Patents

Literature

31results about How to "Reduce or eliminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial kidney dialysis system

InactiveCN101784292AGood for healthImprove the quality of lifeHaemofiltrationMedical devicesDiseaseMetabolite

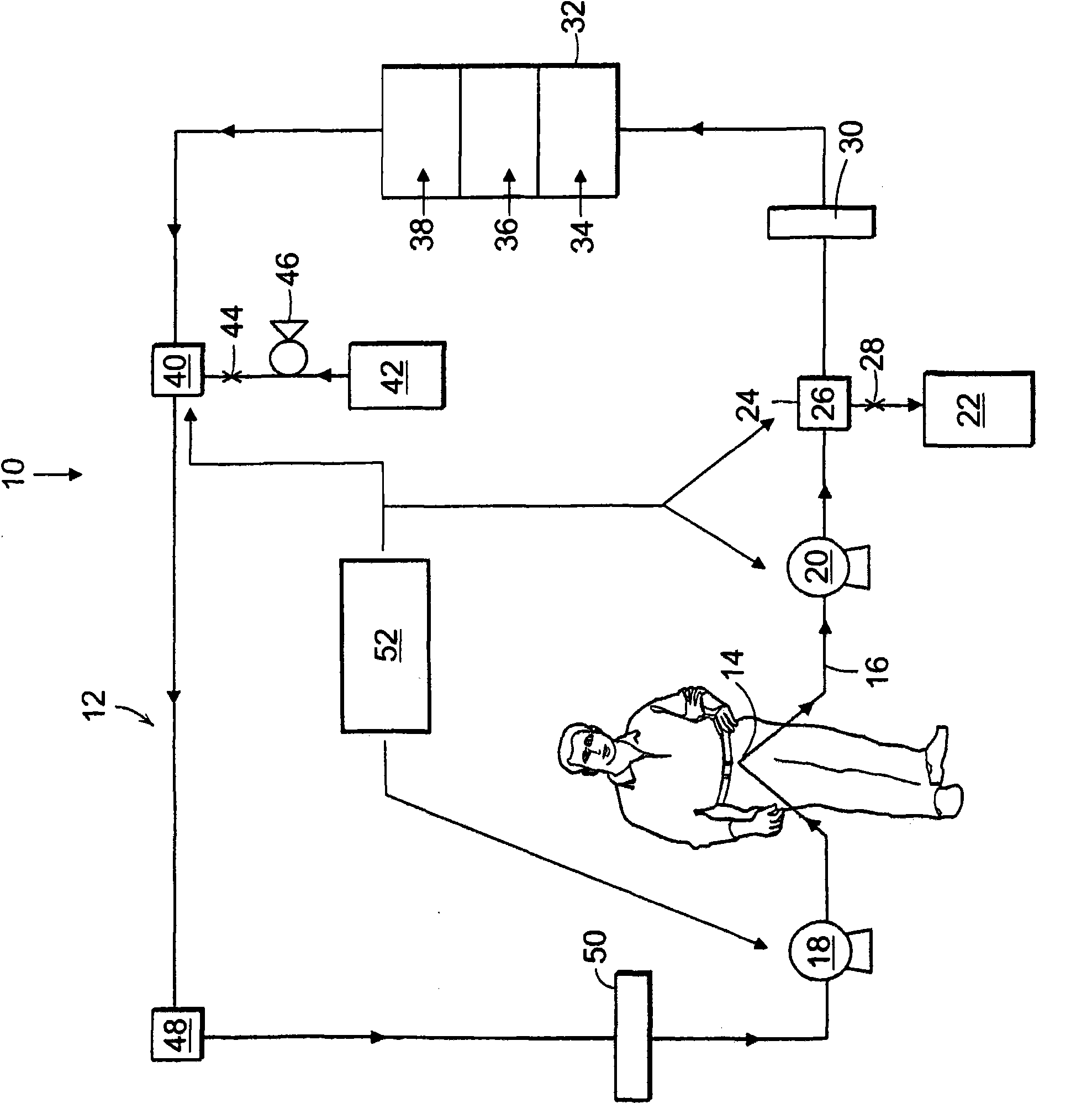

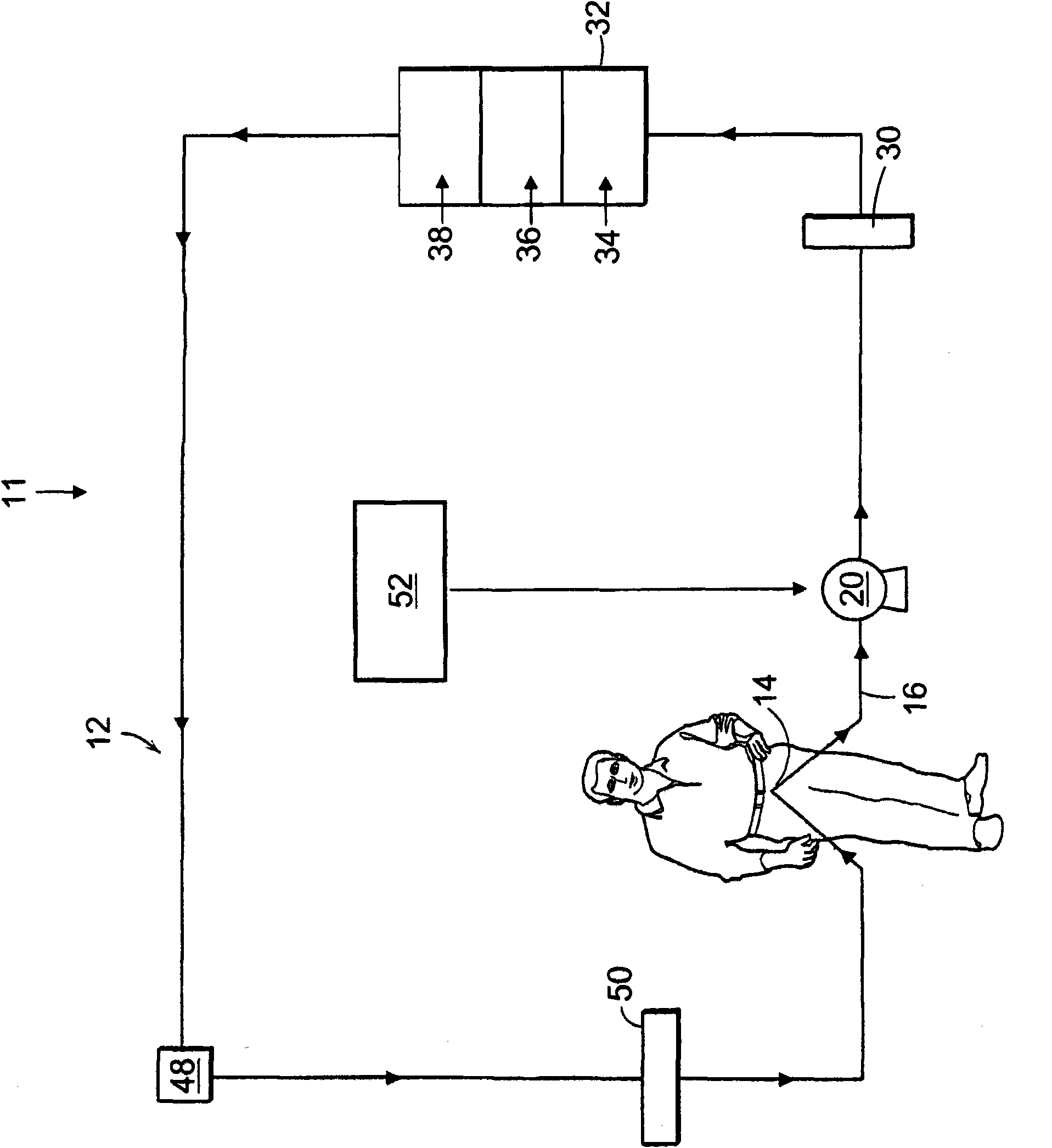

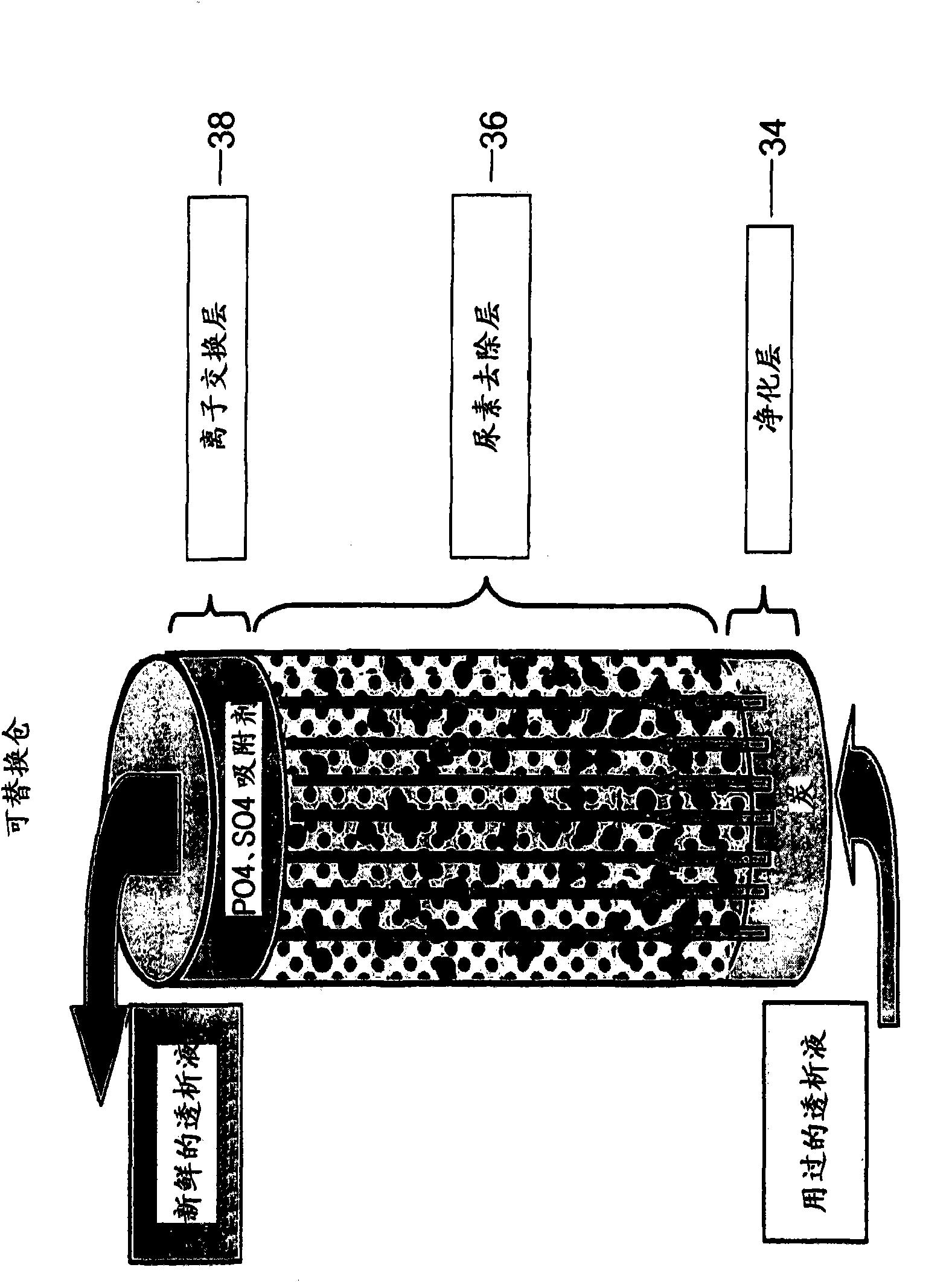

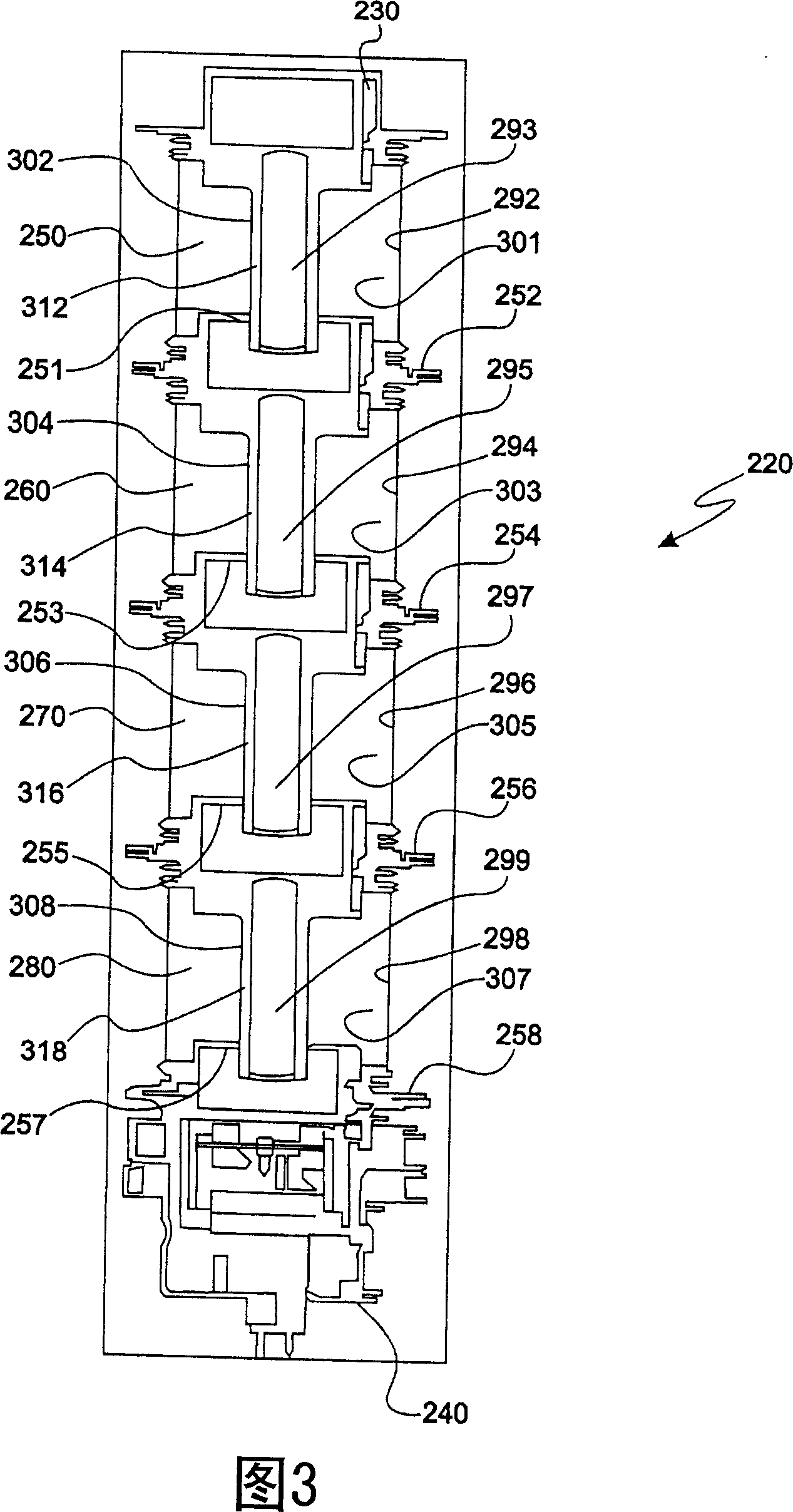

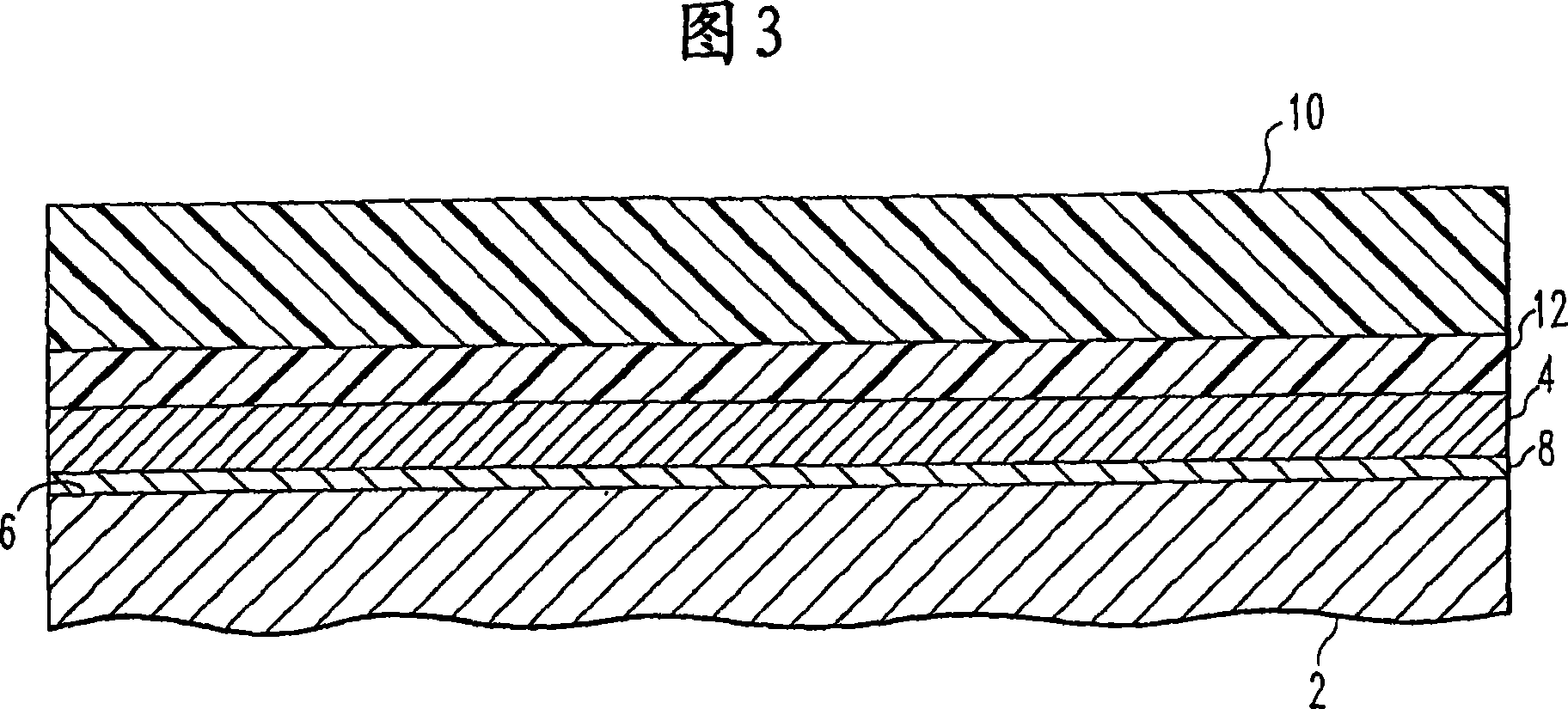

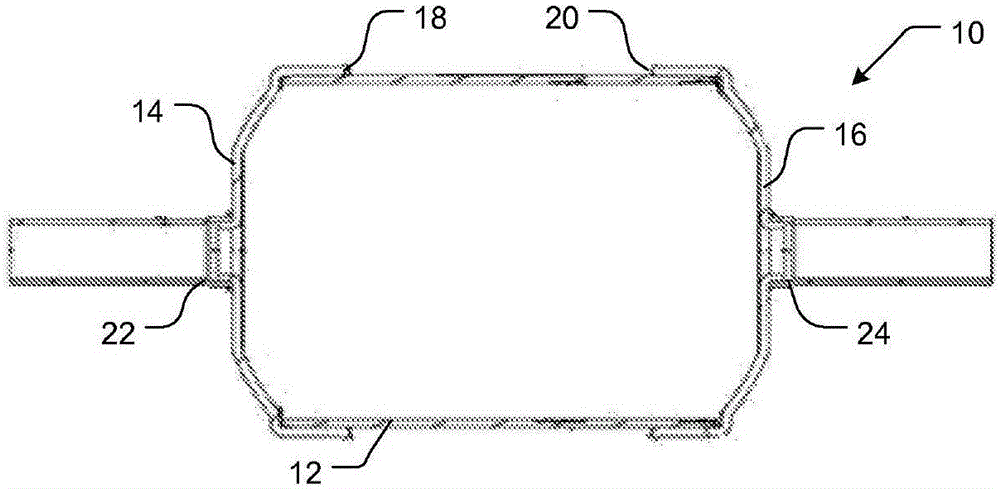

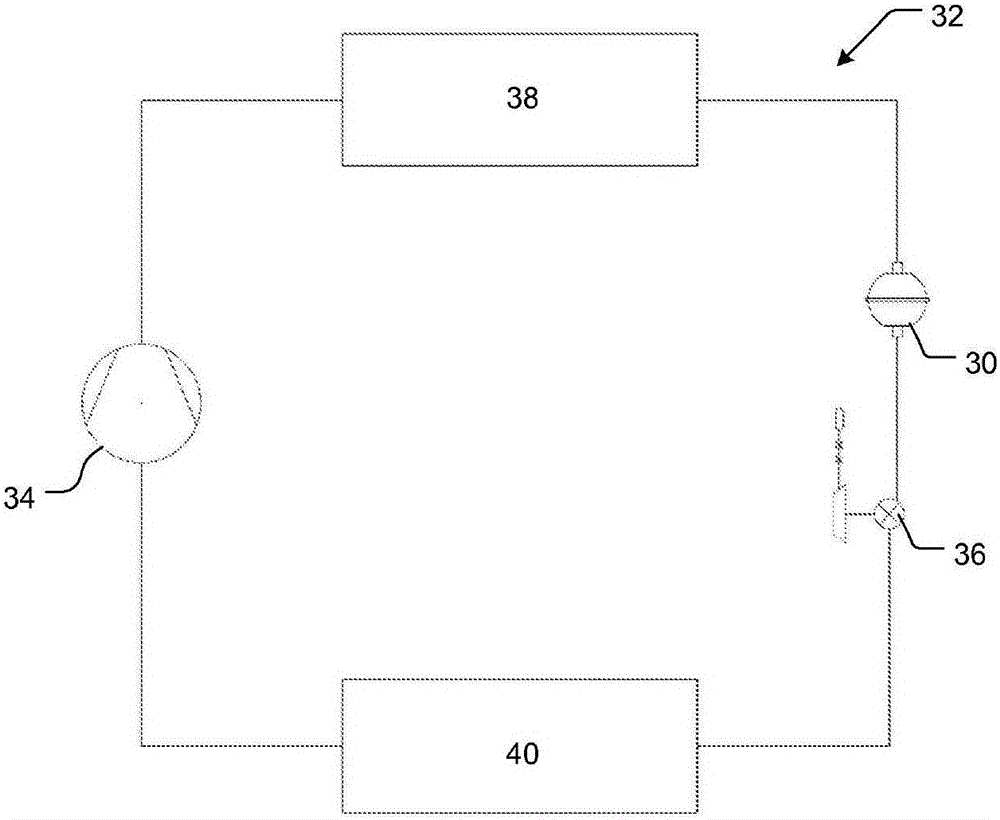

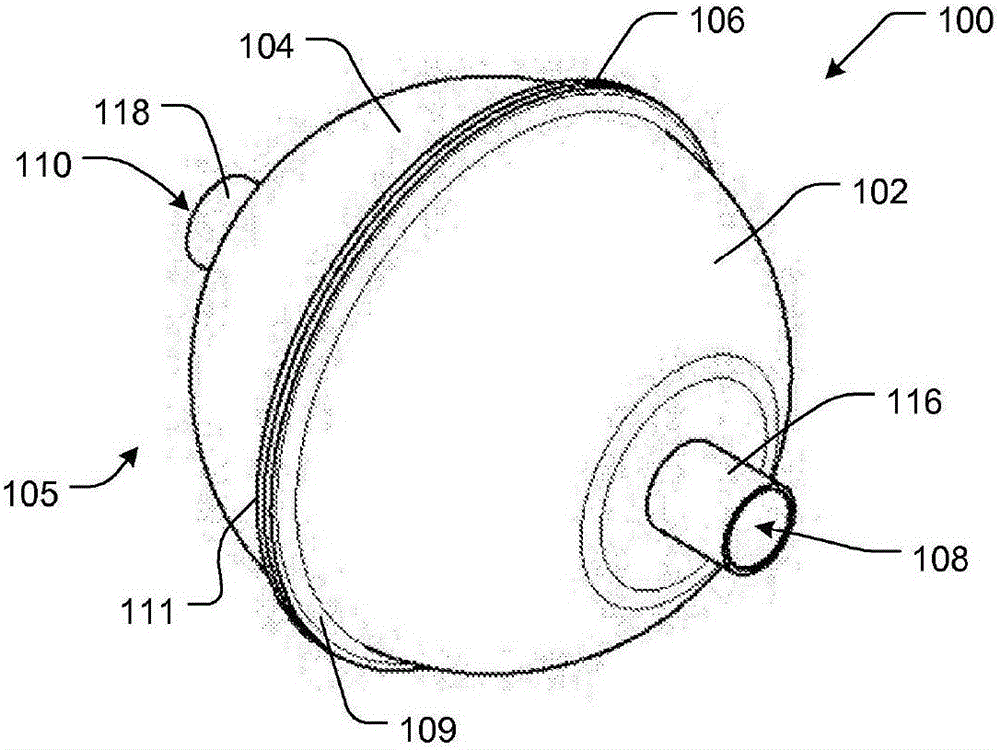

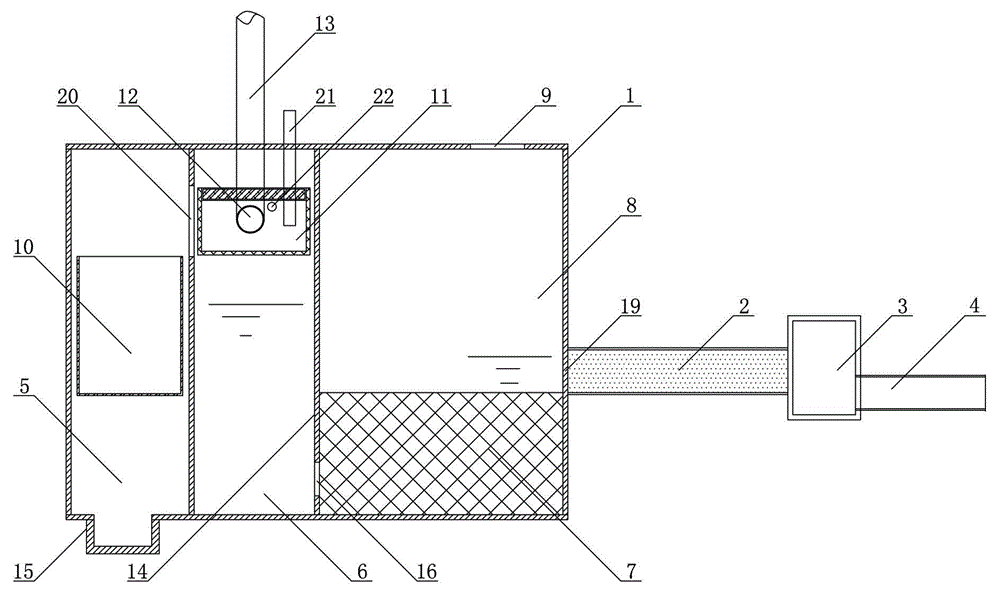

The present disclosure relates to a wearable dialysis system and method for removing uremic waste metabolites and fluid from a patient suffering from renal disease. Uremic waste metabolites can be removed by a wearable peritoneal dialysis device (10) that regenerates the peritoneal dialysis solution without removing positively charged, essential ions from the solution and, consequently, the patient. Fluids can be removed. from the blood of the patient by an implantable fluid removing device (100). Fluids are delivered to the