Tolerance compensating mounting device

A technology of installation device and tolerance compensation, which is applied in the direction of connecting components, threaded fasteners, thin plate connections, etc., and can solve problems such as unsightly dividing lines and small glove boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Selected embodiments of the invention will now be described with reference to the drawings. Those skilled in the art to which the present invention belongs can find out from the content disclosed in the present invention that the following descriptions of the embodiments of the present invention are only for illustration, rather than for the purpose of limiting the present invention, and the present invention is defined by the appended claims book and its equivalents.

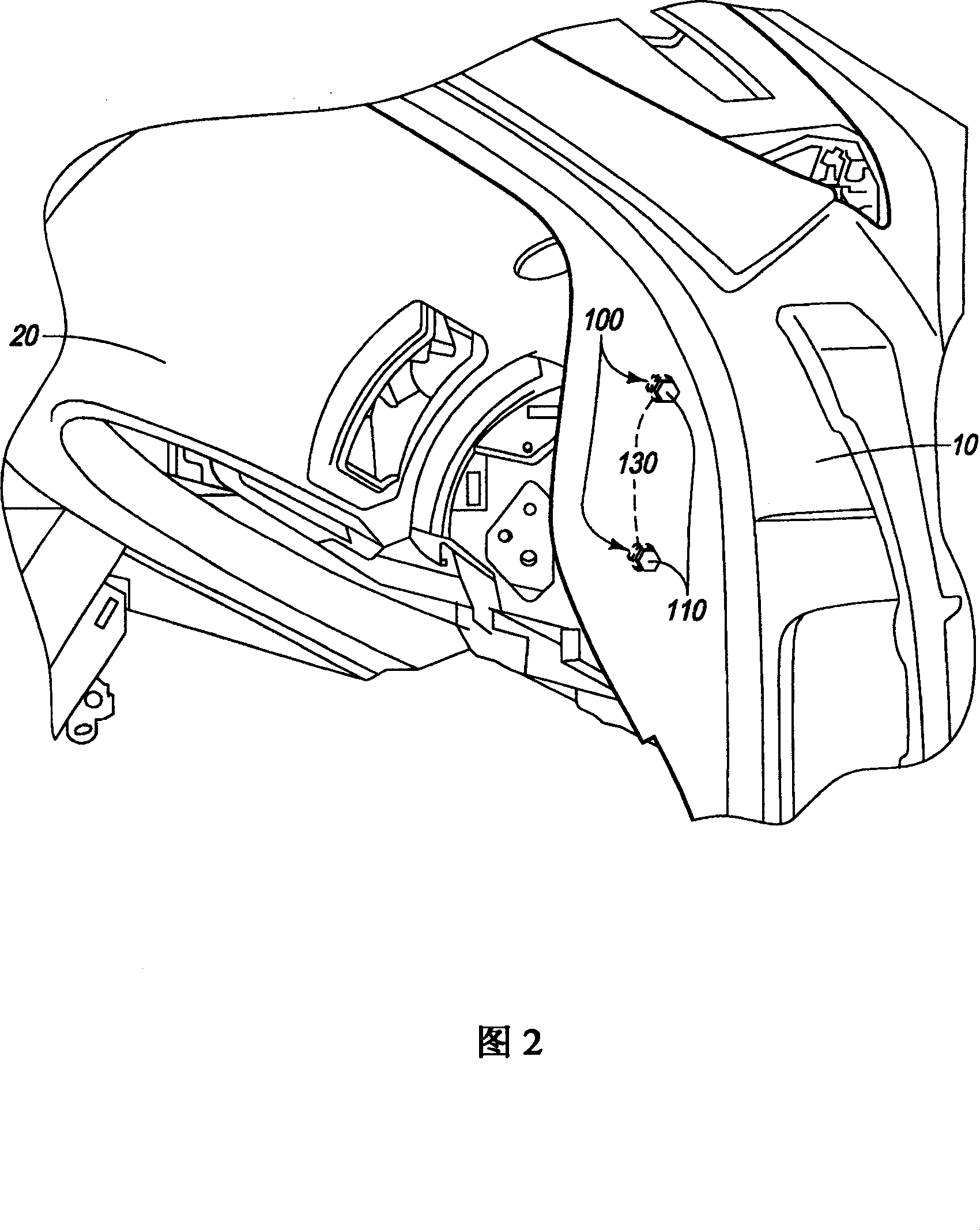

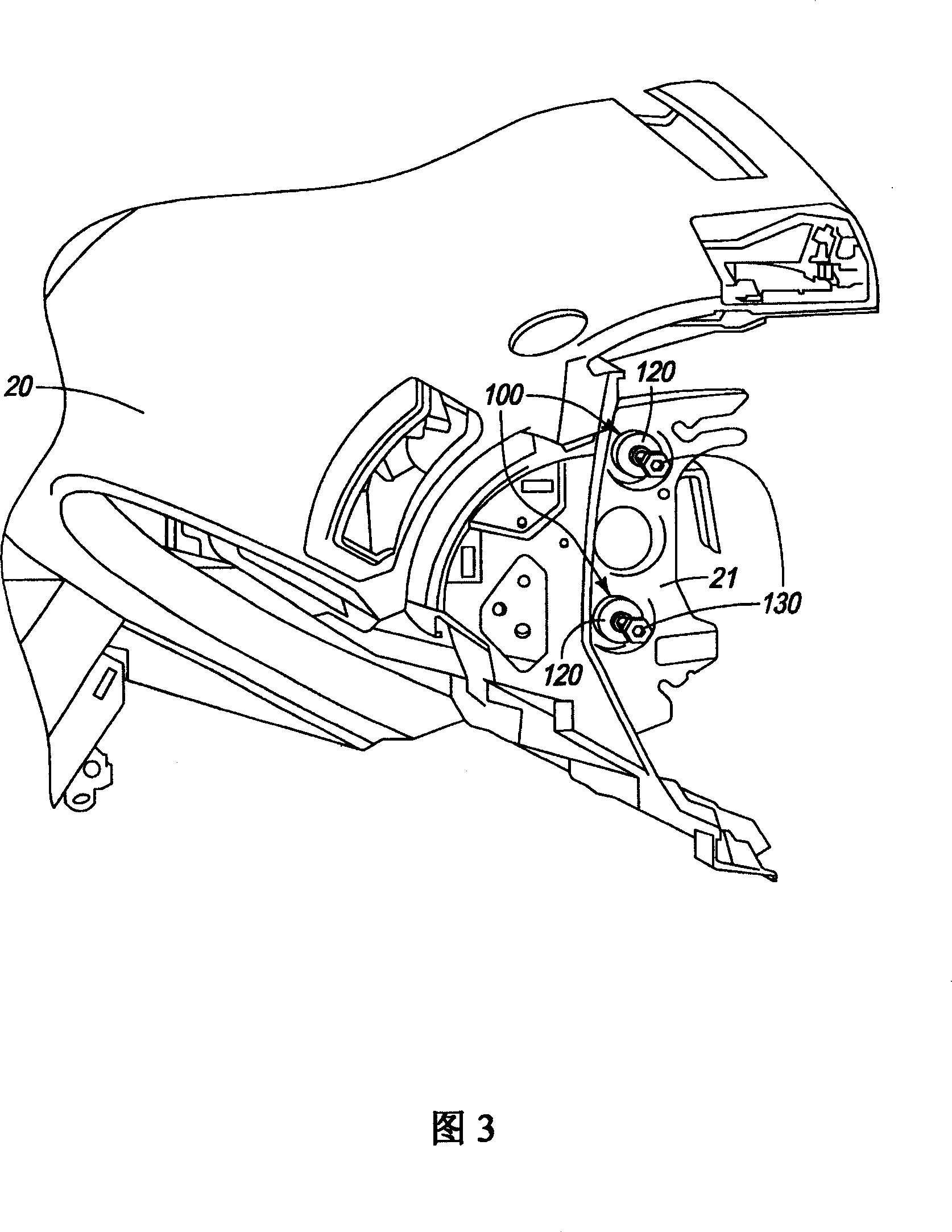

[0024] FIG. 1 is a side view of a vehicle V including a vehicle body 10 . FIG. 2 is a rear perspective view of the front portion of the passenger compartment of the vehicle V on the passenger seat side, showing the vehicle body 10 connected to the instrument panel 20 . FIG. 3 is a rear perspective view of the instrument panel 20 showing the mounted state of the vehicle body 10 before being mounted on the instrument panel. As shown in FIG. 2, in the cockpit assembly of the vehicle V, the instrument pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com