A bend pipe forging die with spring material device

A technology of elastic material and pipe bending, which is applied in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machinery, etc., which can solve the problem that the finished pipe cannot be removed from the mold in time, and achieve simple structure , reduce labor intensity and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

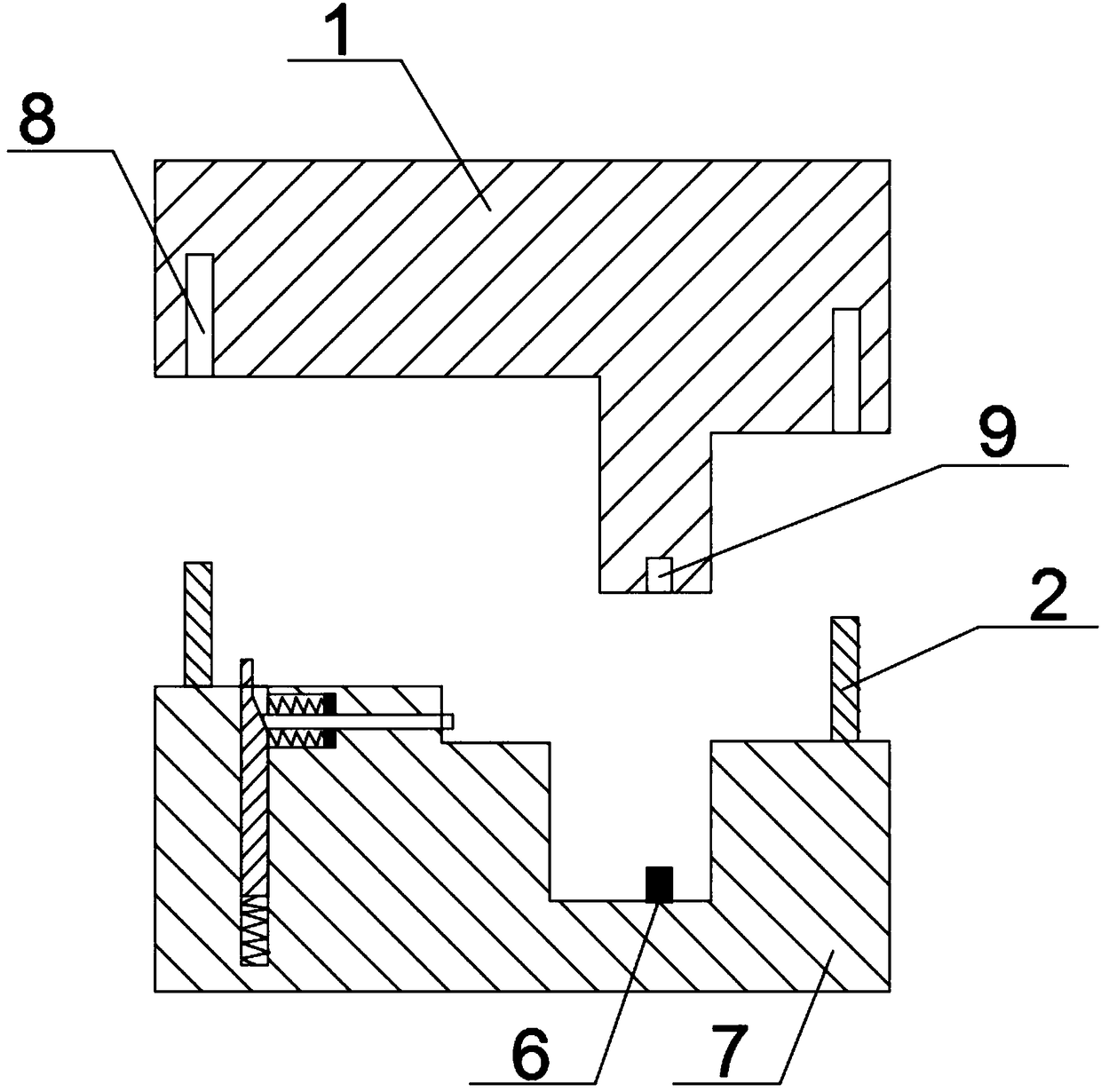

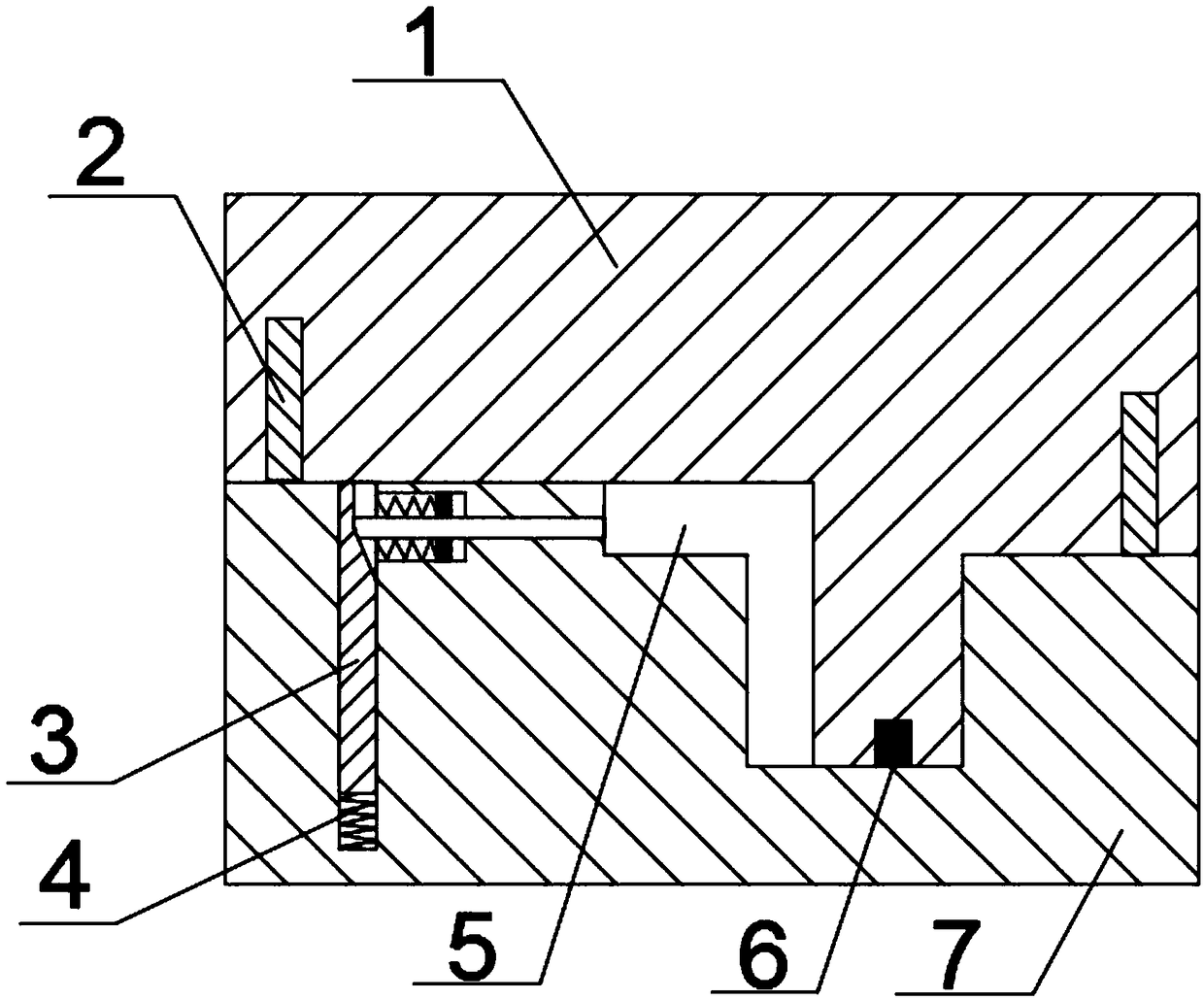

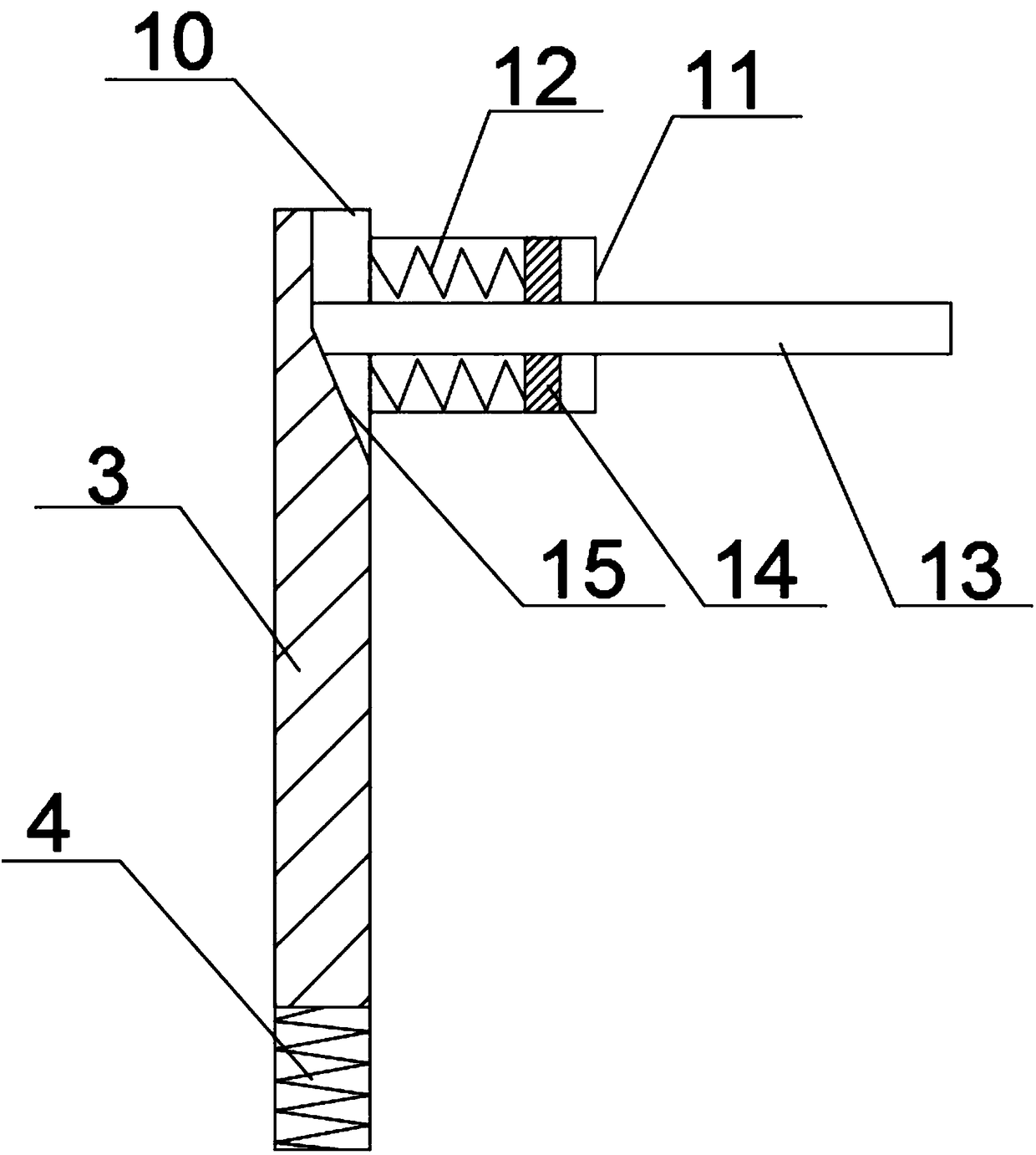

[0024] A bent pipe forging die with an elastic material device, comprising a fixed die 1 and a movable die 7 arranged below the fixed die 1, a convex die is arranged on the forging surface of the fixed die 1, and a forging die is arranged on the forging face of the movable die 7. The concave mold matched with the punch, the punch and the concave mold cooperate to form a forging cavity 5 matching the shape of the elbow; the