BV line bending and stamping device

A technology of stamping device and stamping die, applied in the field of BV line bending stamping device, can solve the problems of unfavorable production cost control, difficult to use with distribution box, different BV line shapes, etc. , reduce the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

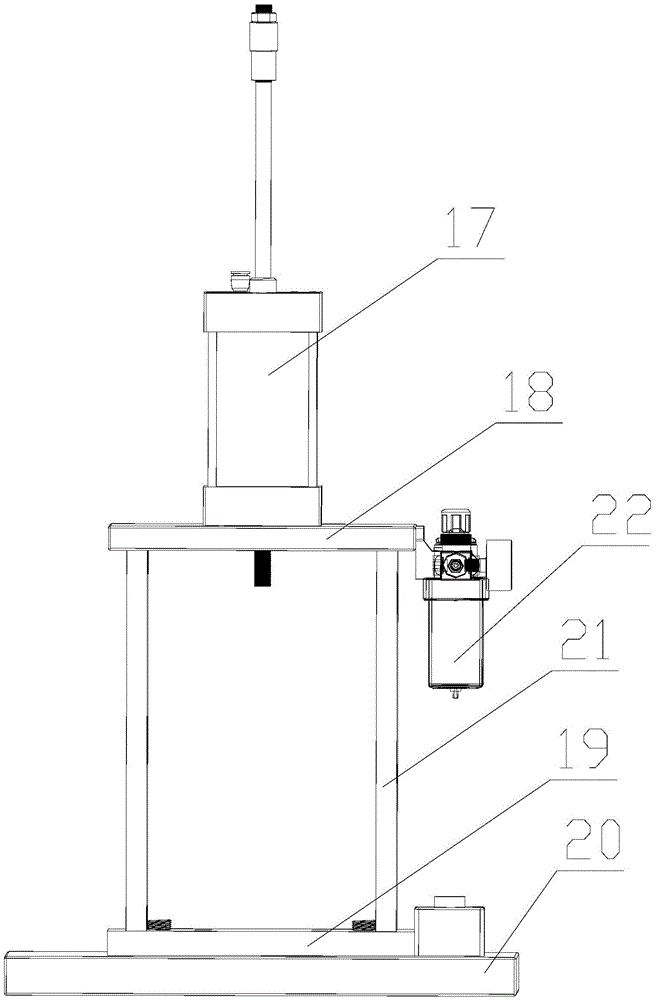

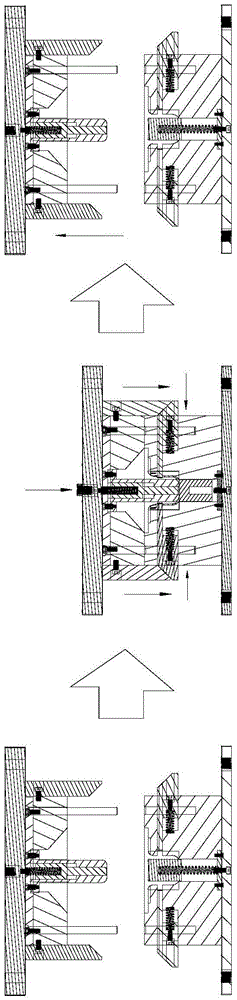

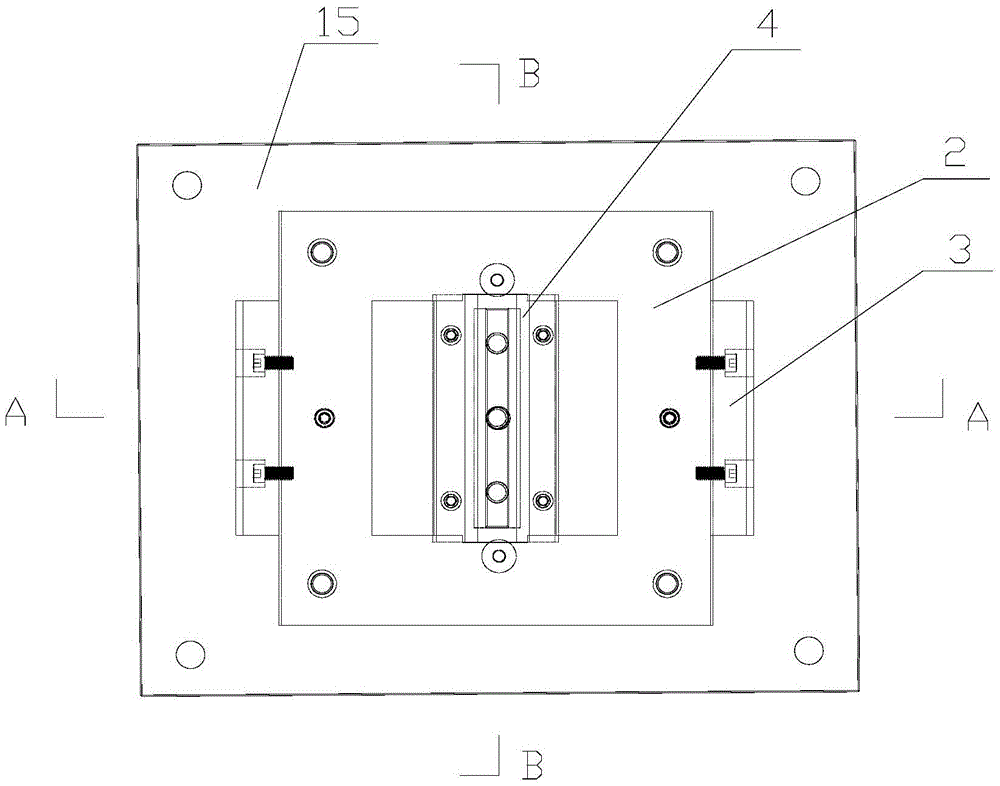

[0046] This embodiment is a BV line bending and punching device, such as figure 1 As shown, including stamping die ( figure 1 Not shown), the punching cylinder 17 and the mold fixing guide frame, the punching mold includes an upper mold and a lower mold, the lower mold is installed on the lower part of the mold fixing guide frame, the upper mold is installed on the upper part of the mold fixing guide frame, and the upper mold is along the mold The fixed guide frame moves up and down above the lower mold, and the end of the punching cylinder is fixedly connected to the top of the upper mold; the top surface of the lower mold is provided with a BV line placement slot, and the BV line placement slot is provided with a bending space for BV line punching 的下孔通槽。 The recessed through slot. The mold fixing guide frame includes an upper mold integral fixing plate 18, a lower mold integral fixing plate 19, a mold fixing chassis 20 and four upper mold guide rods 21. The upper mold guide rod...

Embodiment 2

[0055] This embodiment is a BV line bending and punching device, such as figure 1 As shown, including stamping die ( figure 1 Not shown), the punching cylinder 17 and the mold fixing guide frame, the punching mold includes an upper mold and a lower mold, the lower mold is installed on the lower part of the mold fixing guide frame, the upper mold is installed on the upper part of the mold fixing guide frame, and the upper mold is along the mold The fixed guide frame moves up and down above the lower mold, and the end of the punching cylinder is fixedly connected to the top of the upper mold; the top surface of the lower mold is provided with a BV line placement slot, and the BV line placement slot is provided with a bending space for BV line punching 的下孔通槽。 The recessed through slot. The mold fixing guide frame includes the upper mold integral fixing plate 18, the lower mold integral fixing plate 19, the mold fixing chassis 20, and four upper mold guide rods 21. The upper mold gui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com