Scrap chute mechanism

A chute and waste technology, applied in the field of waste chute mechanism, can solve the problems of difficult discharge of waste, unsmooth discharge, increased mold closing height, etc., and achieve the effect of reducing design restrictions, improving reliability, and smooth discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

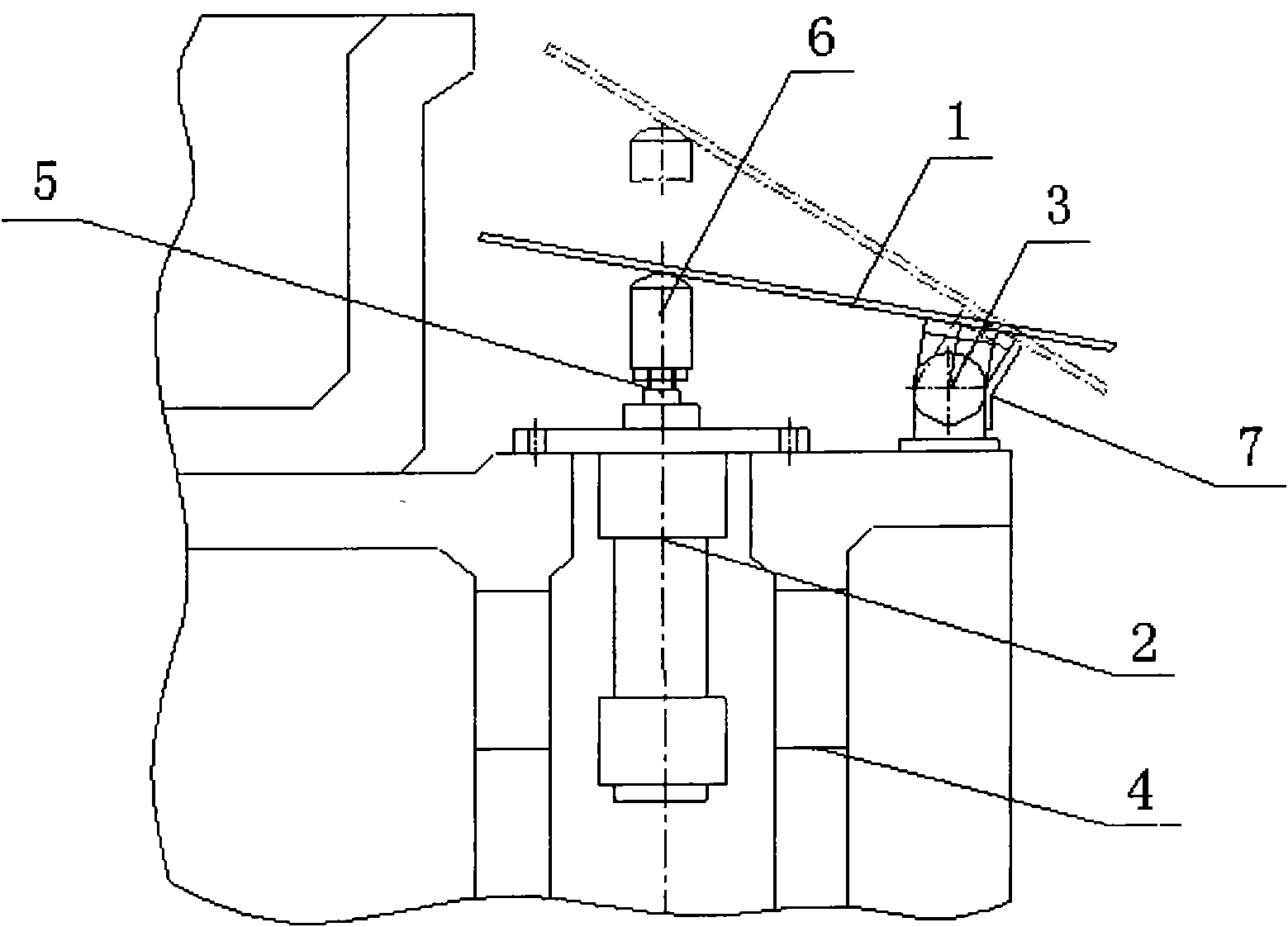

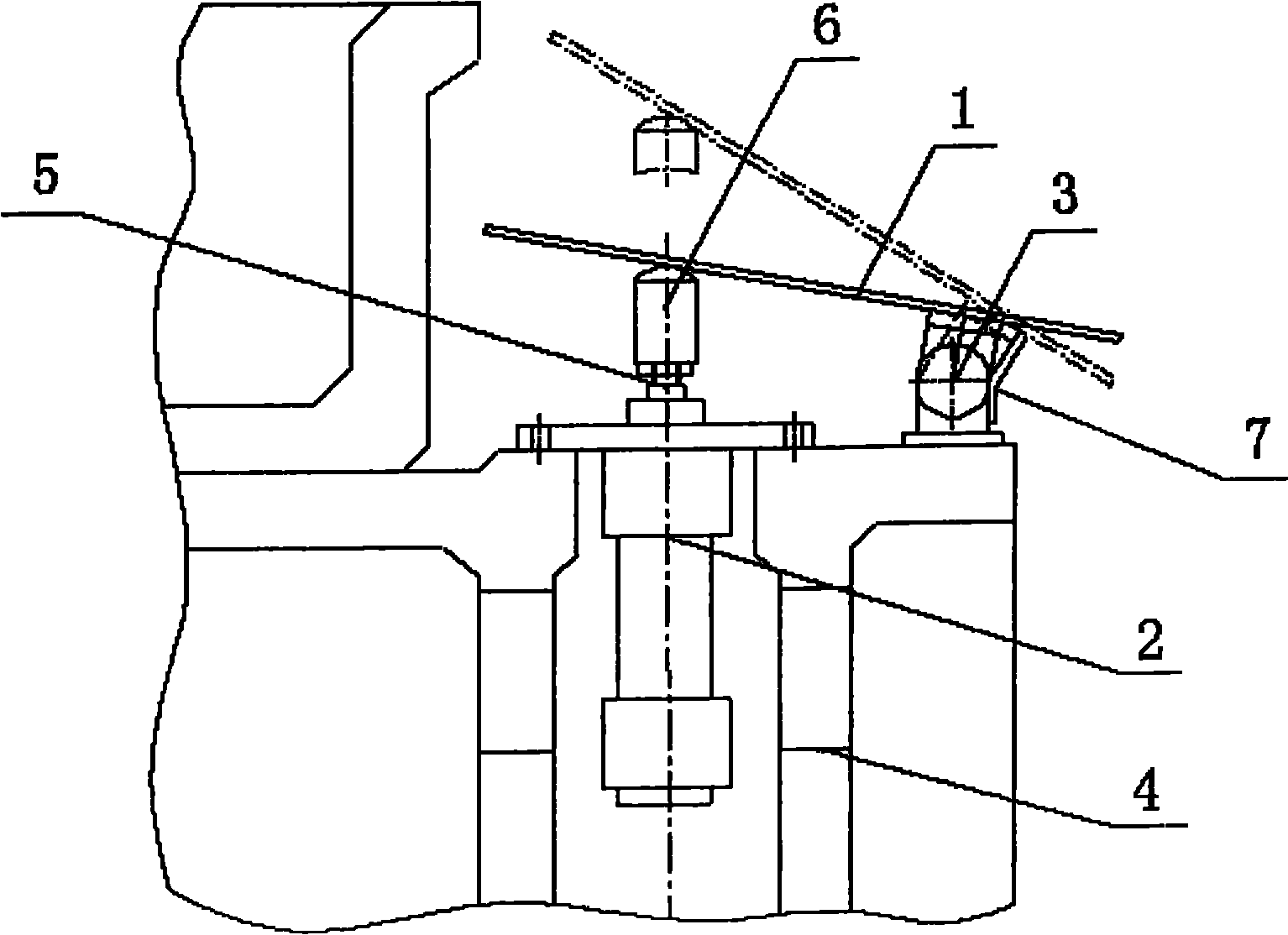

[0016] Such as figure 1 As shown, the waste chute mechanism of the present embodiment includes a waste chute 1 and a cylinder 2, the waste chute 1 is movably mounted on the lower die body 4 through a hinge 3, the cylinder 2 is vertically installed on the bottom of the waste chute 1, and the cylinder The end of the piston rod 3 is equipped with a top pin 6 with a spherical top surface, and the top pin 6 is offset against the bottom of the waste chute 1; the lower die body 4 is equipped with a limit plate 7 for limiting the rotation angle of the waste chute 1, so that The bottom of the positioning plate 7 is fixed on the lower mold body 4, and the upper part of the limiting plate 7 is bent toward the discharge direction.

[0017] When working, the piston rod 5 of the cylinder continuously reciprocates and vertically moves under the action of the gas. When the piston rod 5 moves upward, it can lift the waste chute 1, because the waste chute 1 is restricted by the hinge 3 below it...