bladder and preferably removed from the body of the patient through urination. The wearable dialysis system may be operated continuously or; semi-continuously and be comfortably adapted to the body of the patient while allowing the patient to perform normal activities.

Owner:FRESENIUS MEDICAL CARE HLDG INC

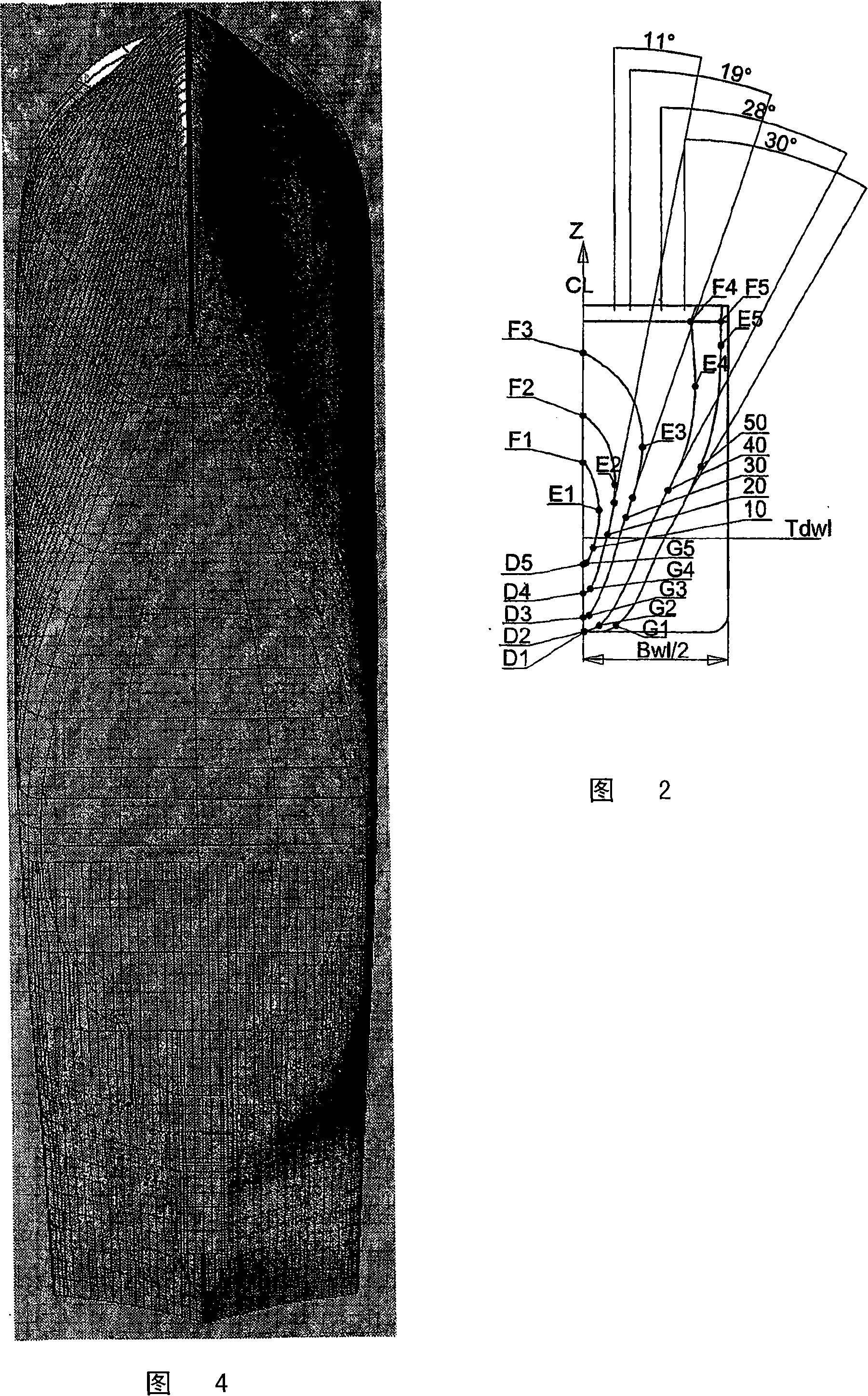

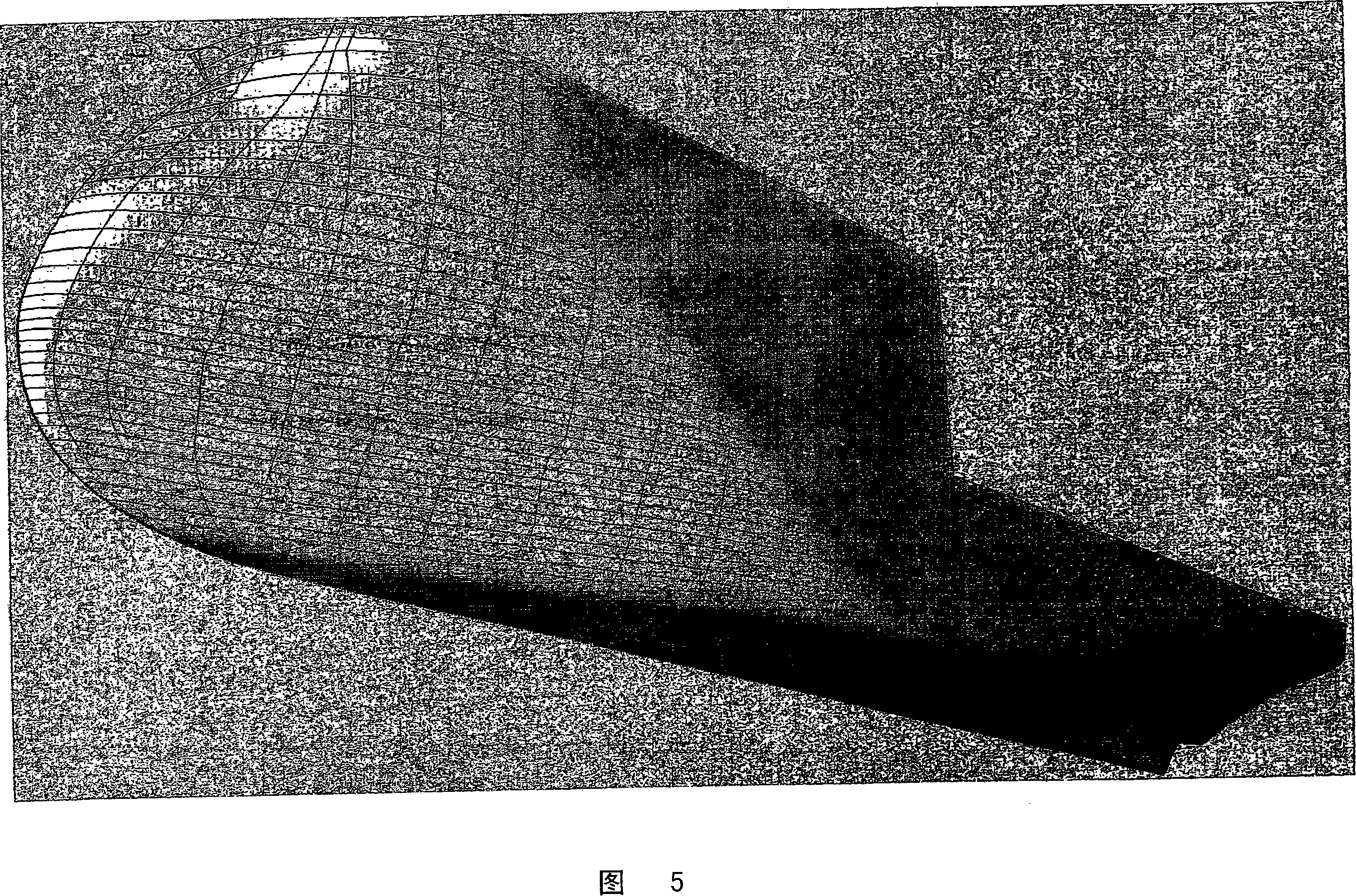

A foreship arrangement for a vessel of the deplacement type

ActiveCN101137536AReduce reflectionReduce slapWatercraft hull designVessel movement reduction by foilsMarine engineeringTransition point

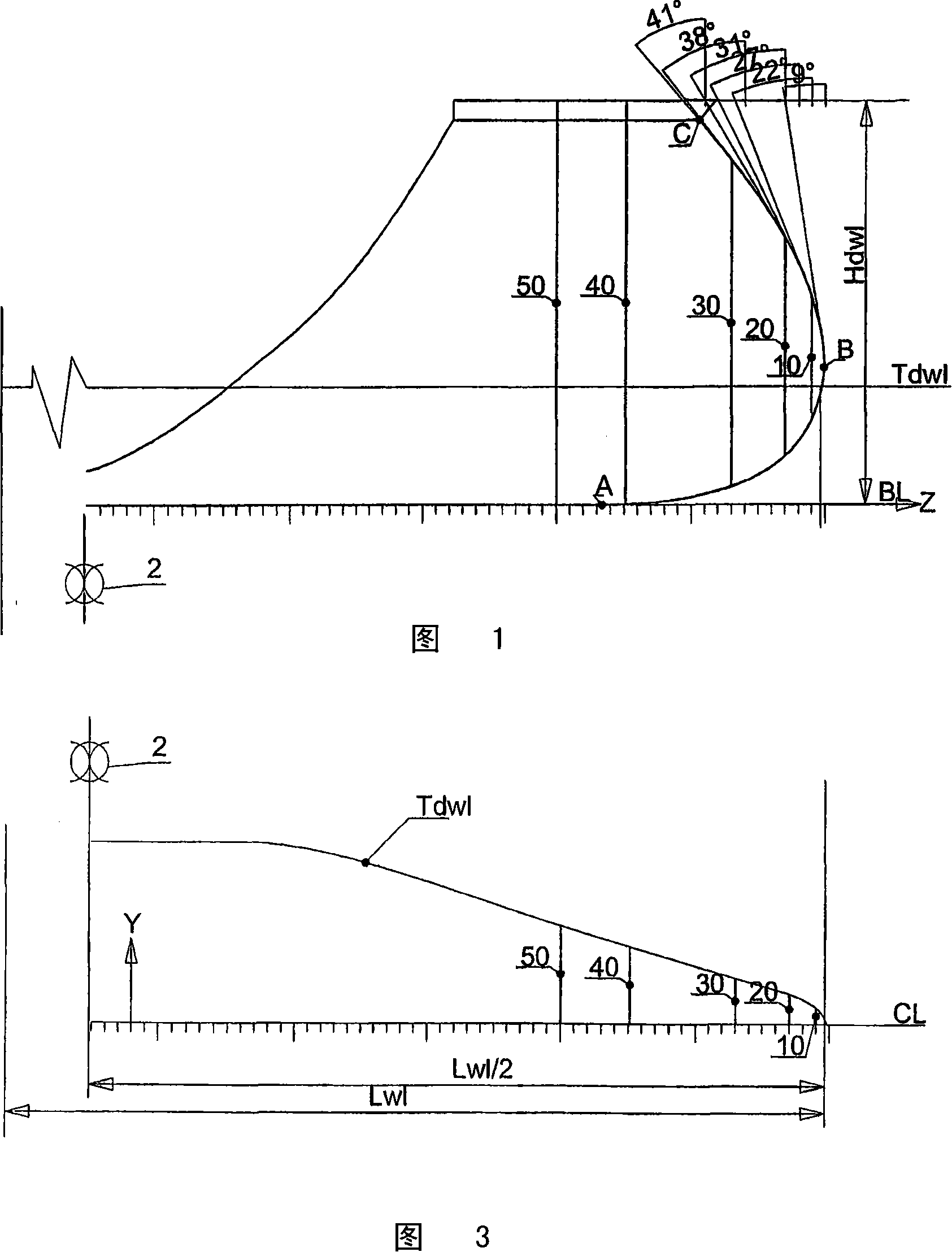

A foreship arrangement for a vessel of the displacement type, which foreship consists of the part of the ship in front of the vessel's midship mark (2) and which vessel has a transversely symmetrical hull form about its centre line (CL) and a substantially conventional bow form below its design water line (Tdwl), characterised in that the stem line (1) of the vessel turns substantially backwards in relation to the length direction of the ship from a transition point (B) at or immediately above the design water line (Tdwl).

