Multi-station hydraulic drawing machine

A stretching machine and multi-station technology, applied in the field of multi-station hydraulic stretching machines, can solve the problems of high energy consumption, reduced production efficiency, reduced production time, etc., and achieves a simple and effective top material system and high quality of processed products. , the effect of high stretching depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

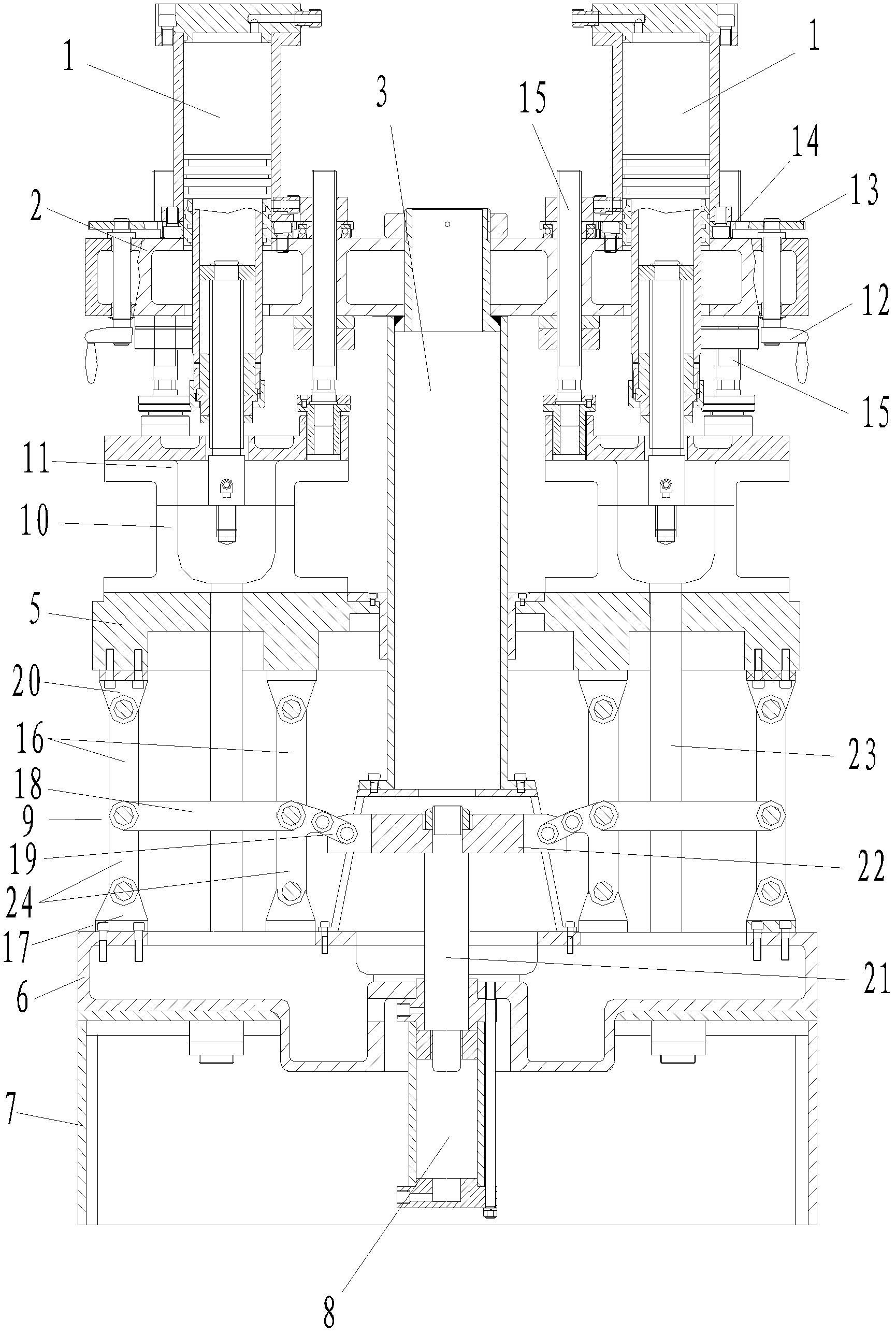

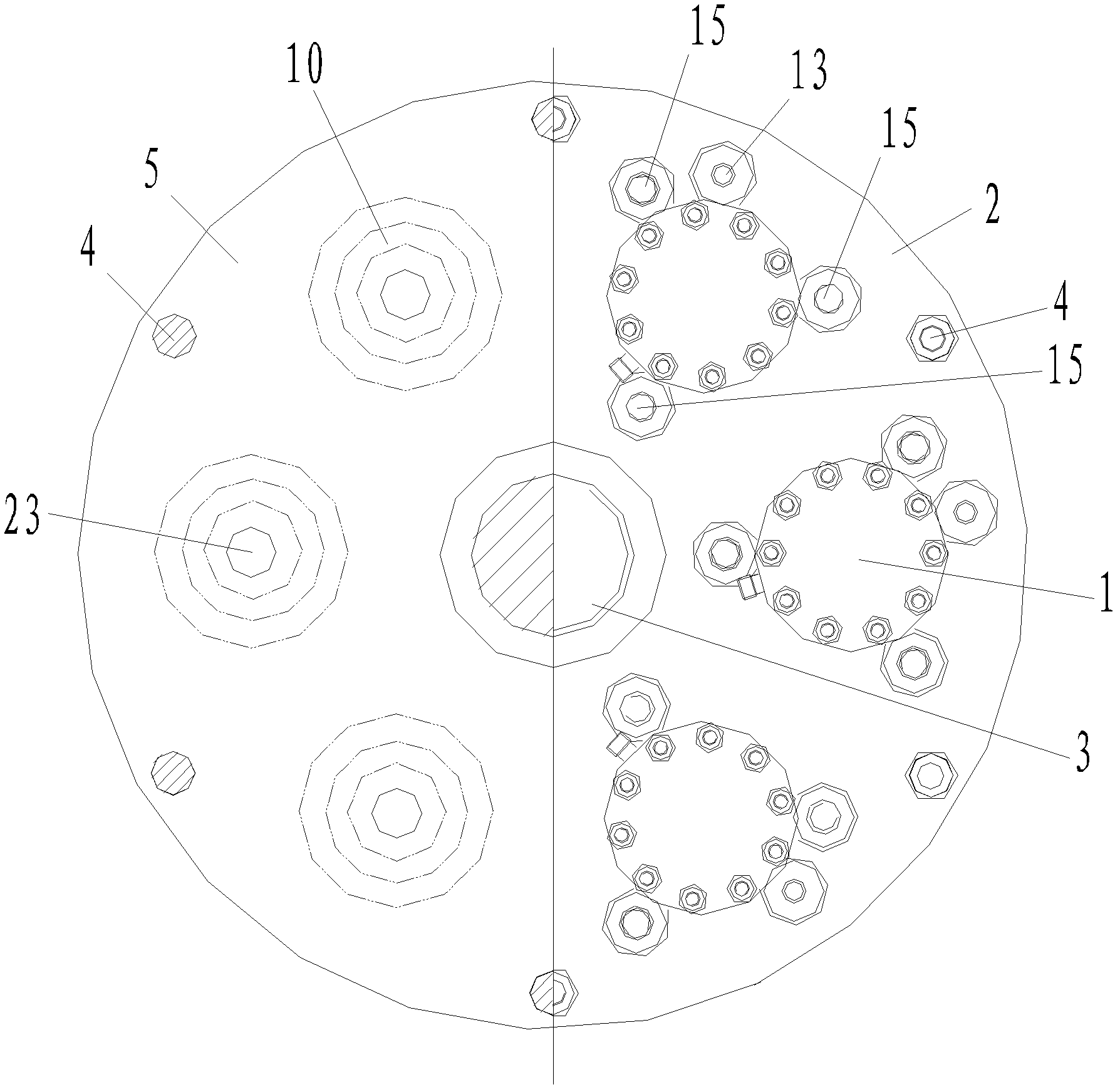