Embodiment 2

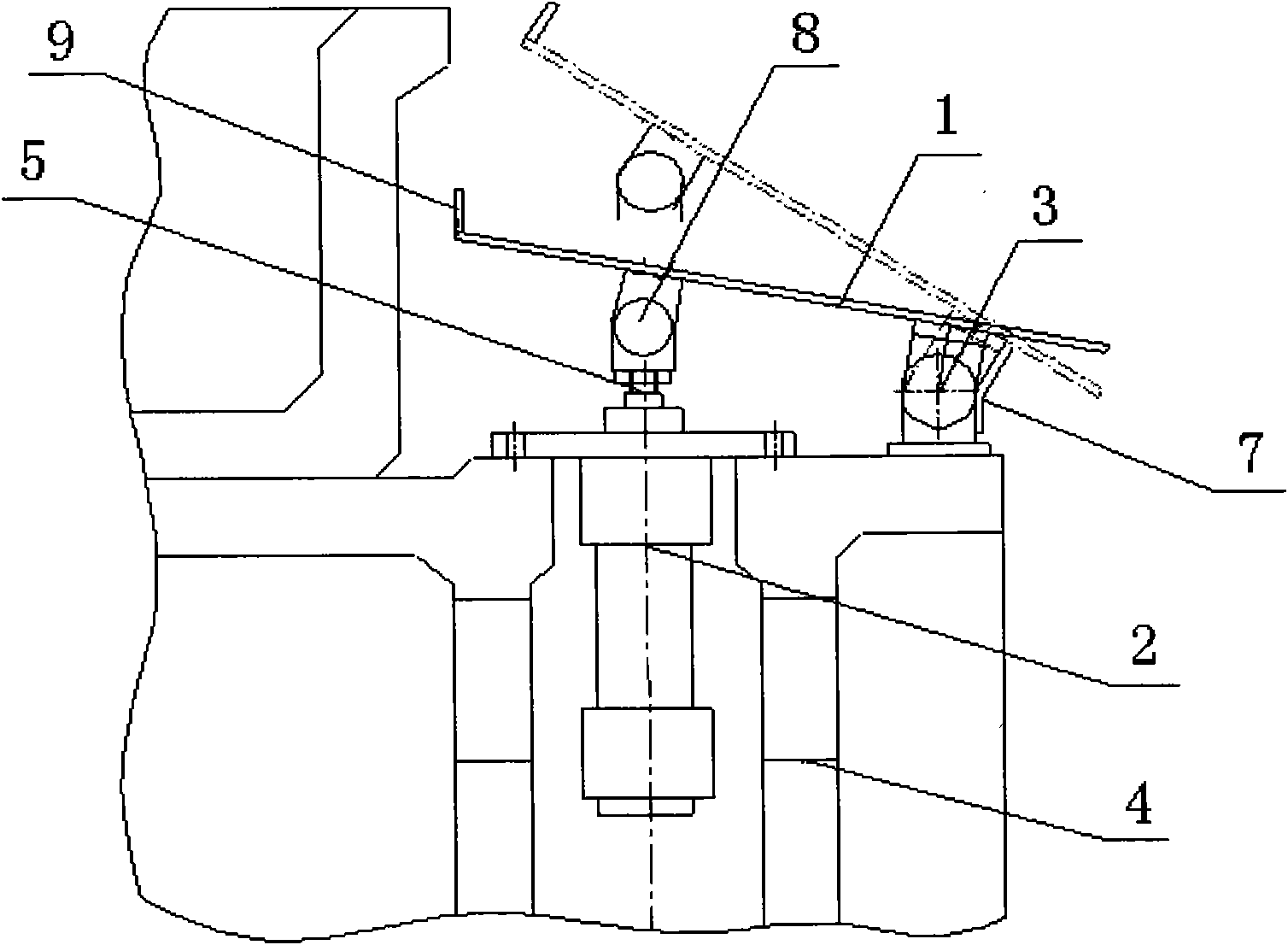

[0019] Such as figure 2 As shown, the waste chute mechanism of the present embodiment includes a waste chute 1 and a cylinder 2, the waste chute 1 is movably mounted on the lower die body 4 through a hinge 3, the cylinder 2 is vertically installed on the bottom of the waste chute 1, and the cylinder The end of the piston rod 3 is flexibly connected to the bottom of the waste chute 1 through a hinge 8; the lower mold body 4 is equipped with a limit plate 7 for limiting the rotation angle of the waste chute 1, and the bottom of the limit plate 7 is fixed on the lower mold body 4, the upper part of the limit plate 7 is bent toward the discharge direction; the end of the waste chute 1 away from the discharge direction is equipped with a vertical rib 9.

[0020] When working, the piston rod 5 of the cylinder continuously reciprocates and vertically moves under the action of the gas. When the piston rod 5 moves upward, it can lift the waste chute 1, because the waste chute 1 is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com