Owner:ULSTEIN DESIGN & SOLUTIONS AS

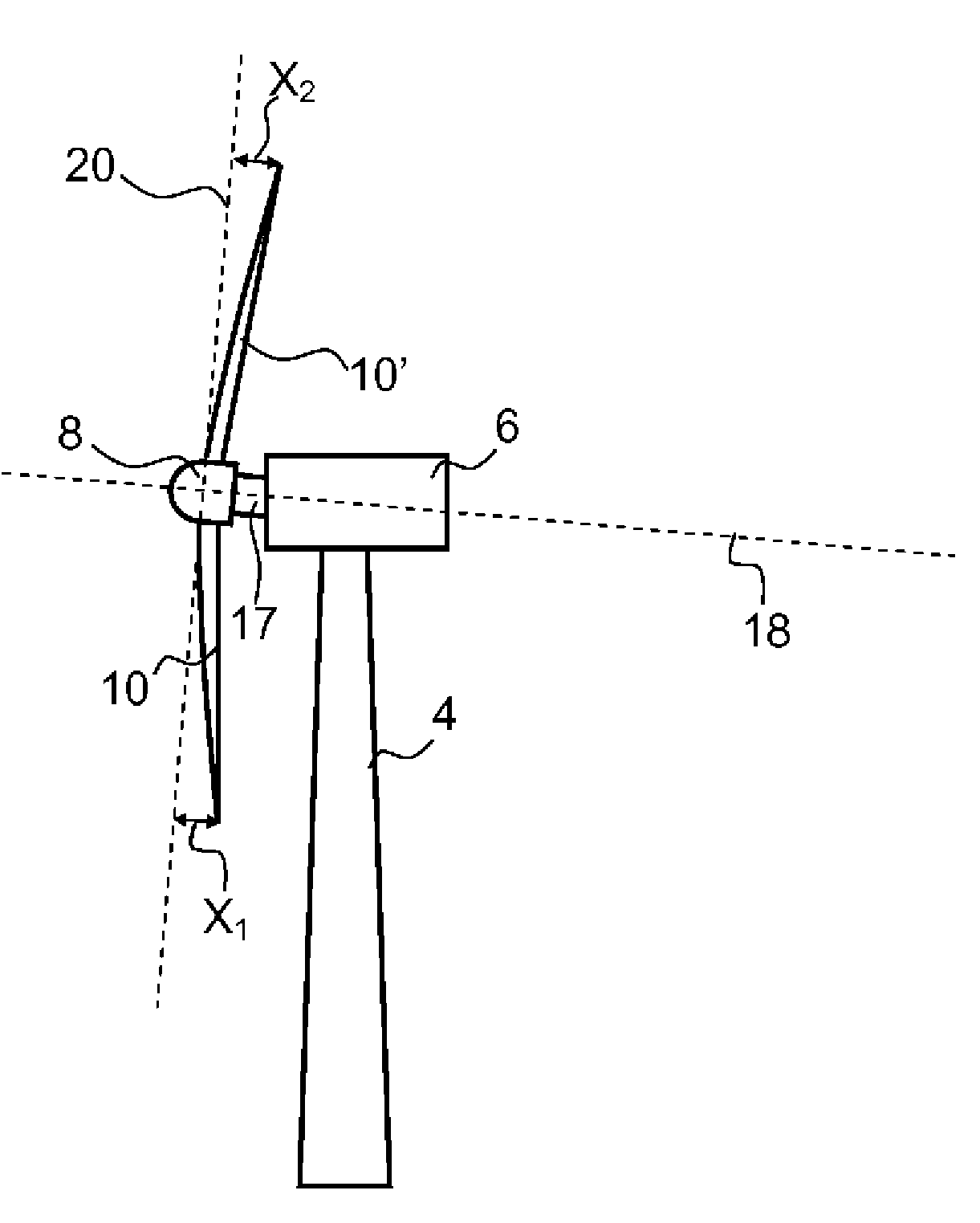

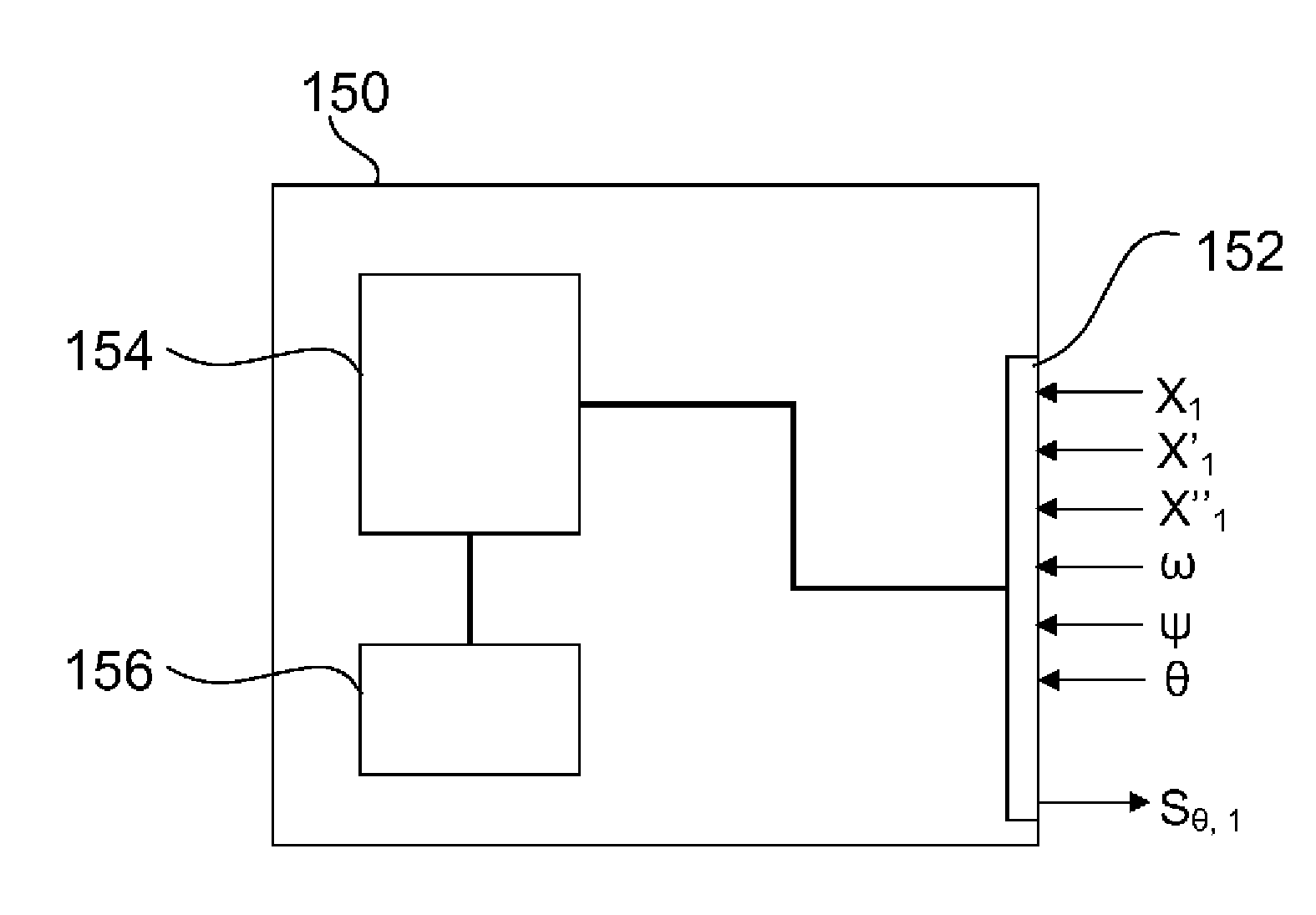

Method of controlling a wind turbine and related system

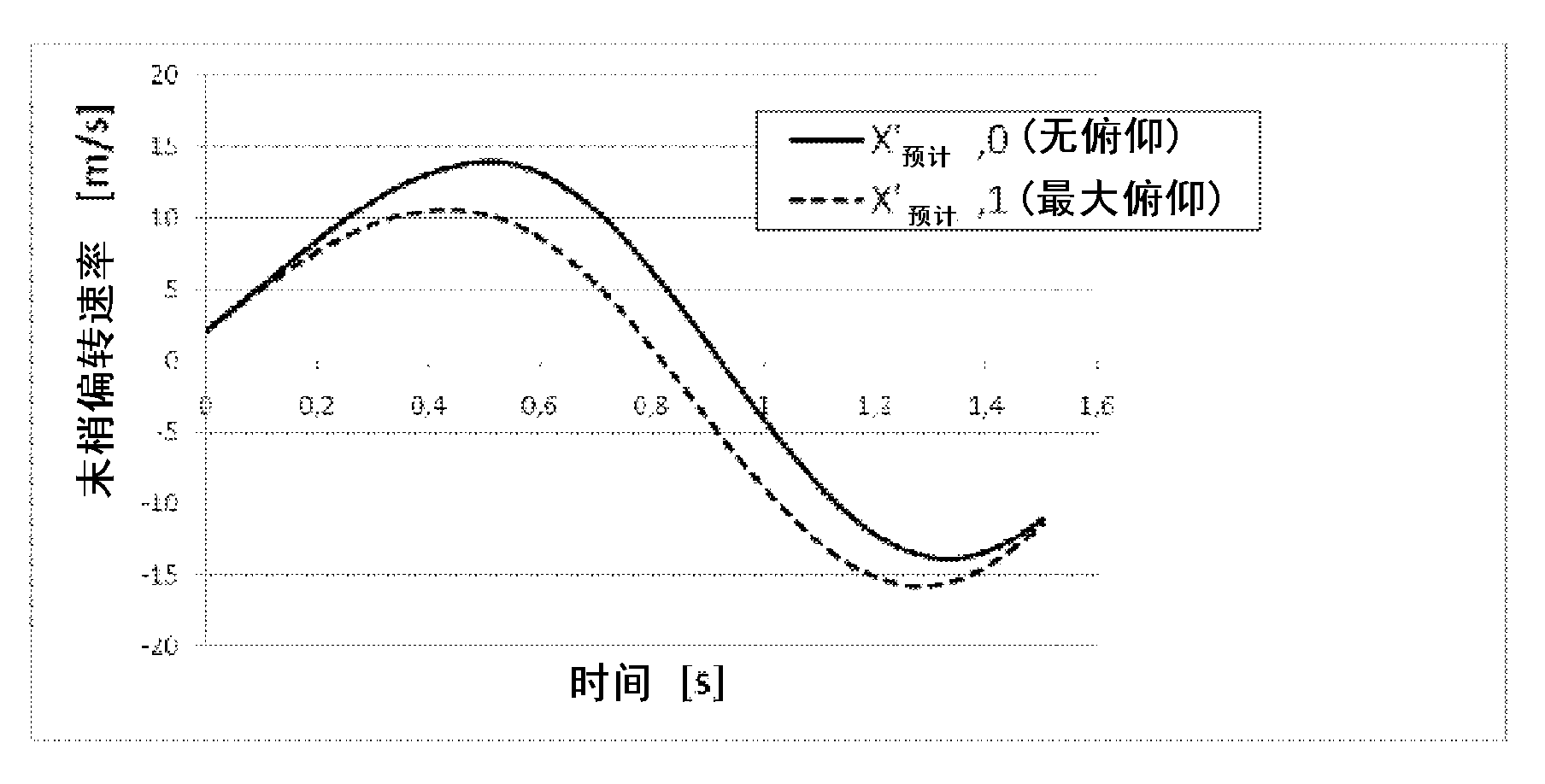

ActiveCN103890383AReduce the numberDegree of reductionAvoid excessive blade deflectionWind motor controlTurbine bladeClassical mechanics

The present invention relates to a method for controlling a wind turbine,in particular a method for controlling pitch of one or more blades of a wind turbine and related system. The method comprises collecting first data indicative of a dynamic condition of the first wind turbine blade and the rotor, the first data comprising rotor data and first deflection data, the rotor data being indicative of the azimuth position and rotational velocity of the rotor in a rotor plane perpendicular to the rotor axis, and the first deflection data being indicative of the position, speed and acceleration of one or more parts of the first wind turbine blade.; Further, the method comprises calculating an expected tower clearance distance at a later time of tower passage for the first wind turbine blade based on the first data including acceleration of one or more parts of the first wind turbine blade, and performing measures to prevent tower collision, if the expected tower clearance distance fulfills a collision risk criterion.

