Patents

Literature

81results about How to "Realize automatic ejection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

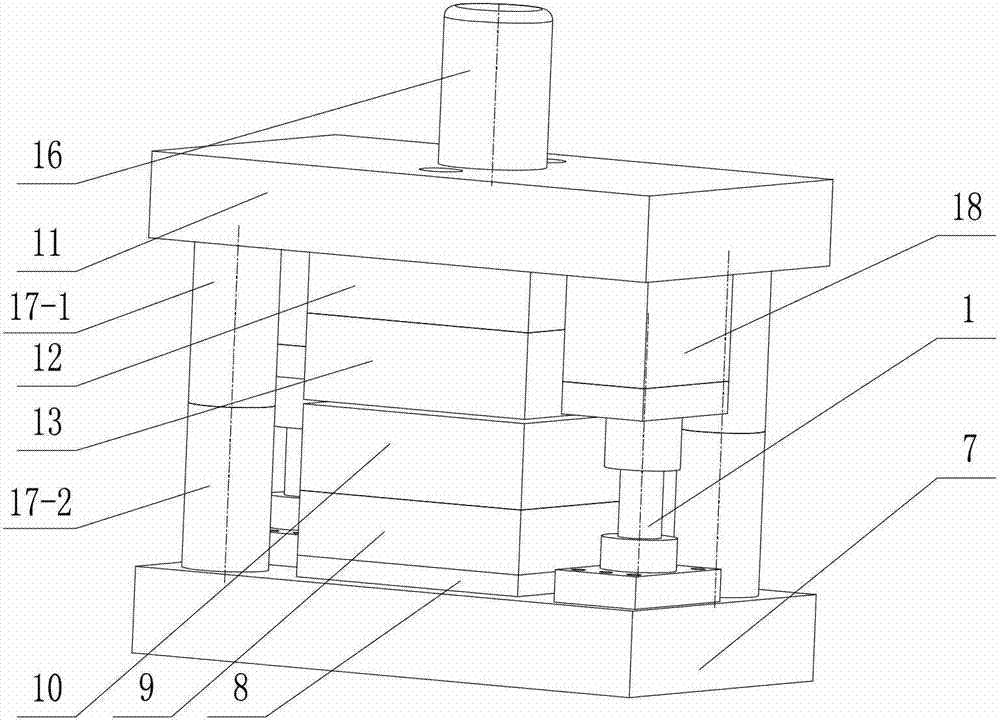

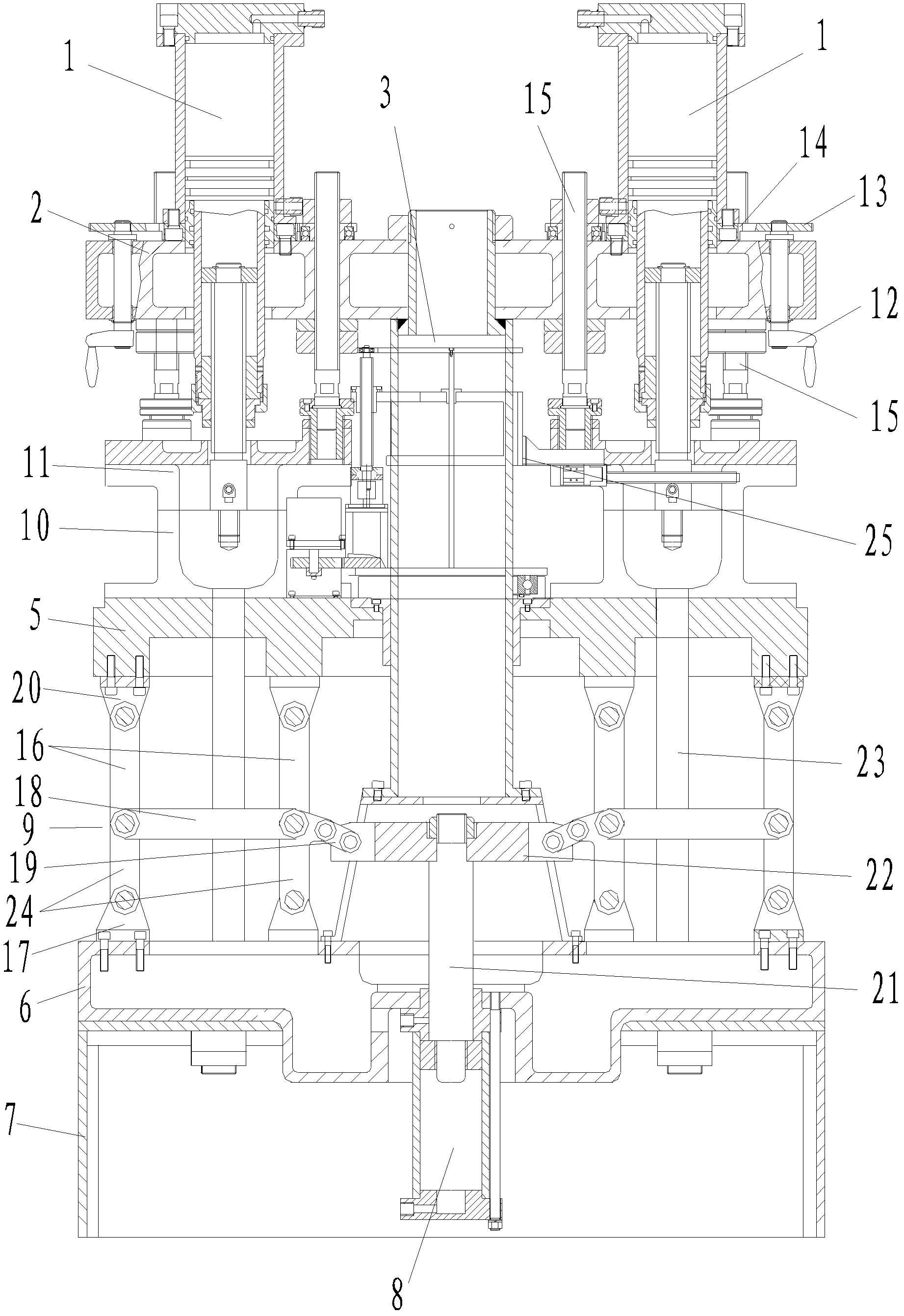

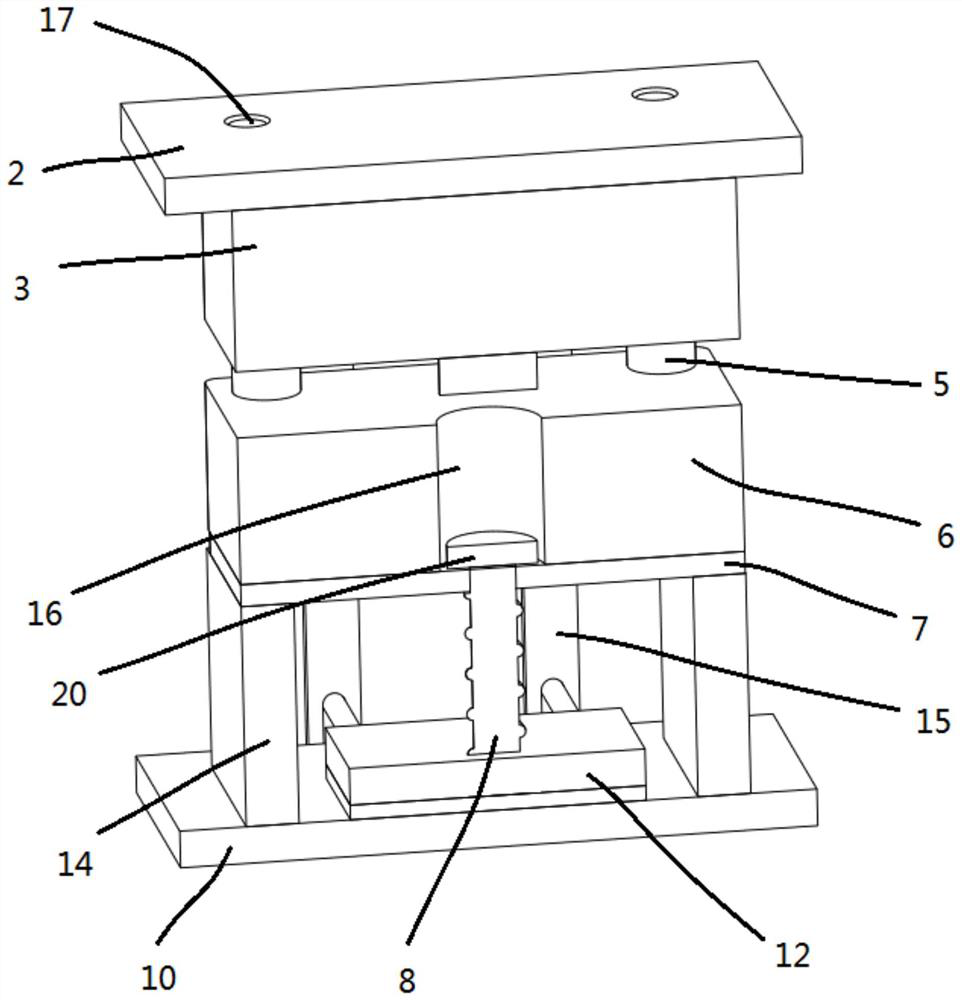

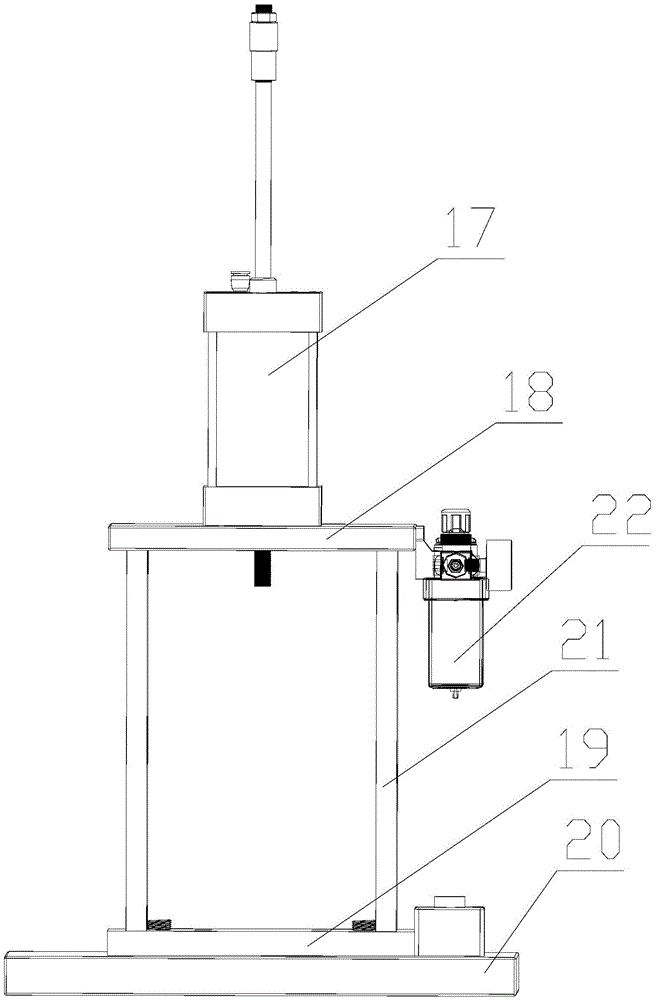

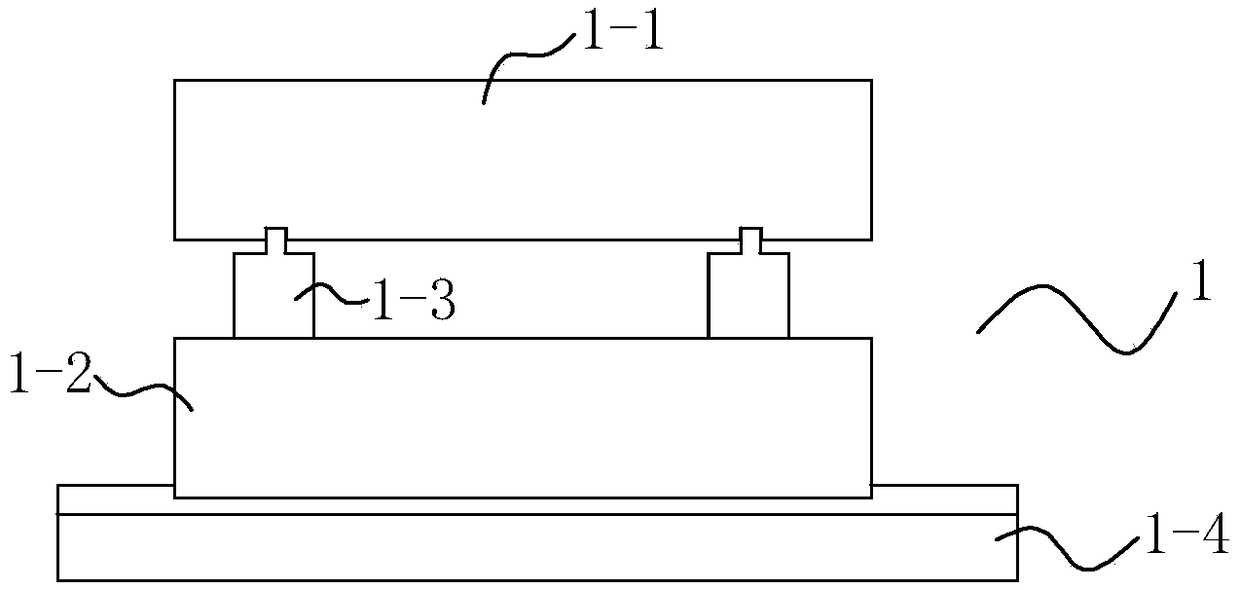

Device and method for preparing aluminum-base composite material by using vacuum impregnation andsolid-liquid direct extrusion

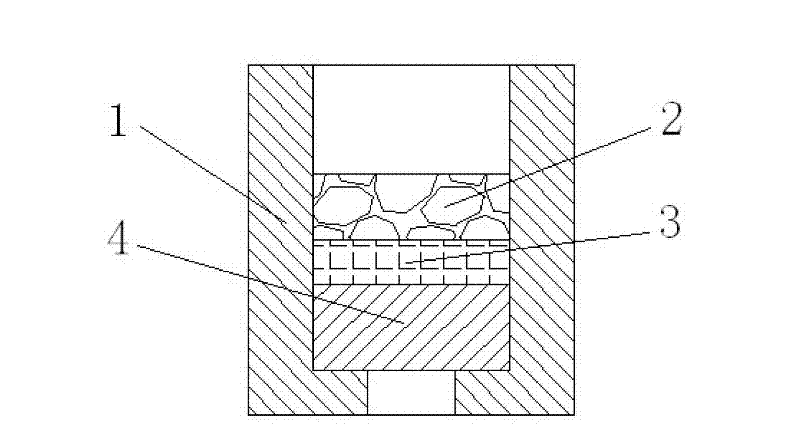

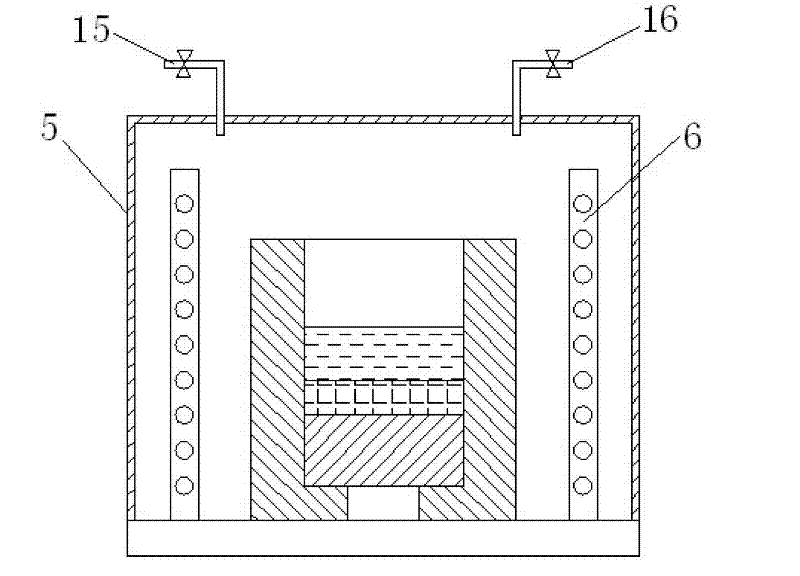

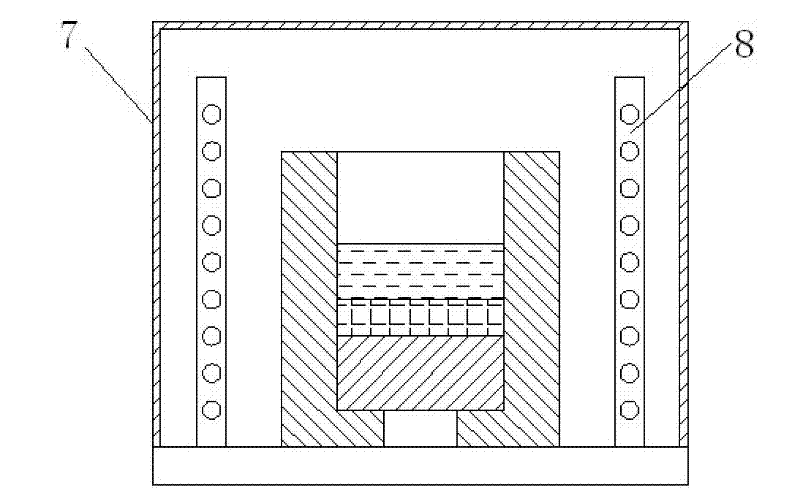

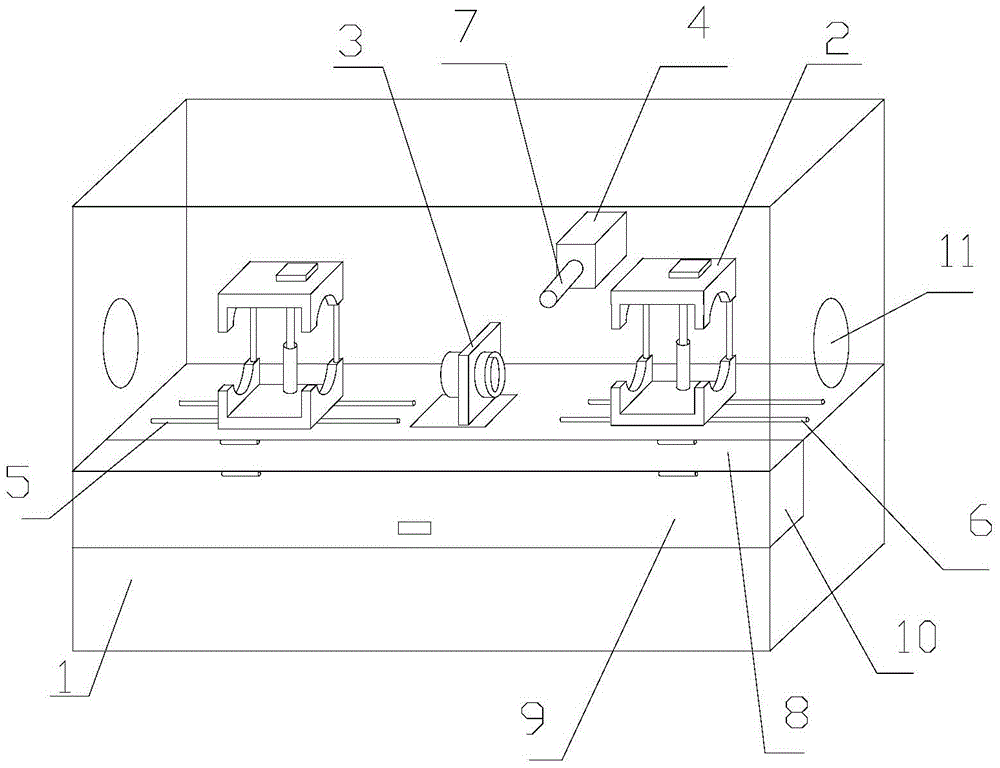

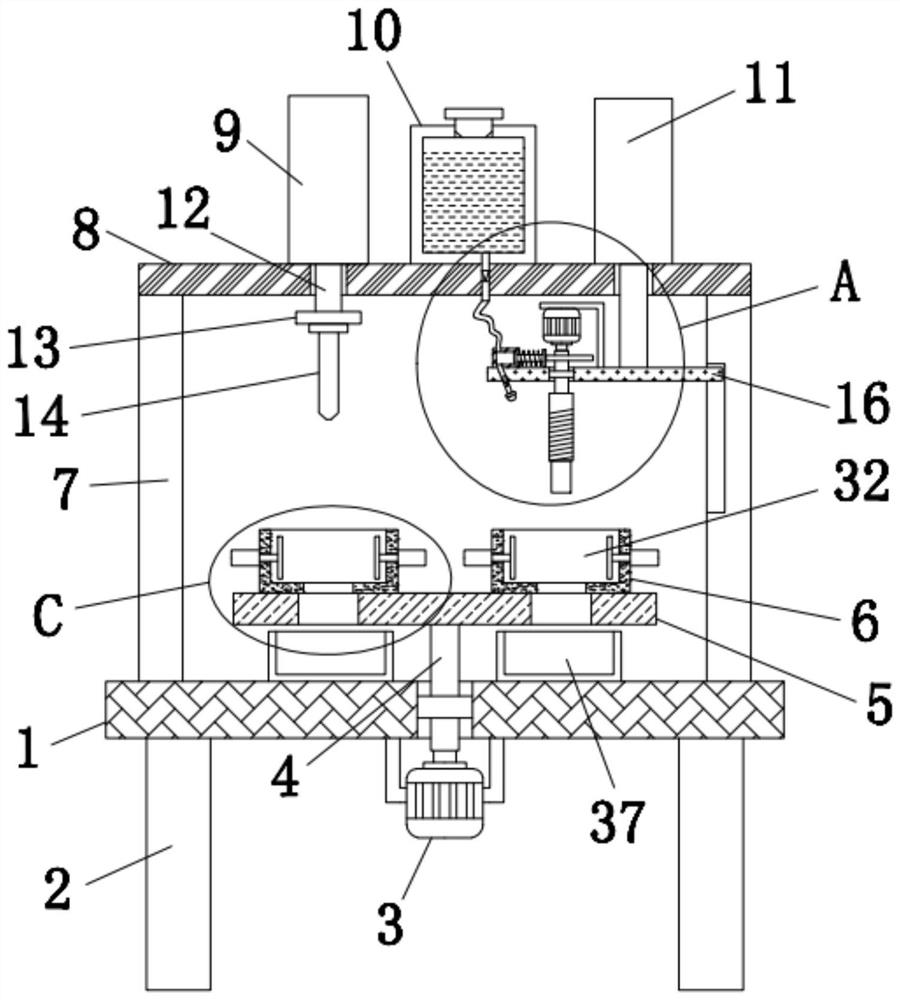

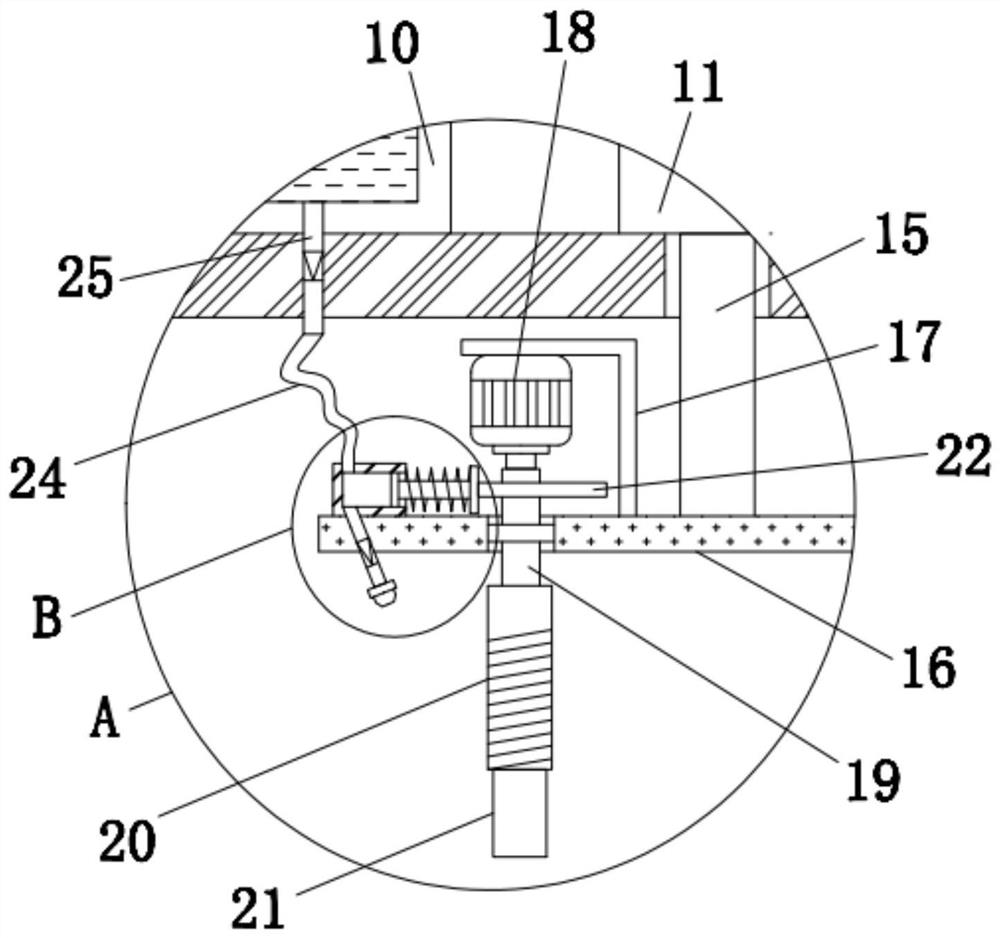

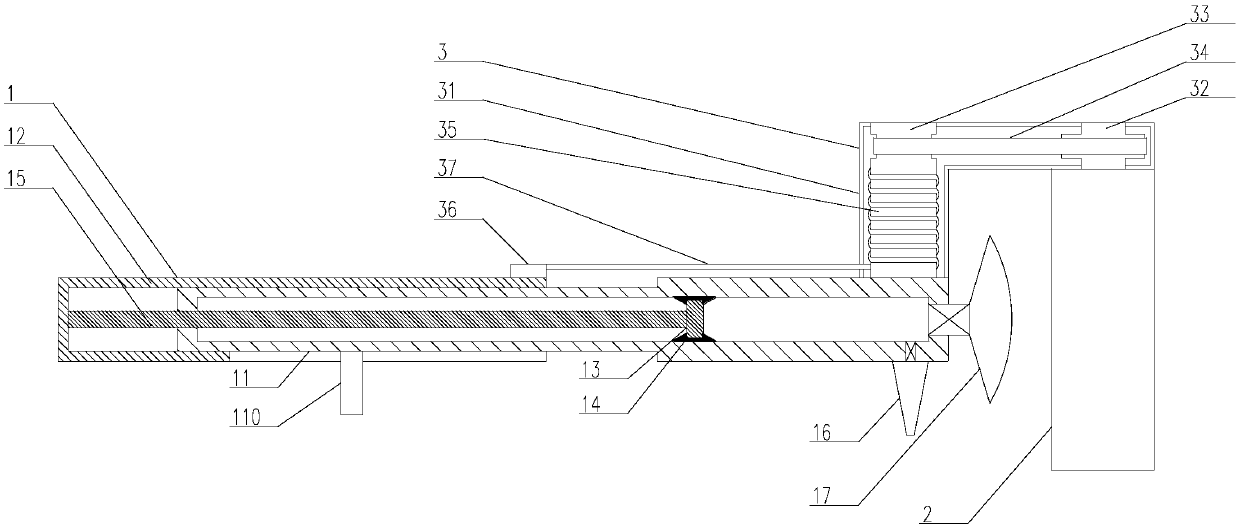

The invention relates to a device and a method for preparing an aluminum-base composite material by using vacuum impregnation and solid-liquid direction extrusion. A smelting furnace is installed on the upper surface of a bottom pallet, the bottom pallet and a mould outer cover are placed on the upper surface of a mould support. A top block is arranged at the bottom of an inner cavity of the smelting furnace. The upper end surface of a top rod is matched with the top block, and the lower end surface of the top rod comes into contact with a piston rod of an ejection cylinder of a four-column hydraulic press. The device accomplishes the four processes of aluminum alloy vacuum smelting, impregnation, extrusion and formation required for preparing the high-performance aluminum-base composite material by using a vacuum furnace, a resistor furnace, the four-column hydraulic press and an extruding and impregnating mould, reduces the defects of shrinkage cavities, shrinkage porosity and cavities of the composite material, increases the density and improves the performance of the aluminum-base composite material, and aluminum-base composite material pieces with different shapes and sizes formed according to the matched degrees of concave dies and convex dies. The device realizes automatic ejection of the aluminum-base composite material through an ejection structure and reduces the formation and processing procedures of parts.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