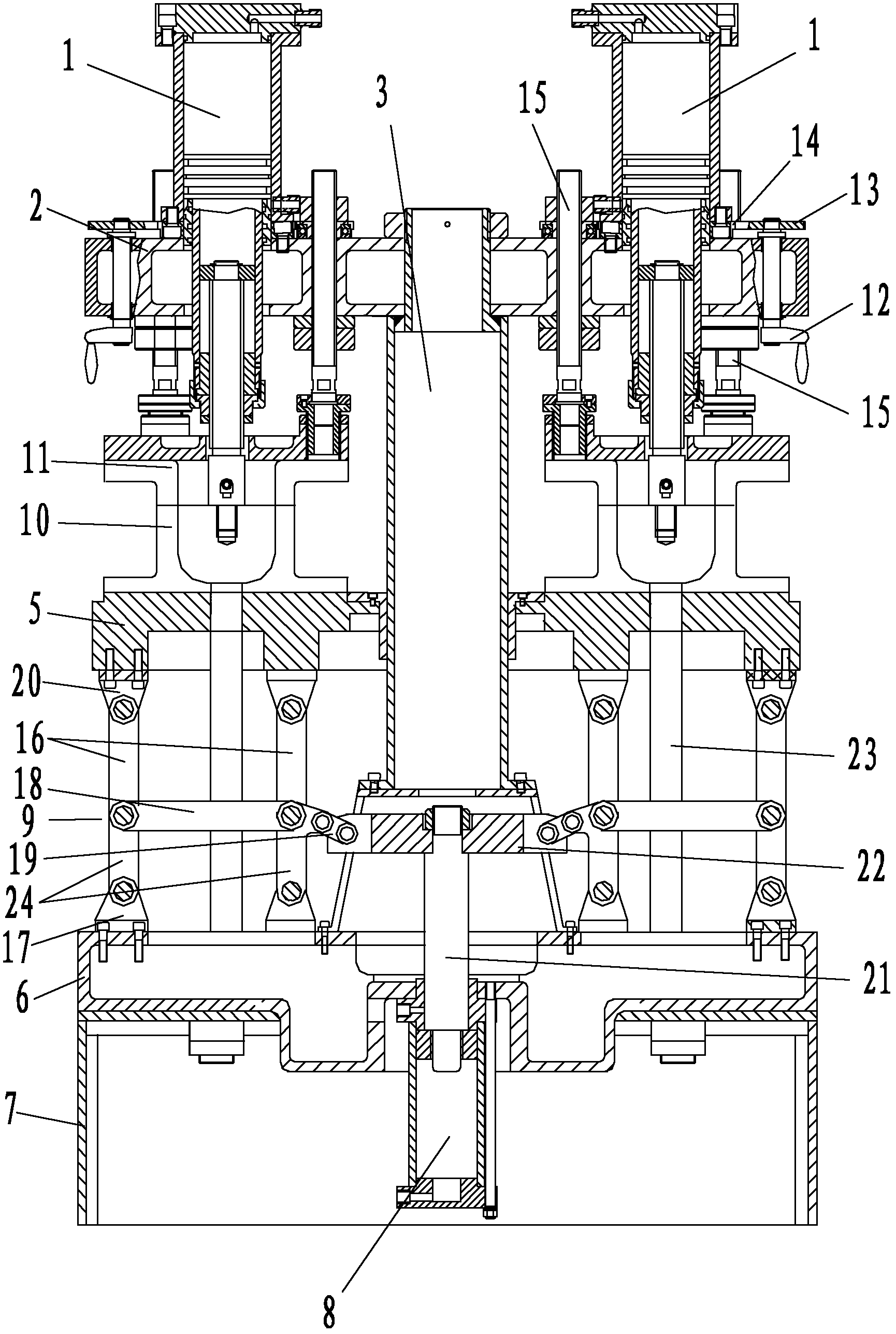

[0016] as attached figure 1 , 2 Shown is that the multi-station hydraulic stretching machine described in the present invention is a six-station hydraulic stretching machine, and six upper hydraulic cylinders 1 are evenly distributed on the upper surface of the upper oil cylinder platen 2 in the circumferential direction; the six-station hydraulic stretcher The machine also includes a base 7 fixed on the ground, a base plate 6 fixed on the base 7, an intermediate column 3 and six circumferential columns 4 are arranged between the upper oil cylinder plate 2 and the base plate 6, and at the same time , the middle column 3 and six circumferential columns 4 support the upper cylinder platen 2 and the worktable 5; the six upper hydraulic cylinders 1 correspond to a mold station on the worktable 5 respectively, and the lower mold 10 is placed on the mold station . The upper oil cylinder platen 2 is provided with six rotatable handwheels 12, the upper part of the handwheel 12 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com