Owner:LM WP PATENT HLDG

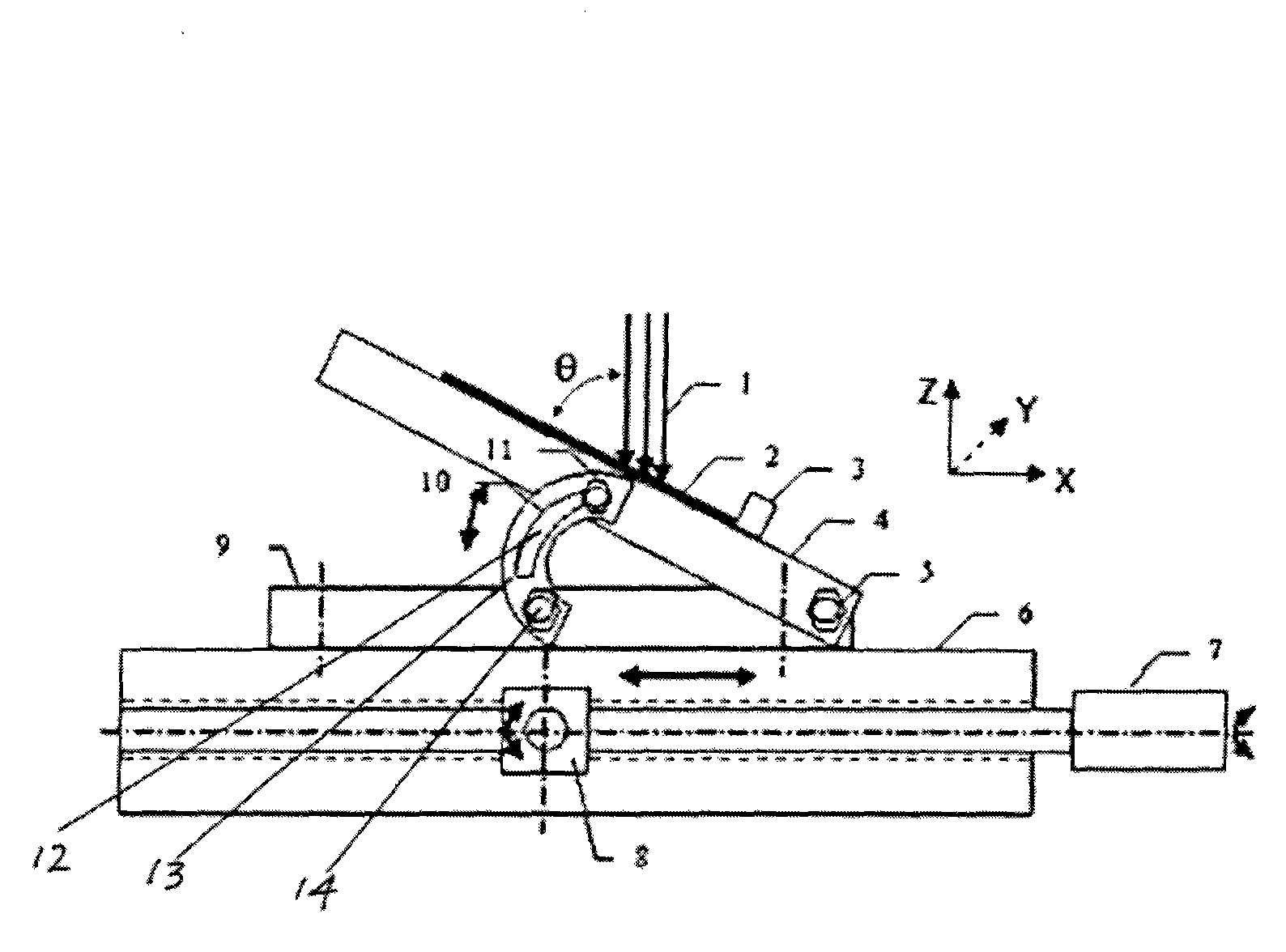

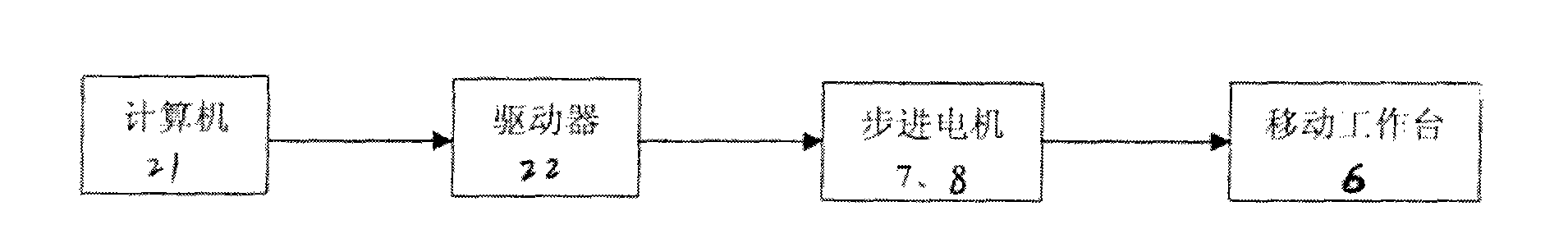

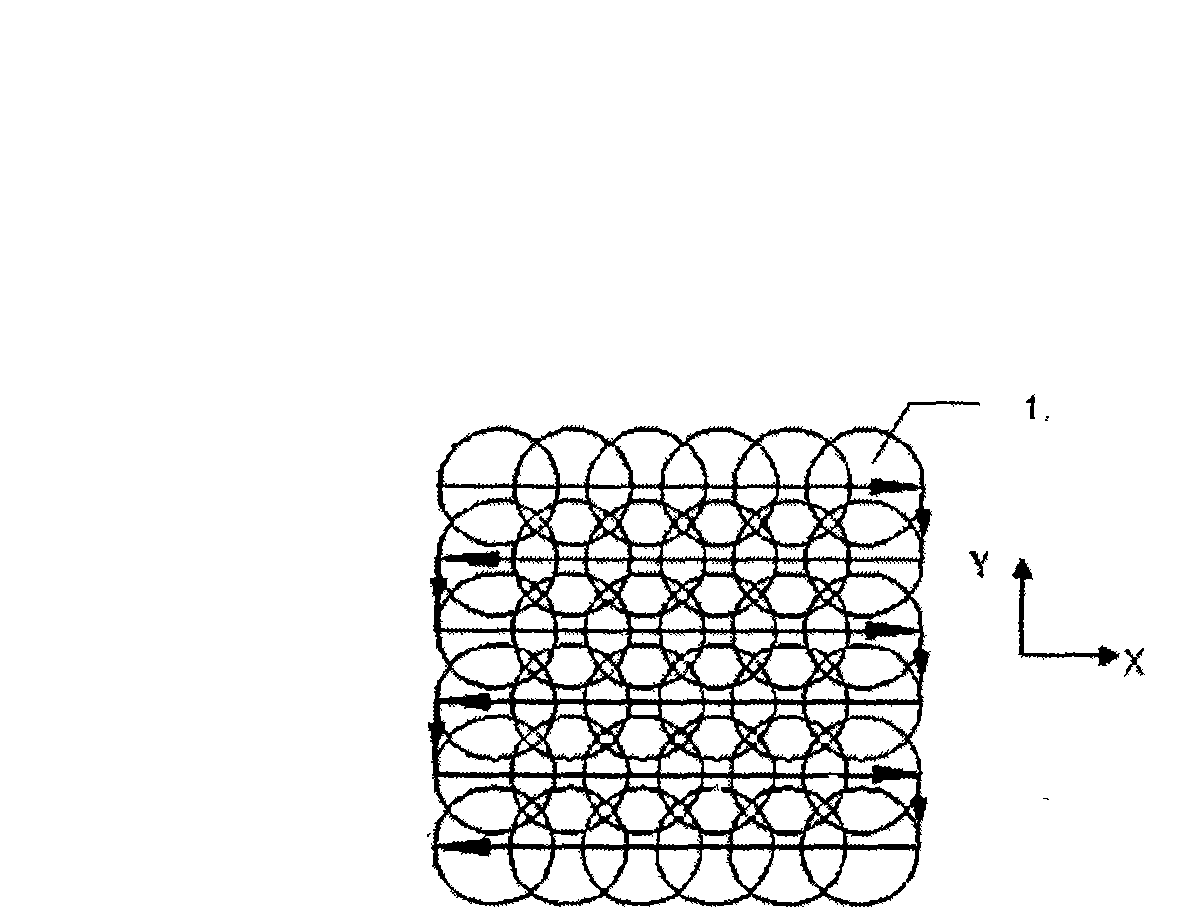

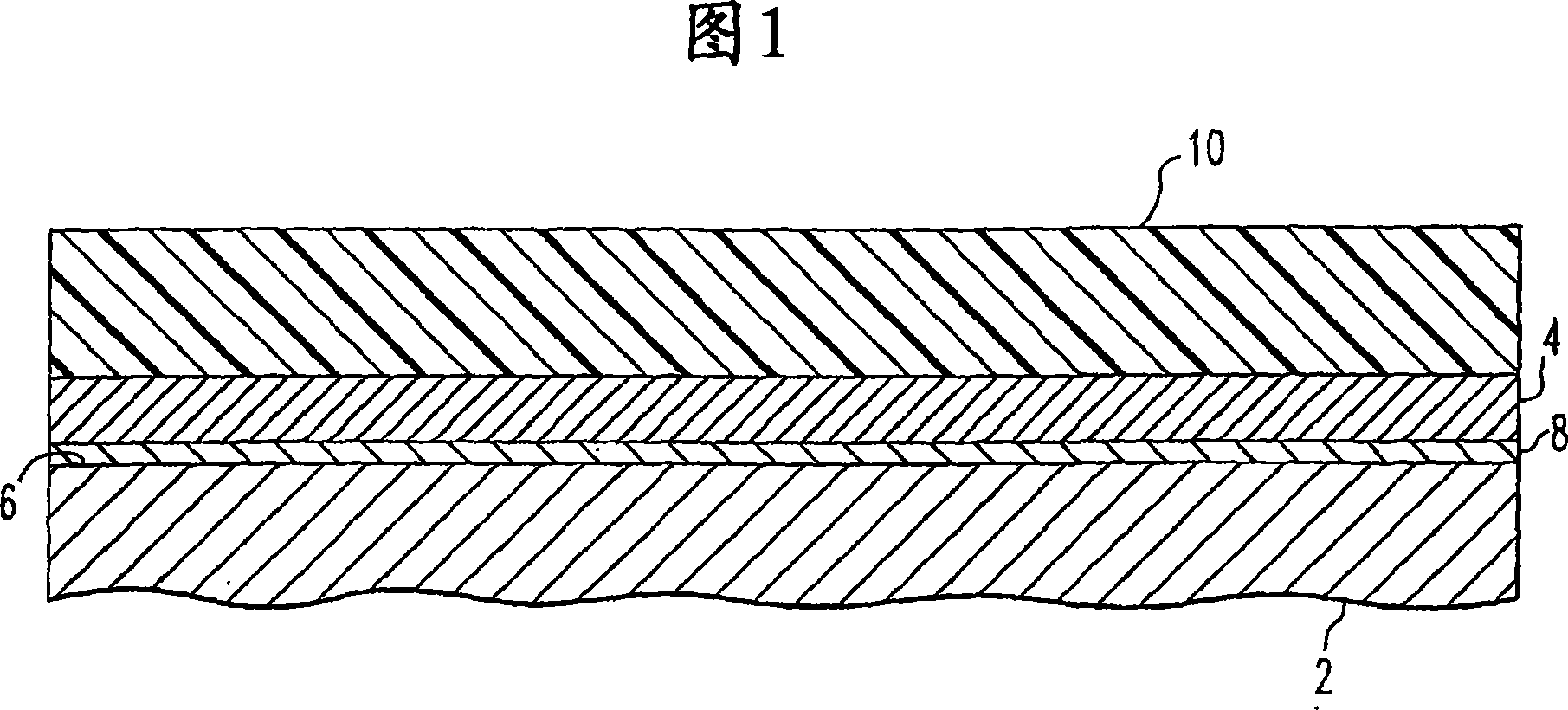

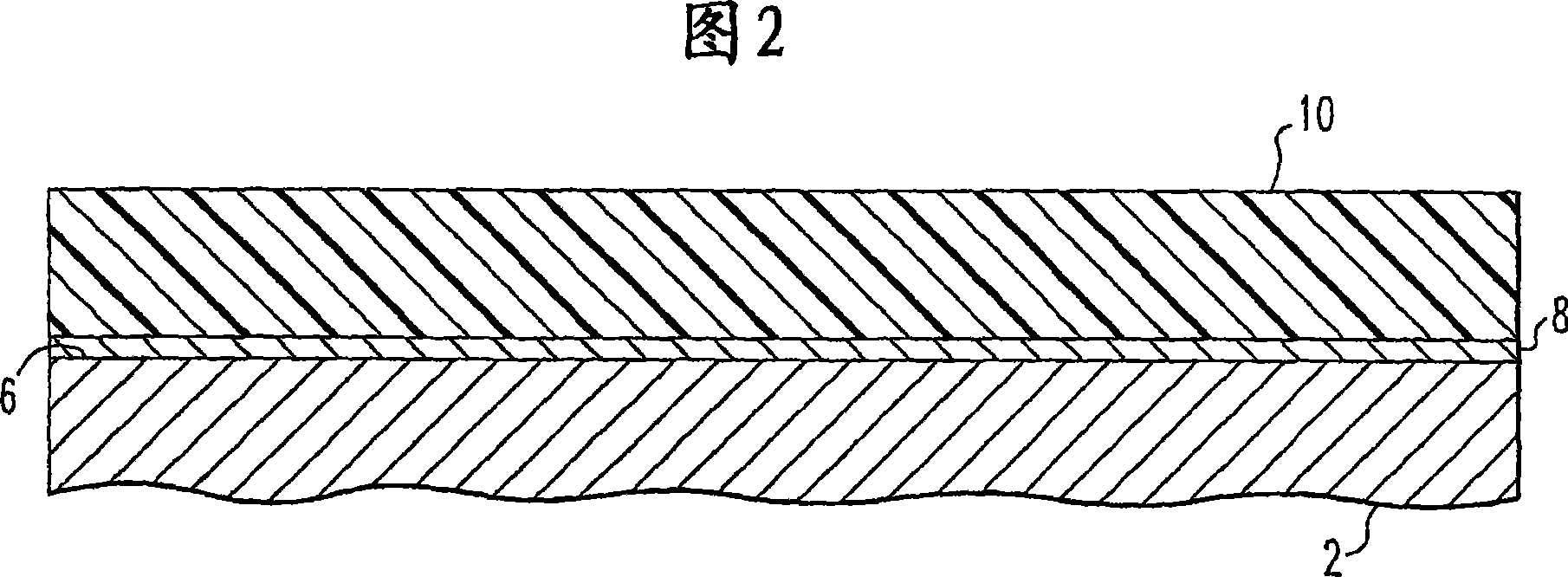

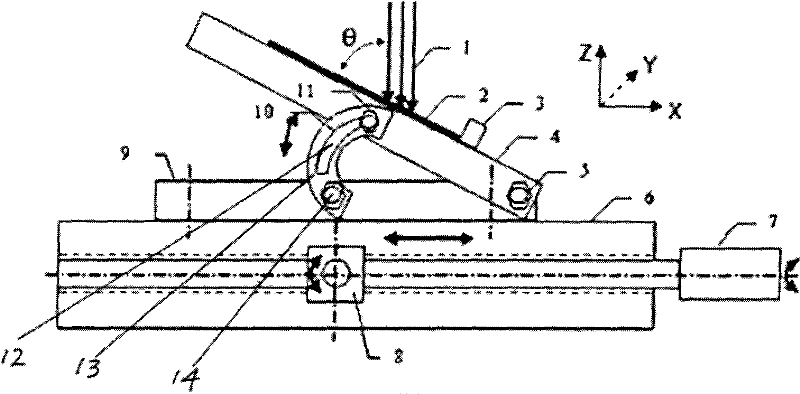

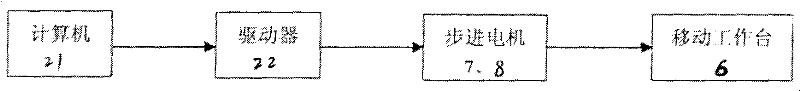

Polishing device and method of sapphire

InactiveCN101664894ALittle thermal impactEliminate the effects ofEdge grinding machinesEngineeringLaser beams

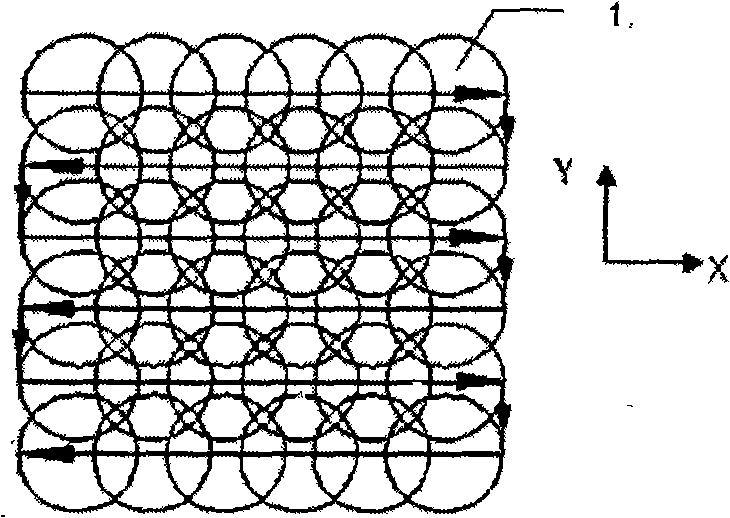

The invention relates to polishing device and method of sapphire. The polishing device comprises a laser beam, a shoe plate, a worktable and a connecting piece, wherein the worktable is provided witha stepper motor driving the worktable to make X-direction movement and a stepper motor driving the worktable to make Y-direction movement, the connecting piece is fixed on the worktable, the shoe plate is arranged on the connecting piece, and a sapphire wafer to be polished is fixed on the shoe plate; the laser beam radiates to the sapphire wafer from the upward side of the sapphire wafer to be polished, and the stepper motor driving the worktable to make the X-direction movement and the stepper motor driving the worktable to make the Y-direction movement are respectively connected with a control device. The invention controls the X-direction movement and the Y-direction movement of a workpiece and the movement track of the workpiece relative to the laser beam by regulating the incident angle of the laser beam and controlling the worktable, thereby realizing the comprehensive scanning and polishing on the surface of the sapphire wafer. The invention can remove very little material, reduce and even eliminate the influence of heat on the sapphire material, thereby obtaining a polished surface with low surface roughness and low subsurface injury degree.

Owner:GUANGDONG UNIV OF TECH

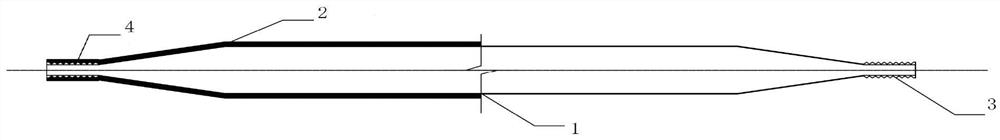

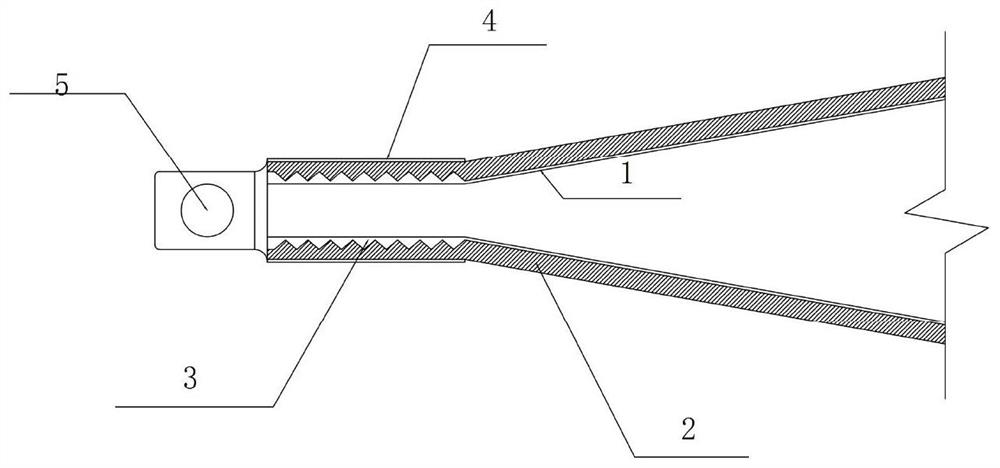

Production method of linearly cut molybdenum wire

InactiveCN106312456AHigh strengthImprove high temperature resistanceElectrical-based machining electrodesFiberRare earth

The invention provides a production method of a linearly cut molybdenum wire. Certain solid solution metal elements are added into molybdenum so as to realize a solid solution strengthening effect. The strength of the molybdenum wire can be properly improved, and the machining performance of the molybdenum wire can be improved. Certain rare earth oxides are added into the molybdenum so as to realize refined grain strengthening and dispersion strengthening effects, crystalline grains can be refined, fiber texture can be strengthened, and the strength, high temperature resistance and wear resistance of the molybdenum wire can be improved. By adopting an intermediate annealing technology, the plasticity can be restored, the internal stress is reduced, the machining difficulty is reduced, and the production and expansion of cracks are reduced or eliminated. By adopting a hot wire drawing machining technology, the plasticity of the material can be kept, and the hardening of the material during the machining of a semi-finished product is reduced. By adopting a finished product multi-mode cold wire drawing technology, work-hardening and strength enhancement effects can be realized. The tensile strength of the linearly cut molybdenum wire made by the production method generally can reach 1900-2300mpa and can meet the requirements of linear cutting users.