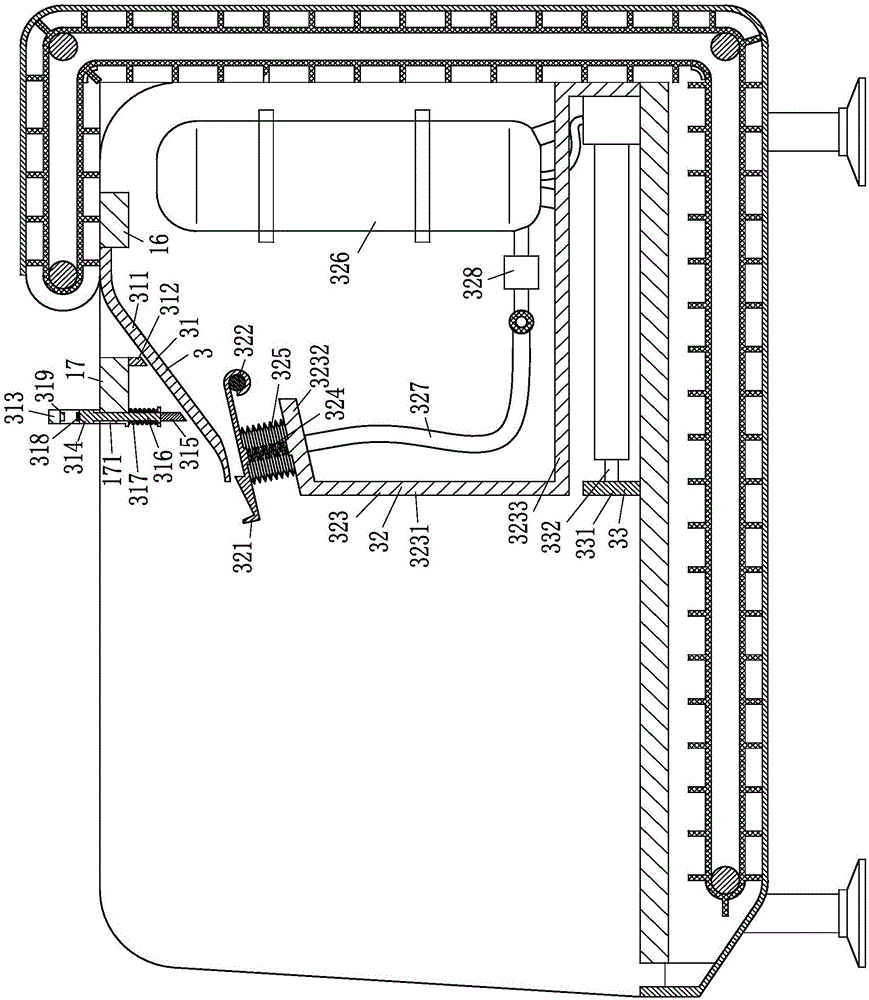

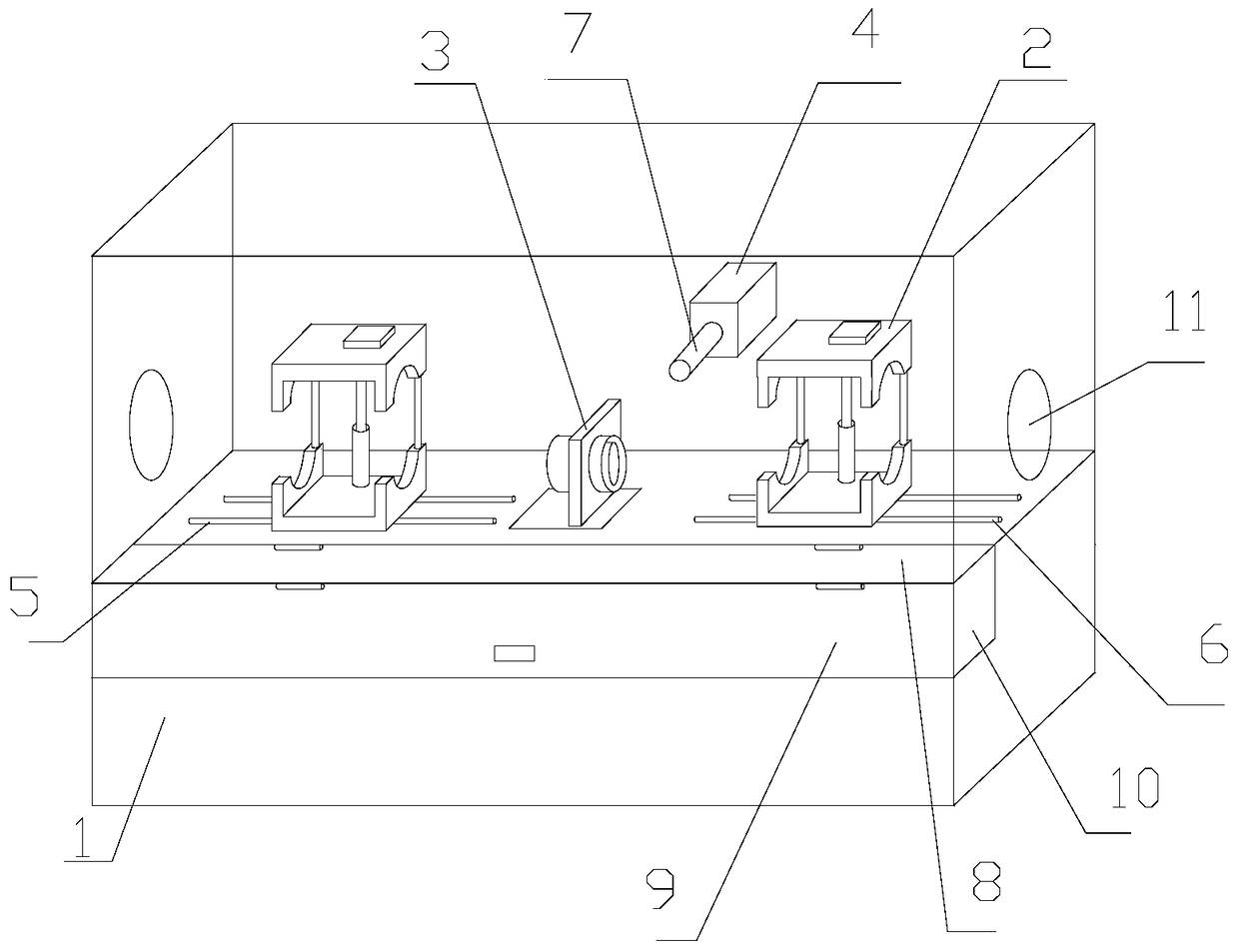

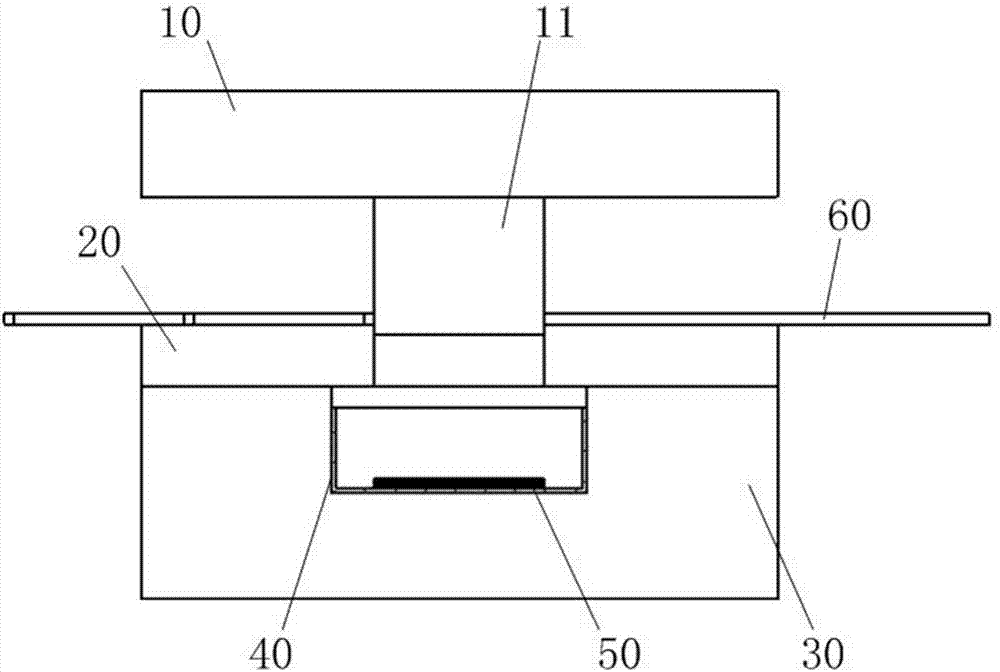

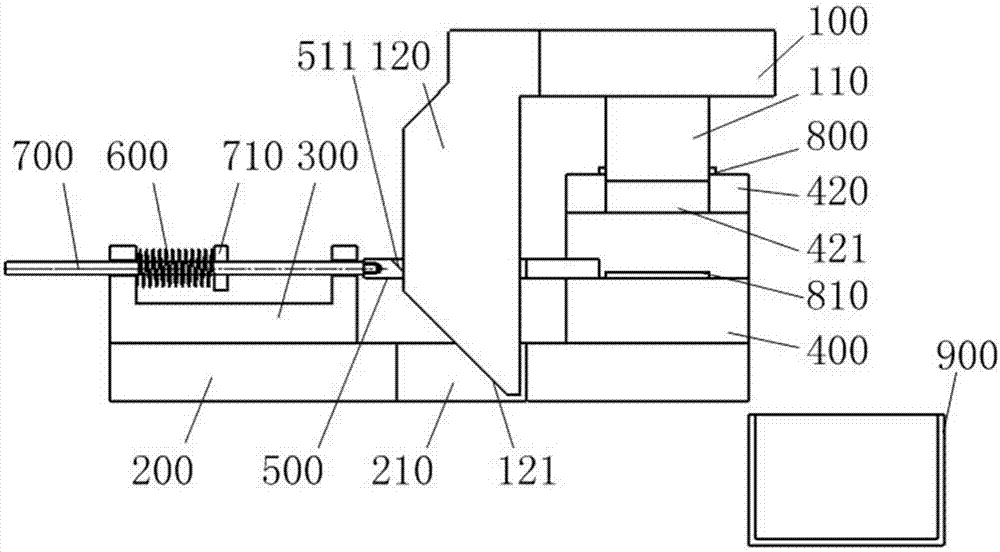

Pipe welding machine

ActiveCN105618946ANo sound qualityAvoid burnsWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringPipe welding

The invention discloses a pipe welding machine. The pipe welding machine comprises a base (1), a welding mechanism, an air cylinder (4), an ejector rod (7) and an outer shell. The outer shell is arranged on the upper surface of the base (1) and forms a working cavity. The welding mechanism is arranged on the upper surface of the base (1). The air cylinder (4) is fixedly connected to the outer shell and arranged on one side of the welding mechanism. A piston rod of the air cylinder (4) moves in the length direction and is connected to one end of the ejector rod (7) and coaxial with the ejector rod (7). The other end of the ejector rod (7) faces a pipe. A groove cavity (10) used for containing the pipe is formed in the other side, opposite to the air cylinder (4), of the base (1). The pipe welding machine overcomes the defect that pipes cannot be taken out after being welded through welding machines in the prior art, and automatic ejection of the welded pipe is achieved.

Owner:绩溪徽腾机械有限公司

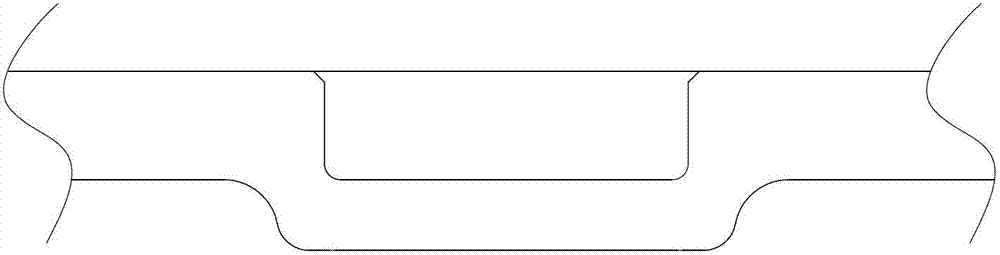

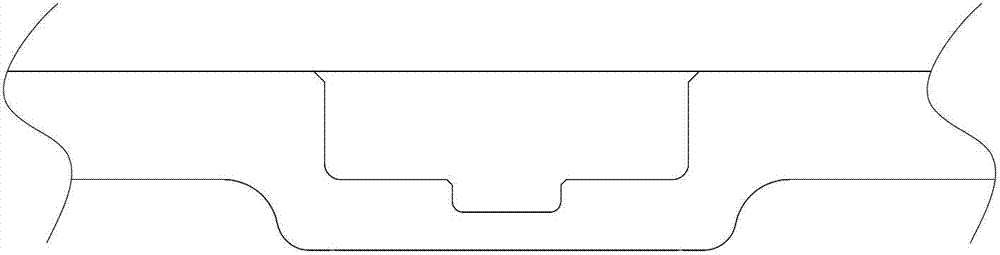

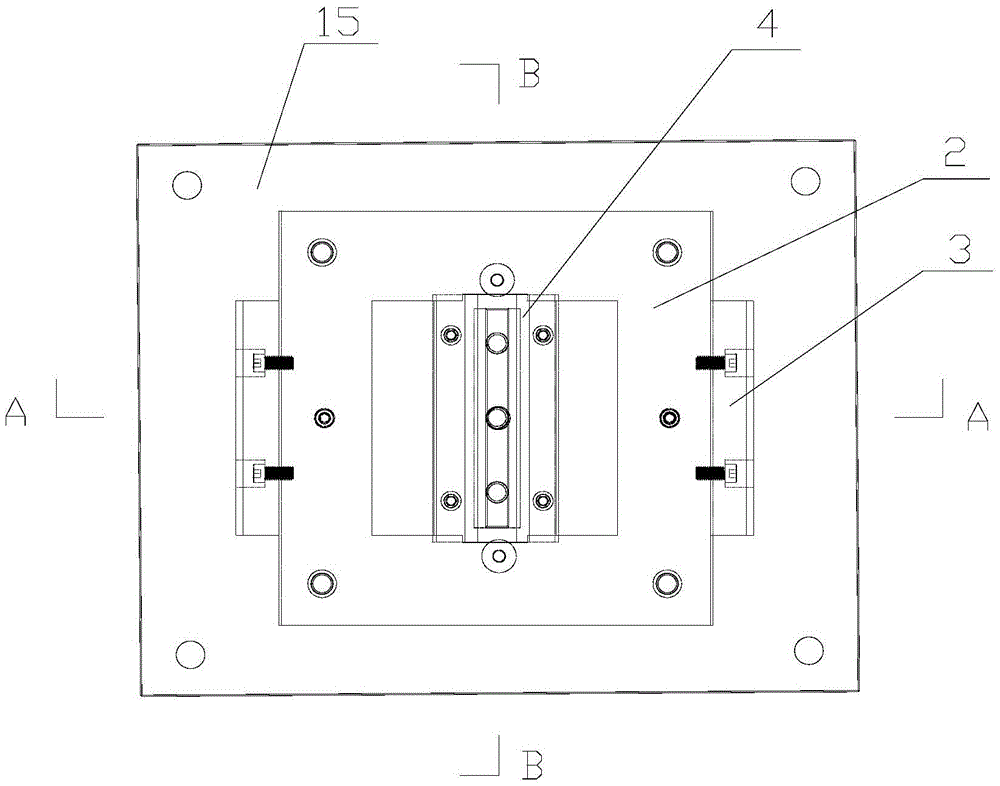

Two-way blank pressing drawing and coining integration die

ActiveCN103084488AGood formabilityHigh precisionShaping toolsEjection devicesEngineeringMechanical engineering

