Device and method for preparing aluminum-base composite material by using vacuum impregnation andsolid-liquid direct extrusion

An aluminum matrix composite material and vacuum infiltration technology, which is applied in the field of material forming, can solve the problems of high critical infiltration pressure, low density, difficult to guarantee high vacuum degree, etc., so as to improve the performance and density of aluminum matrix composite materials. The effect of improving, improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

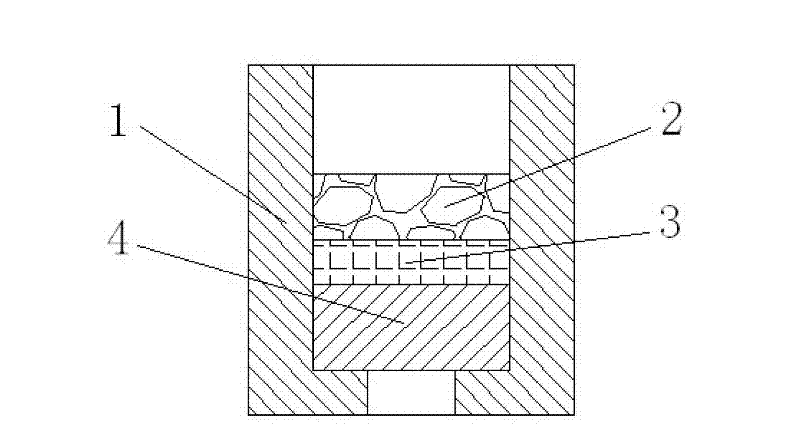

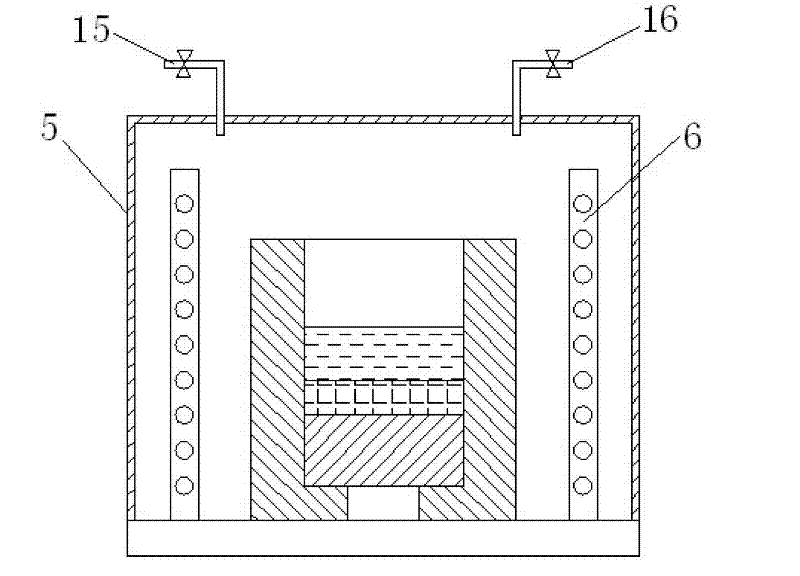

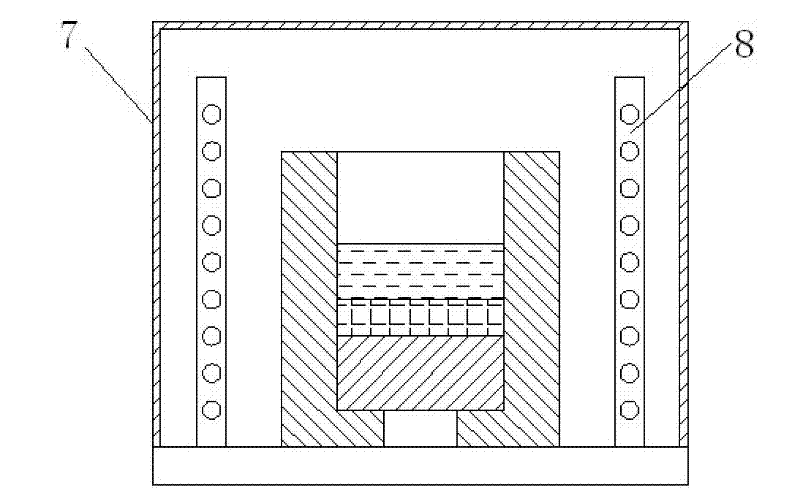

[0028] This embodiment is a vacuum impregnation-solid-liquid direct extrusion device for preparing aluminum-based composite materials, including a melting crucible 1, a top block 4, a punch 9, a bottom pad 10, a push rod 11, a mold support 12, and a mold Overcoat 13 and concave block 14, and the vacuum furnace that is used in conjunction with, electric resistance heating furnace and four-column hydraulic press etc. The melting crucible 1 is placed on the upper surface of the bottom pad 10, and the bottom pad 10 and the mold jacket 13 are directly placed on the mold support 12, and the mold support 12 is fixed on the workbench of the four-column hydraulic press in the test. The top block 4 was placed at the bottom of the inner cavity of the melting crucible 1 before the test. At the center of the mold support 12, the center of the bottom pad 10 and the center of the bottom plate of the melting crucible 1, there are through holes for the ejector rod 11, and the center of the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com