficultWater/sewage treatment by centrifugal separationNuclear fuel reprocessingElectrolysisEngineering

A spent nuclear fuel is reprocessed by dissolving a spent nuclear fuel in an aqueous nitric acid solution and separating and recovering nuclides contained in the resulting fuel solution by solvent extraction. A spent nuclear fuel reprocessing method includes: an electrolytic valence adjustment step in which nuclides contained in the fuel solution is electrolytically reduced without removing fission products or minor actinides until valence of plutonium is at a level at which solvent extraction efficiency is low by using the valence of plutonium contained in the fuel solution as a parameter; and a nuclide separation step in which, by using an extraction solvent which extracts uranium contained in the fuel solution, uranium is distributed from the fuel solution subjected to the electrolytic valence adjustment step to the extraction solvent.

Owner:KK TOSHIBA

Silver-containing electrically-conductive compositions

ActiveUS20190189905A1Improve performanceImprove the overall coefficientPolyurea/polyurethane coatingsPiezoelectric/electrostrictive/magnetostrictive devicesYoung's modulusPolymer chemistry

Owner:EASTMAN KODAK CO

Cooling apparatus

InactiveCN1980727ASemi-permeable membranesEfficient regulation technologiesEvaporationPermselective membrane

A process for introducing a solution into an evaporative cooling apparatus (14), said process comprising a) positioning a selectively permeable membrane (16) between a first solution (18) and a second solution (20) having a higher solute concentration than the first solution (18), such that the solvent from the first solution (18) flows across the selectively permeable membrane (16) to dilute the second solution (20), b) introducing the second solution into an evaporative cooling apparatus (14) in which solvent is removed from the second solution (20) by evaporation, and c) recycling the second solution (20) from step b) to step a) to draw solvent from the first solution (18).

Owner:SURREY AQUA TECH

Closed type drying device

InactiveCN101776374AReduce consumptionDrying solid materials without heatEngineeringMechanical engineering

The invention provides a closed type drying device. The device is used for drying a workpiece after the workpiece is immersed into a solvent and is characterized in that the part in which solvent steam flows during drying is formed into a closed mechanism insulated from the outside; and besides, the closed mechanism is open to the outside when the workpiece is taken out and the periphery of the closed mechanism is covered by cryogenic cooling troughs to form a structure. Through the closed type drying device, the solvent can be recovered, dosage of the solvent is greatly reduced and the cost is reduced, and the amount of discharged solvent is reduced and the pollution of the solvent to the environment is reduced.

Owner:SHANGHAI SHINMEI ELECTRIC CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com