Owner:WUXI ZHENHUA AUTO AUXILIARY PARTS

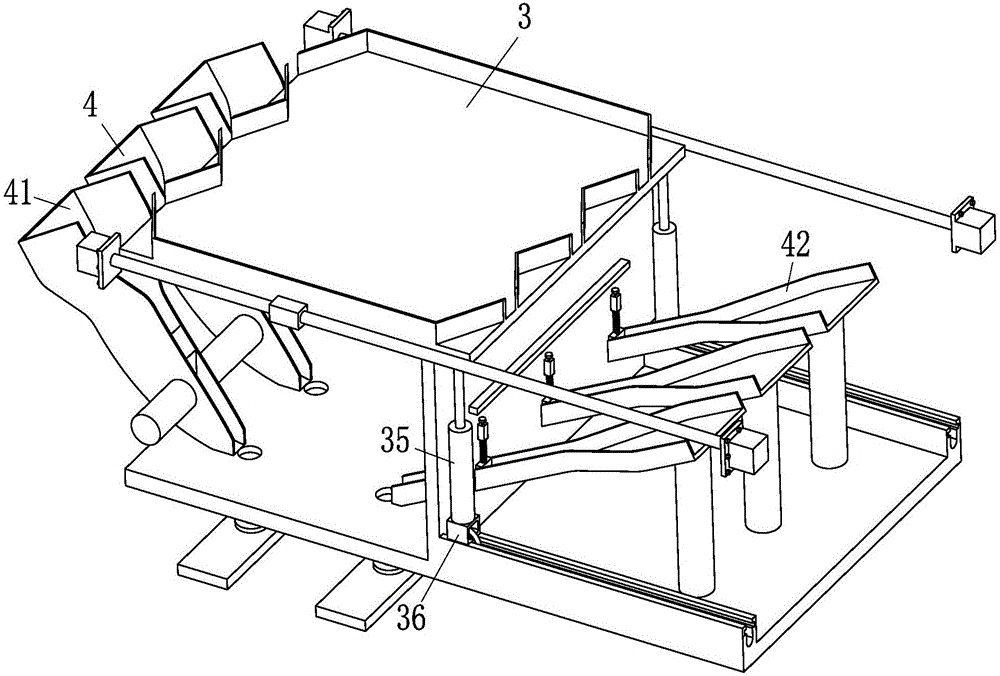

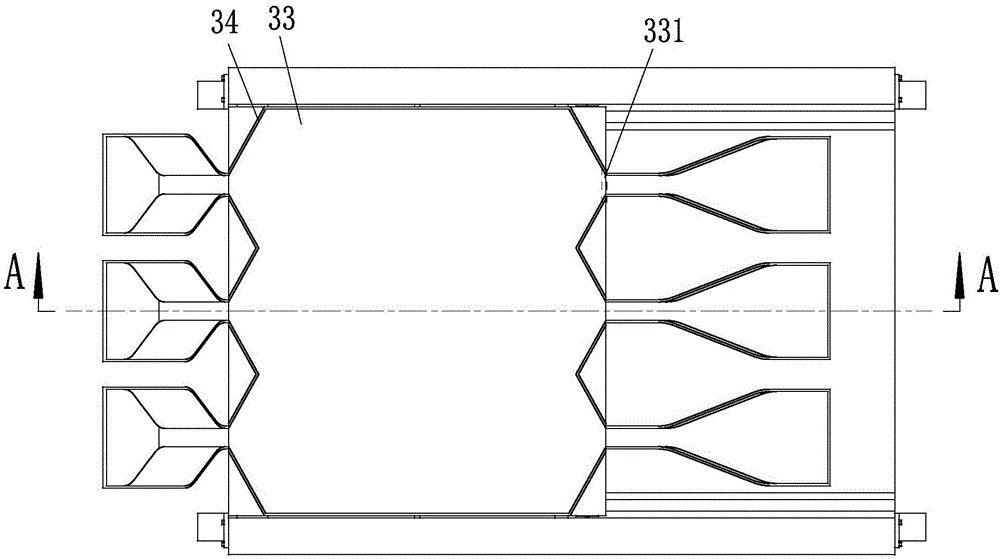

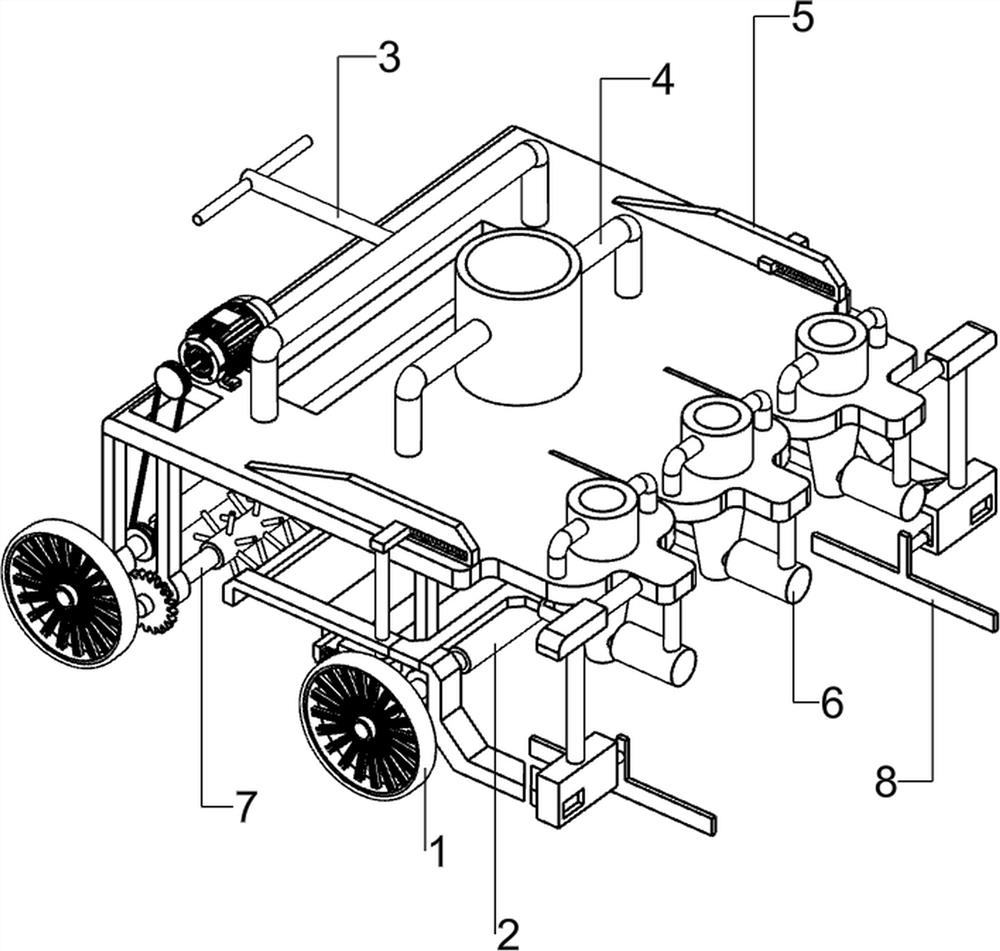

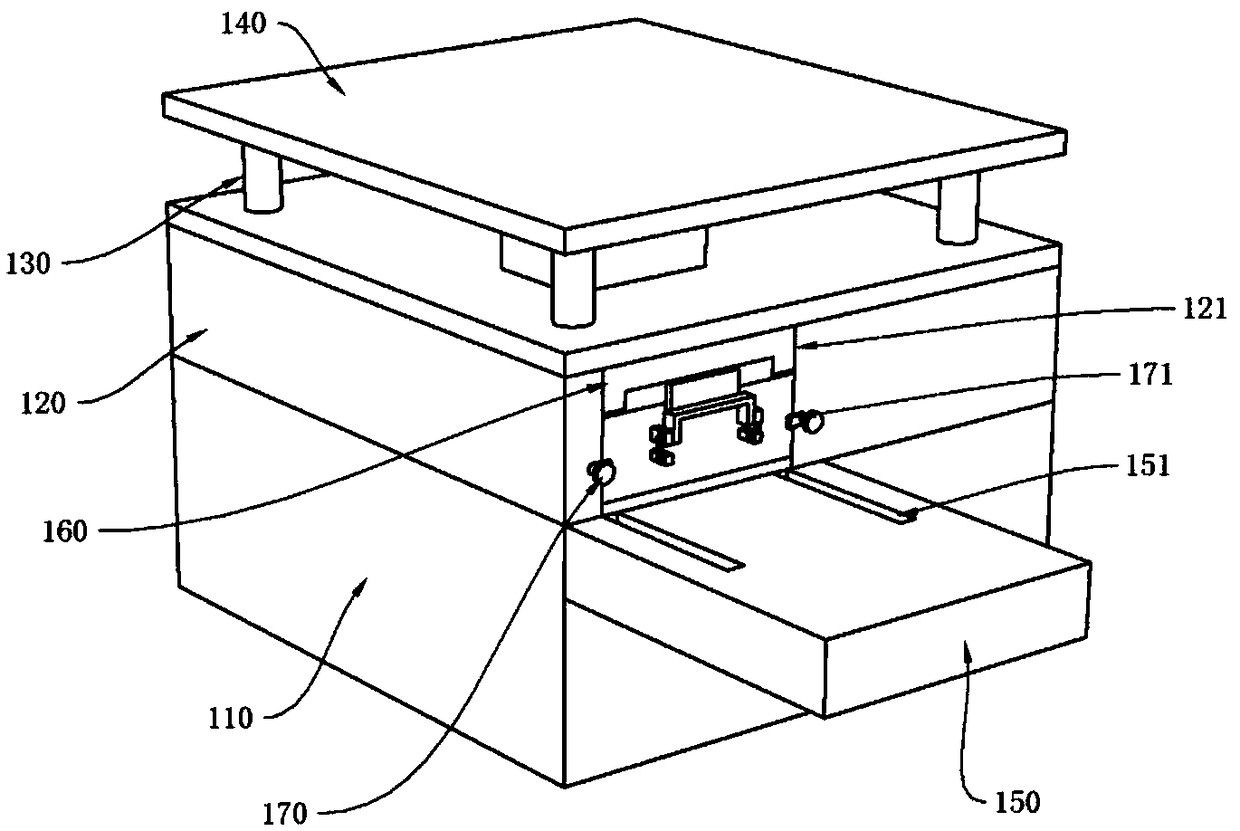

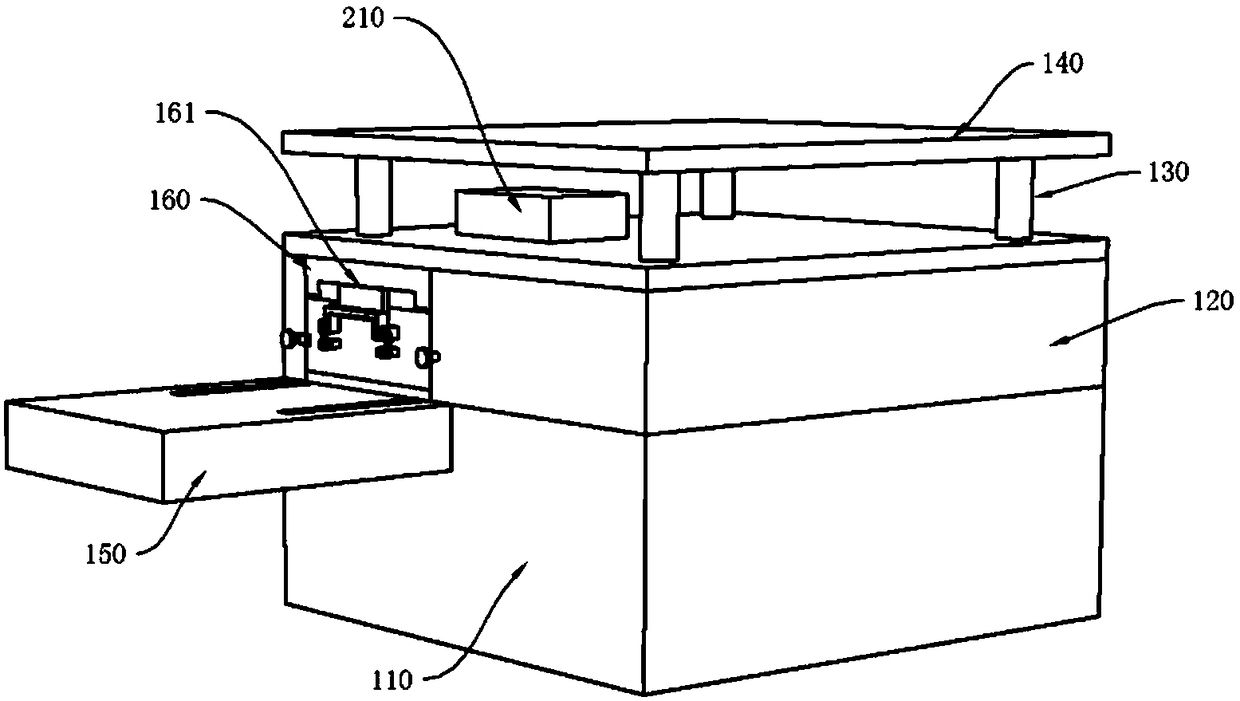

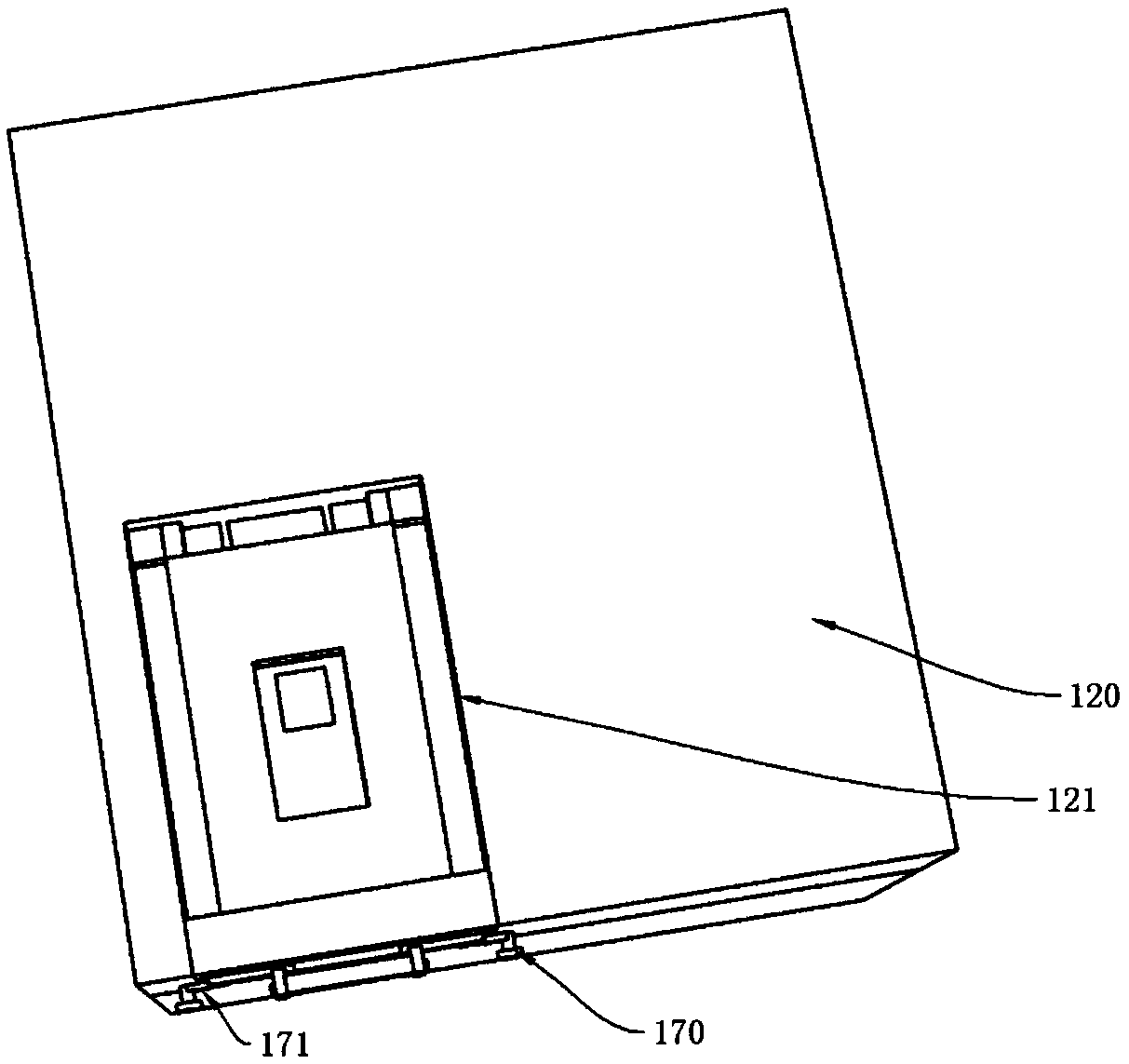

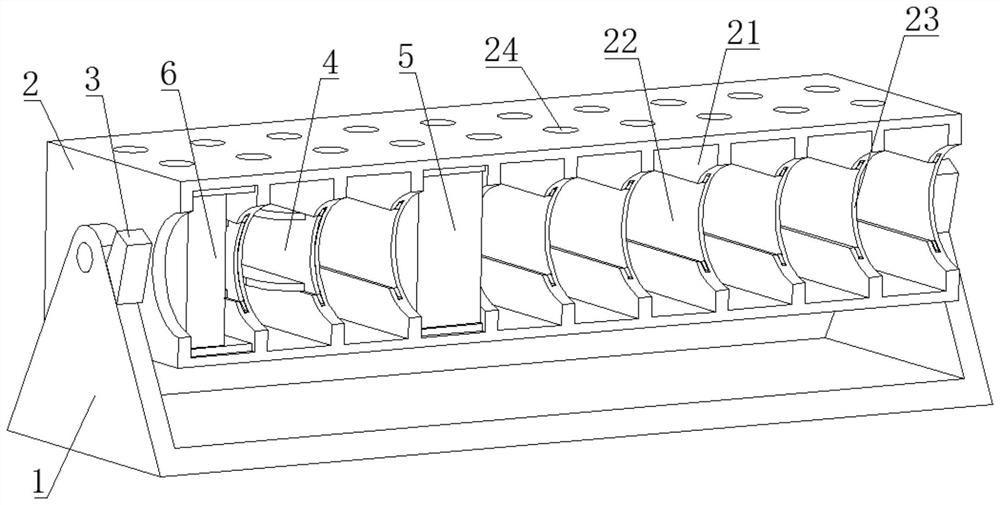

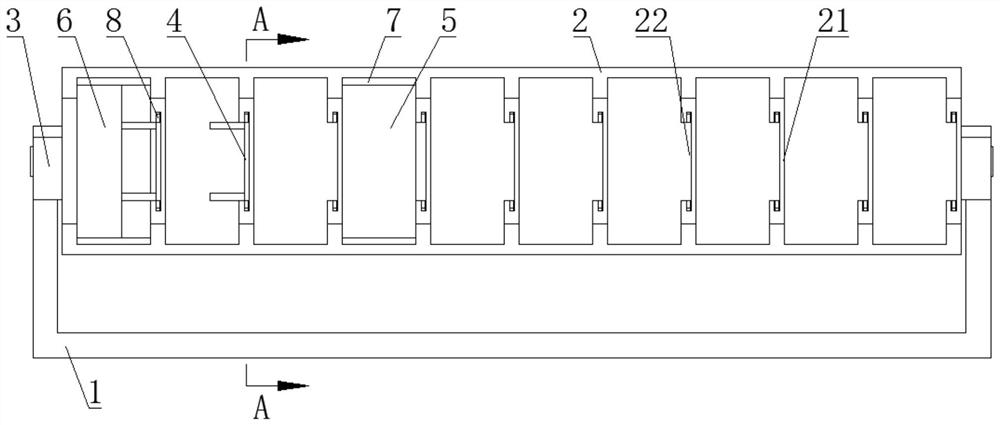

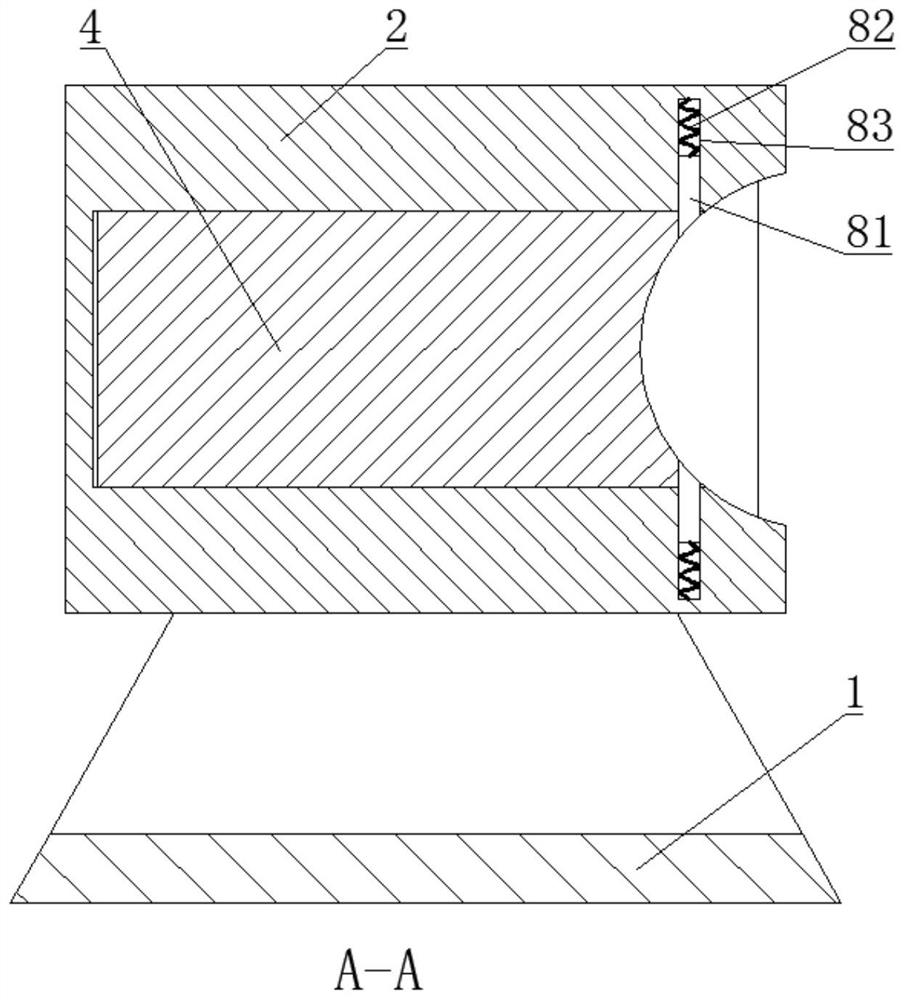

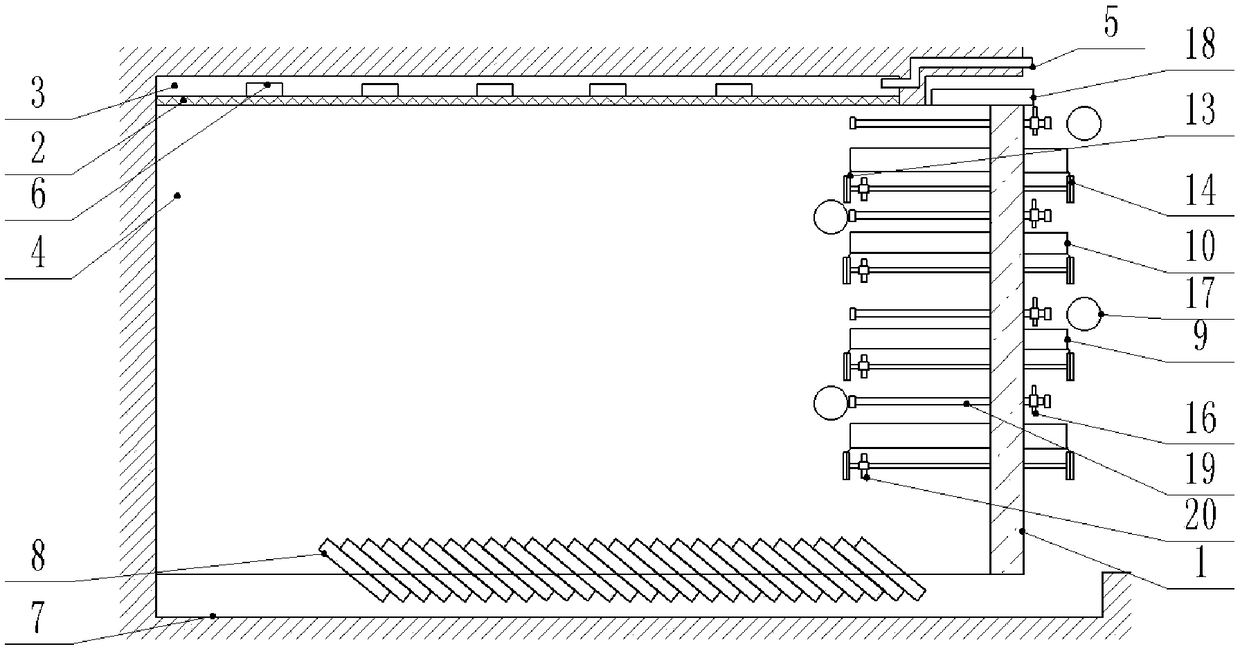

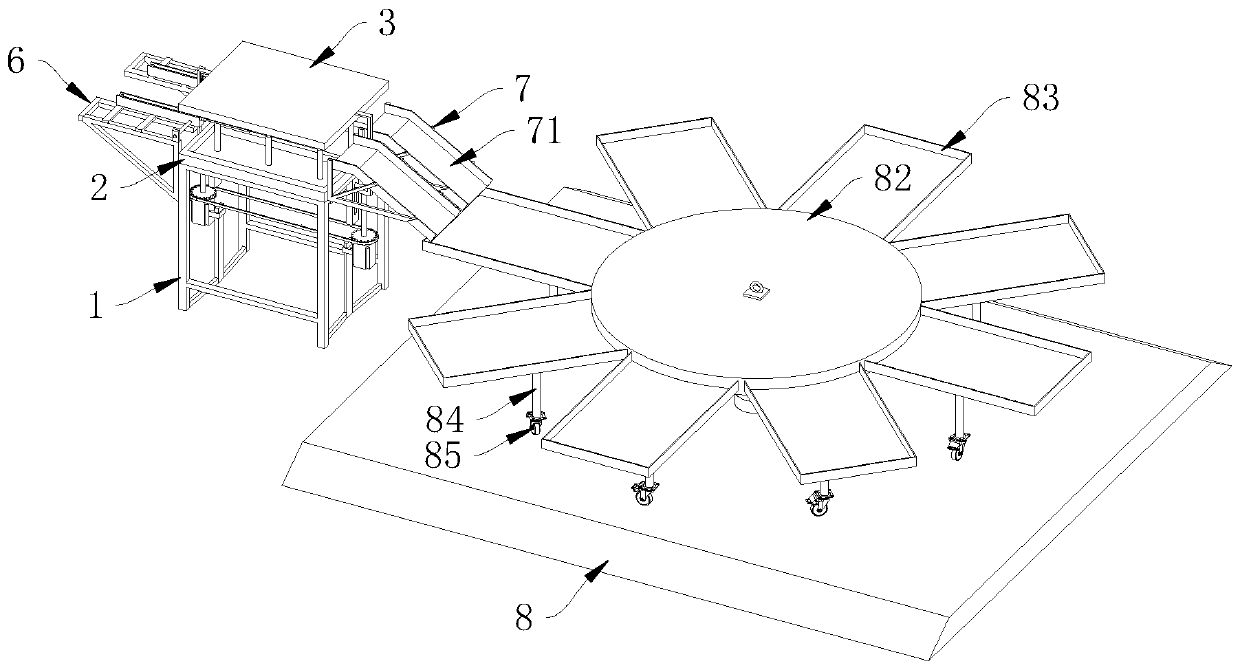

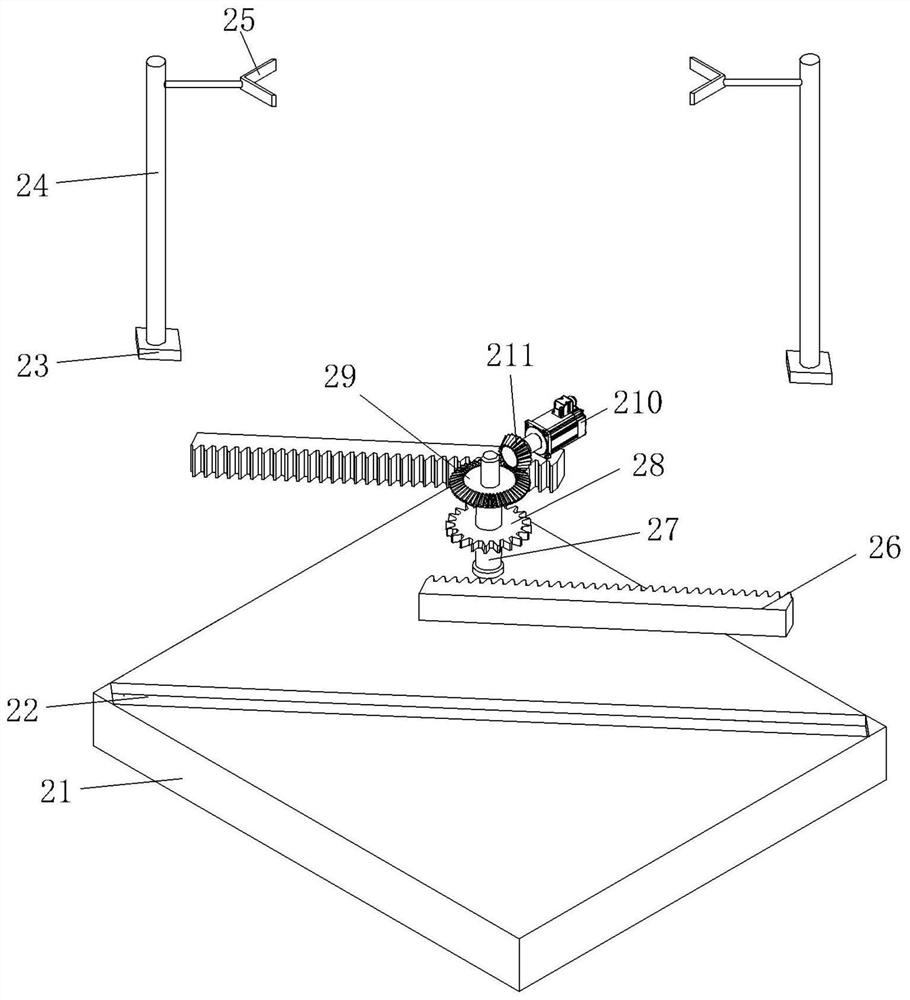

Mathematical probability operation device for coin-toss experiment and control system of the mathematical probability operation device

ActiveCN106409071AImprove experimental efficiencyIncrease interest and understandingEducational modelsTeaching toolMathematical probability

The invention relates to the field of math teaching tools and specifically to a mathematical probability operation device for a coin-toss experiment and a control system of the mathematical probability operation device. The operation device comprises a machine body, a coin ejecting device, a coin receiving device and a coin returning device. The machine body comprises a stand, support plates, a bottom plate, a front baffle plate and a rear baffle plate, and a separator plate. The coin ejecting device comprises six coin ejectors. Each coin eject comprises a coin ejecting plate, a coin supporting plate, a first spring, a first ejecting column, a first iron block, and a first electromagnet. The coin receiving device comprises a rodless push plate cylinder, a sliding block, a coin receiving plate, a limiting plate, a rotating plate cylinder, a connecting base, a rotating wheel and a slide rail. The coin returning device comprises a left returning device and a right returning device. The control system comprises a programmable controller, a sensor unit, an air pressure unit and a servo controller. The operation device and the control system can satisfy the needs of frequent mathematical probability experiments and enable students to learn the process of coin-toss experiments directly.