movable mold 7 is equipped with an elastic material device, and the forging surface of the movable mold 7 has a downward blind hole 10. The spring material device includes a first spring 4 arranged at the bottom of the blind hole 10 and a pressing rod 3 arranged on the first spring 4. The upper end of the pressing rod 3 extends out of the blind hole 10. The upper part of the pressing rod 3 is a wedge-shaped surface 15, wedge-shaped A through hole 11 is opened at the position corresponding to the forging cavity 5, and a push rod 13 cooperating with the wedge-s...

Embodiment 2

[0027] Based on Embodiment 1, the through hole 11 is a stepped hole, and the connecting plate 14 is fixed on the push rod 13 in the stepped hole with a larger diameter, and the connecting plate 14 is connected to the outer wall of the blind hole 10 through the return spring 12 . During demoulding, when the push rod 13 is thrust out of the movable mold 7, the connecting plate 14 moves with the push rod 13, so that the return spring 12 is in a stretched state, and when the forging die is not in use, the push rod 3 can Push against the push rod 13 so that the return spring 12 is always in a stretched state, and when the mold is closed, the depression rod 3 moves down, and the push rod 13 is automatically retracted into the movable mold 7 under the action of the return spring 12 .

Embodiment 3

[0029] Based on the above-mentioned embodiment, the two ends of the movable mold 7 are respectively provided with guide columns 2 extending upwards, and the two ends of the fixed mold 1 are respectively provided with guide grooves 8 matching with the guide columns 2 . During the movement of the movable mold 7 to the fixed mold 1, the guide column 2 enters the guide groove 8 to ensure that the movable mold 7 and the fixed mold 1 will not deviate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com