An automatic grinding manipulator

A technology of manipulators and workbenches, which is applied in the direction of grinding racks, grinding machine parts, grinding slides, etc., and can solve the problems of grinding wheel bursting, grinding dust diffusion pollution, manual counting errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

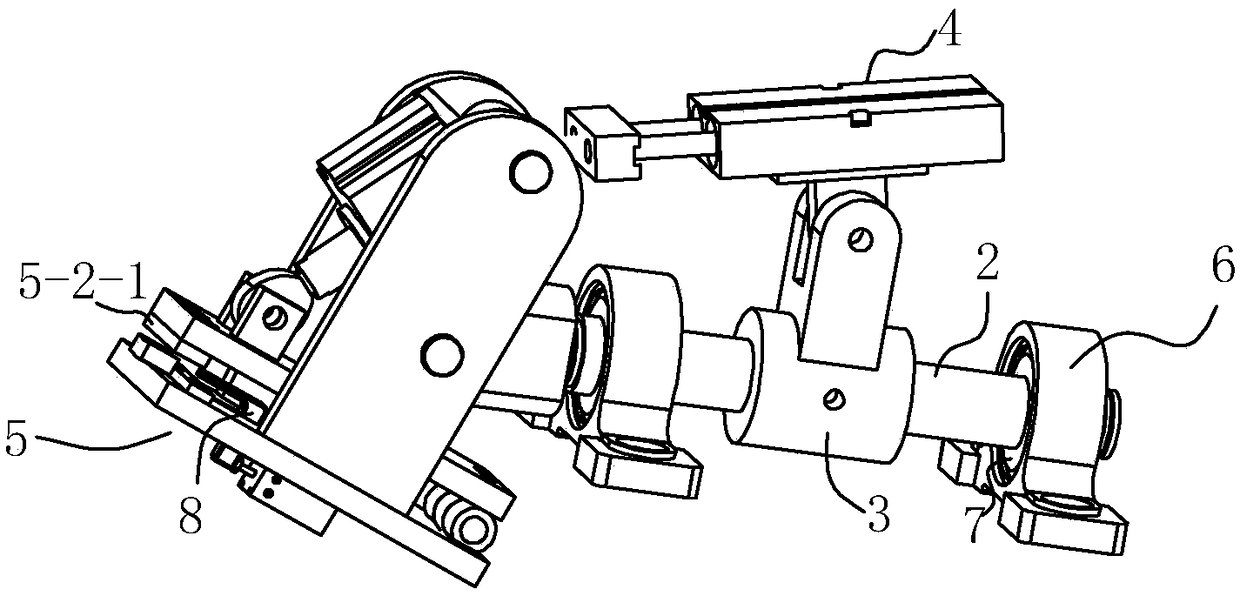

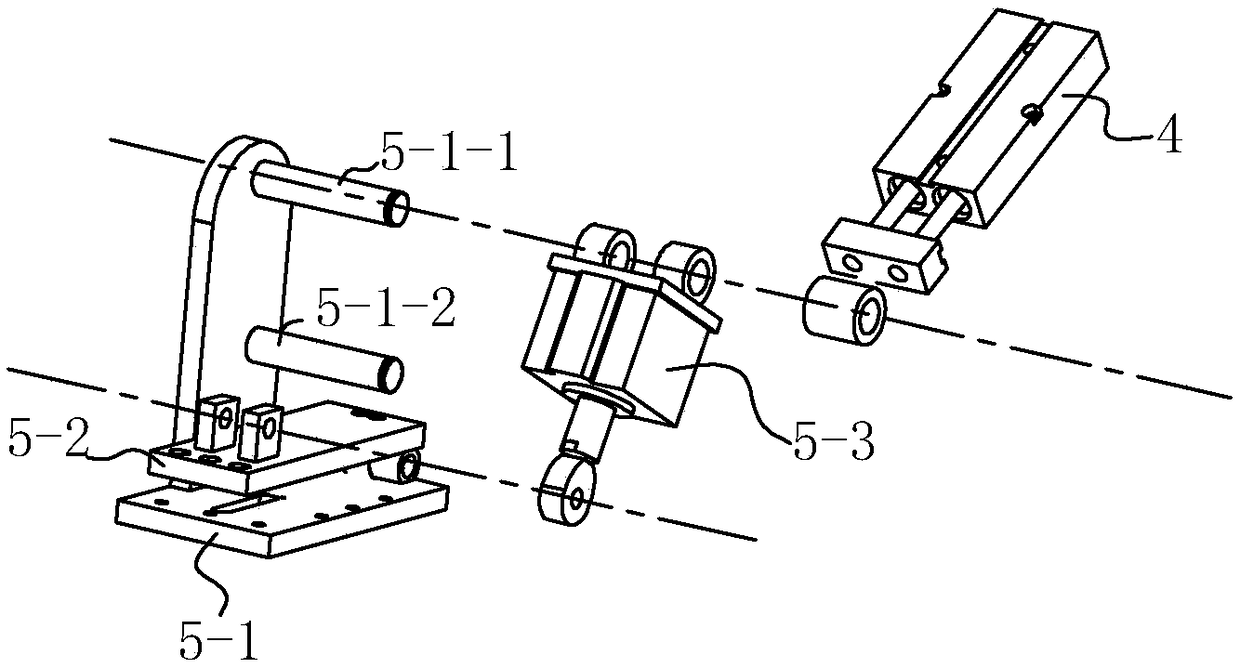

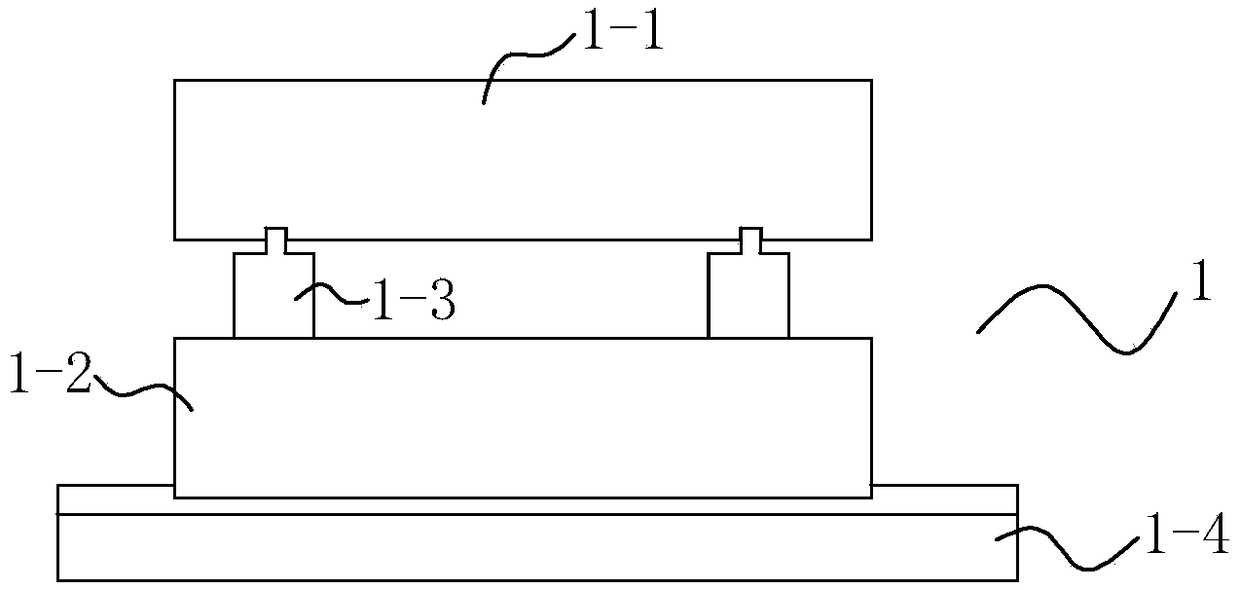

[0021] refer to Figure 1 to Figure 2 , a kind of automatic polishing manipulator of the present invention, comprises workbench 1, and described workbench 1 can move in the horizontal direction, and described workbench 1 is fixedly installed with main shaft 2, and described main shaft 2 is provided with and can move along main shaft 2 Freely sliding slider 3, a double-rod cylinder 4 is arranged above the main shaft 2, one end of the double-rod cylinder 4 is hinged on the slider 3, and the other end of the double-rod cylinder 4 is hingedly provided with a clamp 5 , the clamp 5 includes a base 5-1 and an upper pressing plate 5-2, one end of the upper pressing plate 5-2 is hinged on the base 5-1, and a single-rod cylinder 5-3 is arranged above the upper pressing plate 5-2 , the other end of the upper platen 5-2 is hinged to one end of the single-rod cylinder 5-3, the base 5-1 is fixedly provided with the first shaft 5-1-1 and is arranged on the first shaft 5-1-1 The second shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com