Owner:ANHUI UNIV OF SCI & TECH

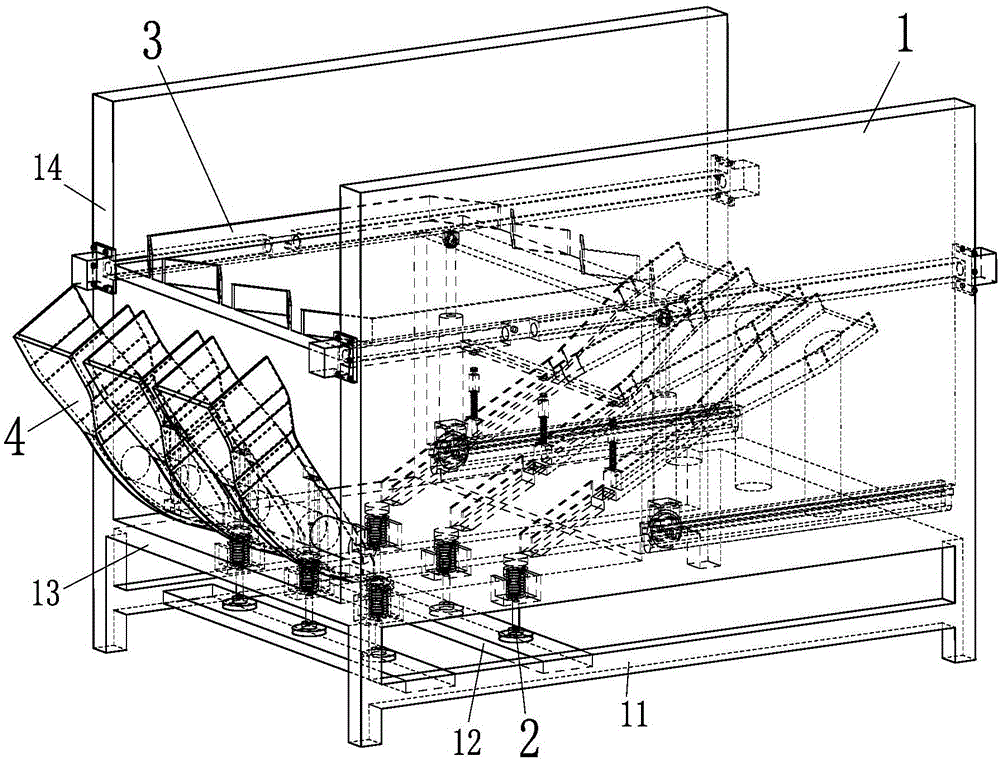

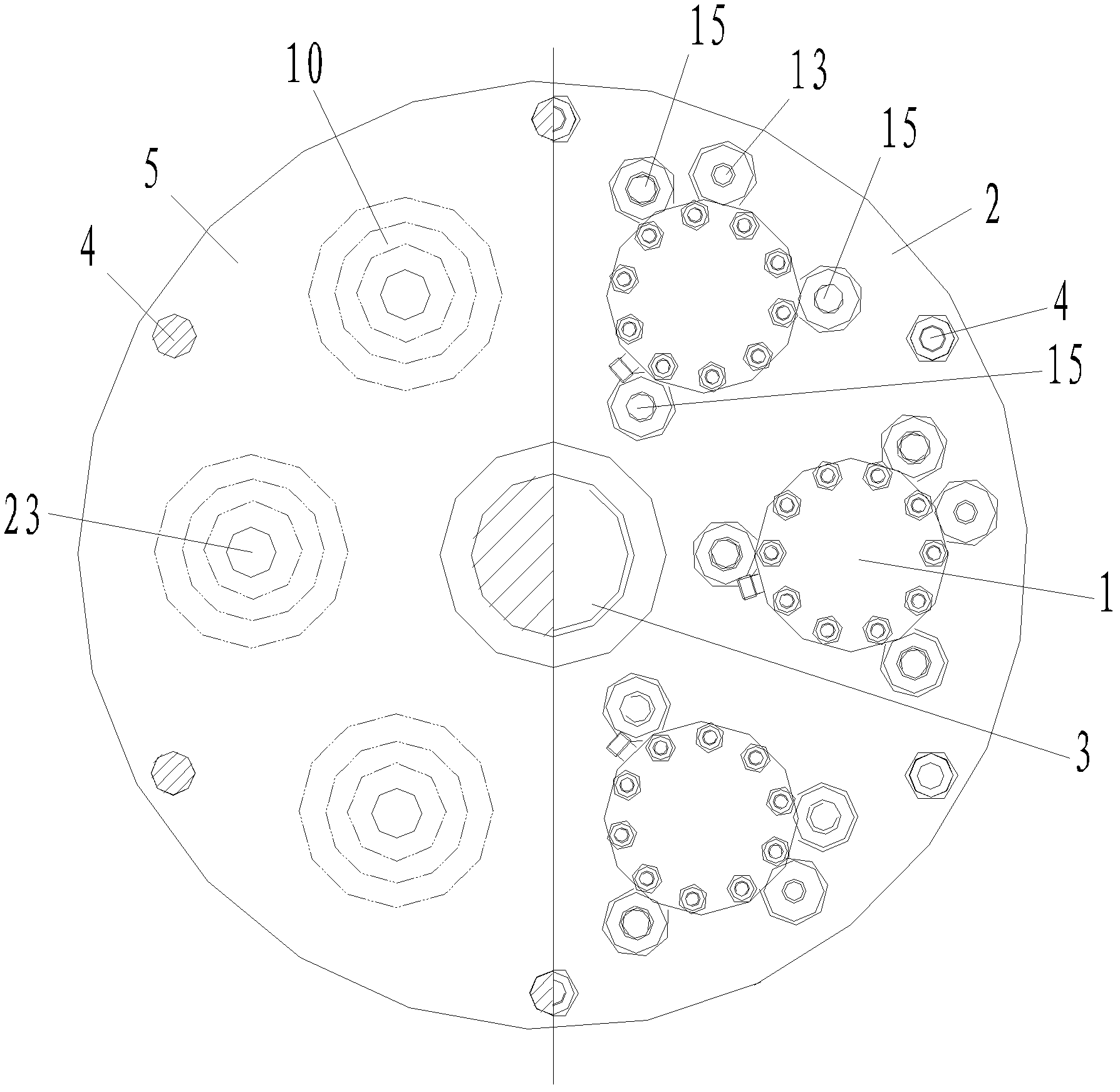

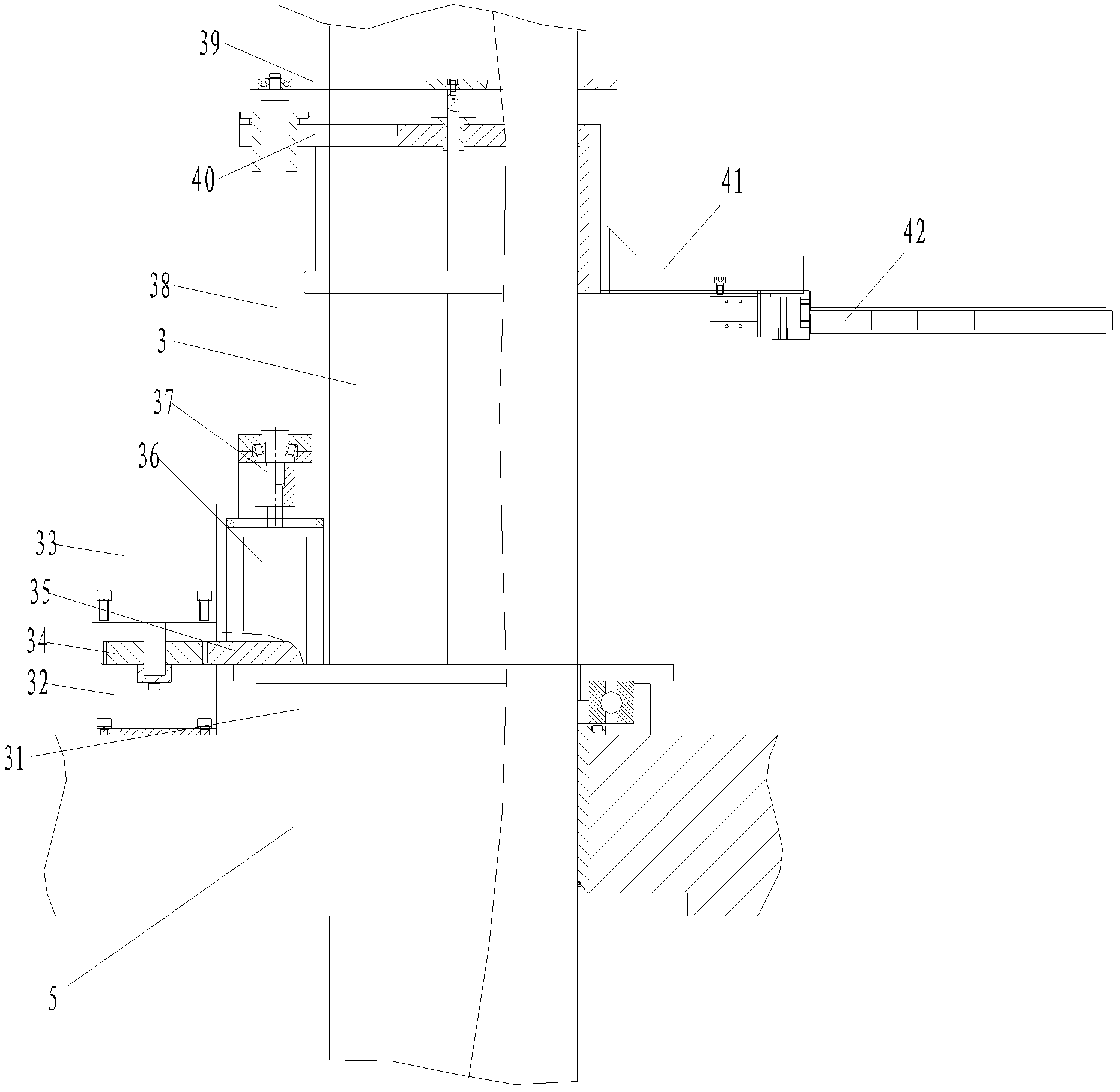

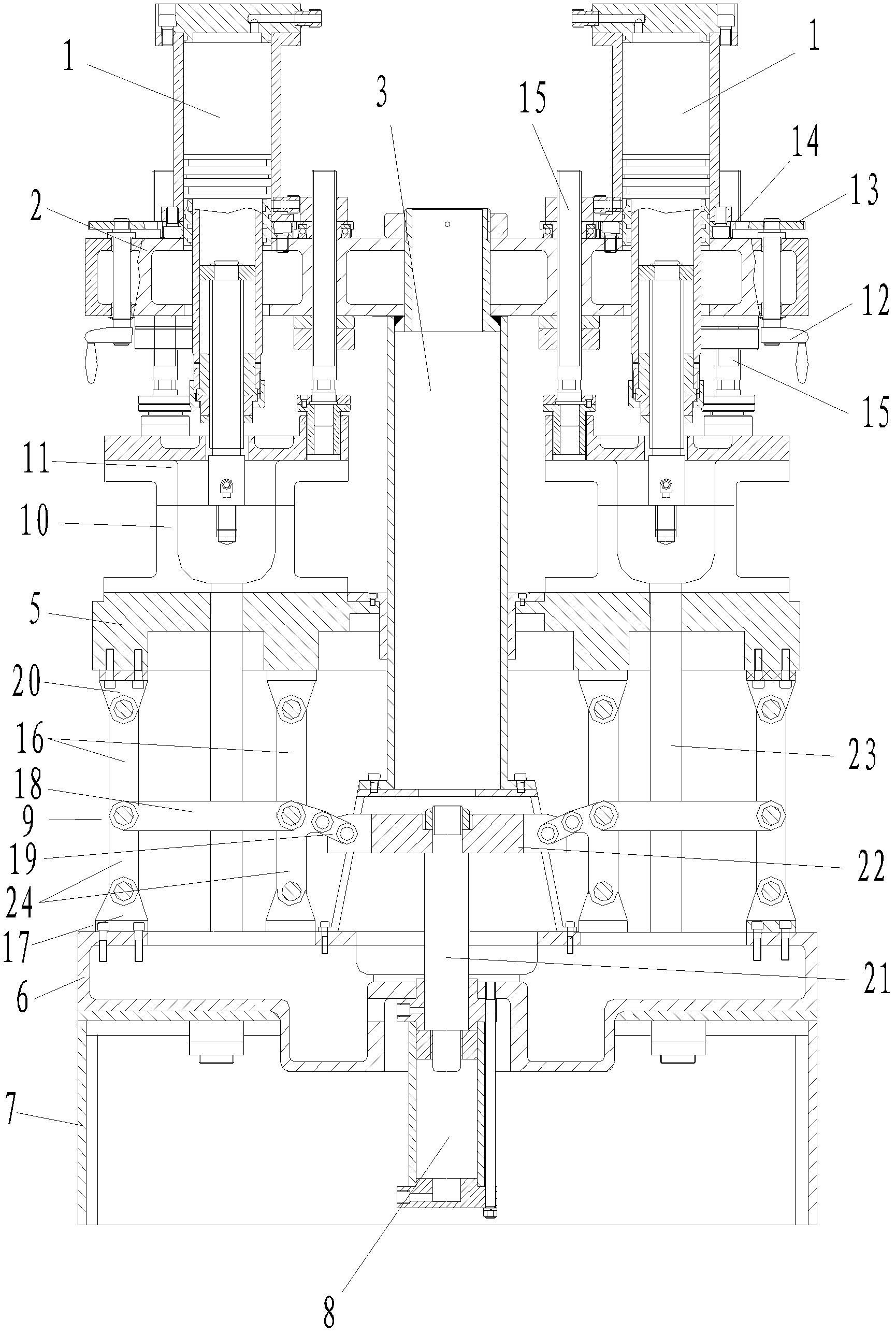

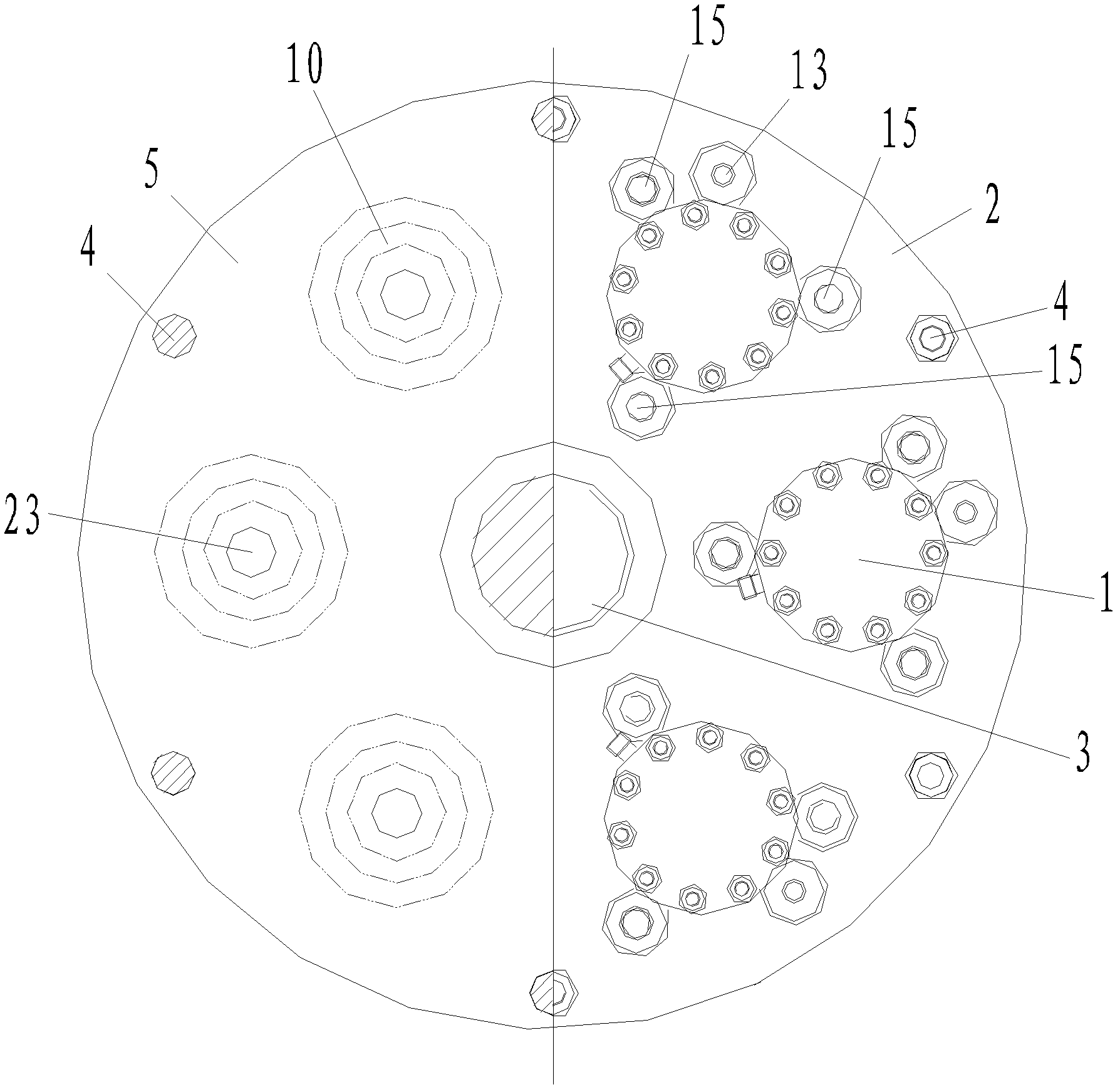

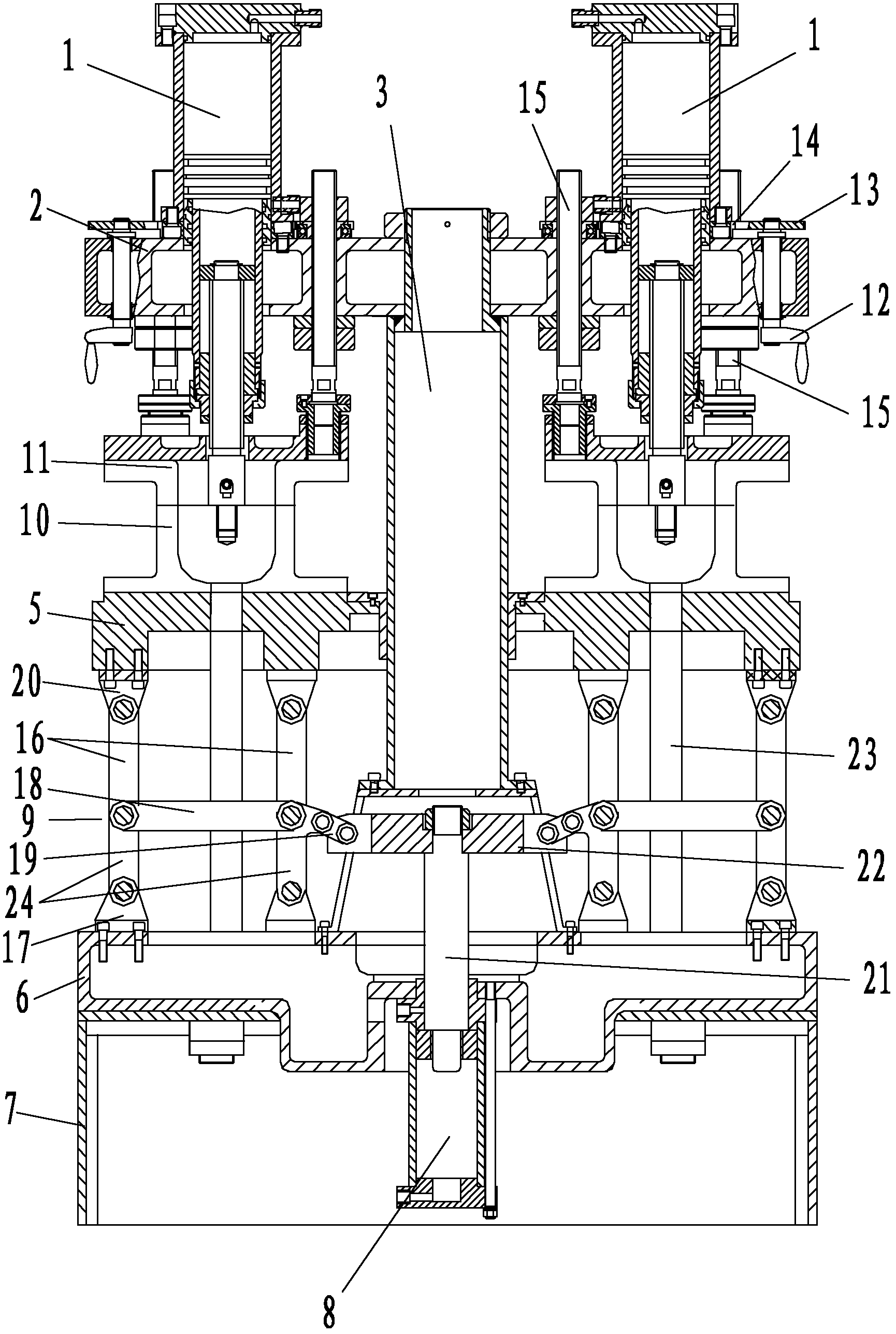

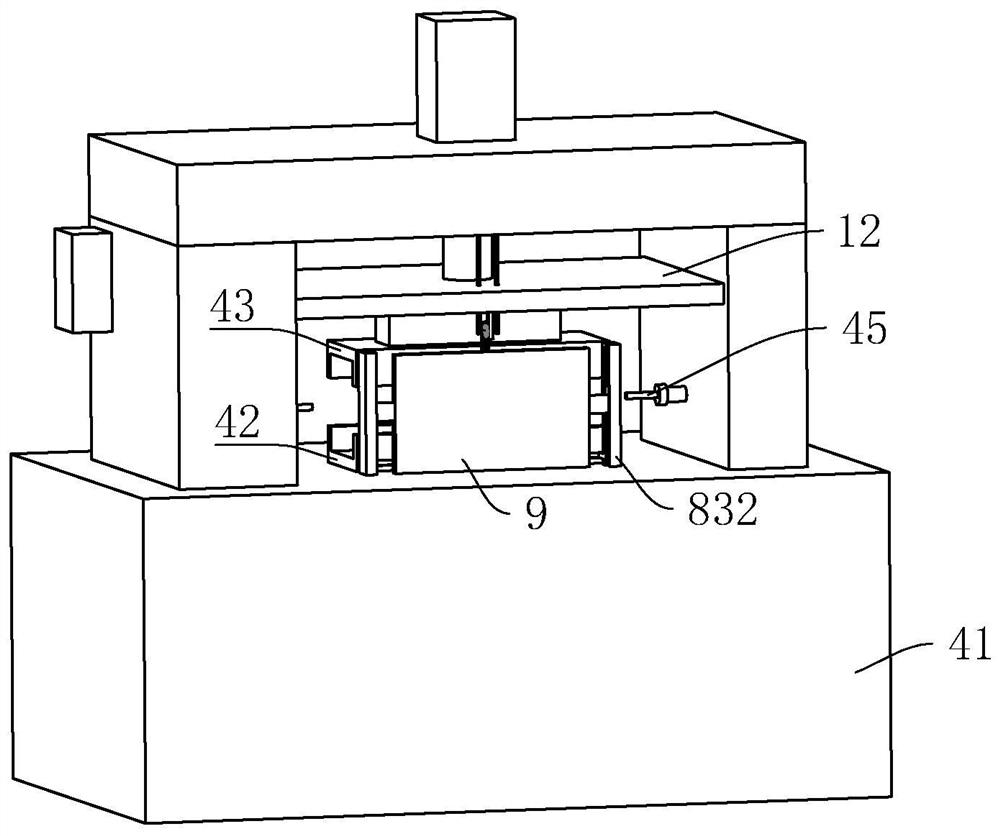

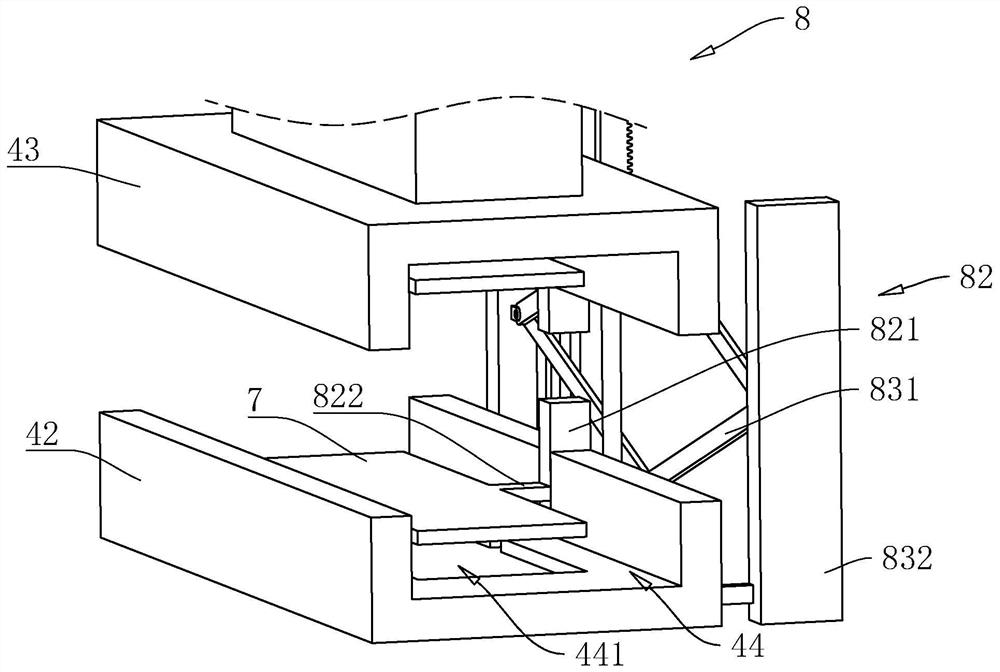

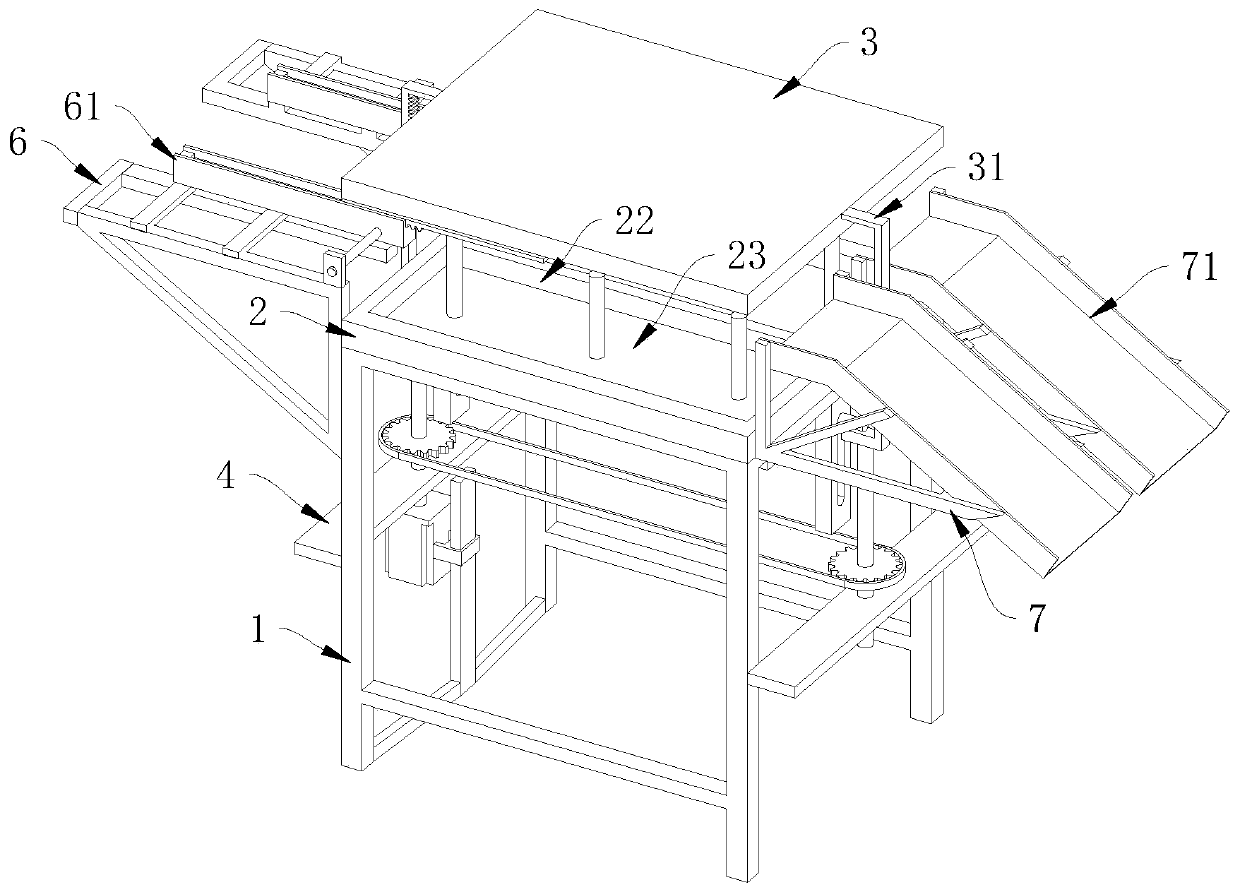

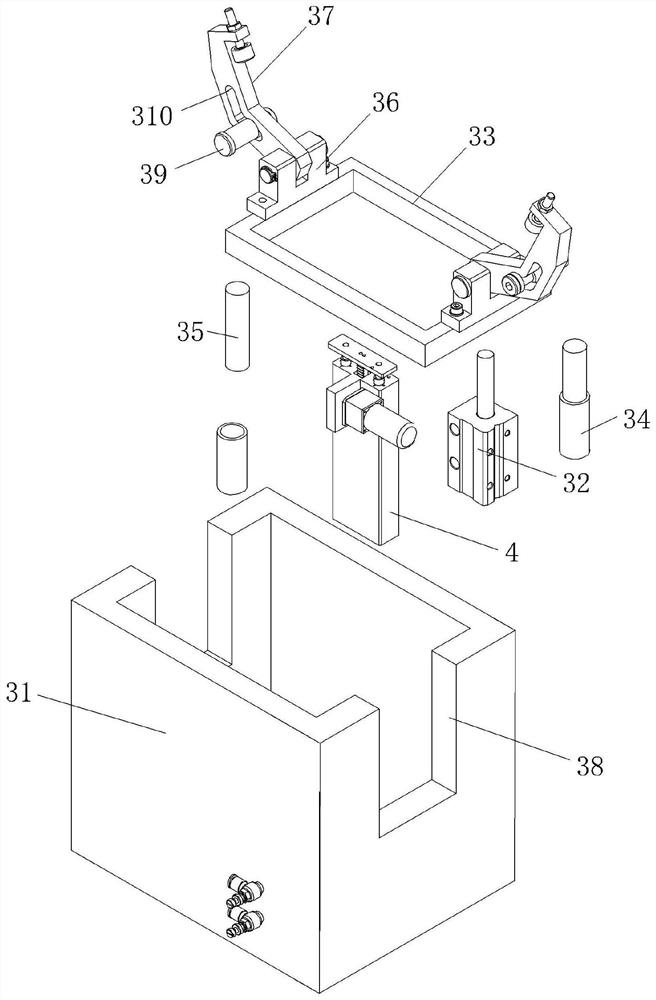

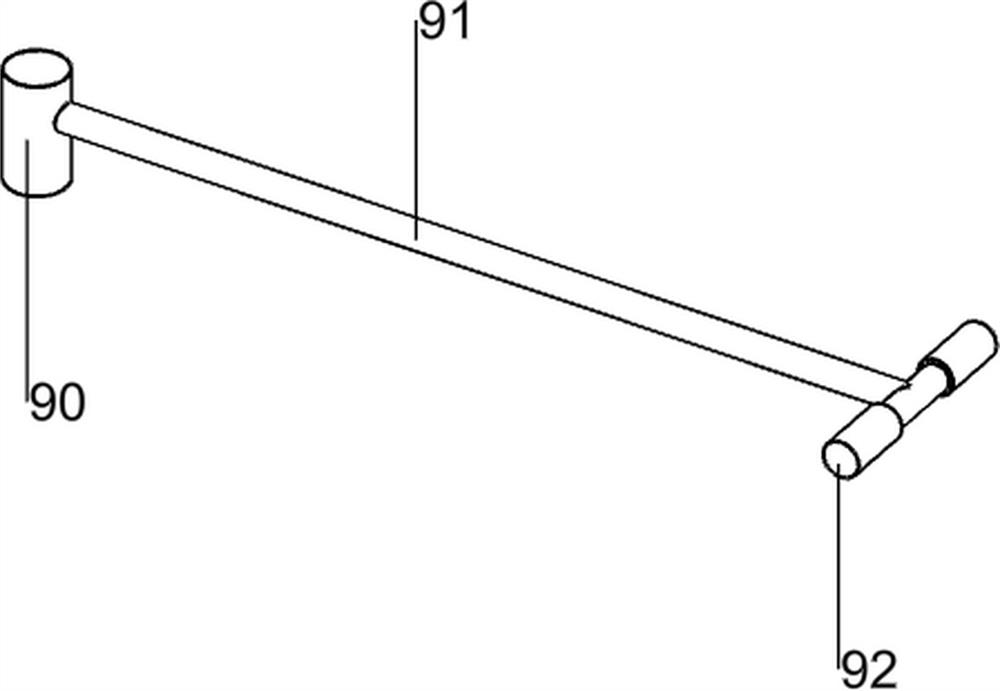

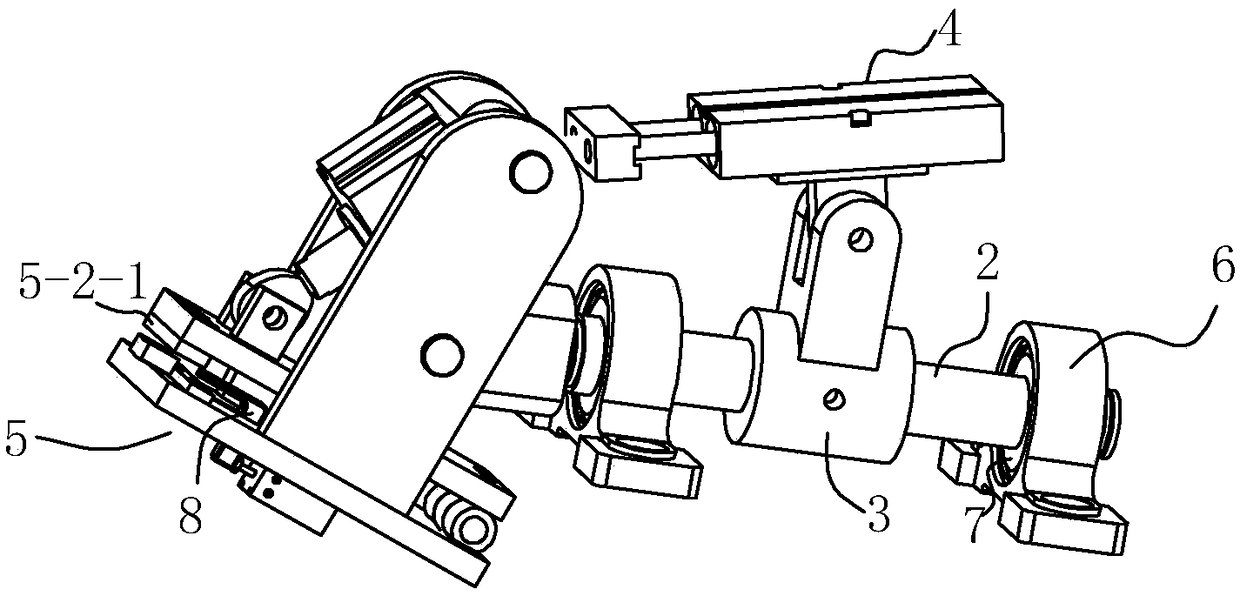

Multi-station hydraulic stretcher with transposition manipulator

InactiveCN102527807ARealize automatic ejectionImprove flexibilityProgramme-controlled manipulatorMetal-working feeding devicesHydraulic cylinderEngineering

The invention relates to a multi-station hydraulic stretcher with a transposition manipulator, which comprises a base, a bed bedplate, an upper oil cylinder bedplate, a middle upright, a peripheral upright and the transposition manipulator. The base is fixed on the ground; the bed bedplate is fixed on the base; the middle upright and the peripheral upright support the upper oil cylinder bedplate and a working bedplate between the upper oil cylinder bedplate and the bed bedplate; a plurality of upper hydraulic cylinders are distributed on the upper oil cylinder bedplate in the peripheral direction; a crankshaft mechanism is arranged between the bed bedplate and the working bedplate; the working bedplate is driven to move up and down by the crankshaft mechanism; the positions on the working bedplate, which correspond to the upper hydraulic cylinders, are provided with die stations; the transposition manipulator is arranged on the working bedplate and can rotate left and right to clamp and put down a workpiece; according to the invention, a plurality of independent die stations are arranged on the stretcher, so that the repeated stretching process on the same product on the same stretcher can be implemented; and meanwhile, the transposition manipulator can be used for carrying out automatic transposition on the workpiece.

Owner:SUZHOU YUEHAI STRETCHING MACHINERY

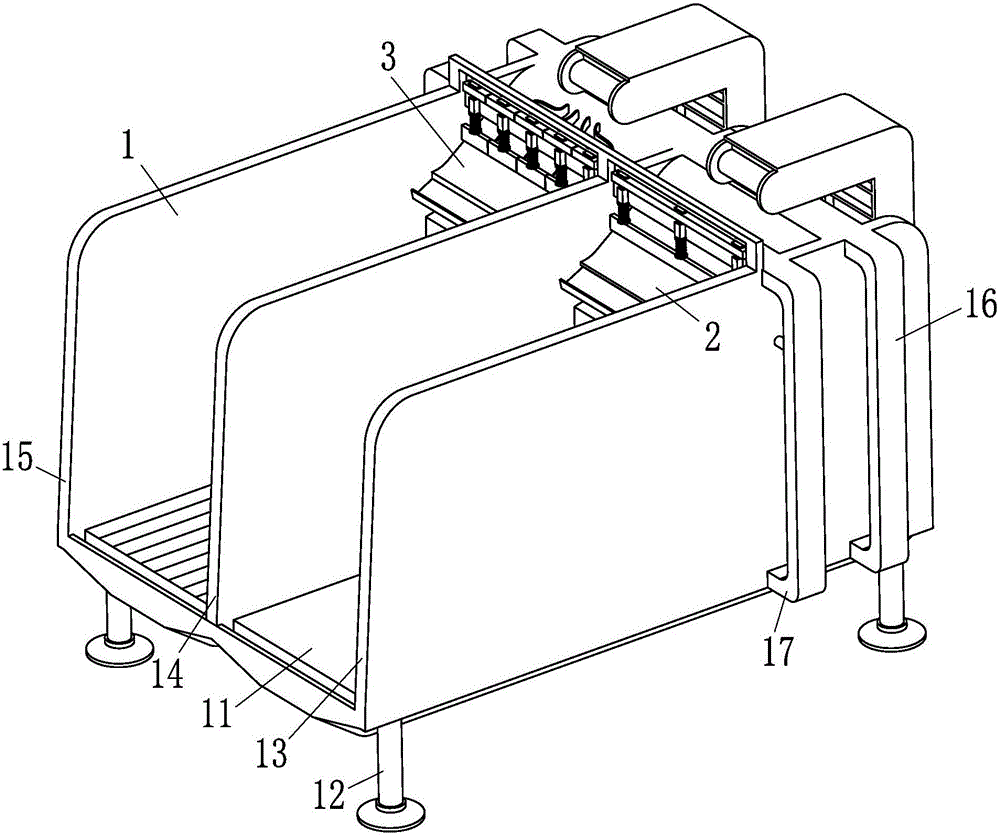

Glass cleaning equipment for building

PendingCN112605043ARealize automatic movementImprove work efficiencyCleaning using liquidsStructural engineeringMechanical engineering

Owner:许书倩

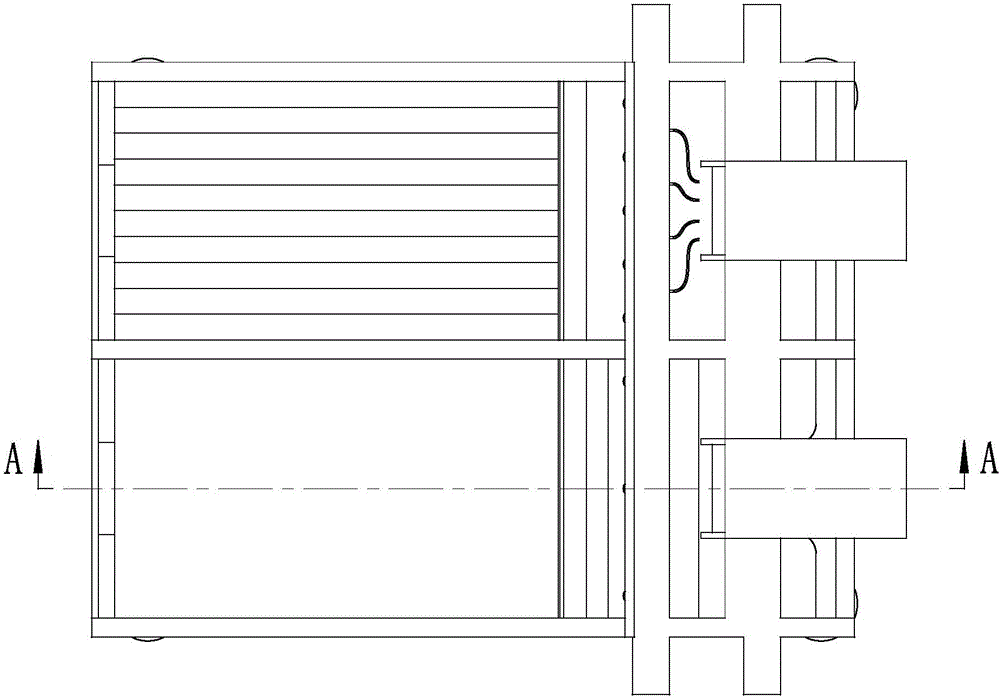

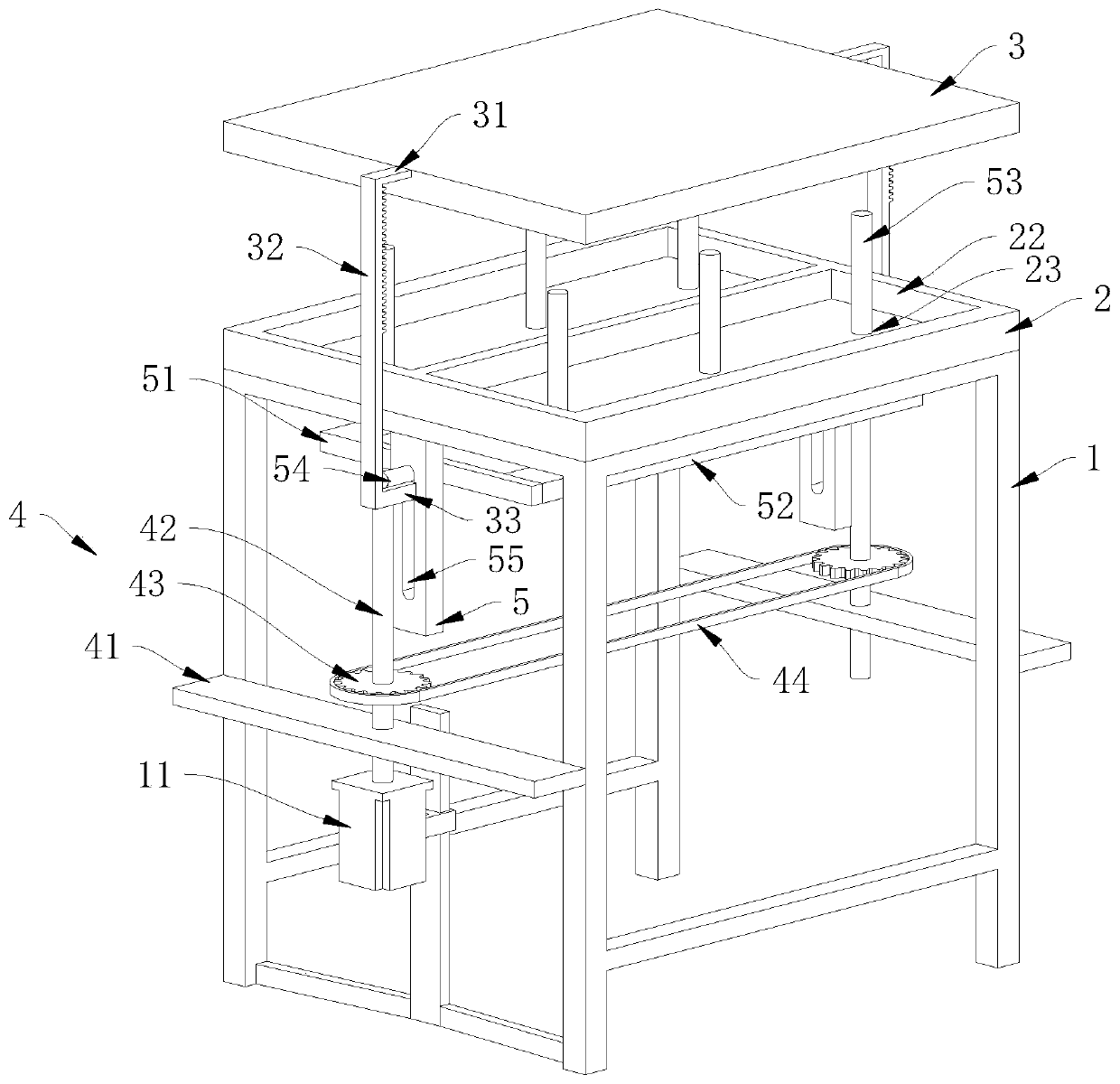

Multi-station hydraulic drawing machine

InactiveCN102554006AImprove flexibilityRealize automatic ejectionHydraulic cylinderPulp and paper industry

The invention relates to a hydraulic drawing device, in particular to a multi-station hydraulic drawing machine which comprises a base, a machine base bedplate, an upper oil cylinder bedplate, a middle column and columns, wherein the base is fixedly arranged on the ground, and the machine base bedplate is fixedly arranged on the base; the upper oil cylinder bedplate is supported between the upper oil cylinder bedplate and the machine base bedplate by the middle column and the columns, and a plurality of hydraulic cylinders are distributed on the upper oil cylinder bedplate in the circumferential direction; and a crank mechanism is arranged between the machine base bedplate and a working bedplate, and drives the working bedplate to move up and down, and mould stations are arranged on the working bedplate corresponding to the upper hydraulic cylinders. By arranging a plurality of independent mould stations on the drawing machine, the multiple drawing processes on the same product can be realized on the same drawing machine, so that the machining efficiency is improved.