Owner:佛山朕华照明材料有限公司

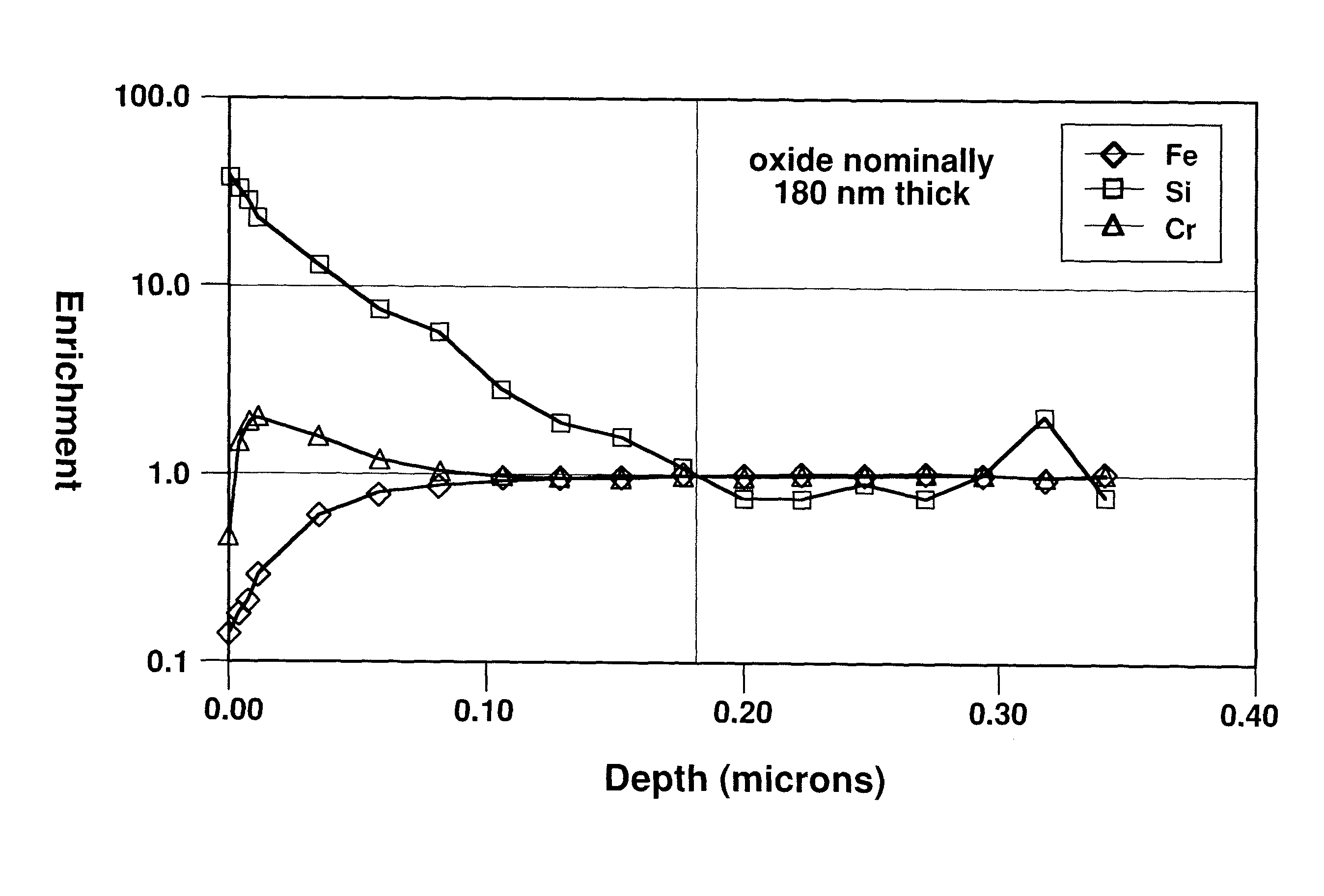

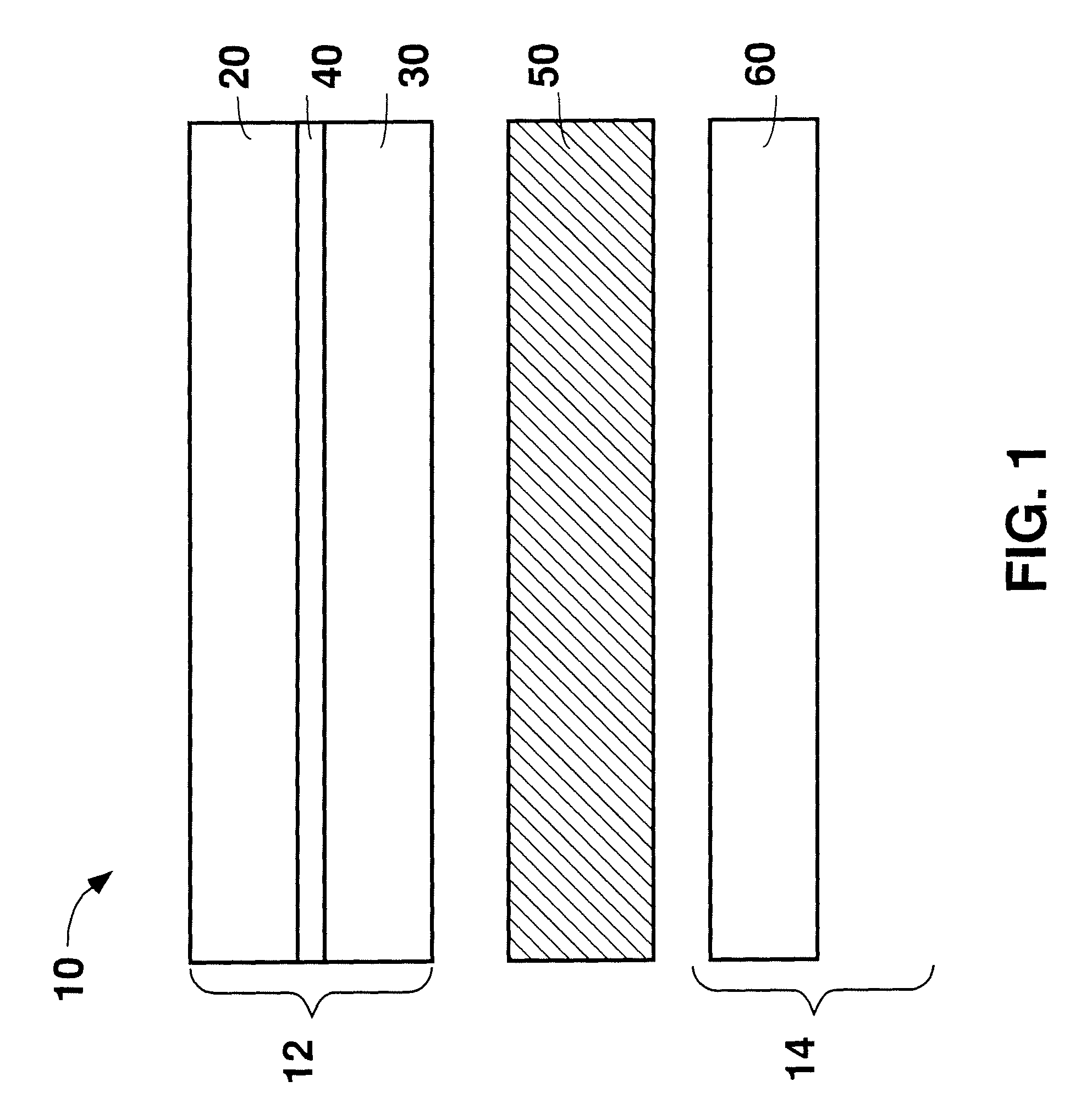

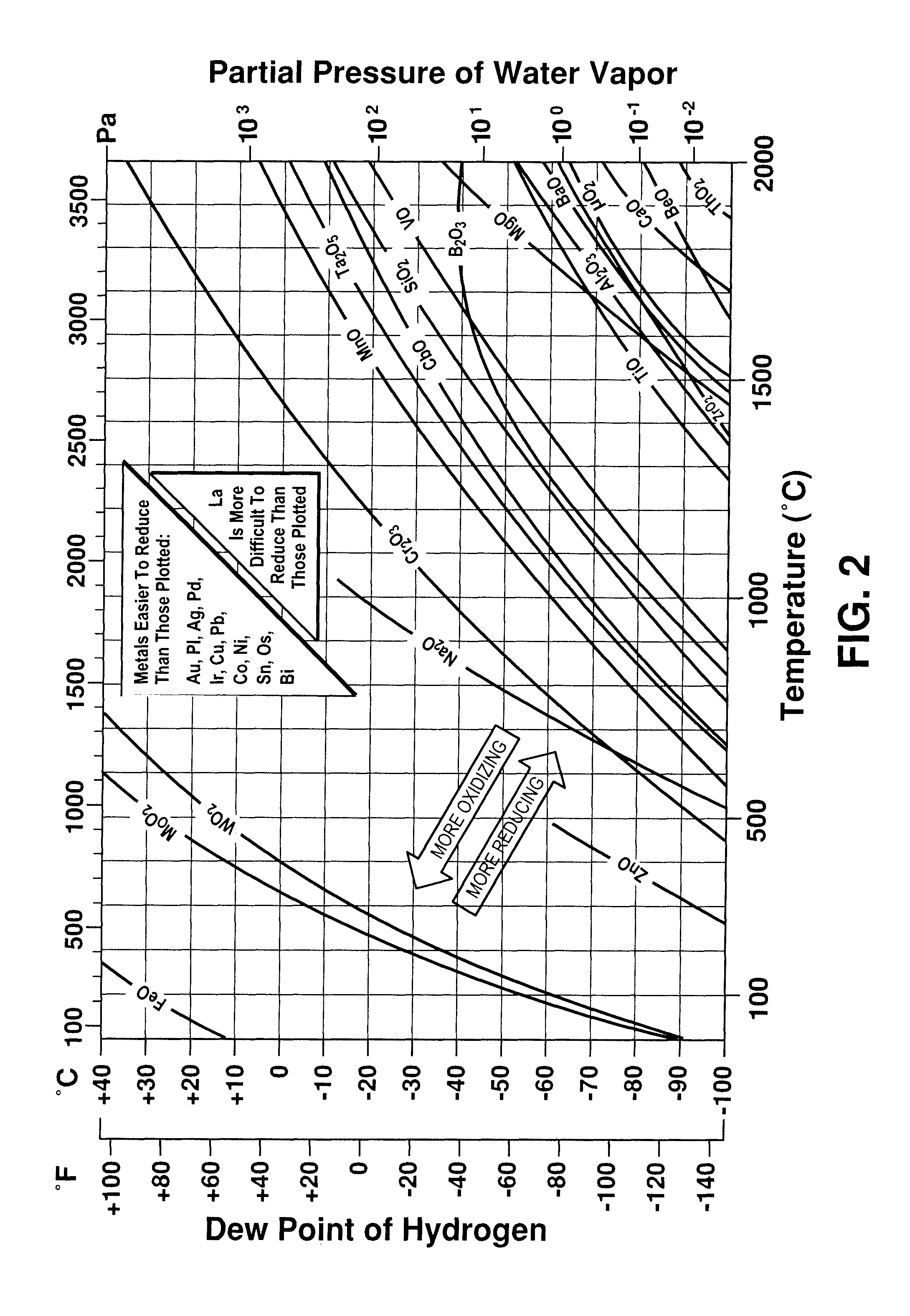

Method for reducing formation of electrically resistive layer on ferritic stainless steels

ActiveUS20080236710A1Trend downReduce or eliminate)Final product manufactureSolid state diffusion coatingElectrical resistance and conductanceFerrosilicon

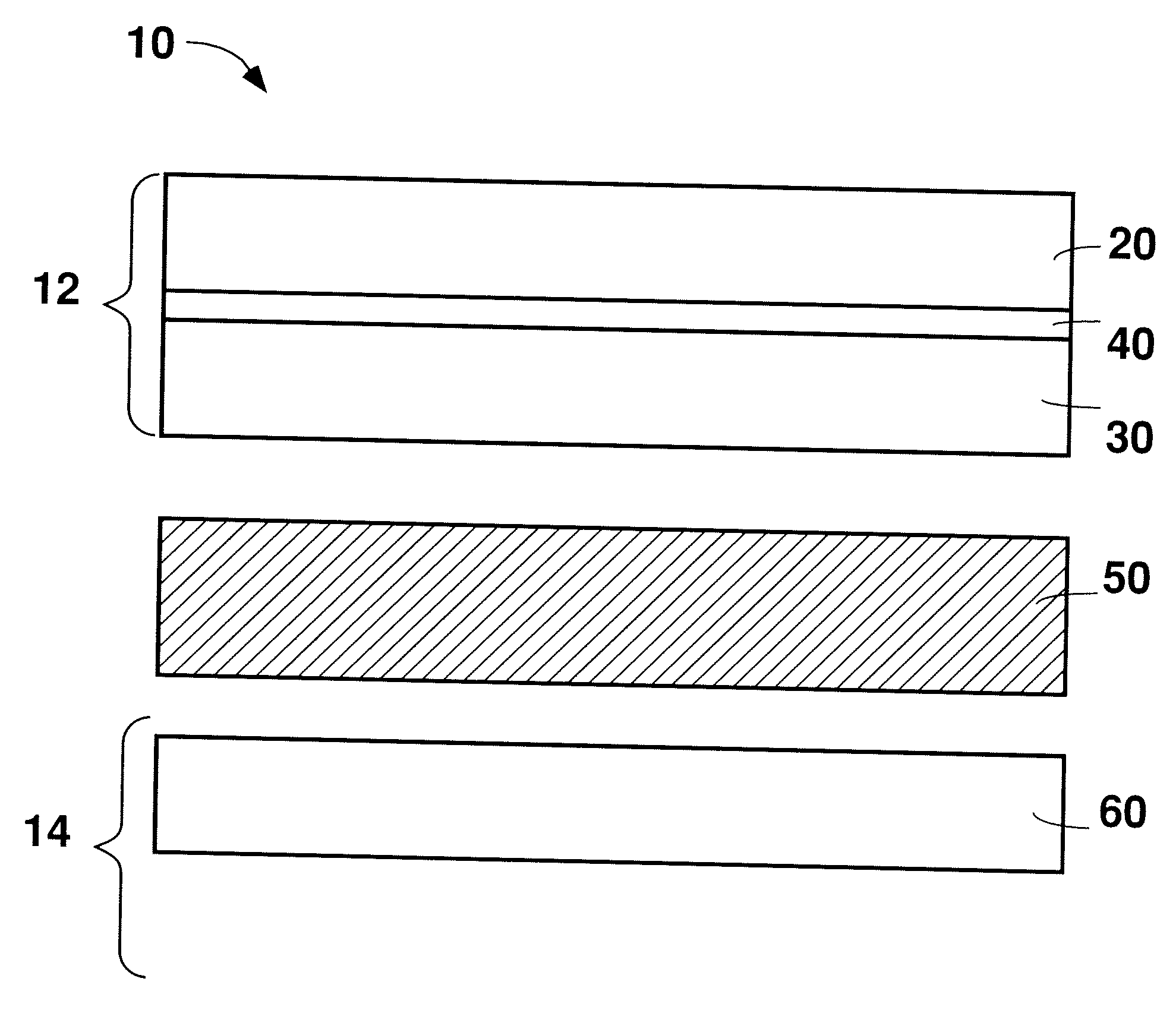

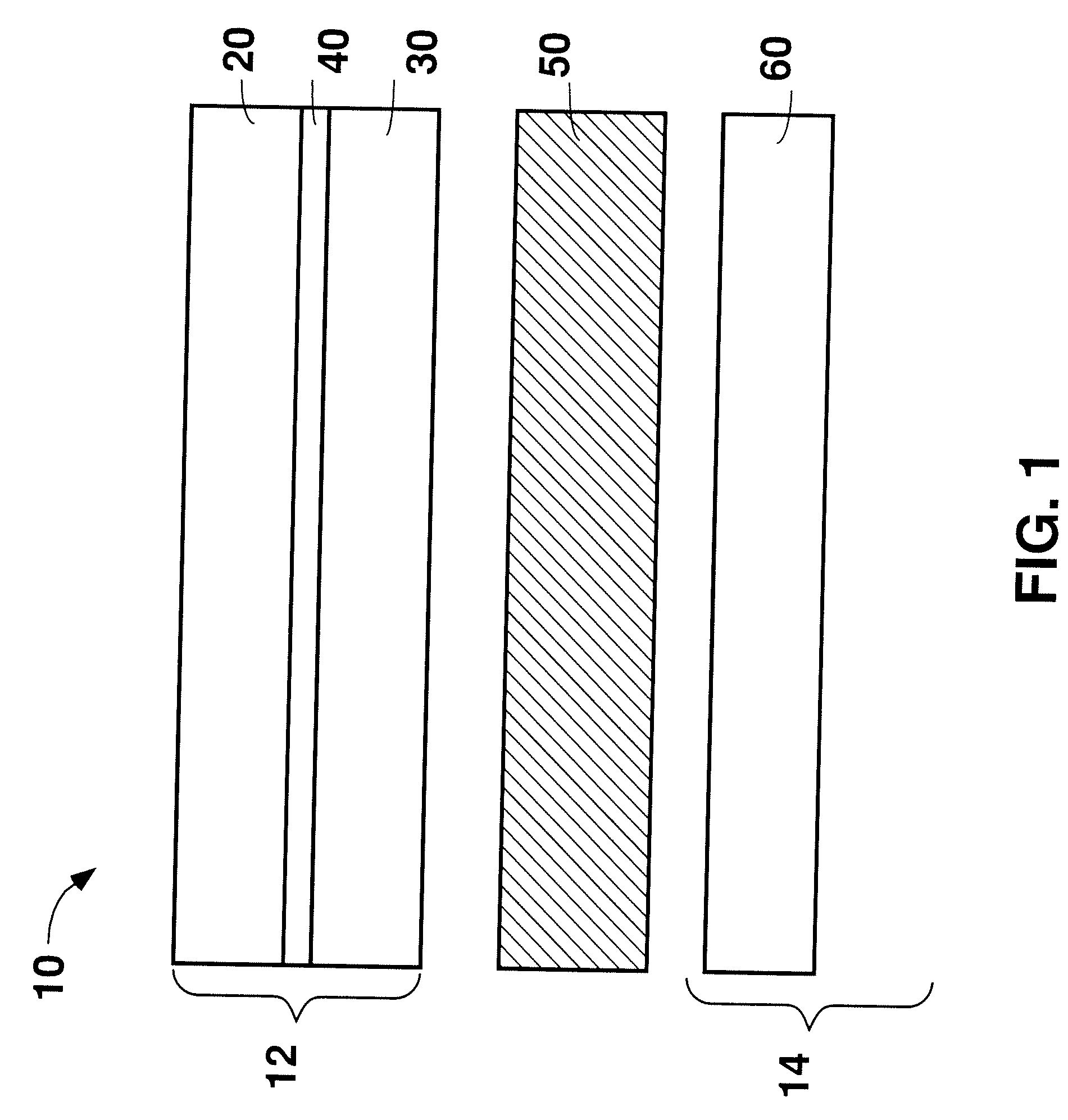

A method of reducing the formation of electrically resistive scale on a an article comprising a silicon-containing ferritic stainless subjected to oxidizing conditions in service includes, prior to placing the article in service, subjecting the article to conditions under which silica, which includes silicon derived from the steel, forms on a surface of the steel. Optionally, at least a portion of the silica is removed from the surface to placing the article in service. A ferritic stainless steel alloy having a reduced tendency to form silica on at least a surface thereof also is provided. The steel includes a near-surface region that has been depleted of silicon relative to a remainder of the steel.

