Special-shaped pipe fitting production line and production process thereof

A special-shaped pipe fitting and production process technology, which is applied to the special-shaped pipe fitting production line and its production process field, can solve the problems of reducing work efficiency, time-consuming and laborious, etc., and achieves the effect of saving power source, reducing cost and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is attached Figure 1-6 The application is described in further detail.

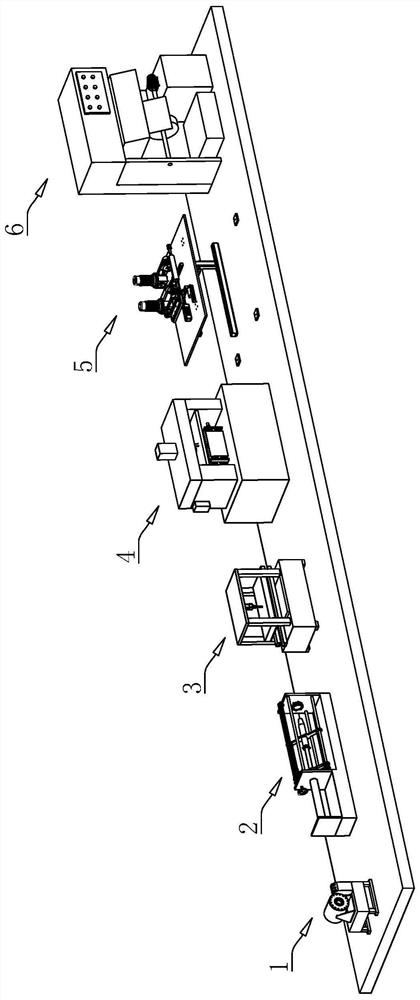

[0046] The embodiment of the application discloses a special-shaped pipe fitting production line. refer to figure 1 , The special-shaped pipe fittings production line includes a tube shrinking machine 1, a drawing machine 2, a pressing device 3, a water swelling forming machine 4, a cutting device 5 and a light-cutting device 6 arranged in sequence.

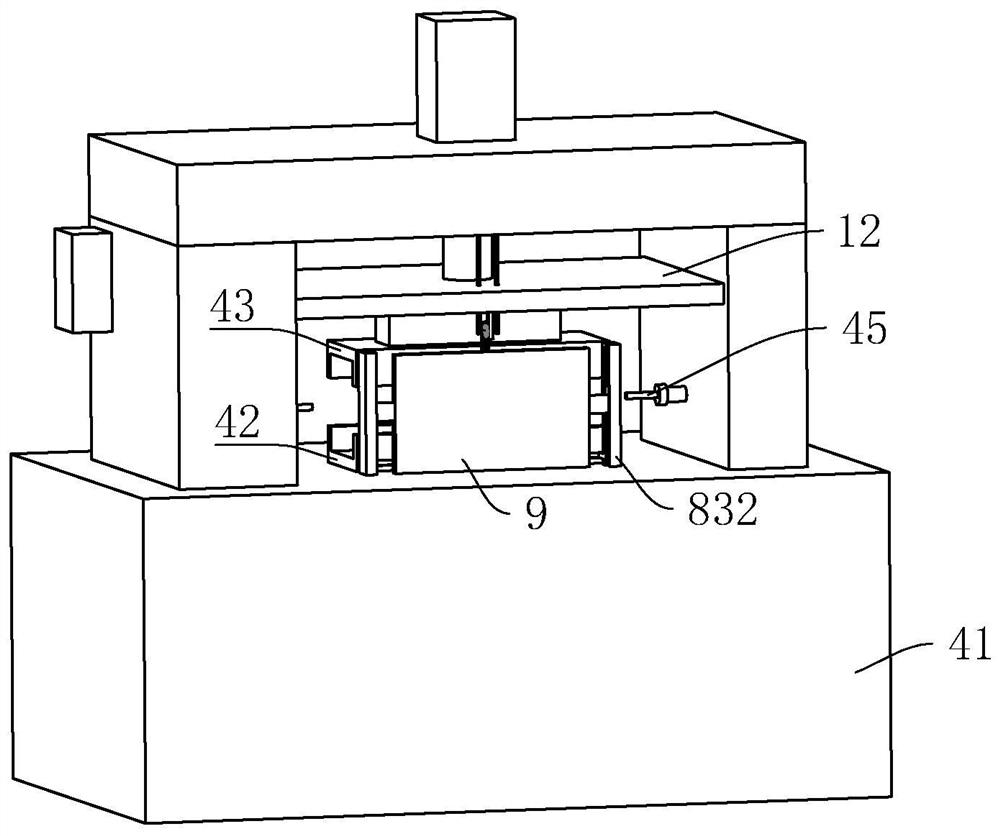

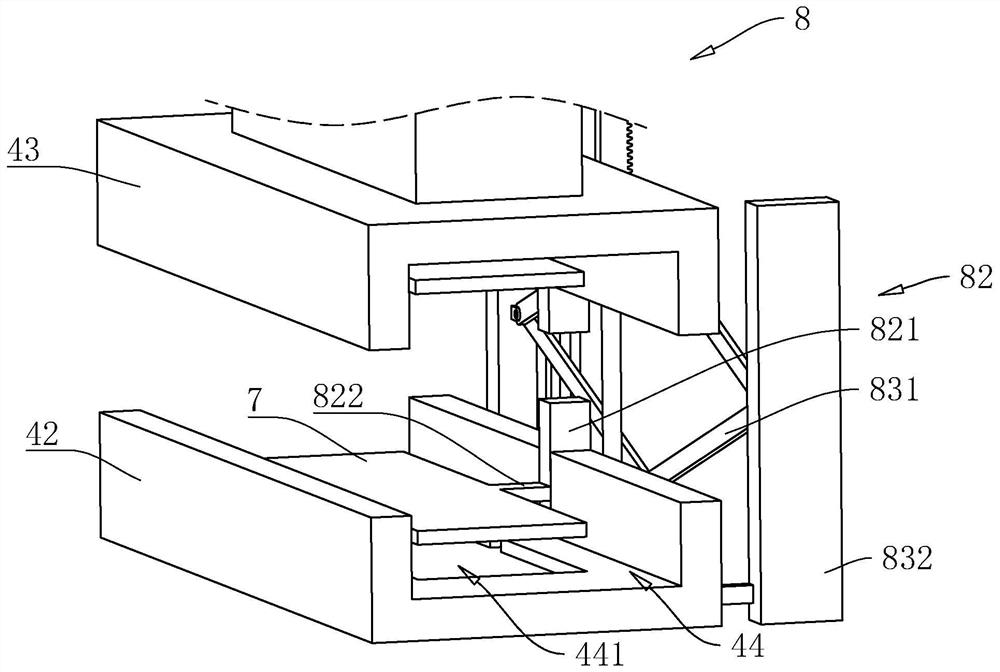

[0047] refer to figure 2 and image 3 The water swelling molding machine 4 includes a frame 41, a lower die 42 fixed on the frame 41, and an upper die 43 that is located directly above the lower die 42 and moves relative to the lower die 42. The frame 41 is fixed with a cylinder, and the cylinder The output end of the output end is fixedly connected with the mounting plate 12 of horizontal layout, and the upper mold 43 is fixed on the lower surface of the mounting plate 12, and the opposite side of the lower mold 42 and the upper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com