Owner:SUZHOU YUEHAI STRETCHING MACHINERY

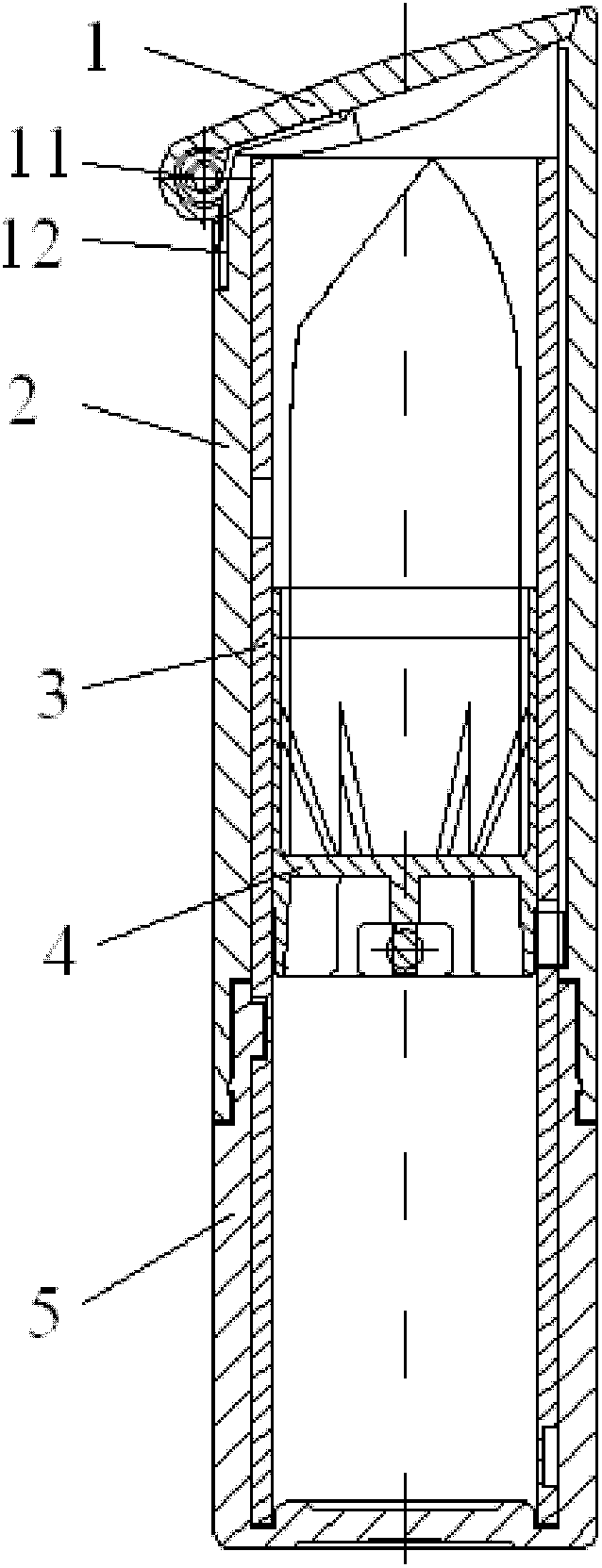

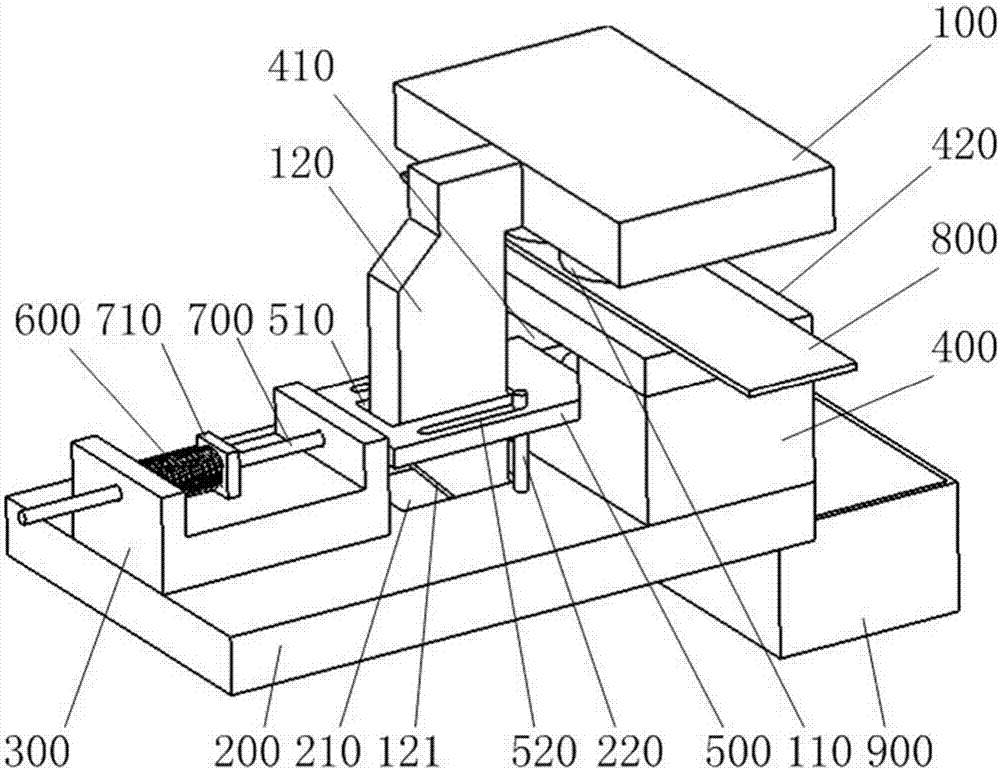

Mathematics simulator used for buffon throwing-pin experiment and its control system

ActiveCN106297467AEnhance interestImprove understandingCosmonautic condition simulationsEducational modelsControl systemProgrammable logic controller

The invention relates to field of mathematics training aid. To be specific, it is a mathematics simulator used for buffon throwing-pin experiment and its control system. Its simulator includes the body, coin inserting device and pin throwing device, wherein the body includes base, landing legs, front lateral plate, medium support plate, back lateral plate, No. 1 annulated column and No.2 annulated column. The coin inserting device and pin throwing device both include sliding device and shooting device. The shooting devices of mentioned coin inserting device and pin throwing device include shooting plate, rotating plate axis, supporting plate, shooting spring, flexible air bag, gas tank, ventilation hose and air pump. The pushing devices of mentioned coin inserting device and pin throwing device include pushing plate and pushing air cylinder. Its control system includes programmable logic controller, sensor unit, air pressure unit and servo controller. The simulator could make students directly sense the process of coin inserting (pin throwing) experiment to increase the interests and understanding of students on probability.

Owner:ANHUI UNIV OF SCI & TECH

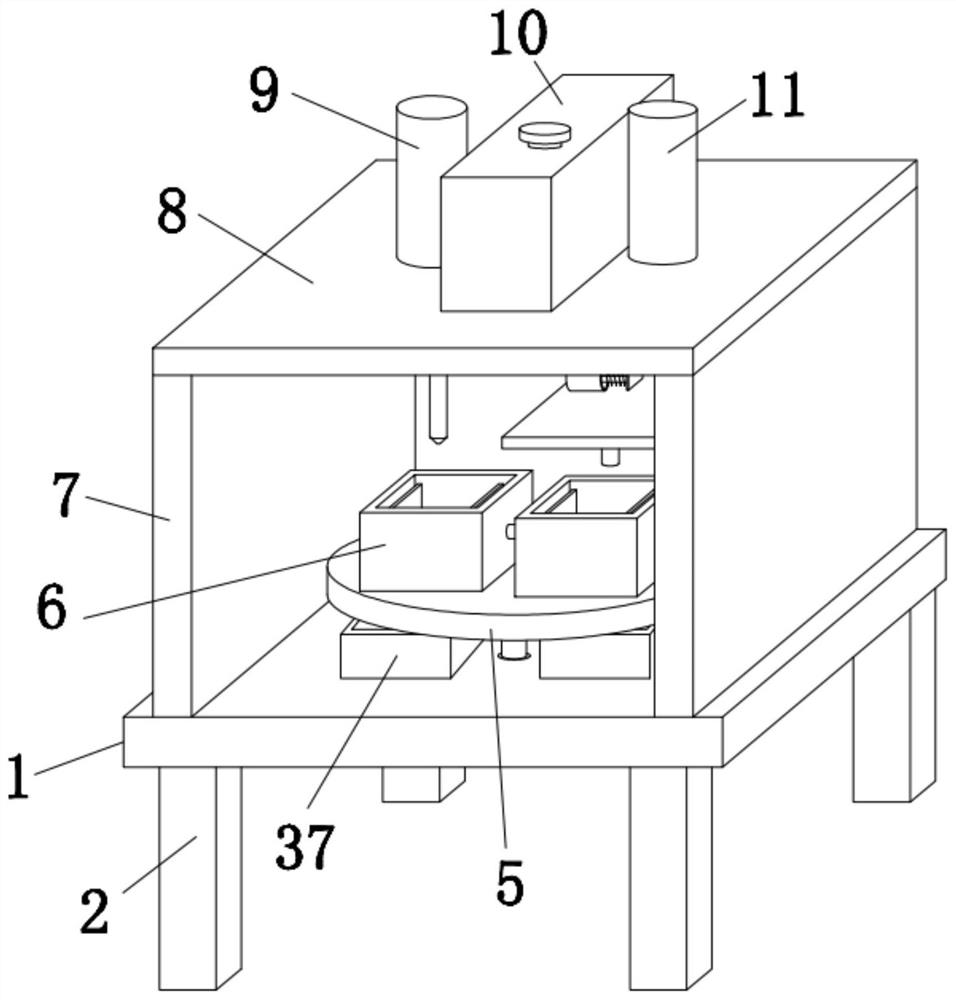

Stamping die for nut production

PendingCN113523092AImprove processing qualityRealize automatic ejectionShaping toolsPerforating toolsPunchingElectric machine

The invention discloses a stamping die for nut production. The stamping die comprises a platform, wherein four supporting legs which are symmetrically arranged in pairs are fixedly arranged at the bottom of the platform, a first motor is fixedly arranged at the bottom of the platform, a mounting hole is formed in the top of the platform, a rotating shaft is rotationally arranged in the mounting hole, the two ends of the rotating shaft extend out of the mounting hole, and the bottom end of the rotating shaft is fixedly connected with the output shaft end of the first motor. The stamping die is reasonable in design and good in practicability, and can realize integrated operation of punching machining of a nut plate material, grinding and tapping of punched holes of nuts, and in the process of grinding and tapping the punched holes of the nuts, cooling liquid can be automatically sprayed to the inner walls of the punched holes of a tapping screw, a grinding column and the nuts for cleaning, cooling and lubricating, the cooling liquid does not need to be manually added by workers, the operation is facilitated, the labor amount of the workers is reduced, the work is facilitated, and the machining quality and the working efficiency of the nuts are improved.

Owner:江苏锦瑞金属制品有限公司

Automatic die retreating type explosive pressing die

ActiveCN112078178AEnsure quality stabilityWon't interfereExplosive working-up apparatusPressesStructural engineeringMechanical engineering

The invention discloses an automatic die retreating type explosive pressing die which comprises a movable die part and a fixed die part. The fixed die part comprises a lower die plate, cushion blocksare arranged on the two sides of the top of the lower die plate, and an ejection reset mechanism is arranged at the position, located on the inner sides of the two cushion blocks, of the top of the lower die plate. The ejection reset mechanism comprises an ejection rod and a reset spring arranged on the outer side of the ejection rod, and an explosive plug is arranged at the top of the ejection rod. A cavity part is arranged above the fixed die part in a matched mode and comprises a cavity plate, the explosive plug and a guide column. An explosive groove is formed in the position, corresponding to a protrusion, of the top of the cavity plate, and the explosive plug is arranged in the explosive groove in an H7 / f6 clearance fit mode. The movable die part comprises an upper die plate, a maledie and a guide sleeve, the male die is arranged at the bottom of the upper die plate, the guide sleeve is arranged on the periphery of the male die, and a protrusion is arranged at the bottom of themale die. The guide column is arranged in the guide sleeve in a matched mode, and the guide column can move along the guide sleeve.

Owner:TAIYUAN UNIV OF TECH

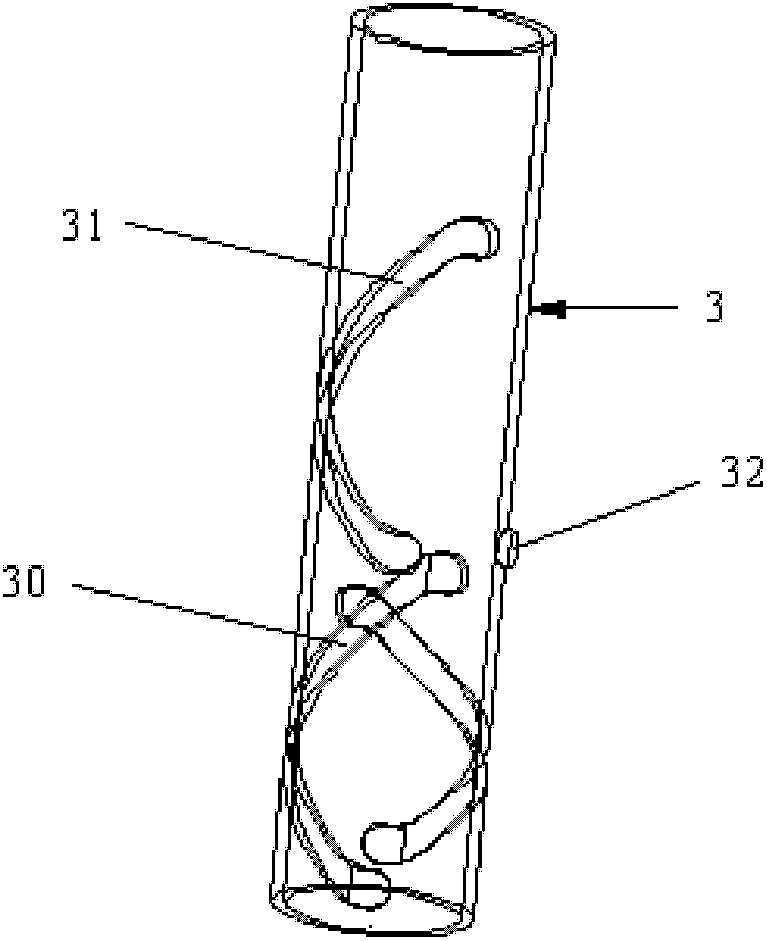

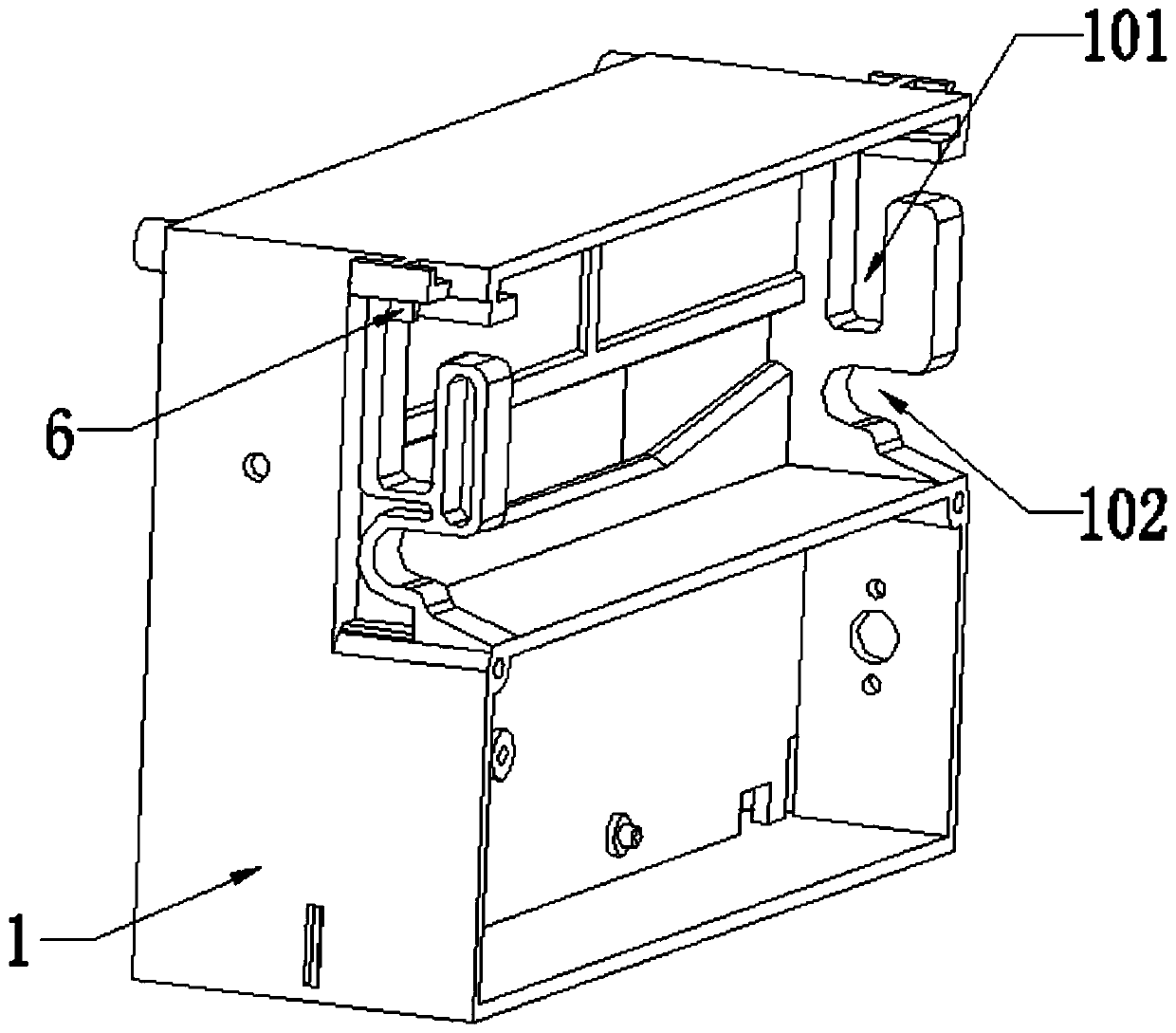

Latch assembly and a gene detection device thereof

ActiveCN109182107AEnsure consistencyImprove detection accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsFlangeGene

The invention discloses a latch assembly and a gene detection device thereof. The latch assembly comprises a side plate, wherein a first flange and a second flange are arranged on the side plate; thesecond flange is installed in a switch chute, and the bottom surface of the first flange is clamped tightly with a detection frame; a switch groove is arranged on one side of the side plate close to the detection frame, and a switch inclined surface is arranged on the switch block; a switch incline surface is close to one end of the first ejector rod, the other end of the first ejector rod passesthrough the limit ring and is loaded into a reset hole; the limit ring is installed at one end of the reset hole, and the other end of the reset hole is communicated with a sliding hole; one end of the first ejector rod installed in the reset hole is provided with a clamping hole; the closed end of the clamping hole is assembled and fixed with one end of the first spring, the other end of the first spring is assembled and fixed with one end of the second ejector rod installed in the clamping hole, and the other end of the second ejector rod passes through the sliding hole and is engaged with the locking clamping groove after being assembled; and a reset ring is also fixed on one end of the first ejector rod which is installed in the reset hole, and a second spring is arranged between the reset ring and the end face of the reset hole which is close to the sliding hole.

Owner:赵勇

Server hard disk locking processing device

ActiveCN112764488AConvenience guaranteedImprove efficiencyDigital processing power distributionComputer hardwareMechanical engineering

The invention discloses a server hard disk locking machining device, and belongs to the technical field of hard disk locking, the server hard disk locking machining device comprises a frame body, a rotary box body and a horizontal limiting block, and the rotary box body is rotationally connected with the frame body; the horizontal limiting block is arranged on the rotary box body and is matched with the frame body to limit the horizontal limit of left and right overturning of the rotary box body; a hard disk plug-in mounting space is formed in the rotary box body, and a detachable hard disk supporting pad is arranged in the hard disk plug-in mounting space; and a locking hole is formed in the side face of the rotary box body. The hard disk is clamped into the hard disk bracket and placed in the hard disk insertion space, the full-thickness hard disk is matched with the hard disk insertion space in thickness, and the half-thickness hard disk is supported and limited through the hard disk supporting pad; the locking holes are aligned with the screw holes of the hard disk and the hard disk bracket, and screws are inserted through the locking holes to realize locking of the hard disk and the hard disk bracket; the rotary box body turns over on the frame body, and the left and right horizontal limiting positions of the rotary box body are limited through the horizontal limiting blocks, so that the convenience of locking is realized; and the locking efficiency and the locking accuracy are improved.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Improved structure of rotary lipstick box

ActiveCN102835812AEasy to useRealize automatic ejectionPackaging toiletriesPackaging cosmeticsLipstickEngineering

The invention discloses an improved structure of a rotary lipstick box. The improved structure comprises a top cover, a body, first and second sleeves and a base, wherein the top cover is articulated with the outer side of the upper end of the body, and the top cover can keep the reset force capable of covering the upper end opening of the body; the base is axially positioned in the bottom end of the body, and the base and the body can freely rotate; and the first sleeve is freely nested in the body, and the second sleeve is freely placed in the first sleeve. The improved structure of the rotary lipstick box integrates the parts of the traditional lipstick box into a whole, when a user uses the improved structure, the automatic ejection and contraction of a lipstick paste can be realized by virtue of rotation based on a single hand, and the improved structure is convenient in use.