Owner:ATI PROPERTIES

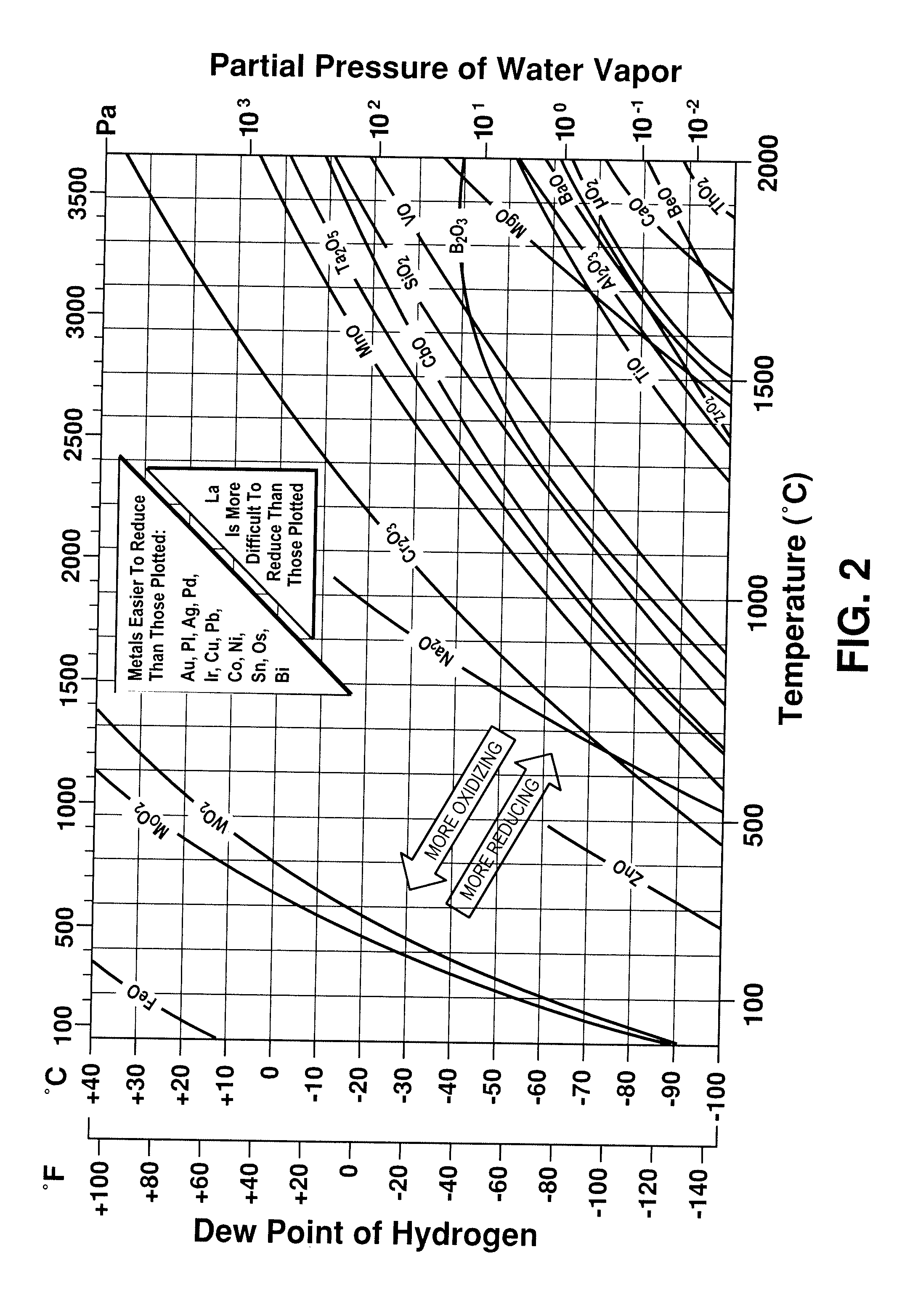

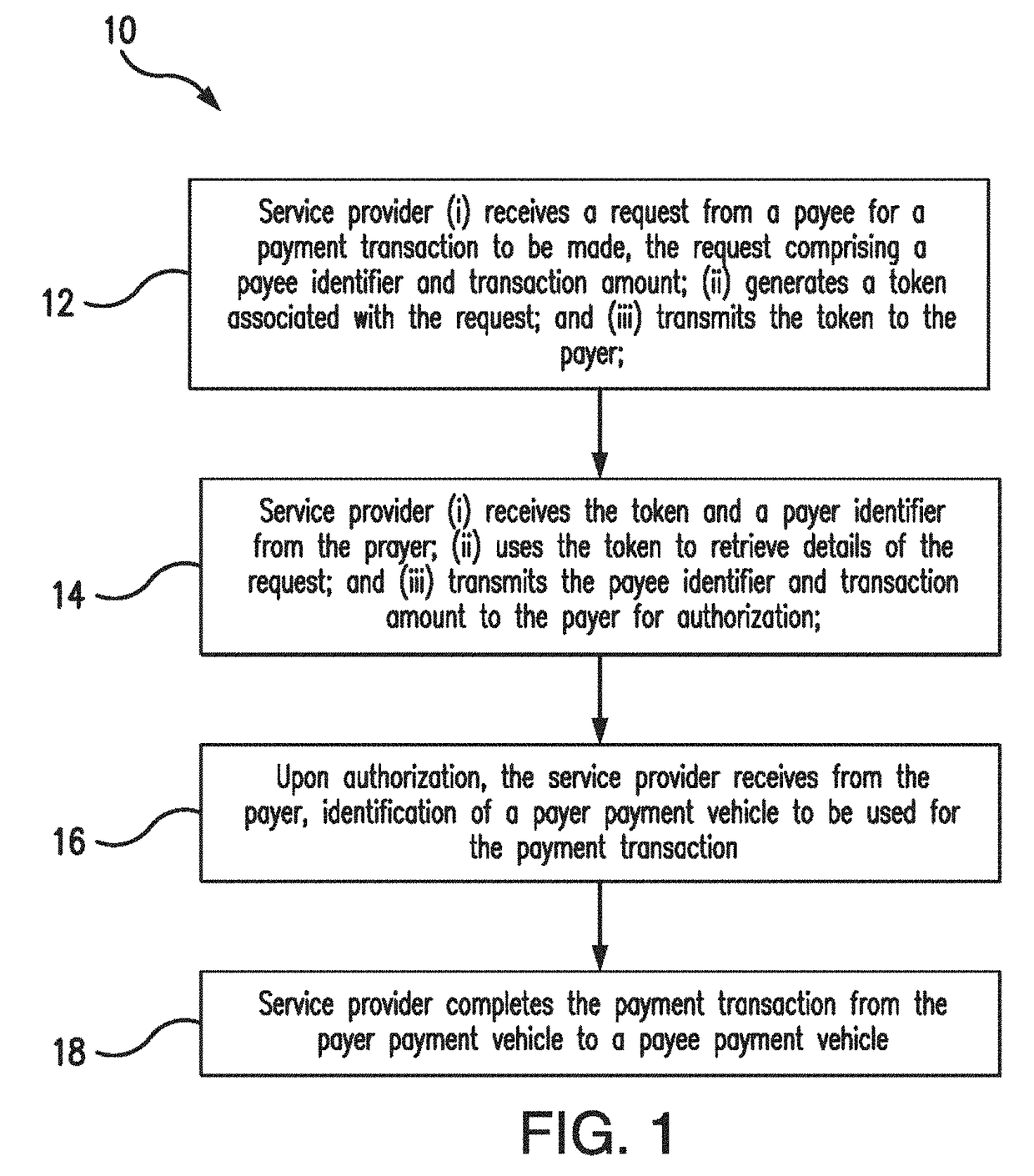

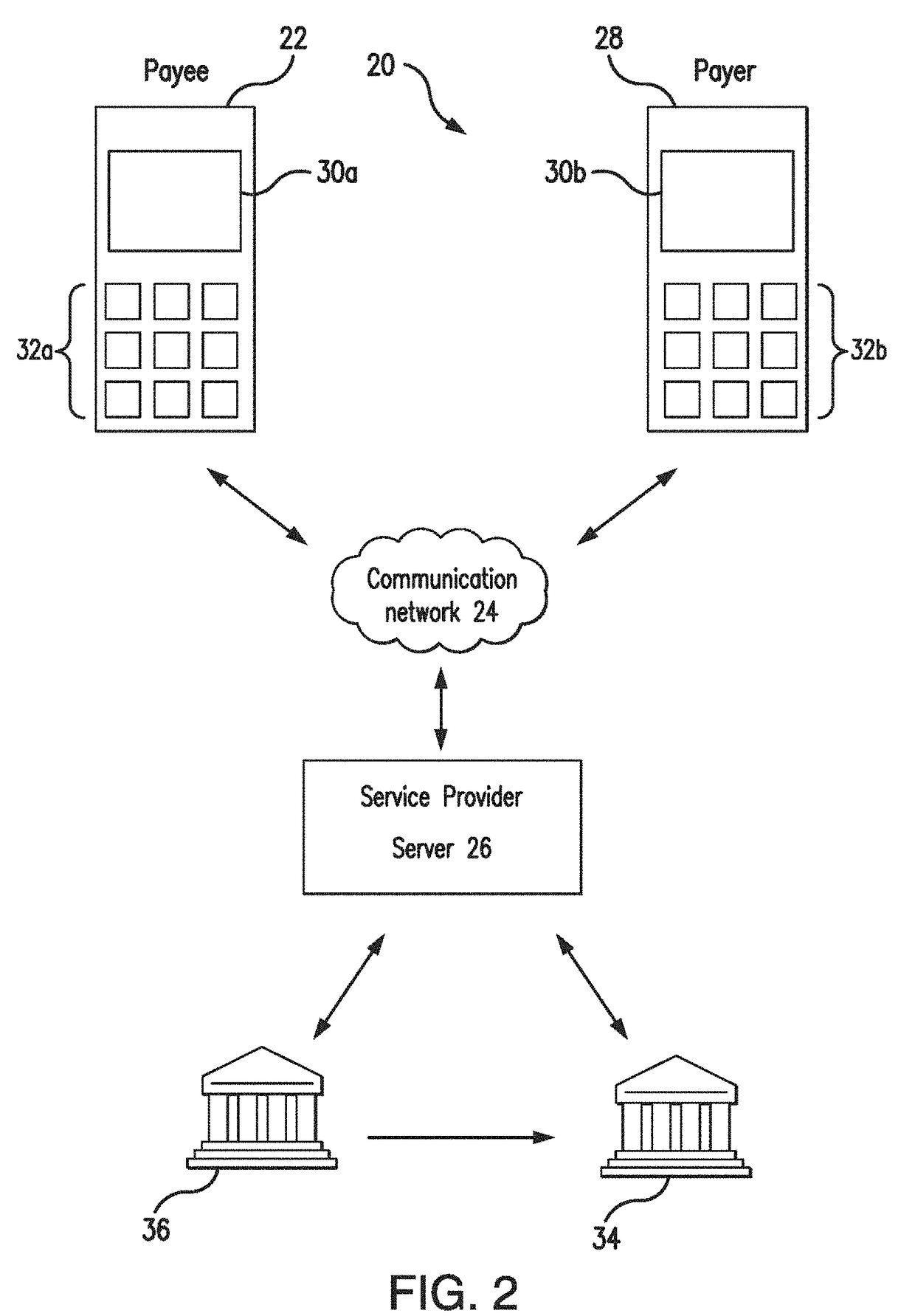

Methods and systems for securing a payment

InactiveUS20180018666A1Easy to solveSimple and safe processOffice automationProtocol authorisationPayment transactionUser identifier

A method and system are presented for securing a payment initiated by a payee. The method comprises the operations of: a service provider (i) receiving a request from a payee for a payment transaction to be made, the request comprising a payee identifier, payer identifier and transaction amount; (ii) generating a token associated with the request; and (iii) transmitting the token to the payer. The service provider (i) receiving the token and a payer identifier from the payer, (ii) using the token to retrieve details of the request, and (iii) transmitting the payee identifier and transaction amount to the payer for authorization. Upon authorization, the service provider receiving from the payer, identification of a payer payment vehicle to be used for the payment transaction such that the service provider may complete the payment transaction from the payer payment vehicle to a payee payment vehicle.

Owner:MASTERCARD INT INC

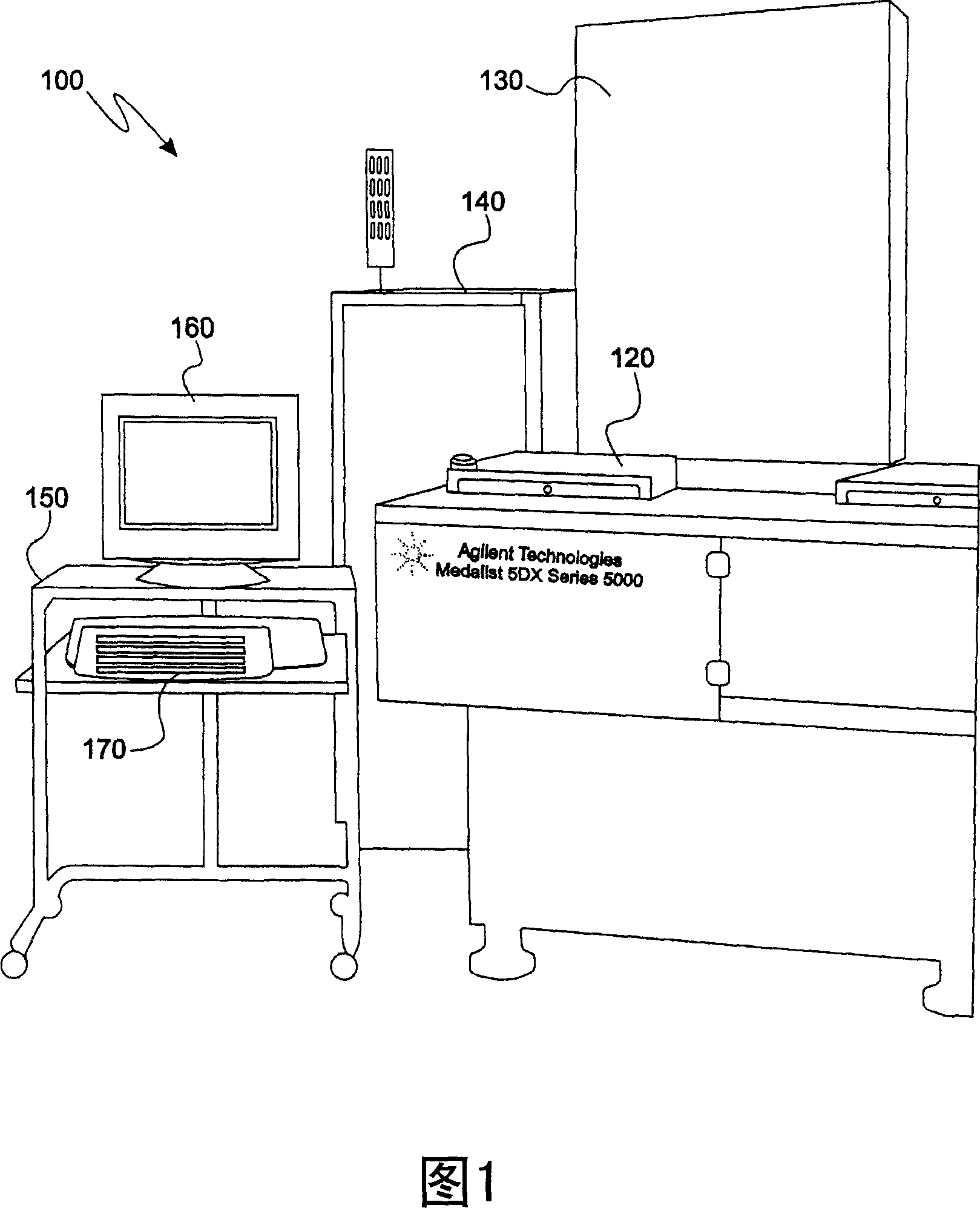

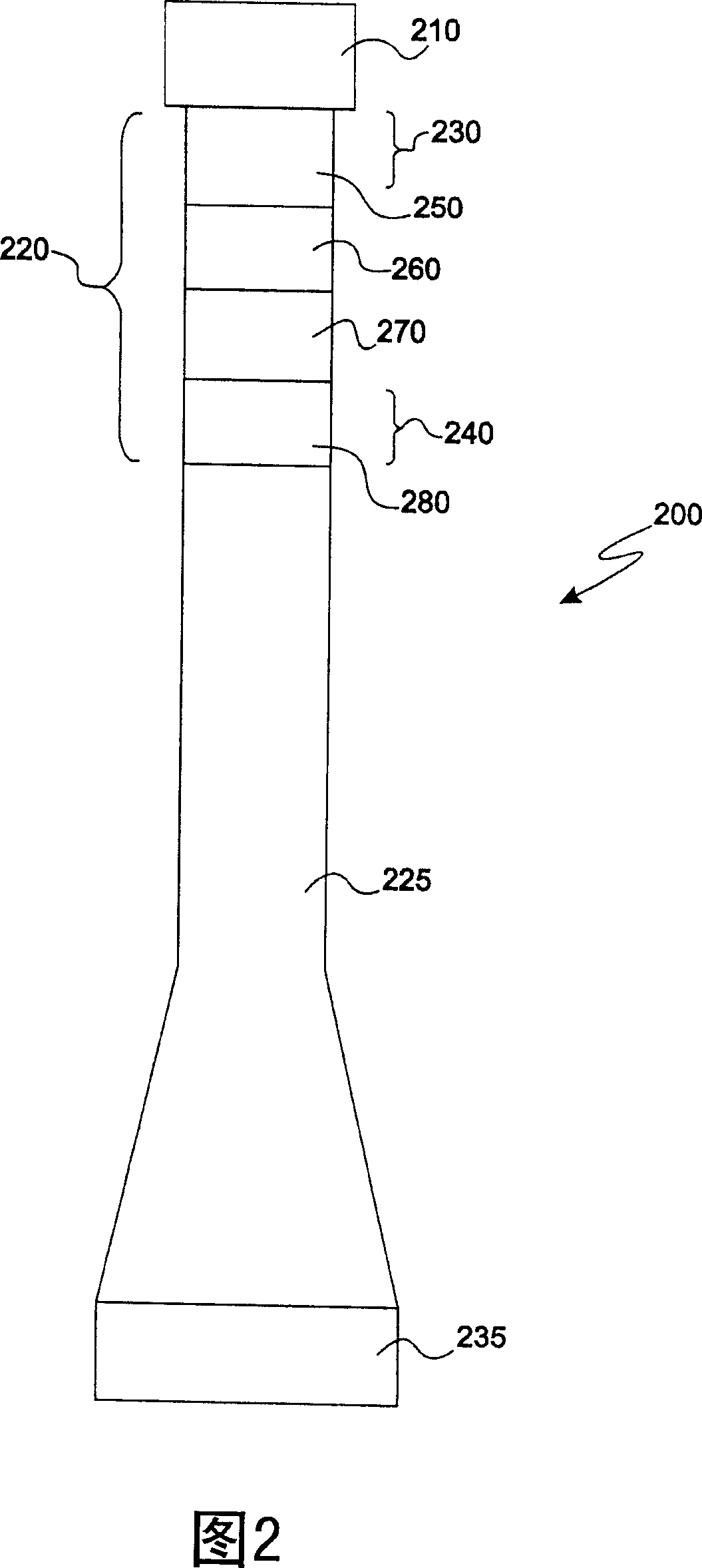

Electron beam accelerator and ceramic stage with electrically-conductive layer or coating therefor

InactiveCN1953638ALow costReduce or eliminateAcceleratorsElectrical componentsX-rayUltimate tensile strength

A ceramic electron beam accelerator is disclosed finding particularly efficacious uses in X-ray electronic circuit imaging and testing applications. The ceramic stage design eliminates the need for placing metal reinforcements between adjoining stages of the accelerator, thereby increasing the accelerator's mechanical robustness and reliability, while also reducing manufacturing costs.

Owner:AGILENT TECH INC

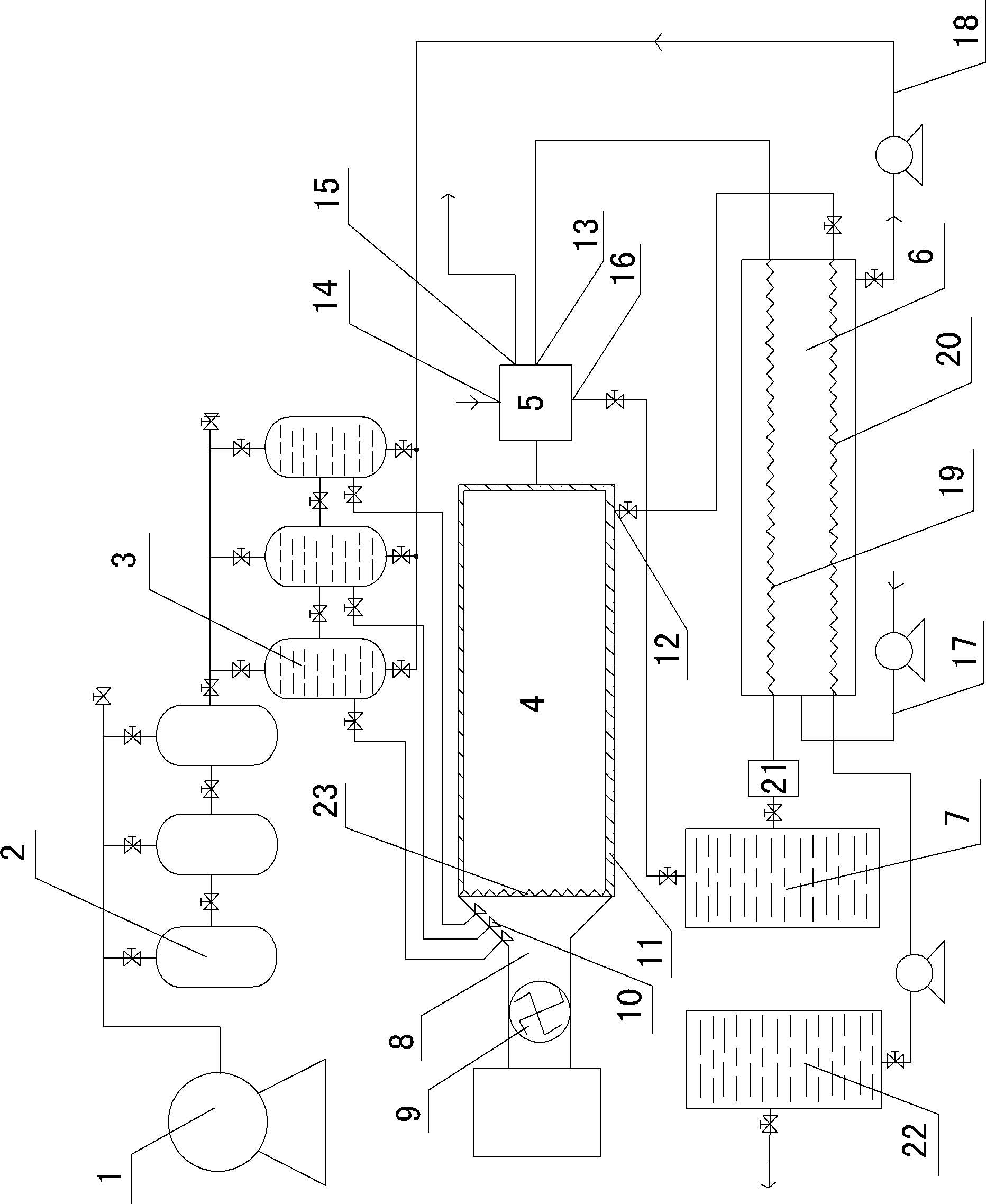

Low-energy consumption pressure spray desalination device and method thereof

InactiveCN102358628AFew moving partsSimple systemGeneral water supply conservationSeawater treatmentSeawaterFresh water organism