Owner:苏州洽兴塑胶有限公司

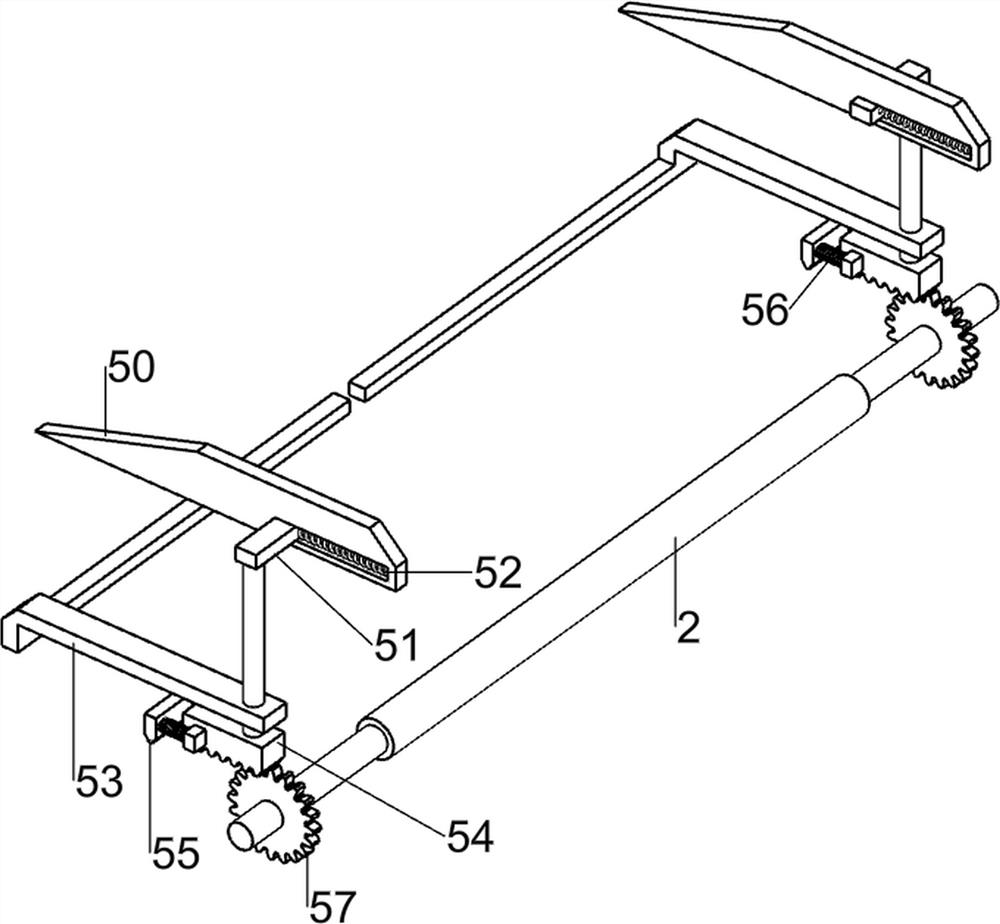

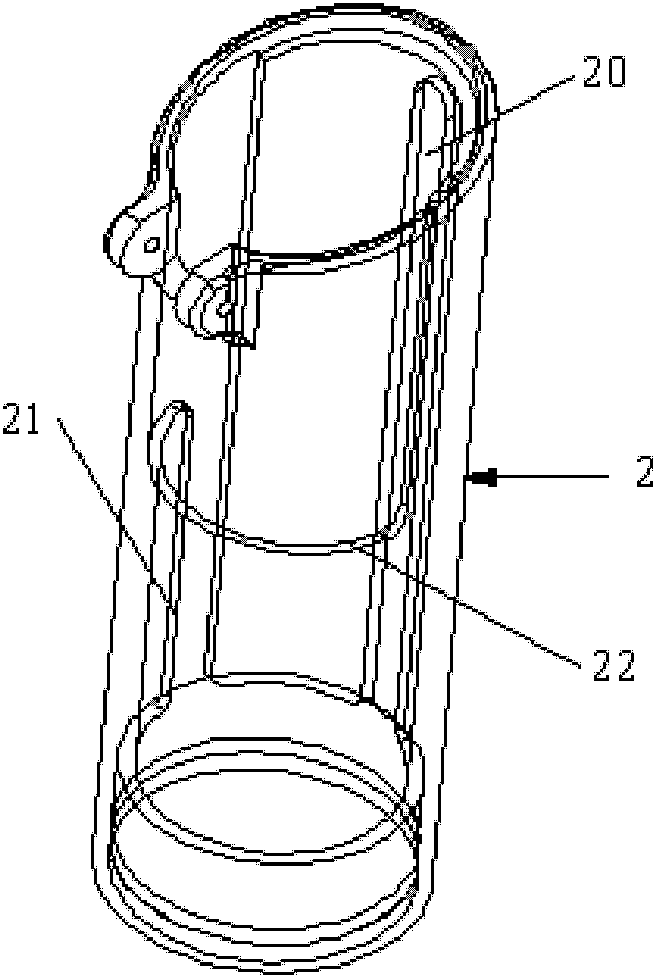

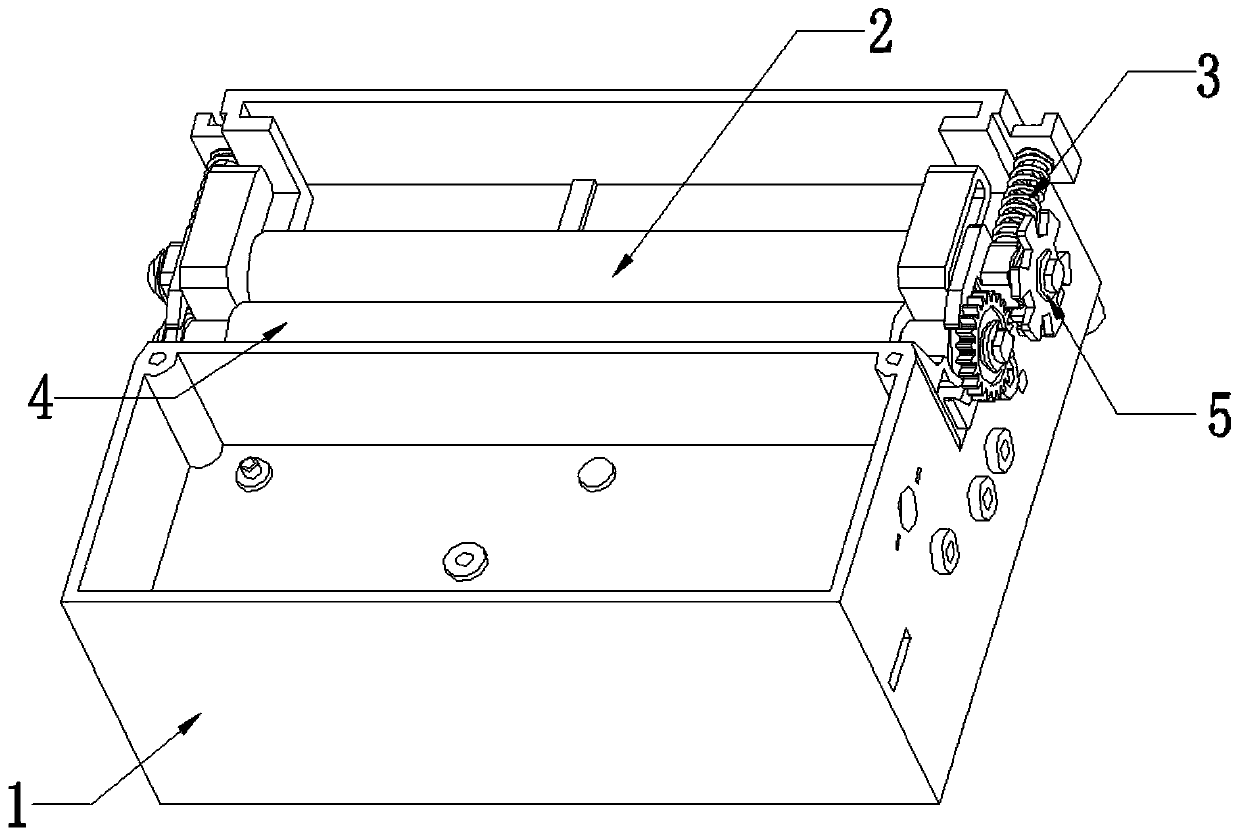

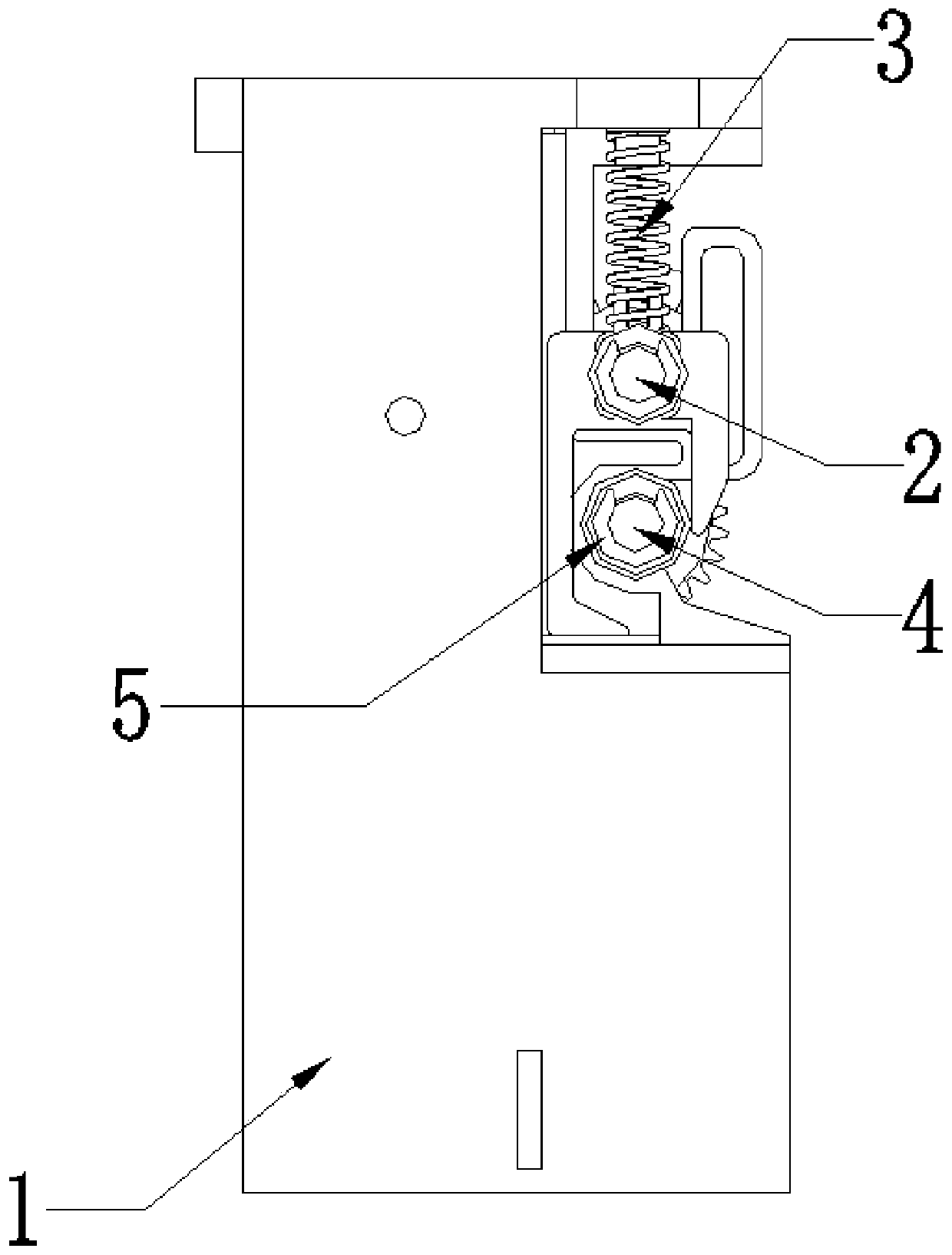

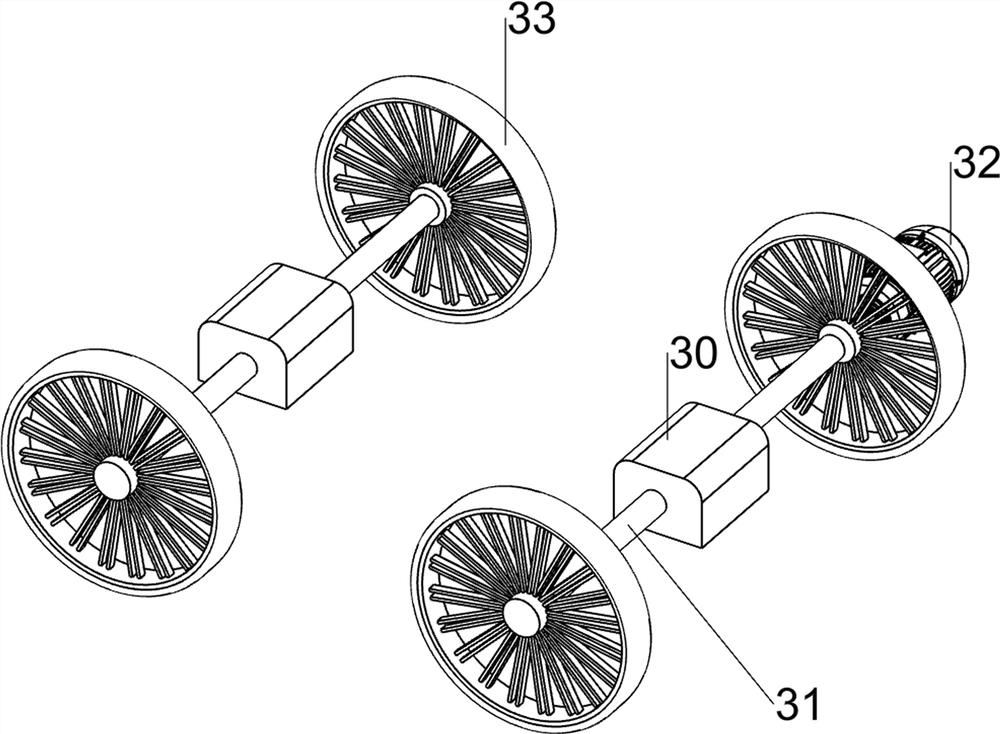

Brand new paper driving structure unit

PendingCN110151035AEasy loadingPrevent prolapseDomestic applicationsWebs handlingDrive wheelEngineering

The invention relates to the technical field of articles of daily use, in particular to a brand new paper driving structure unit. The brand new paper driving structure unit comprises a machine core base, driven wheel assemblies, pressure springs and driving wheel assemblies; driven wheel axle sleeve matched sliding grooves and driving wheel axle sleeve matched grooves are formed in the left side wall and the right side wall of the machine core base correspondingly; the driven wheel assemblies are mounted in the driven wheel axle sleeve matched sliding grooves in the two sides, and the drivingwheel assemblies are mounted in the driving wheel axle sleeve matched grooves in the two sides; and the two pressure springs providing pre-tightening force of the driven wheel assemblies are arrangedbetween the machine core base and the driven wheel assemblies. According to the driving structure unit, the problems of paper loading, skipping and jamming of soft paper, and thickness compatibility of different models can be effectively solved, and the driving structure unit has high applicability and is suitable for being further applied and popularized.

Owner:厦门晟宇顺科技有限公司

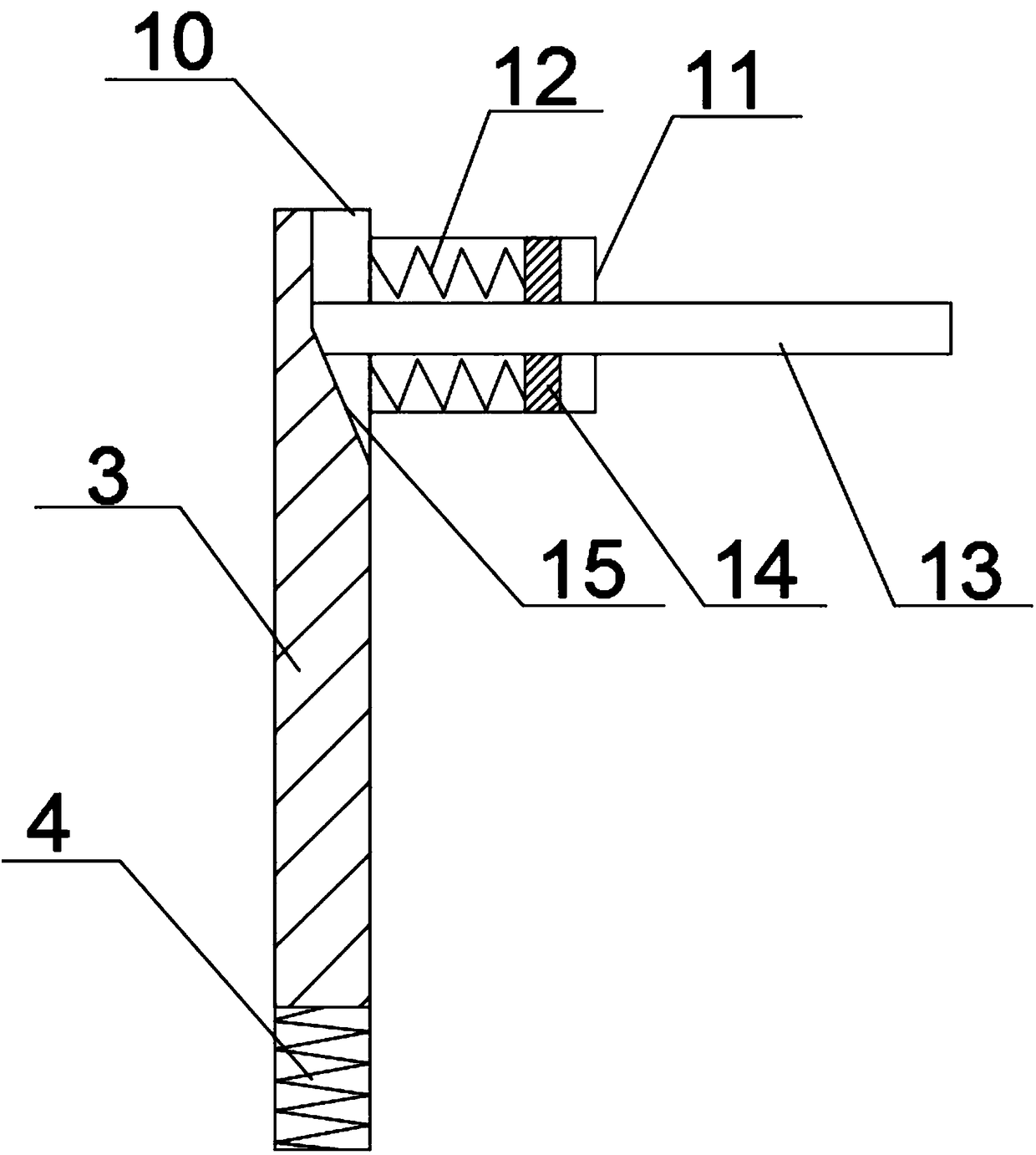

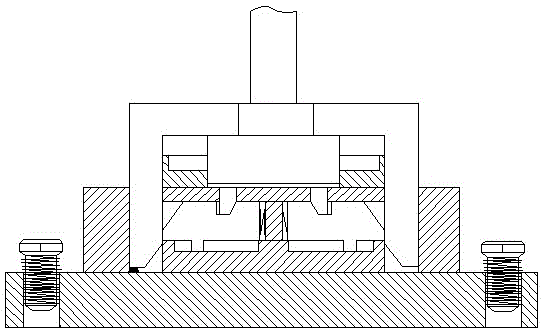

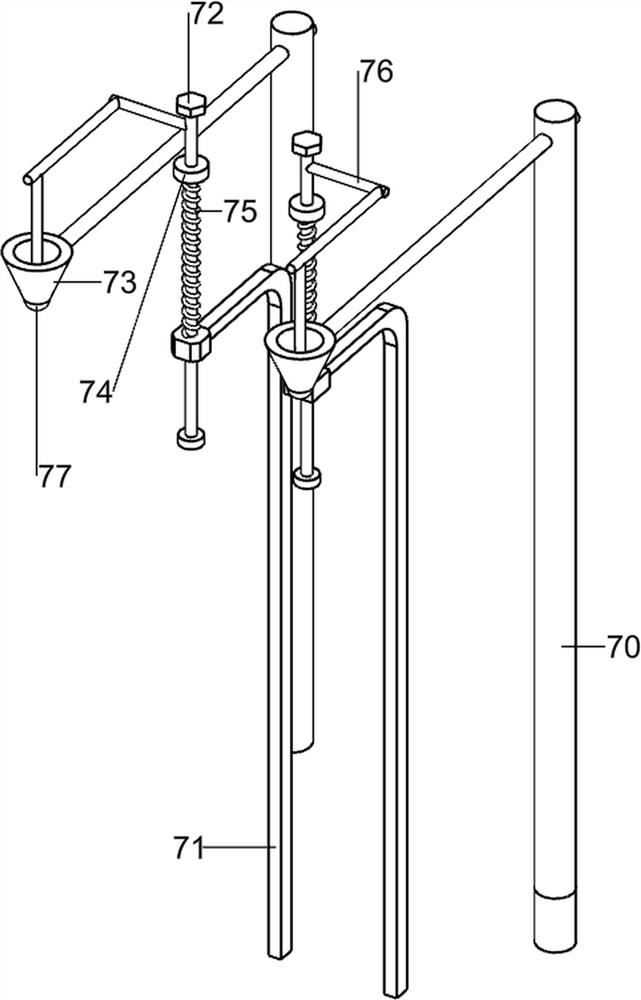

A bend pipe forging die with spring material device

ActiveCN106925709BImprove forging processing efficiencyReduce labor intensityForging/hammering/pressing machinesEngineeringUltimate tensile strength

A bend pipe forging die with a springing device comprises a fixed die body and a movable die body, wherein the movable die body is arranged below the fixed die body; a convex die body is arranged on a forging surface of the fixed die body; a concave die body which is matched with the convex die body is arranged on a forging surface of the movable die body; the convex die body is matched with the concave die body to form a forging cavity of which the shape is matched with that of a bend pipe; the springing device is arranged in the movable die body; a downward blind hole is formed in the forging surface of the movable die body; the springing device comprises a first spring arranged at the bottom of the blind hole and a pressure lever arranged on the first spring; the upper end of the pressure lever extends out of the blind hole; the upper part of the pressure lever is a wedge-shaped surface; a through hole is formed in a position, which corresponds to the forging cavity, of the wedge-shaped surface; a push rod which is matched with the wedge-shaped surface of the pressure lever is arranged in the through hole; and a resetting spring is arranged on the push rod. The springing device is arranged in the movable die body, so that a finished bend pipe can be unloaded from the die when stripped from the die; the labor intensity of workers is reduced; and the forging efficiency of the bend pipe is improved remarkably.

Owner:JIANGSU MINGGE FORGING EQUIP CO LTD

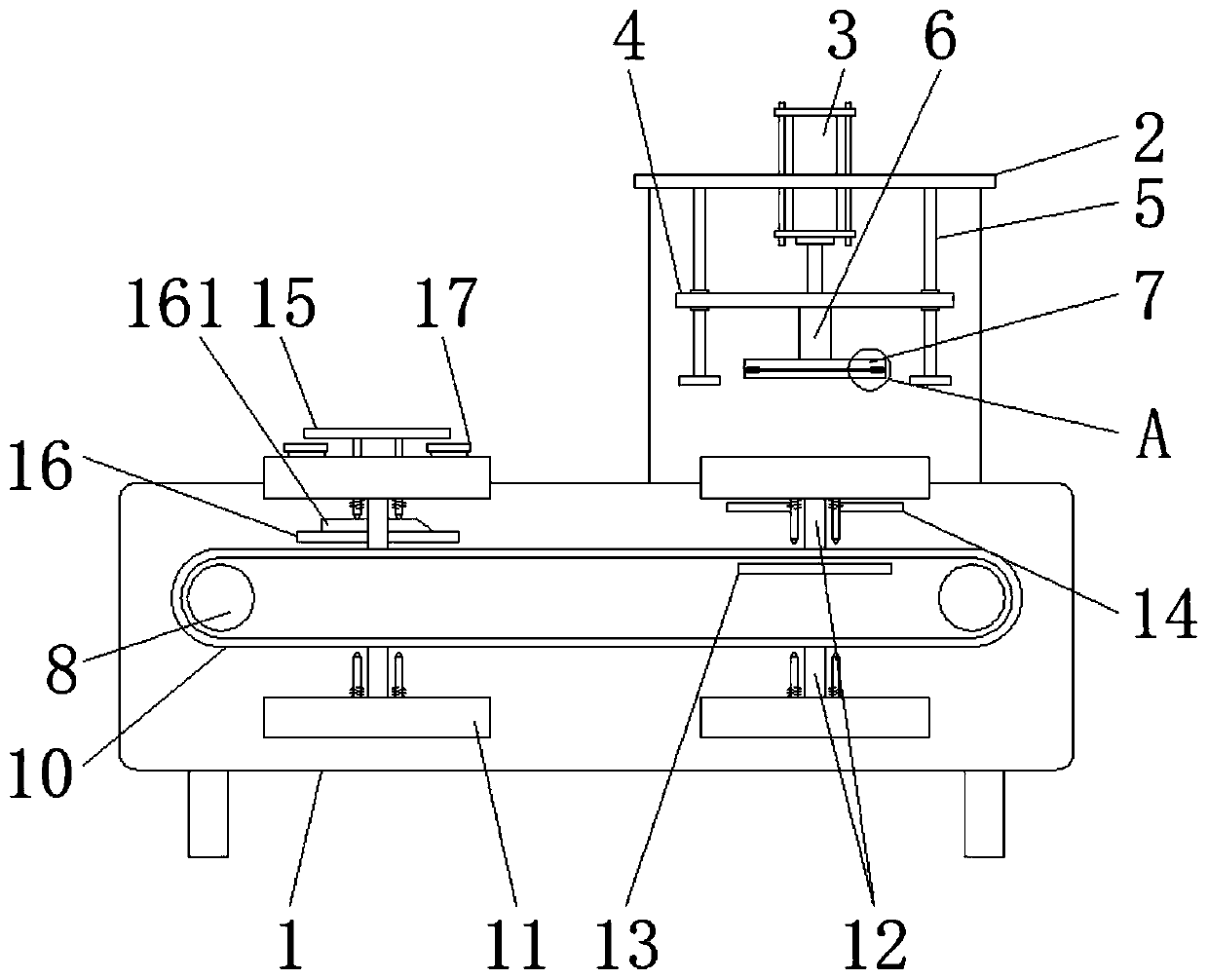

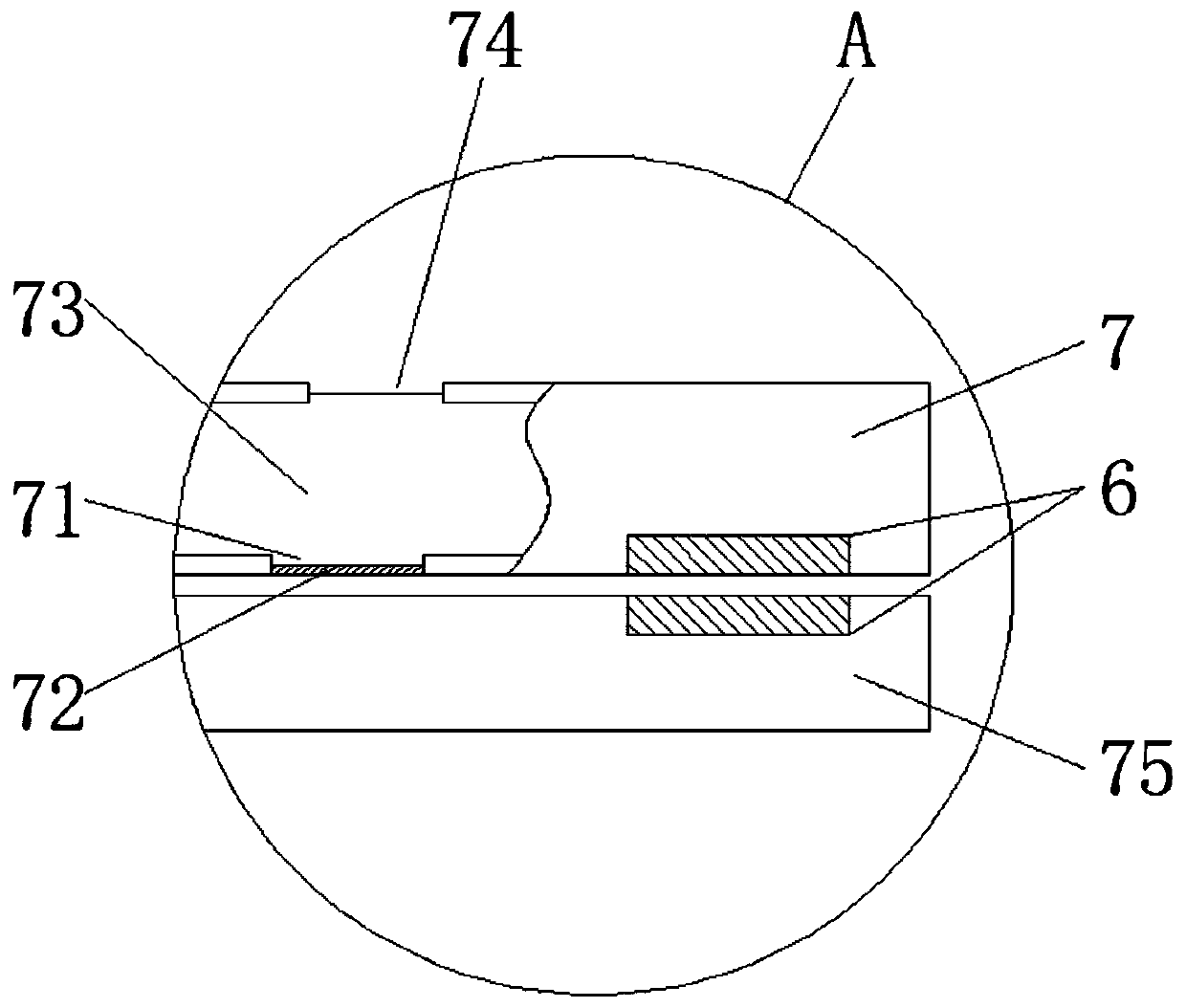

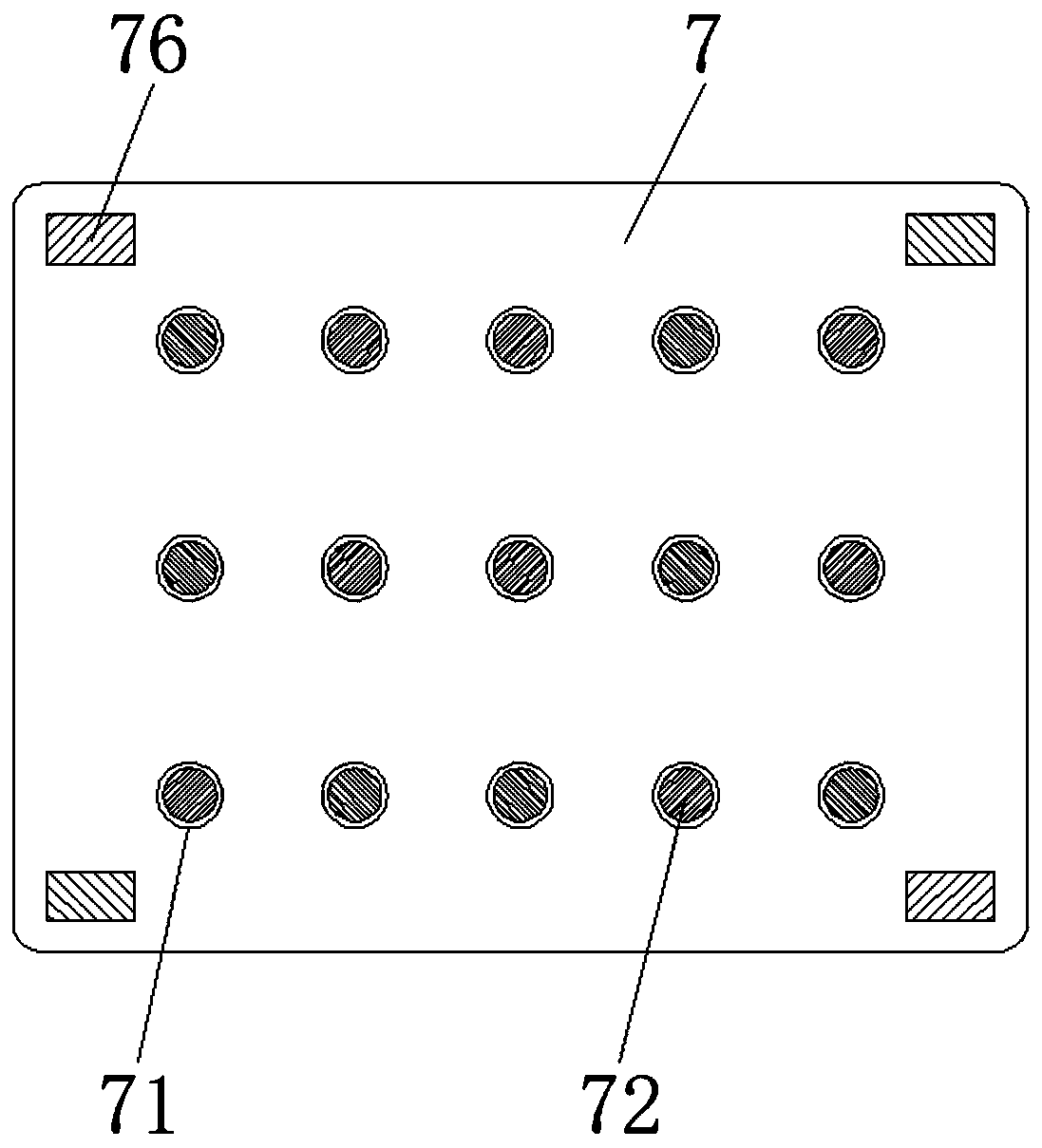

Compacting equipment for processing compound wood slabs based on straw raw material

ActiveCN110815488AThe export is processedRealize automatic ejectionWood working apparatusFlat articlesAgricultural engineeringConveyor belt

The invention discloses compacting equipment for processing compound wood slabs based on a straw raw material. The compacting equipment comprises an equipment outer frame. An equipment supporting rackis mounted at the top end of the equipment outer frame, a conveyor belt is mounted on a roller, horizontally distributed raw material placing boxes are arranged in the equipment outer frame, supporting rods are mounted on the bottom walls of the raw material placing boxes, meanwhile, the inner surface of the conveyor belt is attached to a belt supporting plate, the belt supporting plate is mounted on the side wall of the equipment outer frame, a material supporting plate is arranged in each raw material placing box, a fixed transverse plate is arranged above the conveyor belt, the fixed transverse plate is fixed to the side wall of the equipment outer frame, and a metal limiting plate is mounted at the top end of the equipment outer frame. The compacting equipment for processing compoundwood slabs based on the straw raw material can export inner gas well while guaranteeing that a product does not upwarp and needs not to be trimmed. By adopting a multi-station design, materials are ejected automatically as the conveyor belt operates, so that the compacting equipment is more convenient to use.

Owner:扬州科丰高新产业投资开发集团有限公司

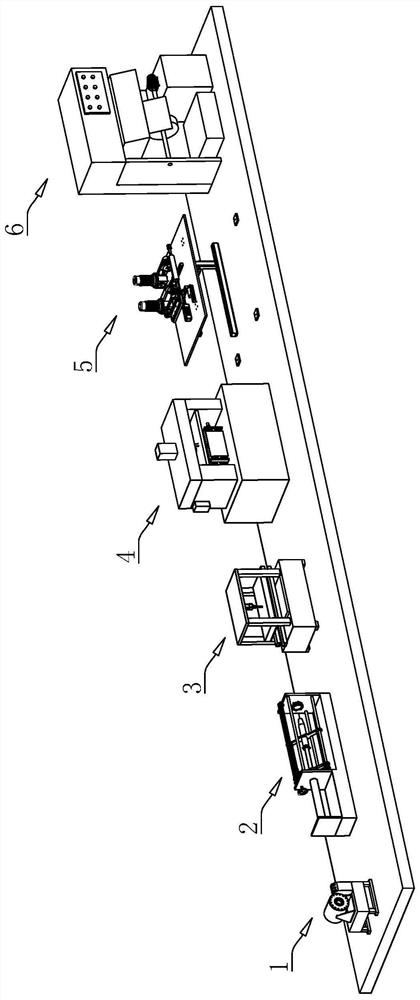

Special-shaped pipe fitting production line and production process thereof

PendingCN114101454AImprove work efficiencyEasy to operateEjection devicesProcess engineeringManufacturing line

The invention relates to a special-shaped pipe fitting production line and a production process thereof, and relates to the field of pipe fitting production, and the special-shaped pipe fitting production line comprises a pipe shrinking machine, a drawing machine, a profiling device, a water expansion forming machine, a cutting device and a polishing device which are arranged in sequence; the special-shaped pipe fitting production process comprises the following steps: S1, pipe shrinkage; s2, stretching; s3, forming is conducted; s4, expanding the pipe; s5, cutting is conducted; and S6, polishing. The demolding device has the beneficial effects that demolding can be conveniently conducted on the pipe fitting subjected to water expansion forming, and the working efficiency is improved.

Owner:应城市鑫异升机械科技有限公司

Novel food cutting device

ActiveCN106827049AImprove stabilityEasy to replaceMetal working apparatusEngineeringMechanical engineering

The invention discloses a novel food cutting device. The novel food cutting device comprises a cutting element and a cutting frame arranged at the lower end of the cutting element, wherein the cutting element comprises a cross rod, a cutting module and a drive rod, and insertion rods extending downwards are fixedly arranged on two sides of the cross rod respectively; a cutting base opposite to the cutting module is arranged at the top end of the cutting frame; insertion holes are formed in the parts, opposite to the lower ends of the insertion rods, of the cutting frame; slipping grooves symmetrical to each other in the horizontal direction are arranged in the cutting frame between the insertion holes; a check block fixedly connected with the cutting frame is arranged between the slipping grooves; a perforated groove penetrating through the outer wall of the cutting frame and communicated with the bottom end in the cutting base is formed in the top end of each slipping groove, lifting pins are arranged in the perforated grooves, a pushing groove is formed in the bottom end of each slipping groove, slipping blocks are arranged in the slipping grooves, an elastic part is arranged between each slipping block and the check block, and a lifting pin slot is formed in the top end of each slipping block. The novel food cutting device is simple in structure, low in manufacturing cost and convenient to maintain and can realize automatic separation after cutting.

Owner:湖南国湘食品有限公司

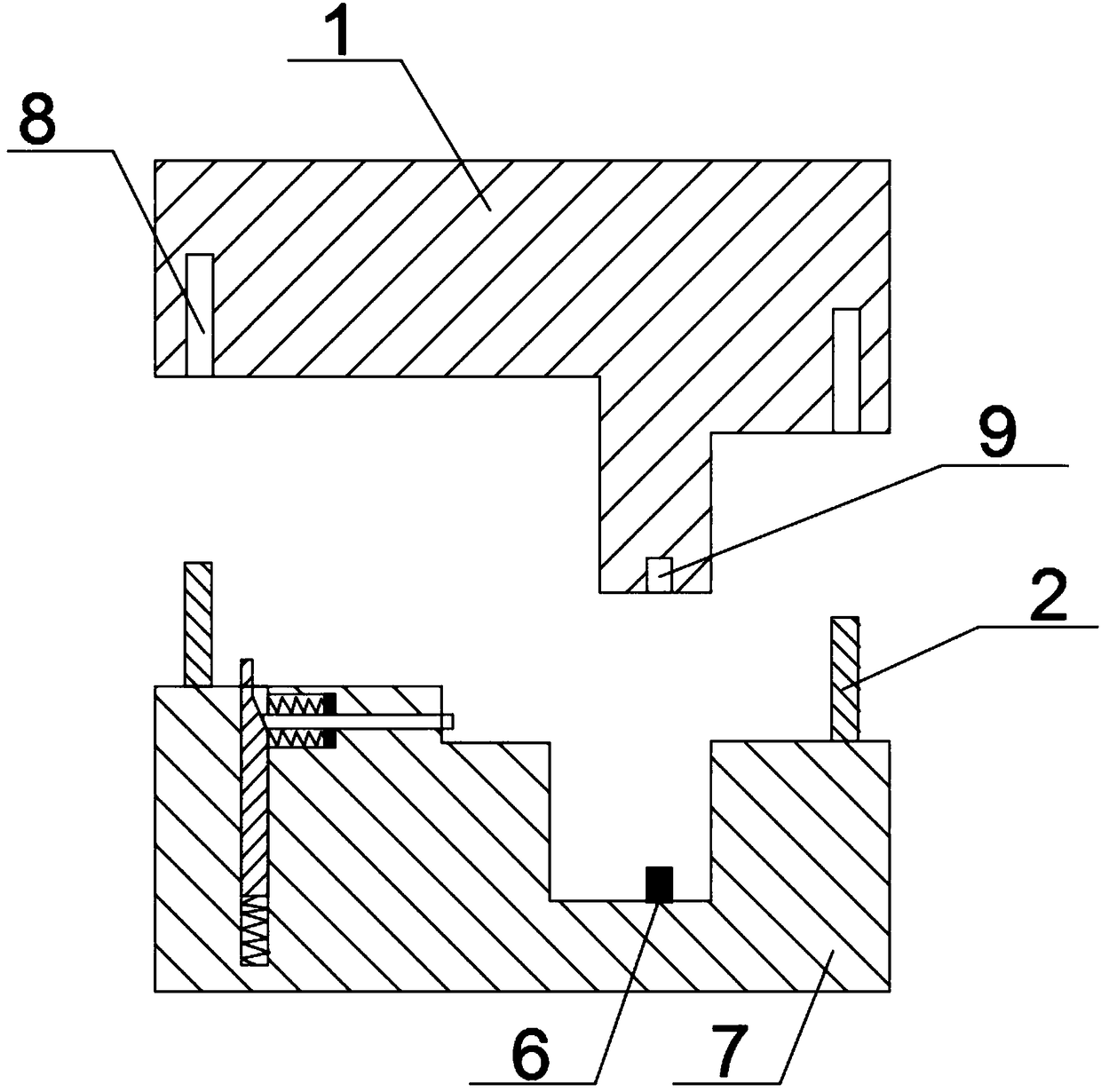

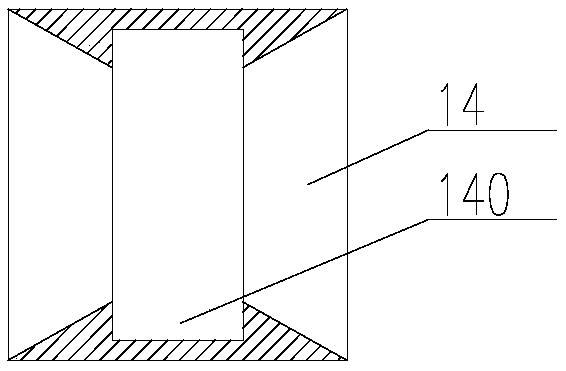

Pipe fitting welding machine

ActiveCN105618946BRealize automatic ejectionNo sound qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a pipe welding machine. The pipe welding machine comprises a base (1), a welding mechanism, an air cylinder (4), an ejector rod (7) and an outer shell. The outer shell is arranged on the upper surface of the base (1) and forms a working cavity. The welding mechanism is arranged on the upper surface of the base (1). The air cylinder (4) is fixedly connected to the outer shell and arranged on one side of the welding mechanism. A piston rod of the air cylinder (4) moves in the length direction and is connected to one end of the ejector rod (7) and coaxial with the ejector rod (7). The other end of the ejector rod (7) faces a pipe. A groove cavity (10) used for containing the pipe is formed in the other side, opposite to the air cylinder (4), of the base (1). The pipe welding machine overcomes the defect that pipes cannot be taken out after being welded through welding machines in the prior art, and automatic ejection of the welded pipe is achieved.

Owner:绩溪徽腾机械有限公司

Bee breeding cave

The invention relates to the technical field of breeding of bees, and discloses a bee breeding cave. The cave includes a cave body; the front end of the cave body is provided with a cave opening, a partition wall for sealing the cave opening is arranged at the cave opening, and an entrance is arranged in the partition wall; a hung ceiling is arranged on the top of the cave body, and an isolation layer is arranged between the hung ceiling and the top wall of the cave body; an air discharging pipe is arranged in the isolation layer, one end of the air discharging pipe is located in the isolationlayer, and the other end passes out to the outer side of the cave body; a breeding chamber is arranged between the hung ceiling and the bottom wall of the cave body, and the hung ceiling is providedwith air discharging openings communicating with the breeding chamber and the isolation layer; a water ditch is dug in the ground located under the bottom of the cave body, and the water ditch is connected with a water inlet pipe; and the bottom of the cave body is provided with an opening, the interior of a plurality of baffles are rotatably connected in the opening and arranged side by side along the direction of the water ditch, the upper ends of the baffles are located in the cave body, and the lower ends are located in the water ditch. The bee breeding cave of the technical scheme provided by the invention can solve the environmental protection problem caused by cooling of air conditioners and the problem of dried air in a current bee breeding room.

Owner:重庆市江津区肖泽明蜜蜂养殖专业合作社

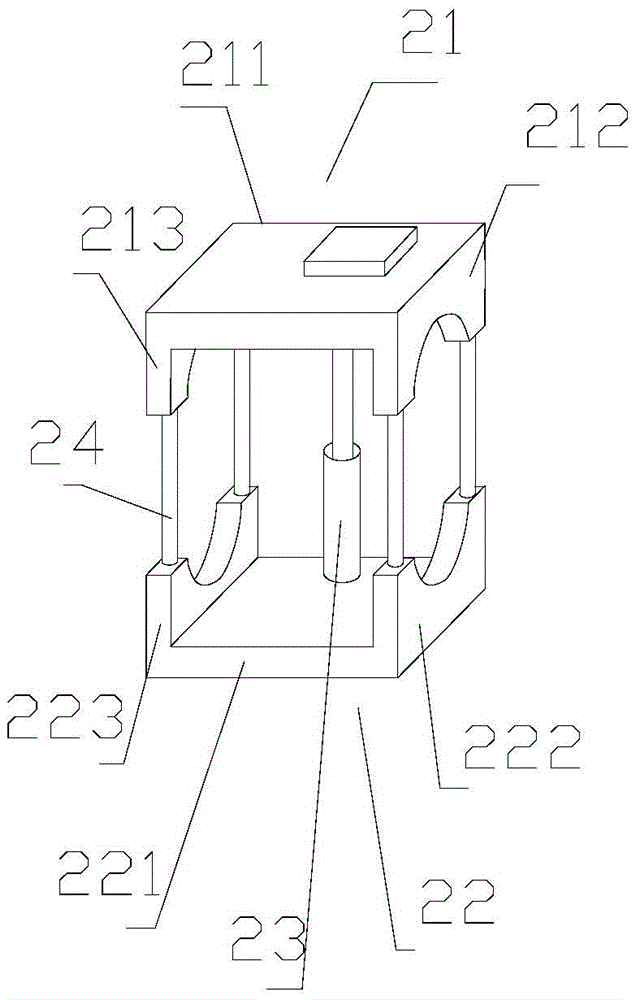

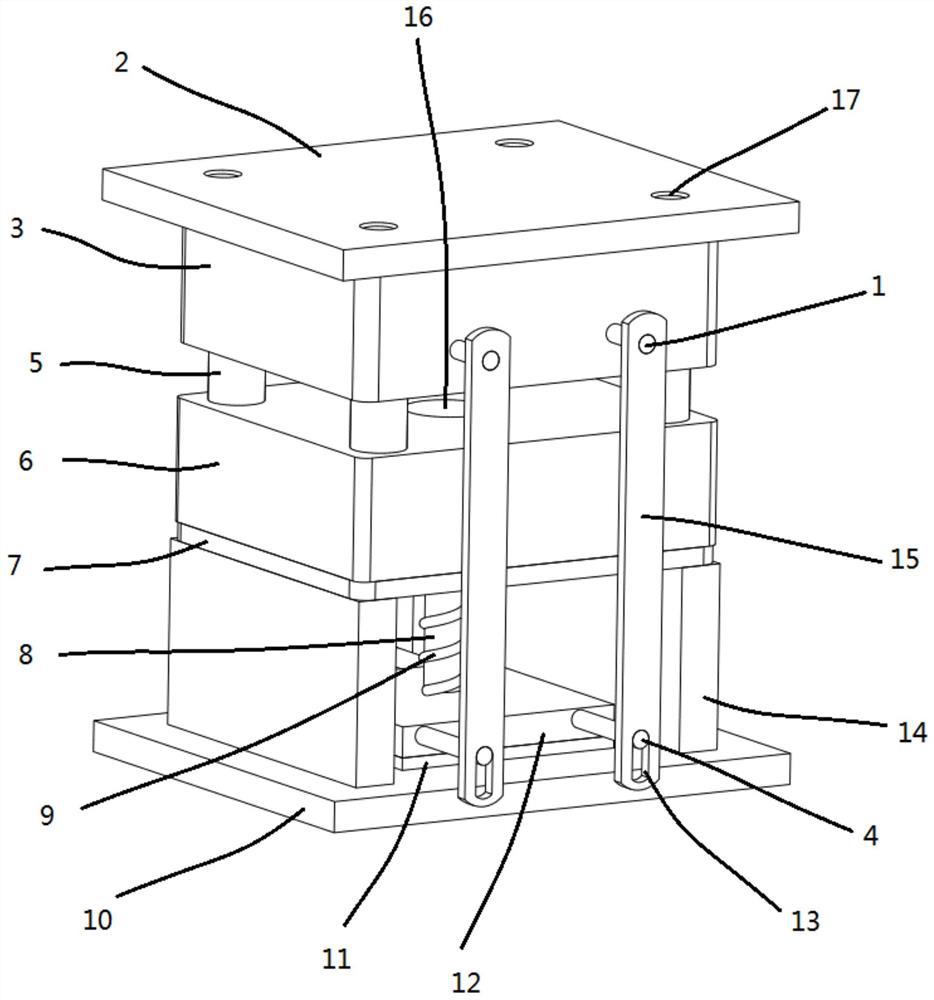

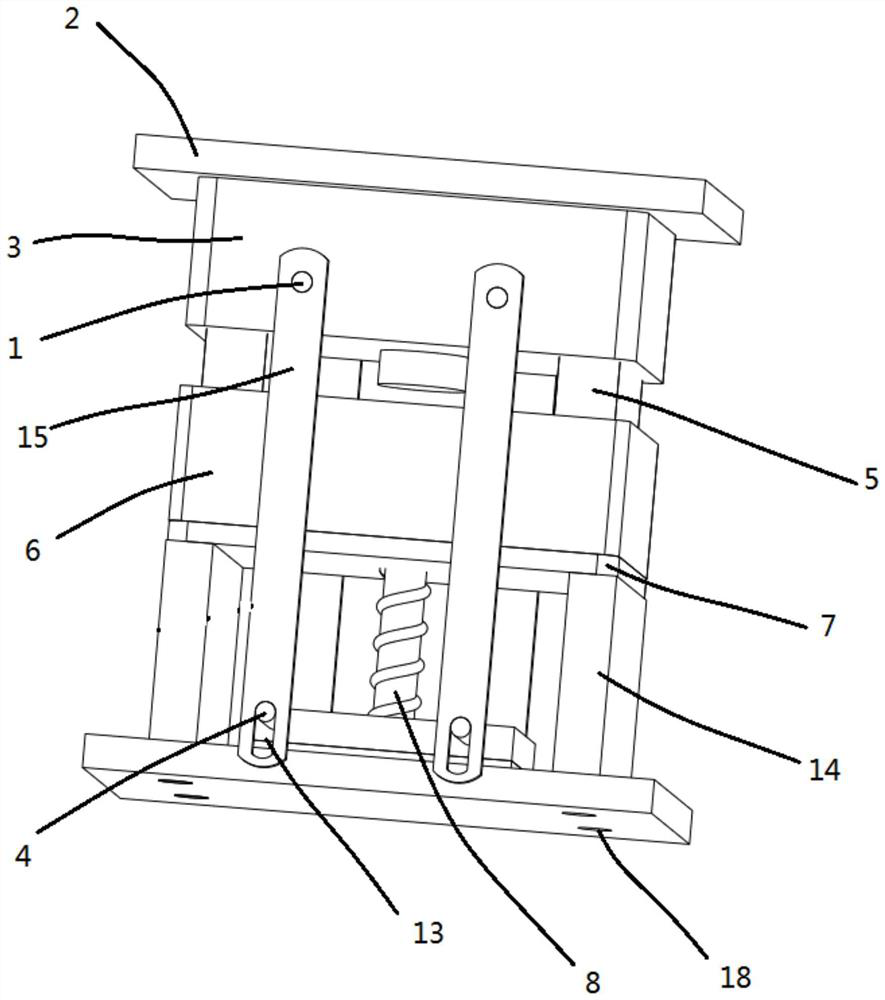

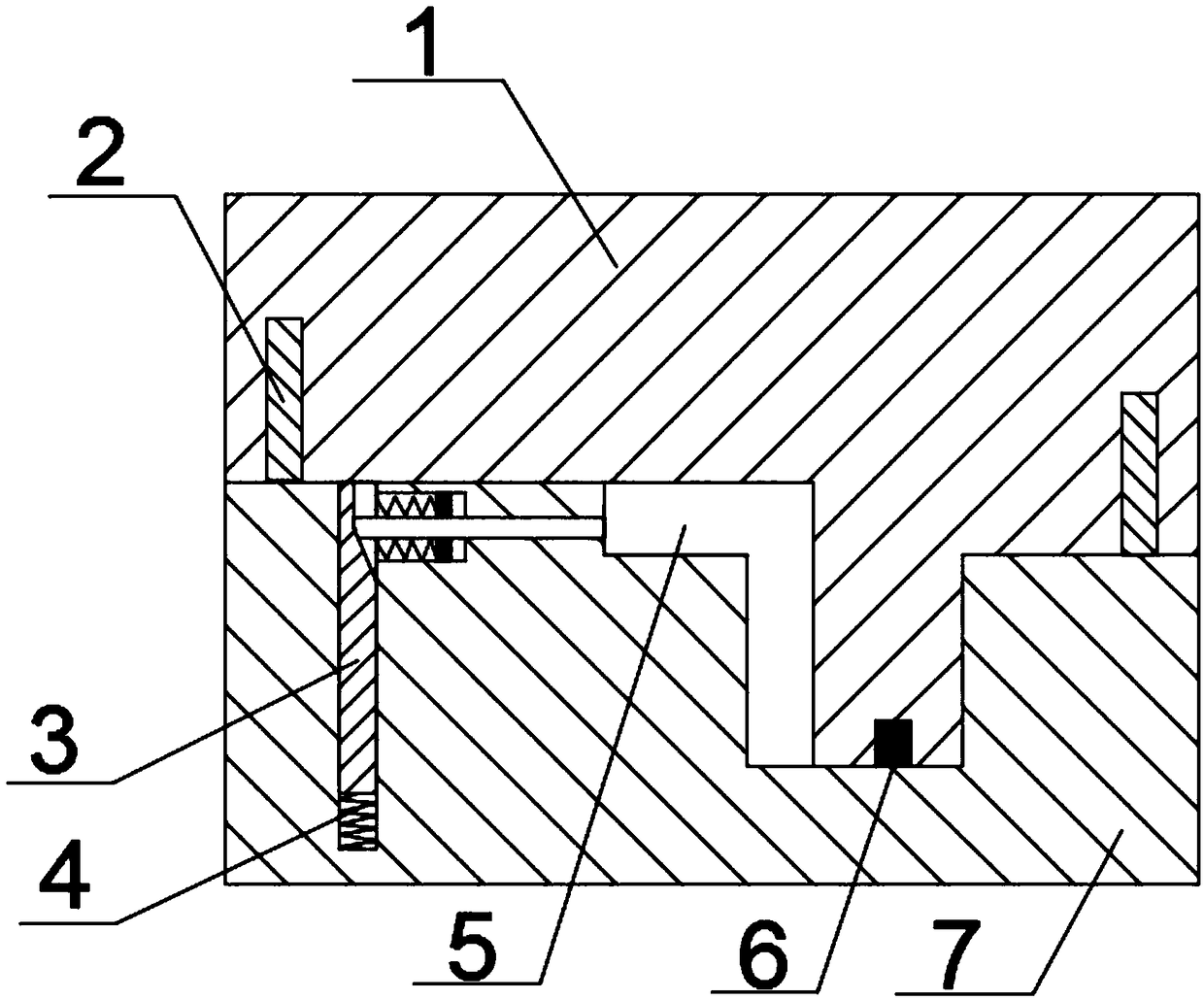

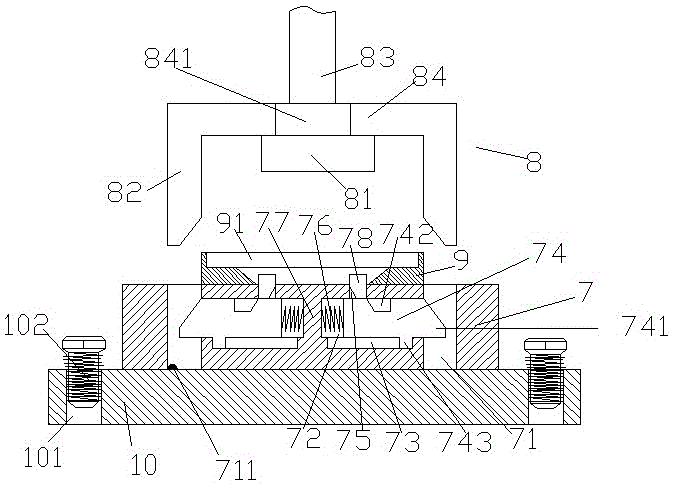

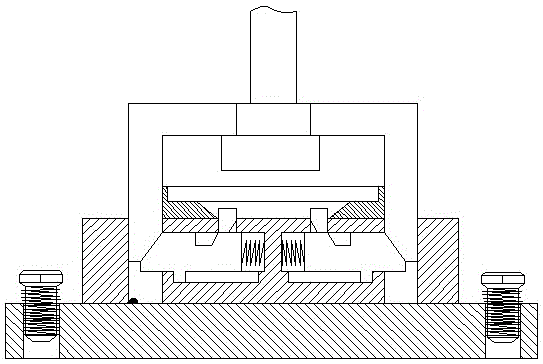

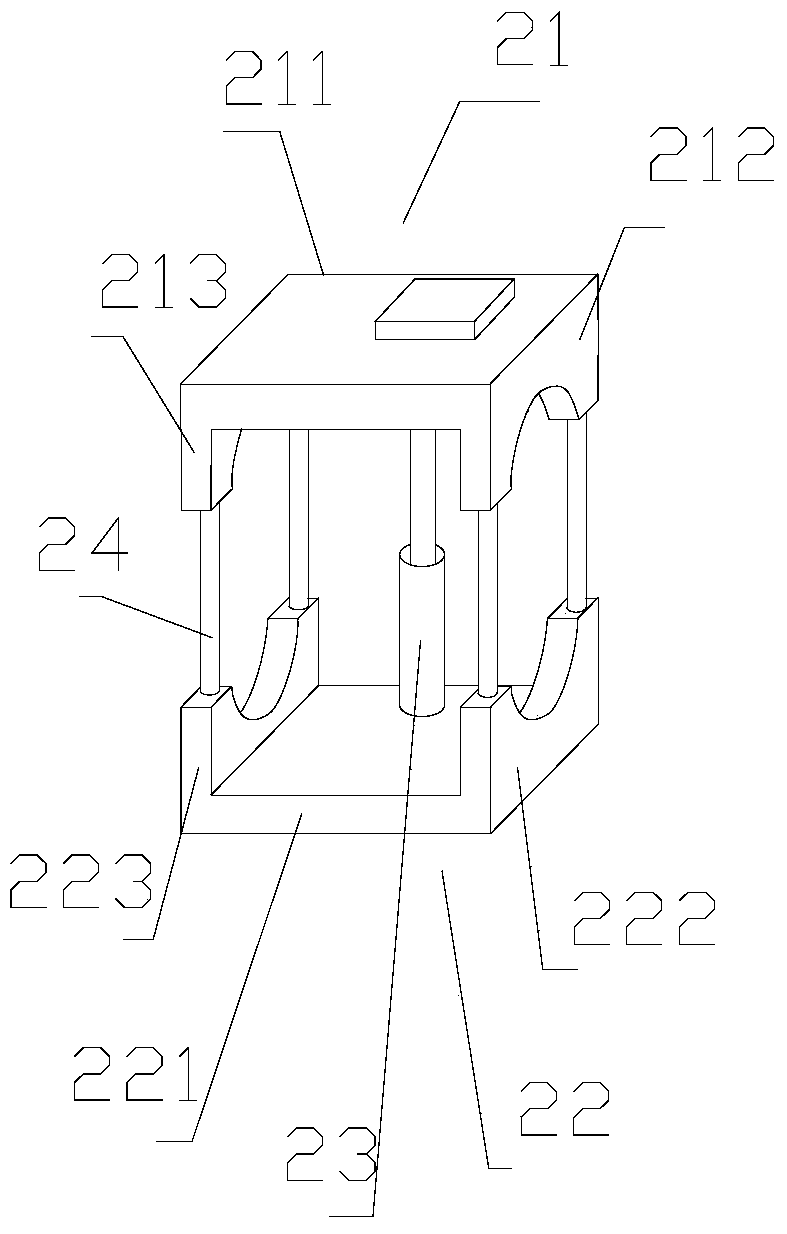

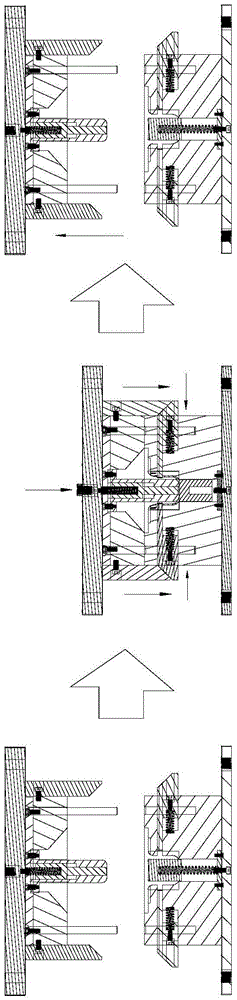

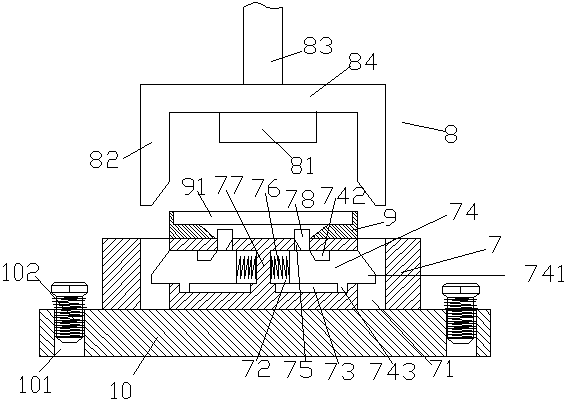

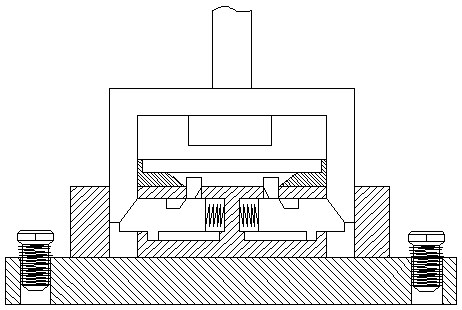

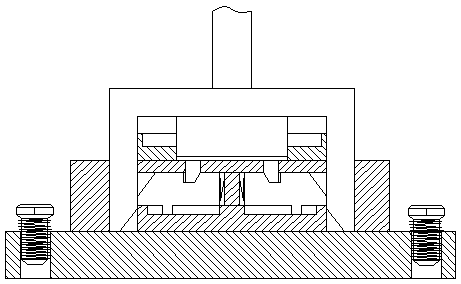

Automatic ejection mechanism and die

InactiveCN107350333ARealize automatic ejectionRealize the collectionMetal-working feeding devicesPositioning devicesEngineeringElastic component

The invention discloses an automatic ejection mechanism and a mold, wherein the automatic ejection mechanism includes an upper template, a lower template, a jacking structure, a fixing structure and an elastic element; wherein, a punch and a driving plate are fixedly arranged on the upper template, The driving plate is provided with a first slope; the lower template is fixedly provided with a cushion block, and a blanking groove is provided on the cushion block; a die is fixedly provided above the backing plate, and a blanking hole is provided on the die; the jacking structure and the falling The trough is slidingly connected, the top material structure is provided with a slide hole, and the slide hole is provided with a second slope that matches the first slope; the fixed structure is fixed on the lower formwork; one end of the elastic element is fixedly connected with the fixed structure, and the elastic element The other end is fixedly connected with the jacking structure. The automatic ejection mechanism and mold provided by the present invention realize the automatic ejection and collection of parts through the cooperation of the first slope and the second slope and the collection box at the ejection end of the parts, thereby saving manpower and improving the production efficiency. Productivity.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

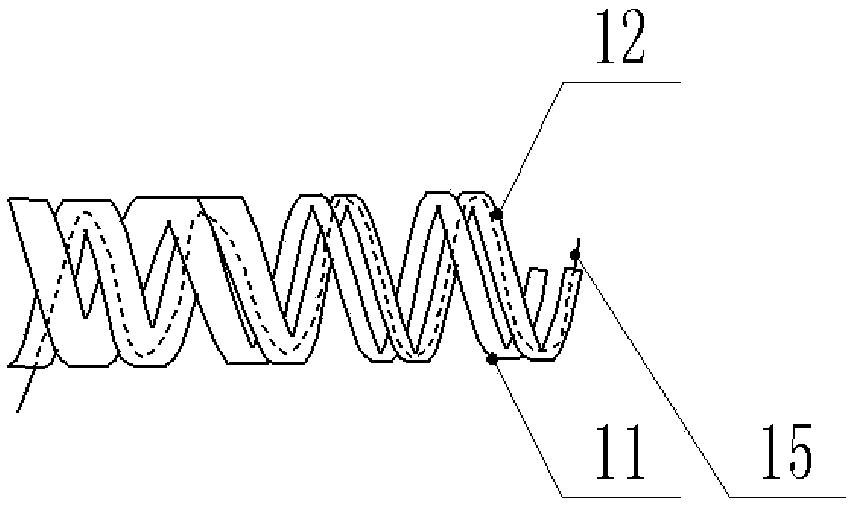

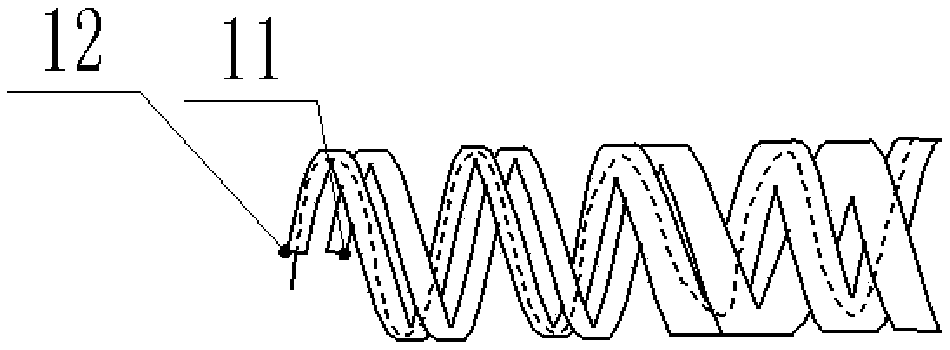

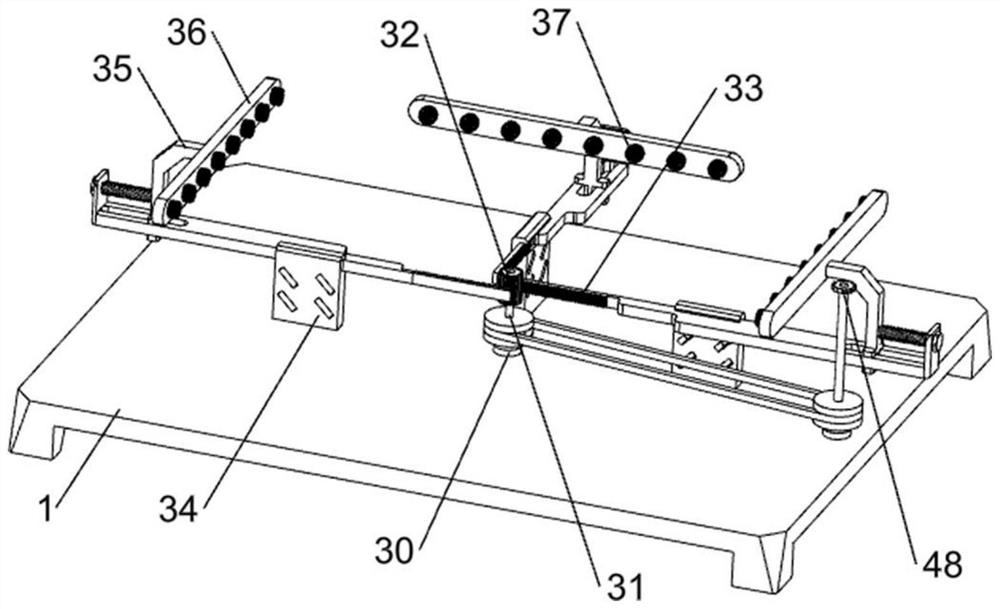

BV line bending and stamping device

The invention discloses a BV line bending and stamping device which comprises a stamping die, a stamping air cylinder and a die fixing and guiding frame. The stamping die comprises an upper die body and a lower die body, the lower die body is installed at the lower portion of the die fixing and guiding frame, the upper die body is installed at the upper portion of the die fixing and guiding frame, the upper die body moves above the lower die body up and down along the die fixing and guiding frame, and the tail end of the stamping air cylinder is fixedly connected with the top of the upper die body; and BV line containing grooves are formed in the top face of the lower die body and a downward-recessed through groove is formed below the BV line containing grooves, wherein a bending space is formed through the downward-recessed through groove when BV lines are stamped. The BV line bending and stamping device is designed to meet the requirement for bending of the BV lines in batches, the device can be suitable for bending the BV lines of different length specifications by arrangement of dies of different structures, use is flexible, the application range is wide, the BV lines of various specifications can be bent in batches, production cost is reduced, and the labor intensity of operators can be lowered.