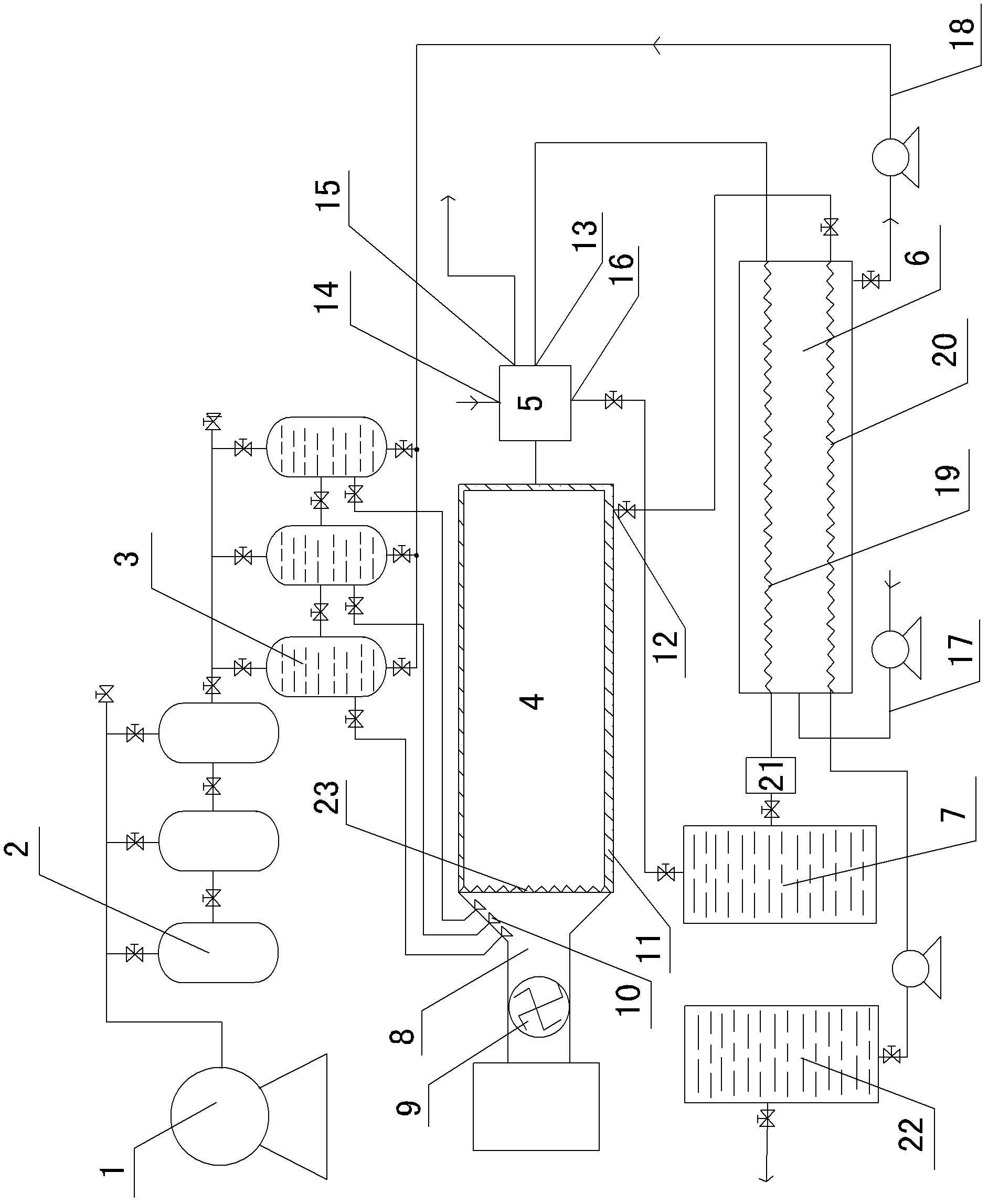

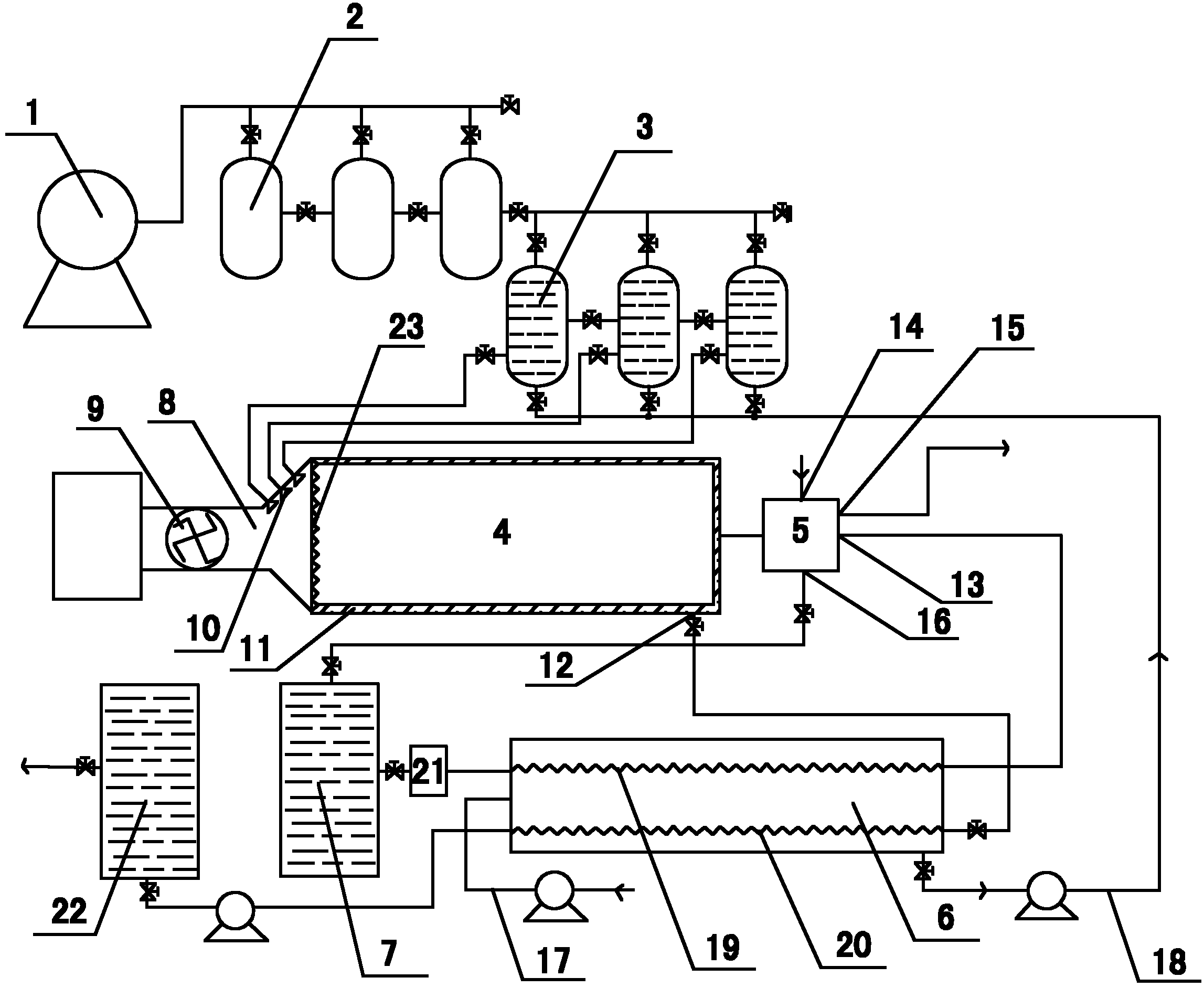

The present invention relates to a low-energy consumption pressure spray desalination device and a method thereof, and belongs to the field of sea-water desalination. The device part mainly comprises an air compressor set, a high pressure air tank, a high pressure hot seawater tank, a desalination and separation chamber, a hot air recoverer, a seawater heat exchanger tank and a freshwater tank. The spray desalination method mainly comprises the following steps: pressing seawater in sprinklers by high pressure, carrying out salt and water separation in the desalination and separation chamber in the high pressure spray manner. According to the present invention, the heat energy recycling and utilizing is realized; the high pressure gas phase power is adopted to transfer the spray, two heat exchanger method of convection and radiation are adopted, and the condensing waste heat is adopted for seawater heat energy recycling, such that the moving parts contacting with the seawater are reduced to the minimum, the system is simple, the operation is safe and stable so as to achieve purposes of low-temperature vaporization, low energy consumption, low investment, high yield, high efficiency and long service life.

Owner:BEIJING YUNTE TECH

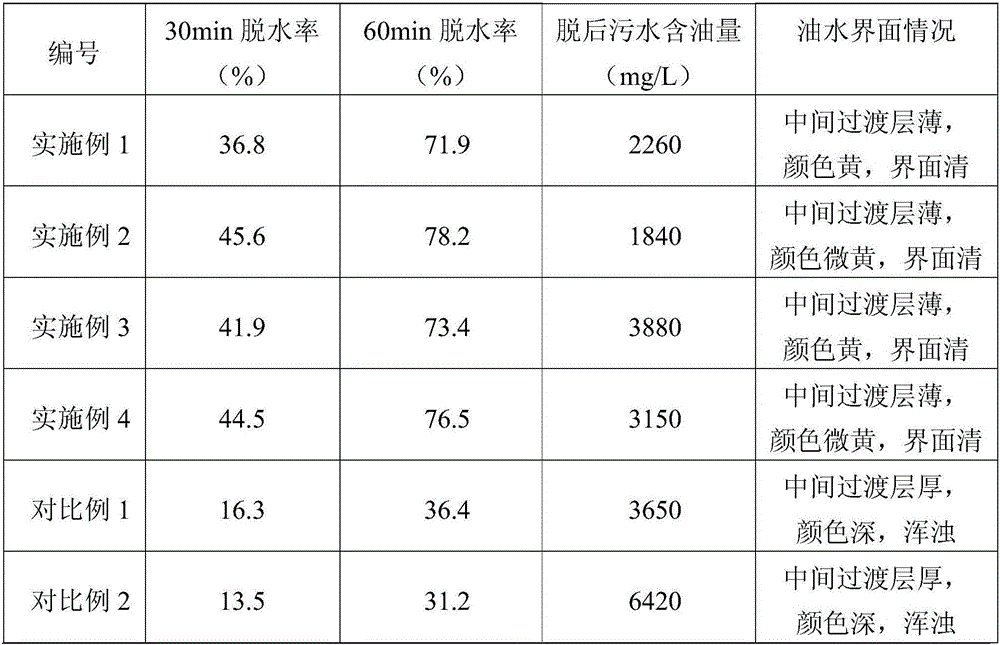

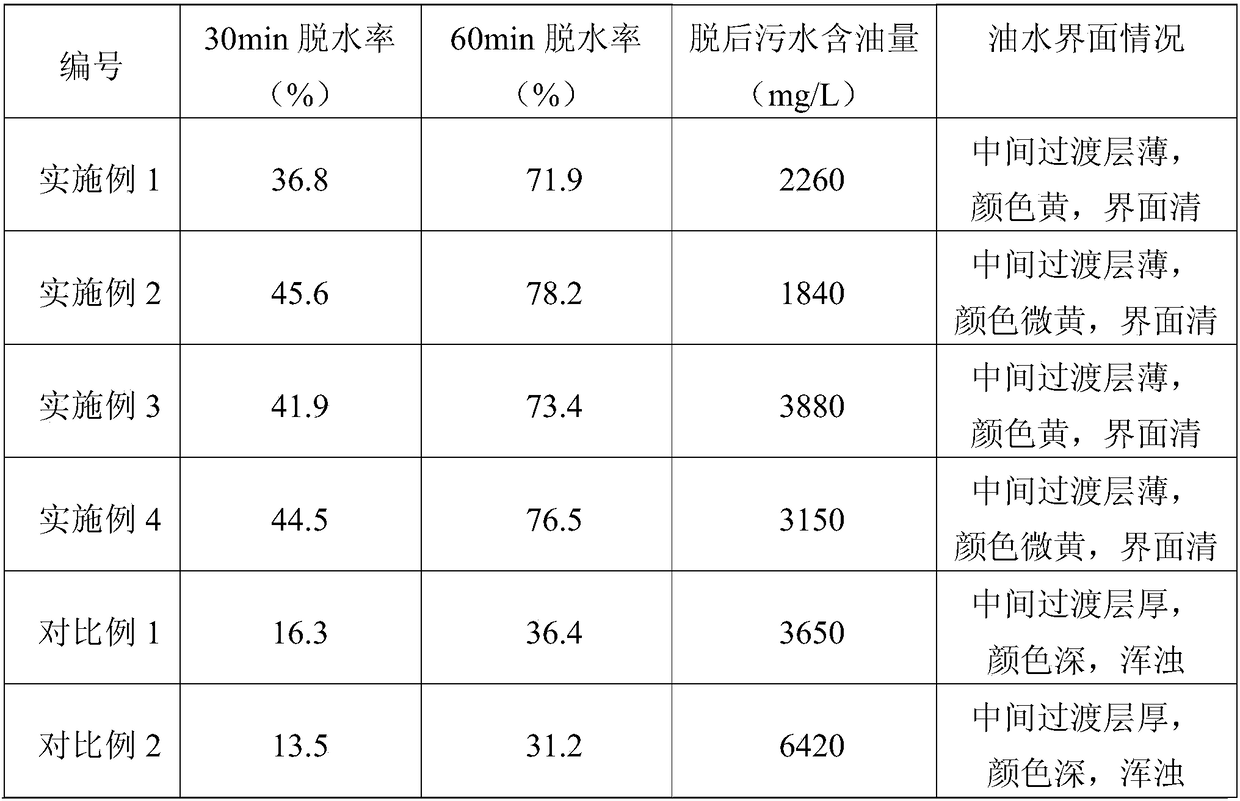

Method for efficiently treating oil field complex oil-water emulsion

ActiveCN106701156AReduce or eliminateChange stabilityDewatering/demulsification with chemical meansAlkaneDemulsifier

The invention provides a method for efficiently demulsifying and dehydrating oil field complex oil-water emulsion. The method comprises the following steps: 1) adding a demulsifier into crude oil and mixing uniformly to obtain primarily treated crude oil; 2) adding a mixture of alkane, alcohol and alcohol ether into the primarily treated crude oil and mixing uniformly, wherein the mixture of the alkane, the alcohol and the alcohol ether consists of three components, namely alkane, monohydric alcohol or polyhydric alcohol, and alcohol ether or alcohol ether ester. The method for efficiently demulsifying and dehydrating the oil field complex oil-water emulsion, provided by the invention, specially aims at a special oil-water emulsifying layer (an intermediate transition layer), ageing oil and the like which are easily formed after dehydration is conducted by singly adopting a demulsifier, the stability of an interfacial film of the oil-water emulsifying layer is effectively broken and the polar environment of interfacial phase is changed on the basis of not changing the use variety and the use mode of the original demulsifier by cooperatively using the specially composed mixture of the alkane, the alcohol and the alcohol ether, and the solubilization effect on asphaltene, colloid, polymers and the like is achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