Owner:昇辉控股有限公司

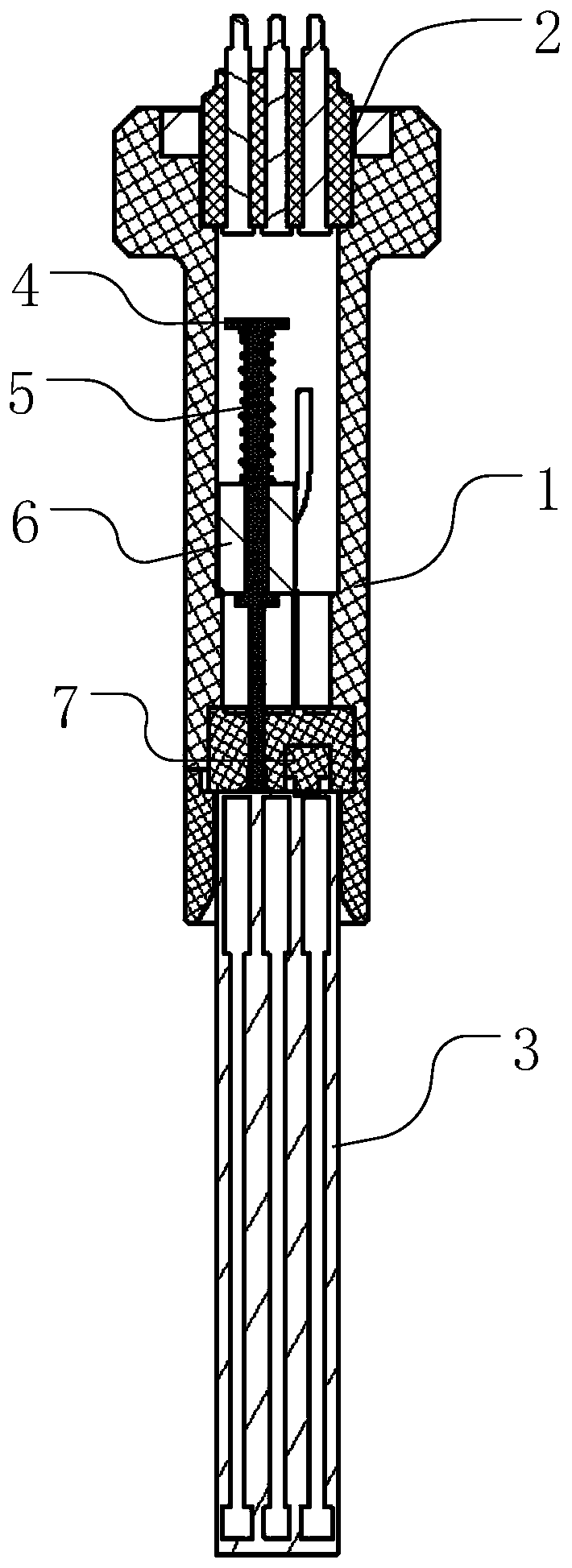

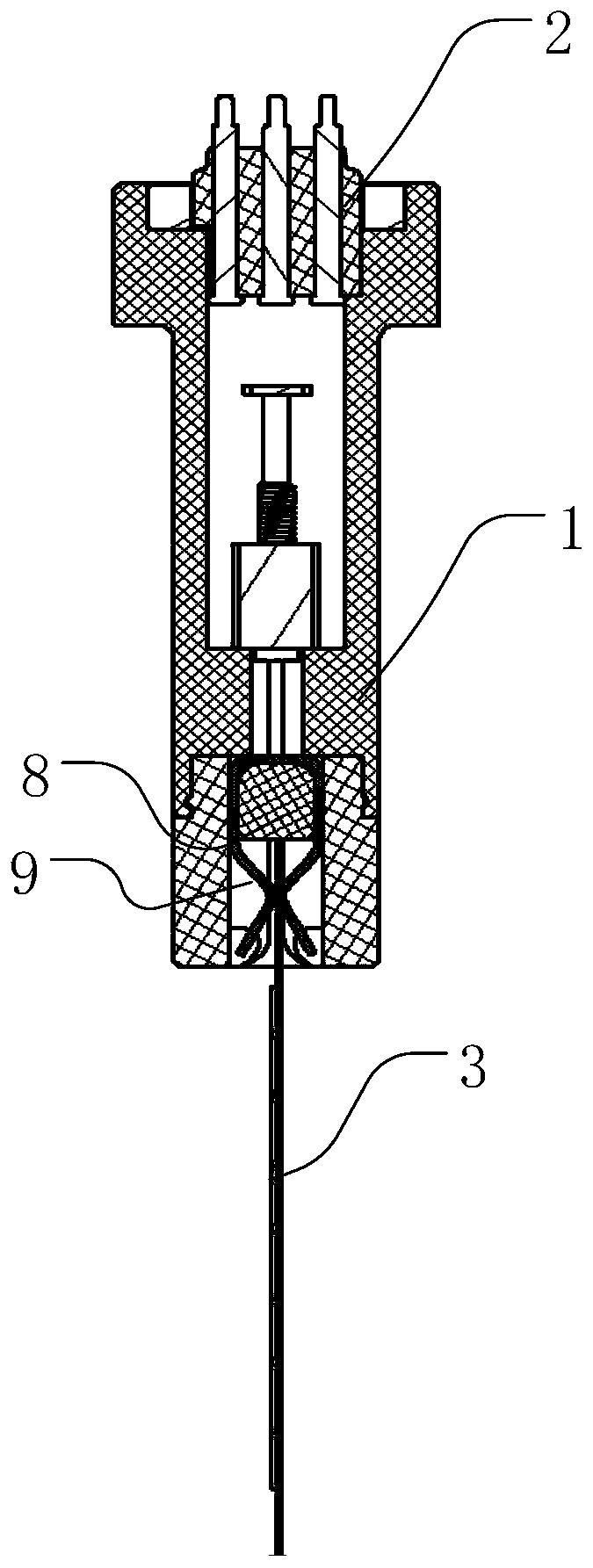

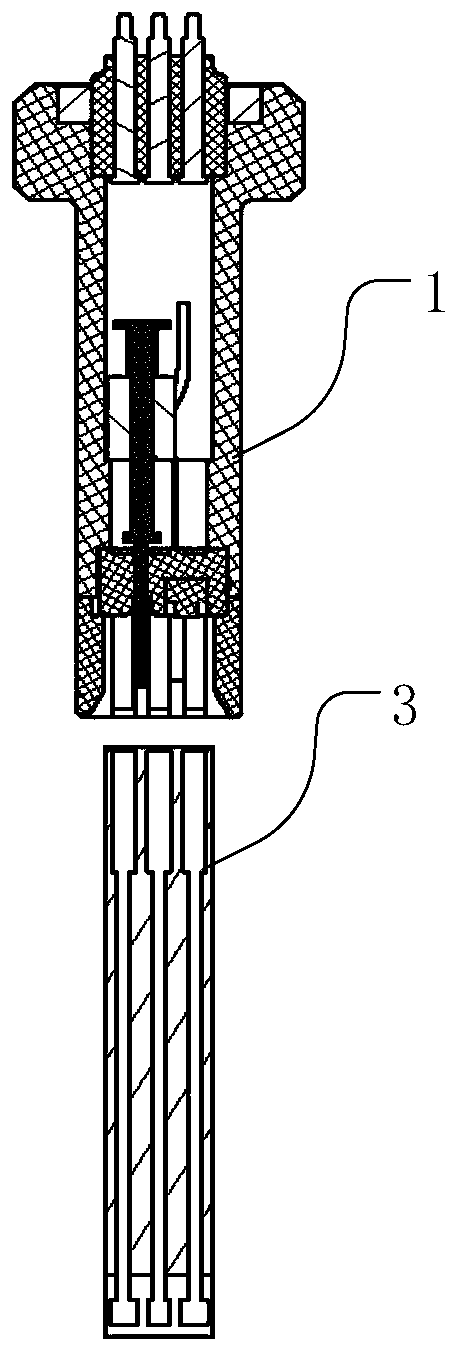

Electric pop-up electrode rod and vitamin detector employing electrode rod

PendingCN110568032AImprove efficiencyRealize automatic ejectionMaterial electrochemical variablesBiochemical engineeringPush pull

The invention belongs to the field of electrochemical detection, and relates to an electric pop-up electrode rod and a vitamin detector employing the electrode rod. The electric pop-up electrode rod comprises an electrode rod and an electrode plate, wherein the electrode plate is inserted onto the electrode rod, a pin is arranged at one side, far away from the electrode plate, of the electrode rodand is used for connecting external equipment, the electrode plate is connected to the electrode rod by an elastic sheet, a bayonet is arranged on the elastic sheet, the electrode plate is inserted into the bayonet, the elastic sheet is connected with a push rod arranged in the electrode rod, a push-pull electromagnet is arranged at one end, far away from the elastic sheet, of the push rod, the push rod props against the electrode plate, and the electrode plate is jacked out of the elastic sheet through driving the push rod by the push-pull electromagnet. The vitamin detector comprises the electrode plate and an analyzer. Electrochemical detection is performed by combination of the repeated electrode rod and the disposable electrode plate, the electrode plate is not needed to be polishedand recycled, and the application efficiency can be improved.

Owner:重庆东渝中能实业有限公司

Slice baking machine

InactiveCN111264573ARealize automatic ejectionRealize automatic demouldingOil/fat bakingPancakes bakingMechanical engineeringPhysics

The invention relates to the field of steamed bun slice processing equipment, and discloses a slice baking machine which comprises a rack, a furnace body and a furnace cover, a partition plate is arranged in the furnace body, and the partition plate divides the furnace body into a pair of slice baking cavities; sliding seats are vertically arranged on the two sides of the rack, a sliding frame isarranged between the pair of sliding seats, a supporting plate is arranged on the sliding frame, a plurality of ejector rods are vertically arranged on the supporting plate, and through holes allowingthe ejector rods to slide are formed in the furnace body in a penetrating mode. Sliding rods are arranged on the two sides of the sliding frame, and sliding holes are vertically formed in the slidingseats. Supporting blocks are arranged on the two sides of the furnace cover, guide rods are vertically arranged on the supporting blocks, and push rods used for abutting against the lower end faces of the sliding rods are arranged on the inner walls of the lower ends of the guide rods. Compared with the prior art, the slice baking machine has the following advantages and effects: the ejector rodsare controlled to move upwards or downwards by opening and closing the furnace cover to realize automatic ejection of formed steamed bun slices, so that automatic demolding of the steamed bun slicesis realized, the labor intensity of workers is reduced, and the production efficiency of the steamed bun slices is improved.

Owner:湖北卧龙神厨食品股份有限公司

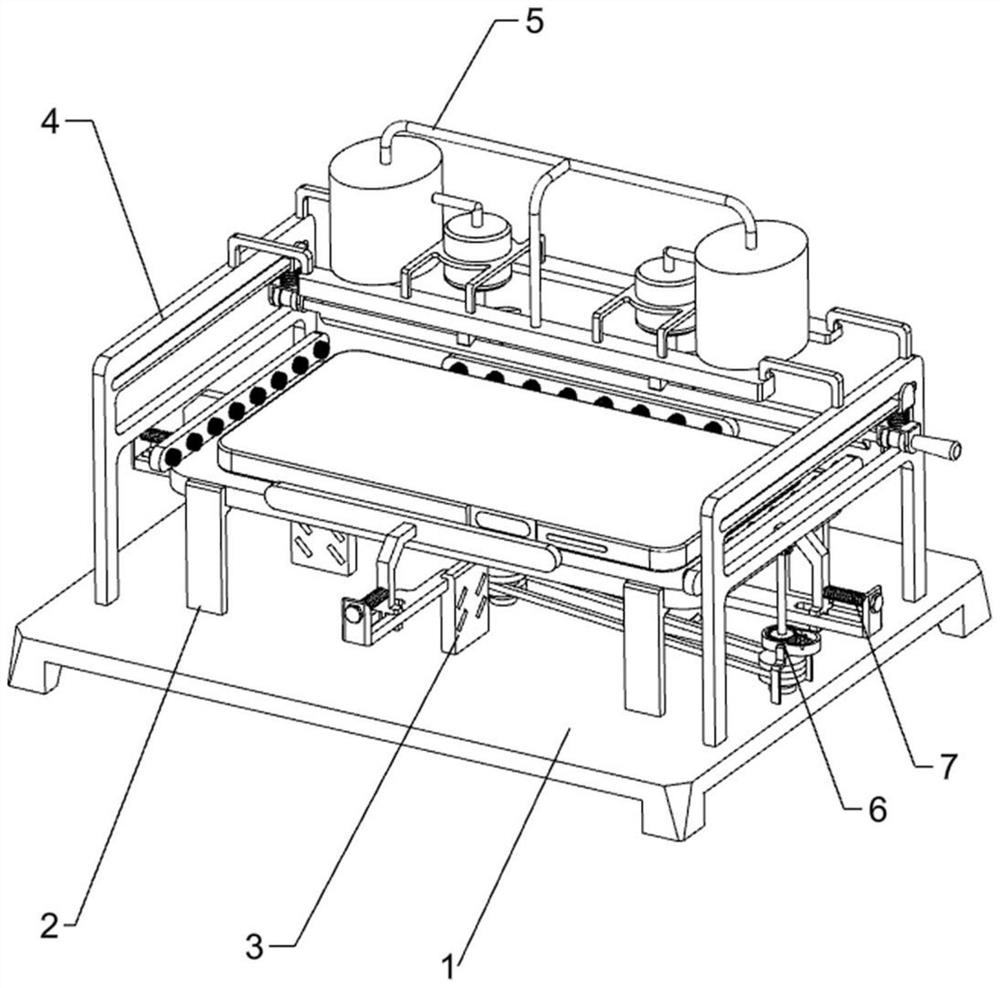

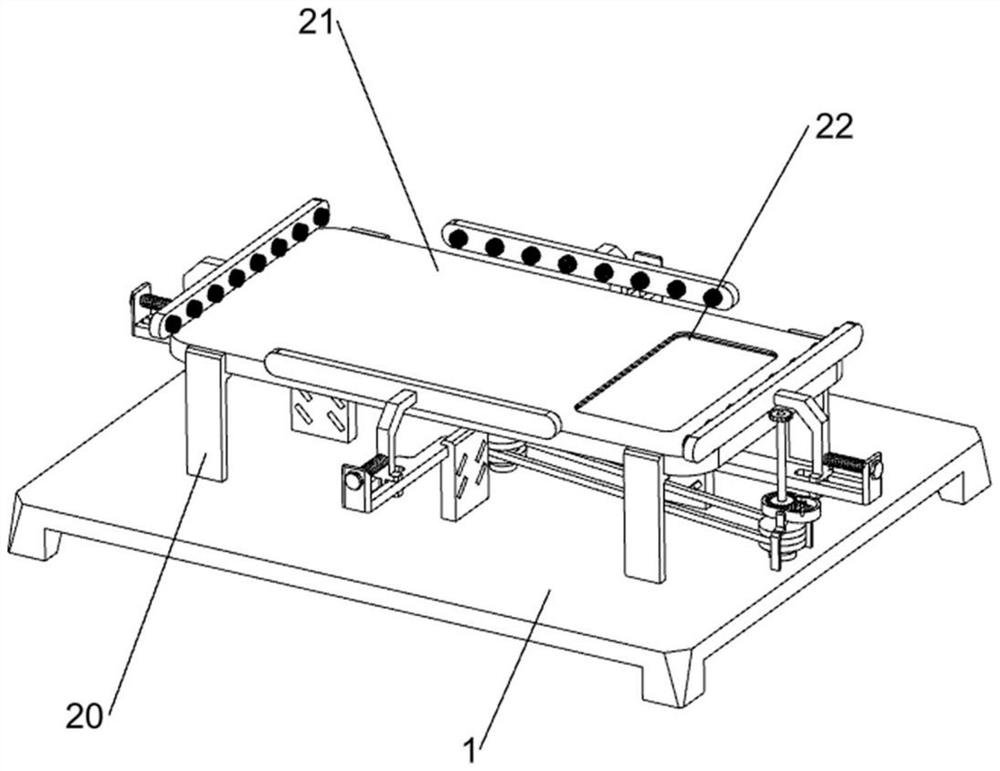

Auxiliary film pasting equipment for mobile phone tempered film

The invention relates to film pasting equipment, in particular to auxiliary film pasting equipment for mobile phone tempered film. The auxiliary film pasting equipment for the mobile phone tempered film can automatically fix a mobile phone, protect a camera and automatically wipe and clean the mobile phone. The auxiliary film pasting equipment for the mobile phone tempered film comprises a bottomplate and a positioning mechanism, and a placing mechanism is arranged on the bottom plate; and the positioning mechanism is arranged on the positioning mechanism and the placing mechanism. The mobilephone is placed through the placing mechanism, and then the mobile phone is clamped under the cooperation of the positioning mechanism, so that clamping of the mobile phone is realized; and by arranging a dust removal mechanism, a mobile phone screen can be wiped, and a dust removal wiper can be tightly attached to the mobile phone through a first spring.

Owner:深圳市唛壳科技有限公司

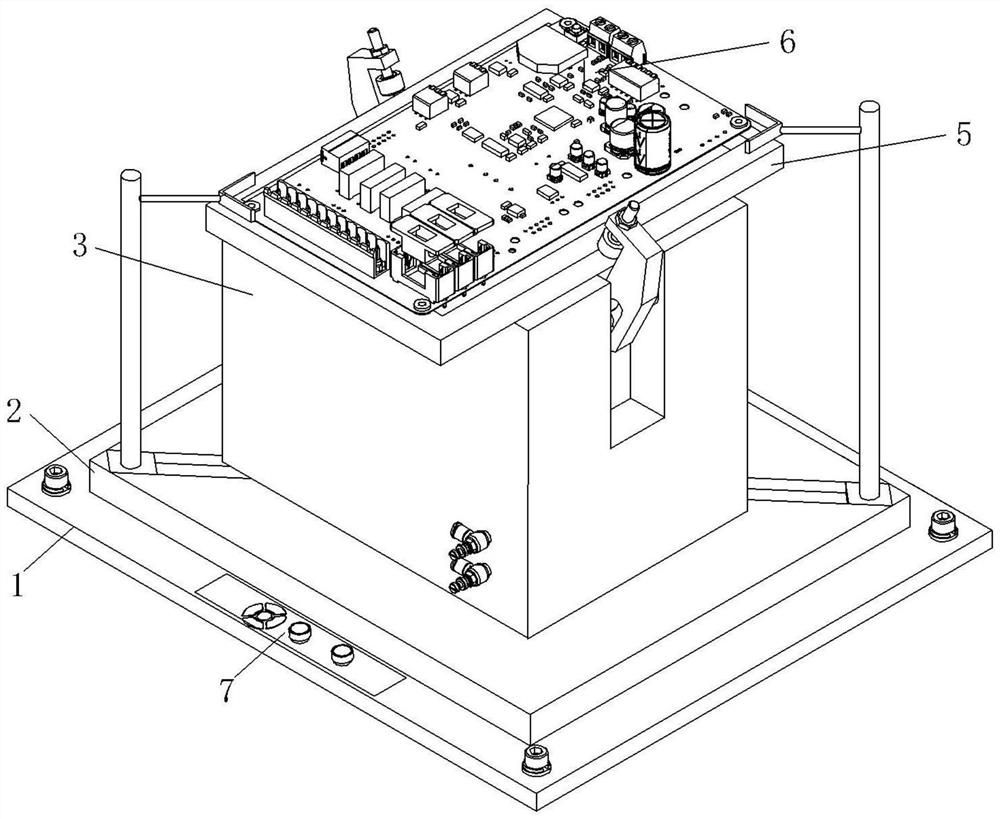

Integrated circuit board element mounting and positioning device

InactiveCN112261782AQuick fixEasy to take outCircuit board tools positioningControl theoryIntegrated circuit

The invention discloses an integrated circuit board element mounting and positioning device which comprises a base, a positioning mechanism, a fixing mechanism, a jacking mechanism, a rectangular frame, an integrated circuit board and a control button. The positioning mechanism is arranged in the center of the top end of the base; the fixing mechanism is arranged in the center of the top end of the positioning mechanism; the jacking mechanism is arranged in the center of the top end of an inner cavity of the fixing mechanism in the vertical direction; the rectangular frame is arranged at the top end of the fixing mechanism; and the integrated circuit board is placed on the upper surface of the rectangular frame in the front-back direction. According to the integrated circuit board elementmounting and positioning device, the positioning accuracy of the integrated circuit board can be guaranteed while rapid positioning and fixing of the integrated circuit board are guaranteed, automaticjacking of the integrated circuit board can be achieved after mounting of the integrated circuit board element is completed, a worker can conveniently hold and take out the circuit board, and loosening of surface elements of the integrated circuit board due to improper holding is avoided.

Owner:汪受喜

A tool for painting walls

InactiveCN106836755BRealize automatic ejectionQuick paintBuilding constructionsAutomatic controlEngineering

The invention provides a tool for wall painting, and relates to the field of decorating tools. The tool for wall painting is exquisite in structure, easy and convenient to operate and good in sealing effect, and the material utilization rate can be increased through automatic control over a piston. The tool for wall painting comprises a handrail, a roller and a connecting assembly. The roller is connected to one side of the handrail through the connecting assembly and is perpendicular to the handrail. The handrail comprises an inner rod body, an outer sleeve body, the piston, a sealing pad, a connecting rod, a suction nozzle and a spray head, wherein the inner rod body is hollow, and one end of the inner rod body is connected with the connecting assembly. When the tool for wall painting is in use, an operator can place the suction nozzle into a paint barrel firstly and pull the outer sleeve body outwards at the same time, so that paint is sucked into the inner rod body; and then the inner rod body or the outer sleeve body is repeatedly waved on a wall in the same direction, so that the paint is sprayed out automatically, and the wall is painted rapidly. By adoption of the tool for wall painting, the utilization rate of the paint is effectively increased, and environmental pollution during construction is reduced.

Owner:王子睿

Movable color steel tile cleaning machine for construction industry

InactiveCN112588657AReduce workloadRealize automatic movementCleaning using toolsRoof toolsConstruction industryProcess engineering

The invention relates to a cleaning machine, in particular to a movable color steel tile cleaning machine for the construction industry. The technical problem to be solved is to provide the movable color steel tile cleaning machine for the construction industry, which can realize automatic cleaning and is time-saving and labor-saving. The movable color steel tile cleaning machine for the construction industry comprises a base, a mounting block arranged at one side of the top of the base, a moving mechanism arranged on the base, and a cleaning mechanism arranged on the base. Through cooperationof the moving mechanism, the cleaning mechanism and a lifting mechanism, the equipment can be automatically moved, meanwhile, the color steel tiles are automatically and continuously cleaned, so thatthe workload of people can be reduced; and through cooperation of a flushing mechanism and a liquid discharging mechanism, water can be automatically sprayed out, and meanwhile, cleaning liquid automatically flows out to clean the color steel tiles.

Owner:高雄

A food cutting device

ActiveCN106863459BImprove stabilityEasy to replaceMetal working apparatusEngineeringMechanical engineering

The invention discloses a food cutting device which comprises a cutting piece and a cutting frame arranged at the lower end of the cutting piece. The cutting piece internally comprises a transverse rod, a cutting module and a transmission rod, the two sides of the transverse rod are each fixedly provided with a downwards-extending insertion rod, a cutting base arranged opposite to the cutting module is arranged at the top end of the cutting frame, insertion holes are formed in the positions, opposite to the lower ends of the insertion rods, in the cutting frame, sliding grooves arranged in a left-and-right equal manner are formed in the positions, between the insertion holes, in the cutting frame, and a stopping block fixedly connected with the cutting frame is arranged between the sliding grooves; the top end of each sliding groove is provided with a hole groove penetrating the outer wall of the cutting frame and communicated with the bottom end of the interior of the cutting base, an ejection pin is arranged in each hole groove, and a pushing groove is formed in the bottom end of each sliding groove; and a sliding block is arranged in each sliding groove, an elastic piece is arranged between each sliding block and the corresponding stopping block, and an ejection pin groove is formed in the top end of each sliding block. The food cutting device is simple in structure, automatic separation can be achieved after cutting is finished, the manufacturing cost is low, and maintenance is convenient.

Owner:宿松县佳兴米业有限公司

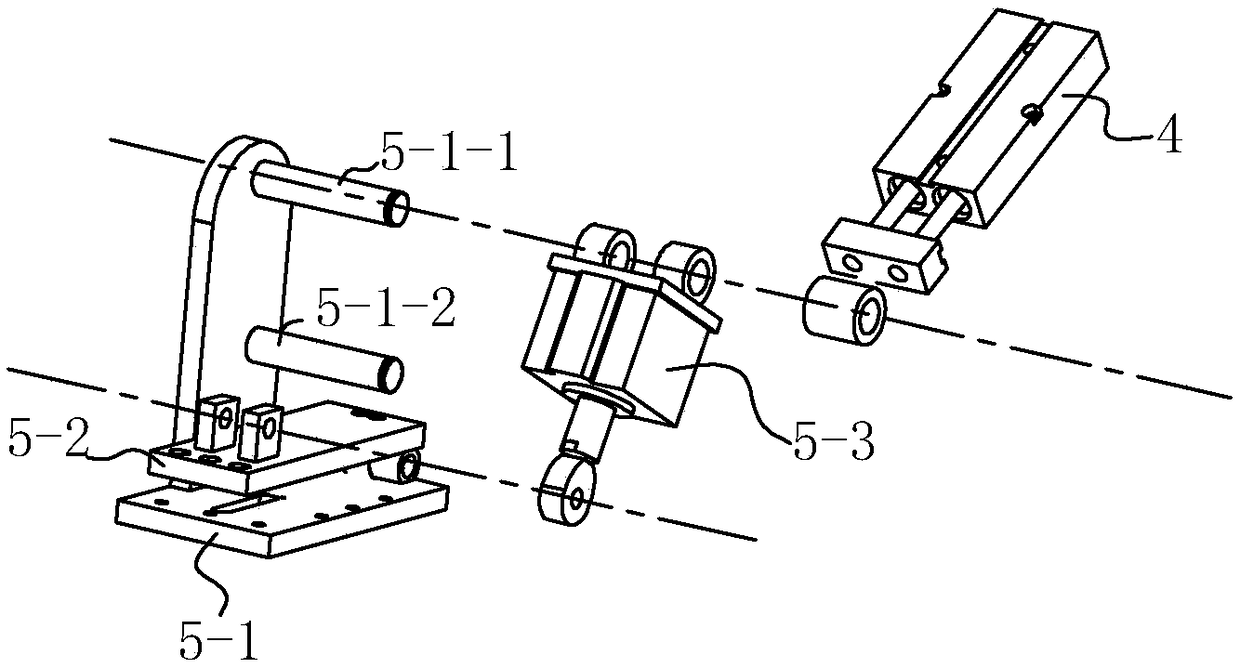

An automatic grinding manipulator

ActiveCN106826422BRealize automatic ejectionRealize automatic collectionGrinding carriagesGrinding drivesControl systemEngineering

The invention discloses an automatic polishing manipulator which is provided with composite structure of normal mechanism structures such as a single-rod air cylinder, a dual-rod air cylinder and a link-slider mechanism. The composite structure is in coordination with a sensor and a control system, so that soft connection of diamond workpiece relative to a grinding wheel can be achieved, bursting of the grinding wheel due to hard contact is avoided effectively, and potential safety hazards are omitted. The automatic polishing manipulator is provided with a movable workbench, a finished-product conveying belt, a finished-product collecting device and a counter, so that automatic operation from clamping to collecting of products can be realized, the conventional manual operation is replaced, counting error is avoided, processing efficiency is improved greatly, and labor cost is saved. The whole processing is carried out in an air-tight environment, diffusion of dust generated during polishing can be avoided effectively and pollution to environment is reduced greatly.

Owner:BEIJING INST OF TECH ZHUHAI CAMPUS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com