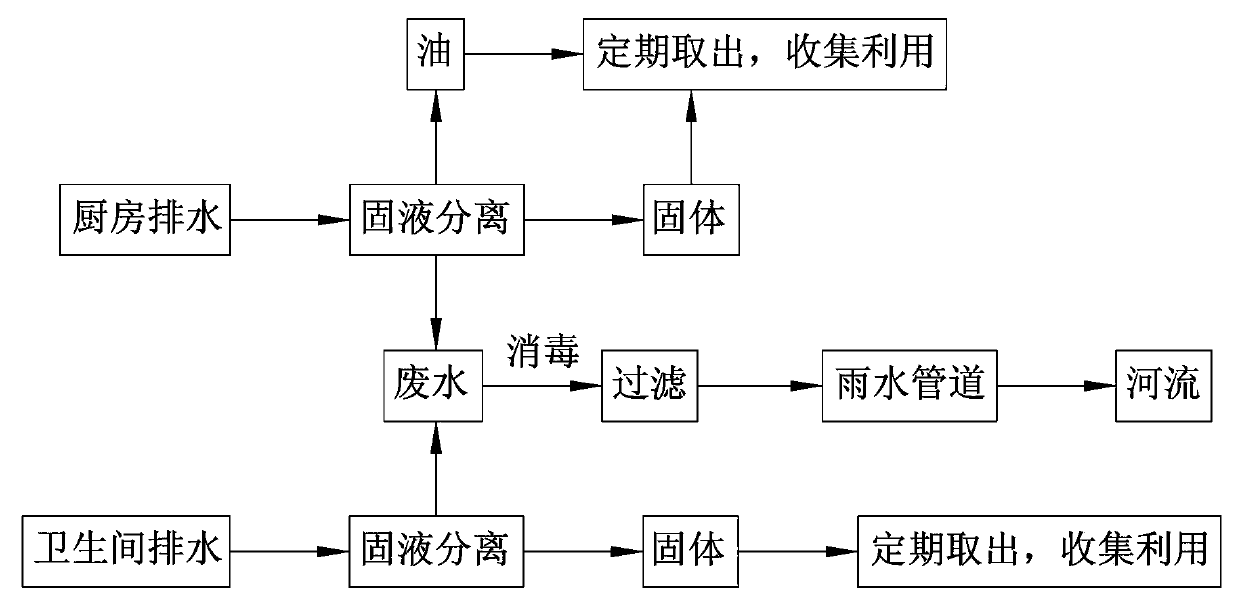

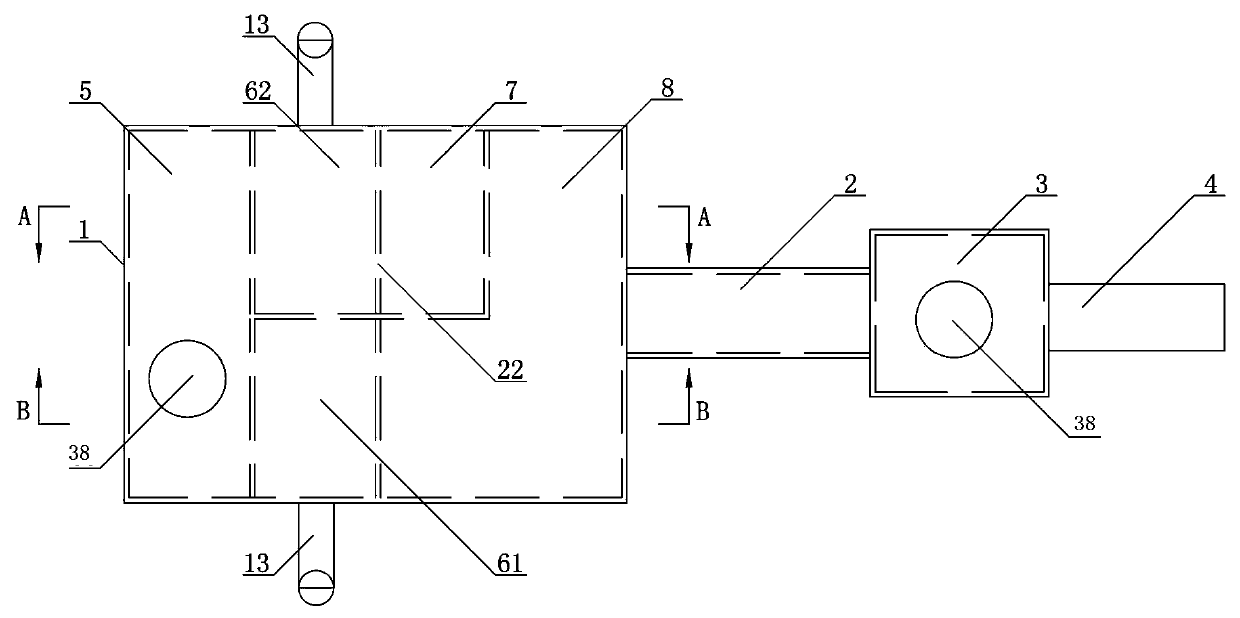

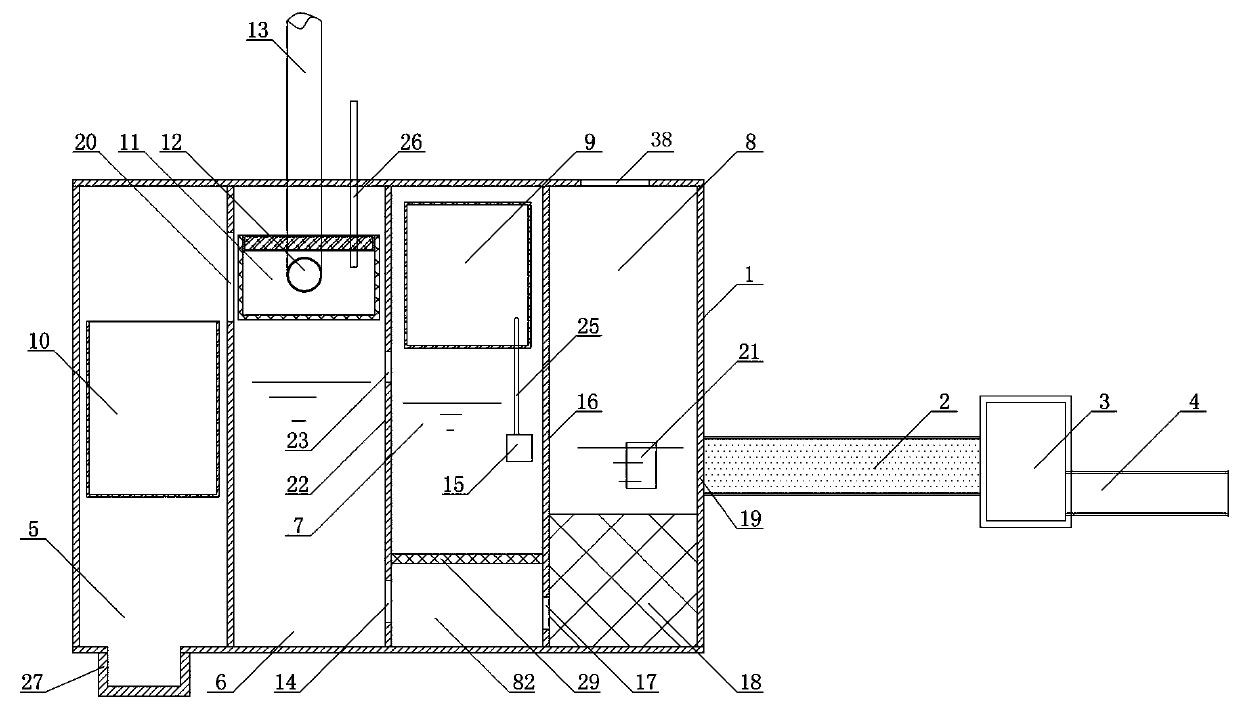

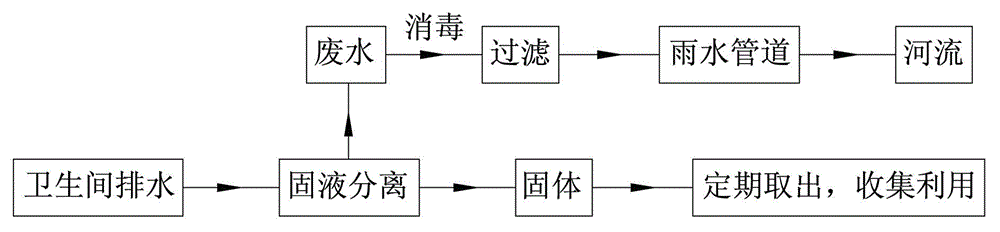

Method and device for treating water drained from kitchens and bathrooms

InactiveCN103739166AAvoid new pollution problemsSolve pollutionMultistage water/sewage treatmentWater storageWastewater

The invention relates to a method and a device for treating water drained from kitchens and bathrooms. A method for treating water drained from kitchens and bathrooms comprises the following steps: 1) immediately filtering sewage drained from kitchens so as to realize solid-liquid separation; 2) carrying out oil-water separation on liquid sewage; 3) immediately disinfecting sewage drained from bathrooms, and then filtering the sewage so as to realize solid-liquid separation; 4) disinfecting the wastewater subjected to oil-water separation, mixing the obtained water with the sewage subjected to solid-liquid separation in the 3), and further filtering the obtained mixture; 5) after the obtained water is subjected to further depth processing and reaches the standards, discharging or reusing the obtained product. A device for treating water drained from kitchens and bathrooms is provided with a solid-liquid separation chamber and a water storage chamber arranged in a sewage tank, the solid-liquid separation chamber is divided into a solid-liquid separation chamber for water drained from kitchens and a solid-liquid separation chamber for water drained from bathrooms, an oil storage tank communicated with the solid-liquid separation chamber for water drained from kitchens is arranged in the sewage tank, and sewage in the water storage chamber enters a filter pipe. According to the invention, the discharge of sanitary sewage and the cyclic utilization of wastes in communities are realized.

Owner:王凤蕊

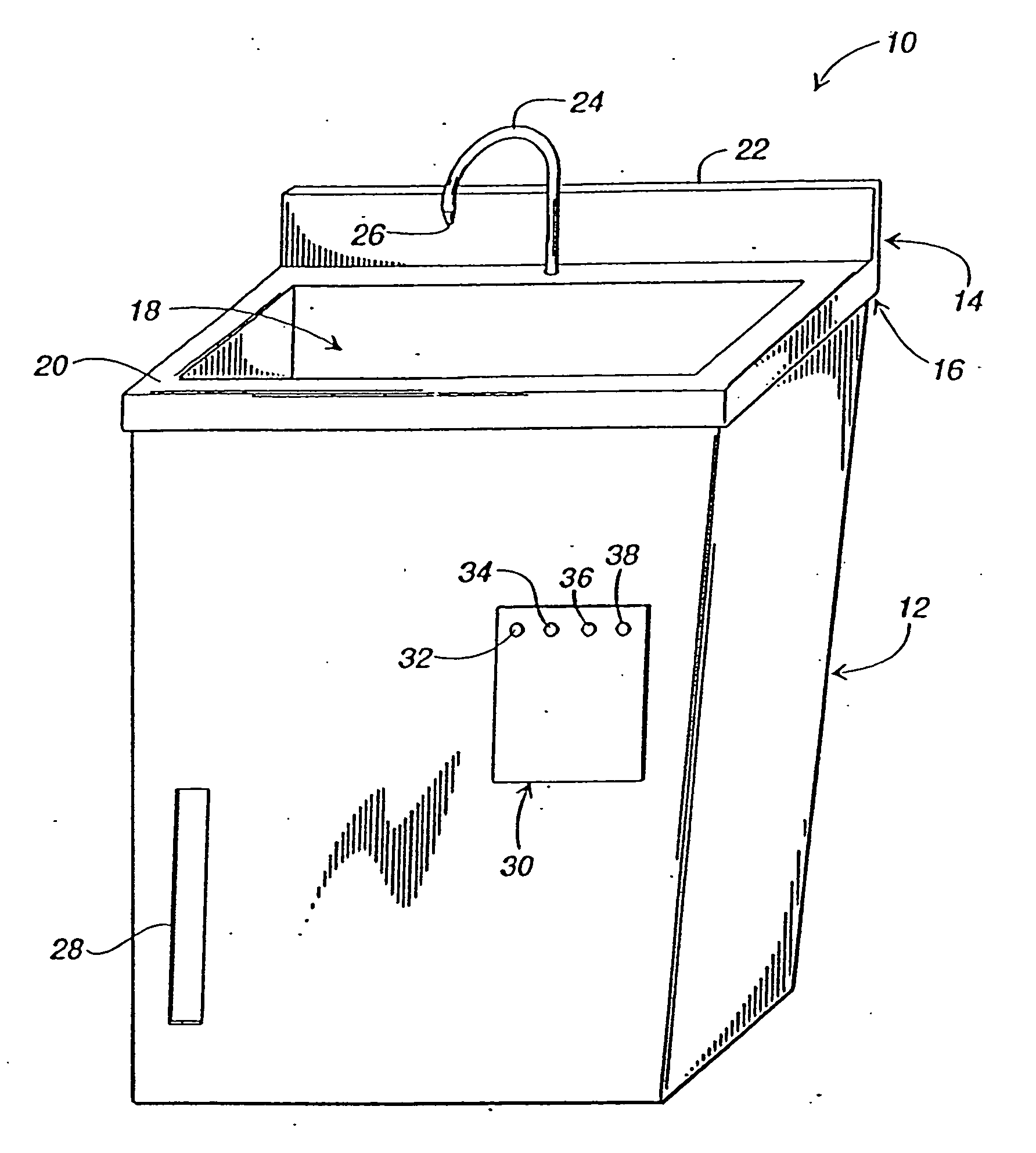

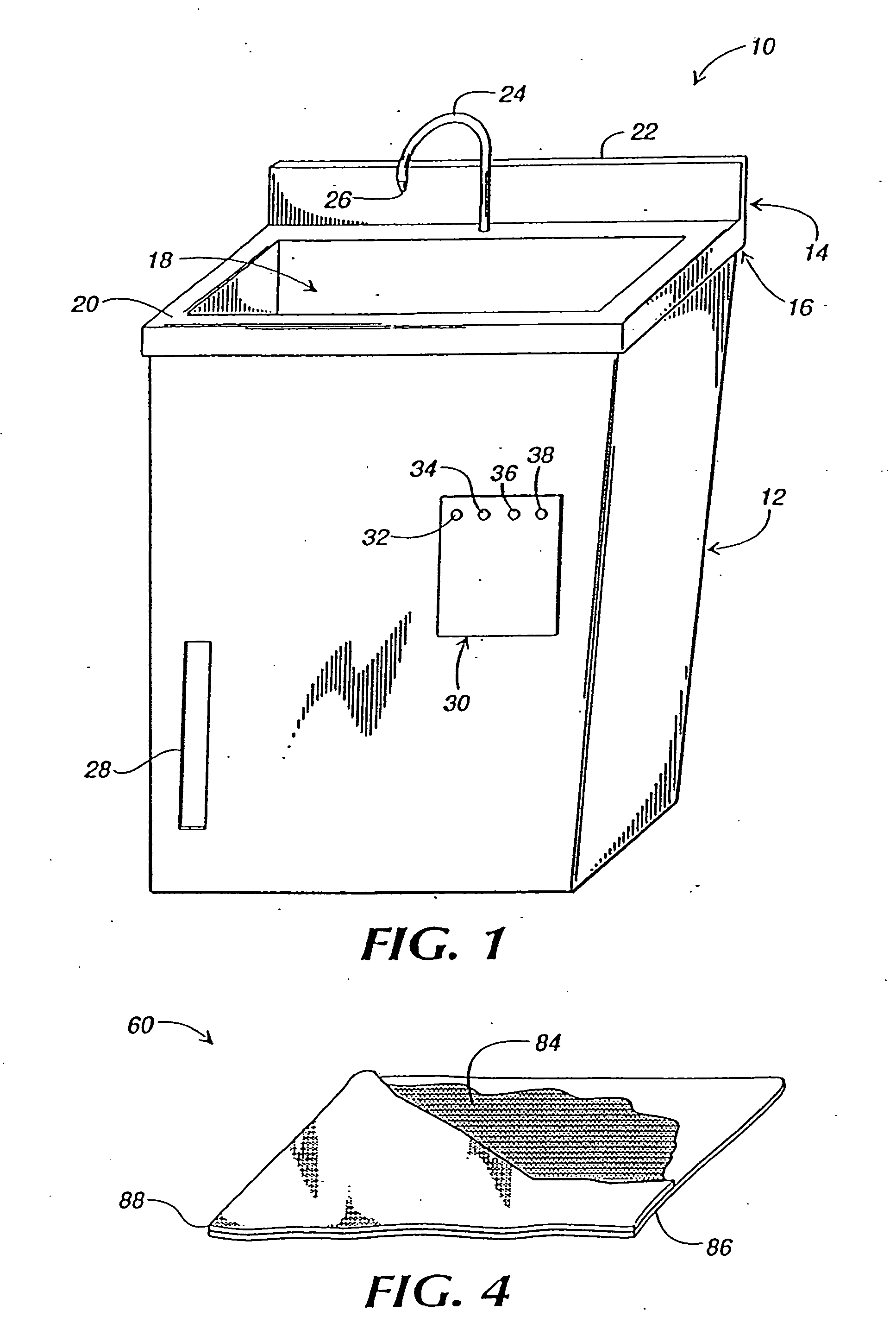

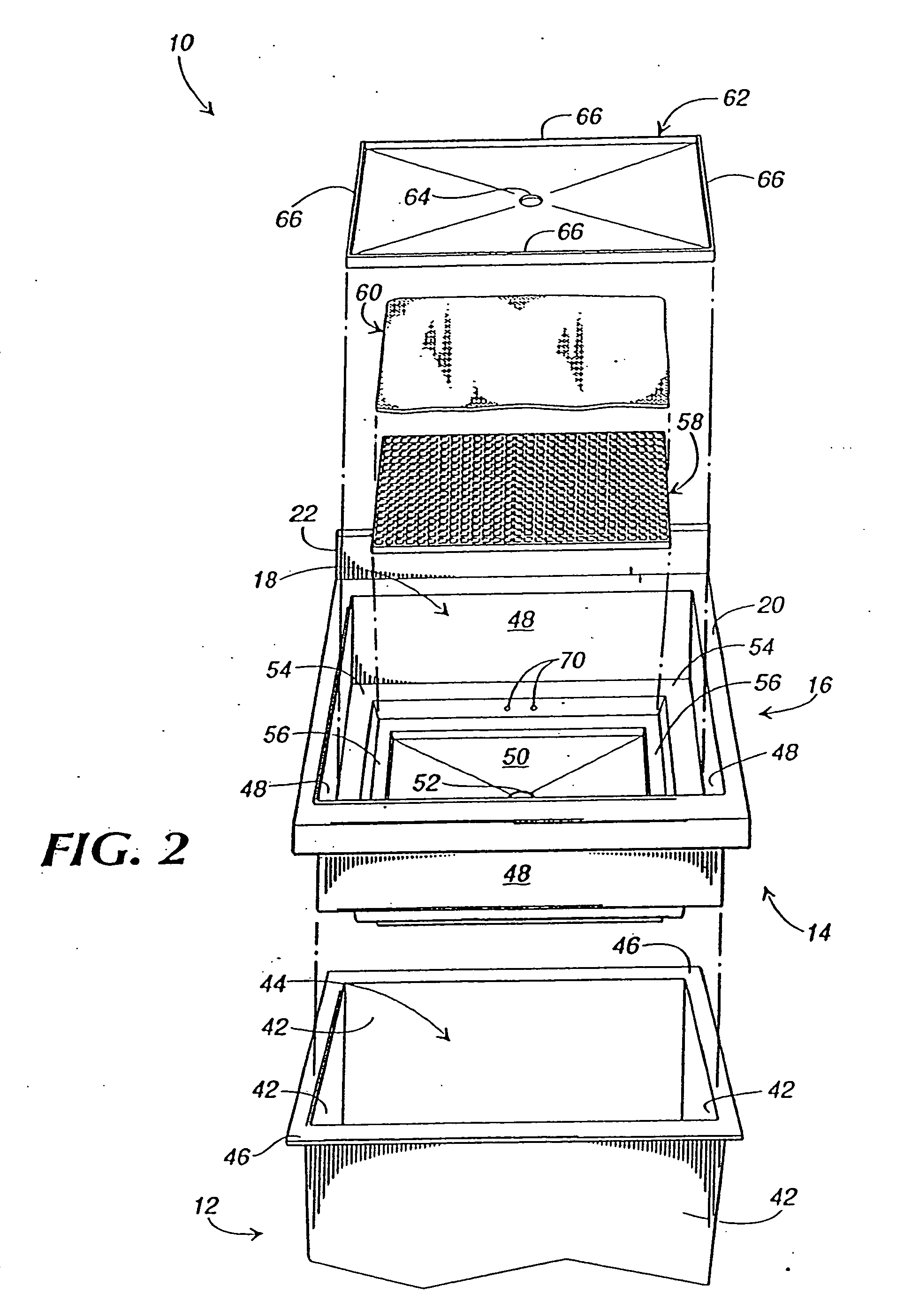

Parts washing system

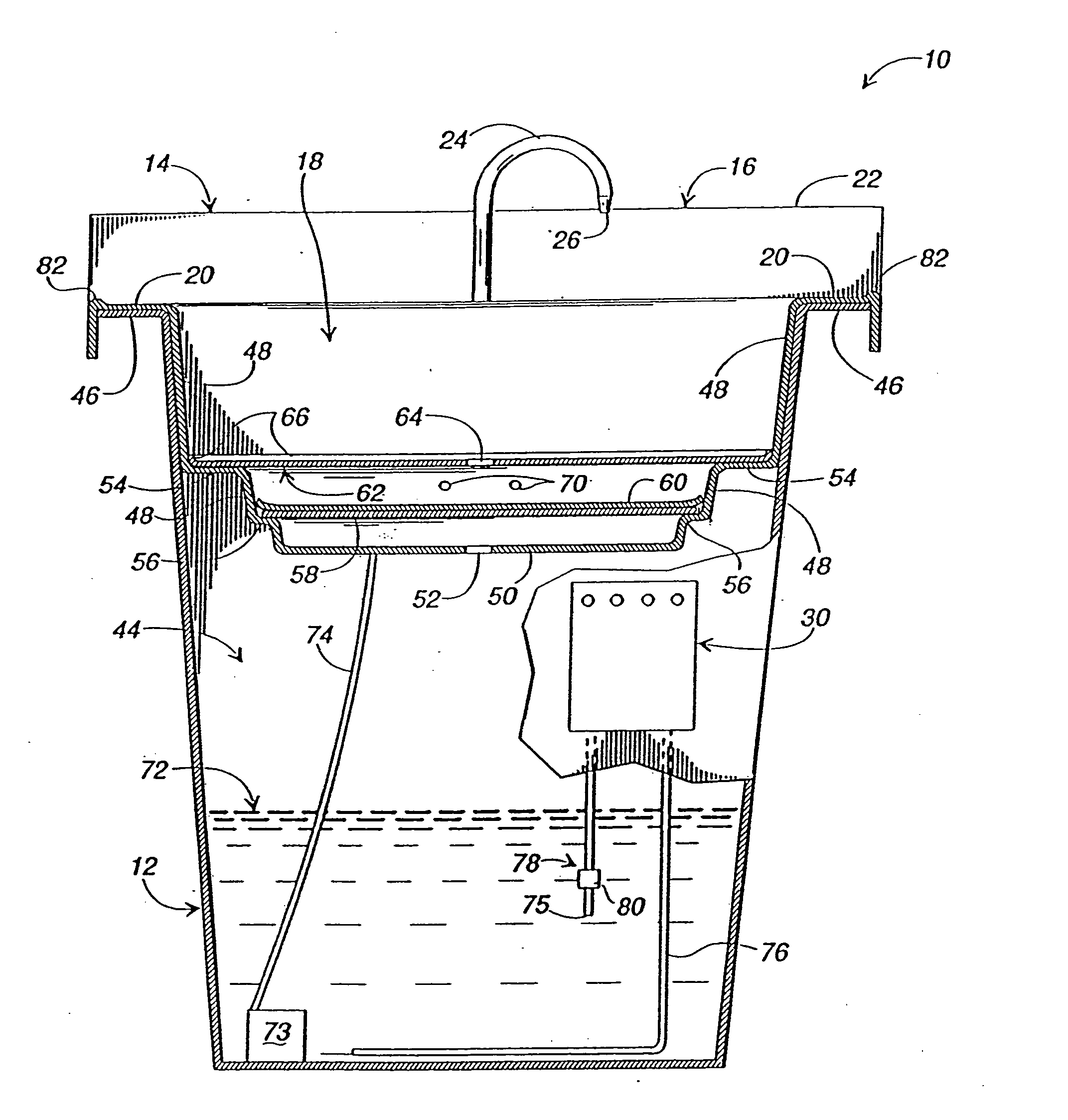

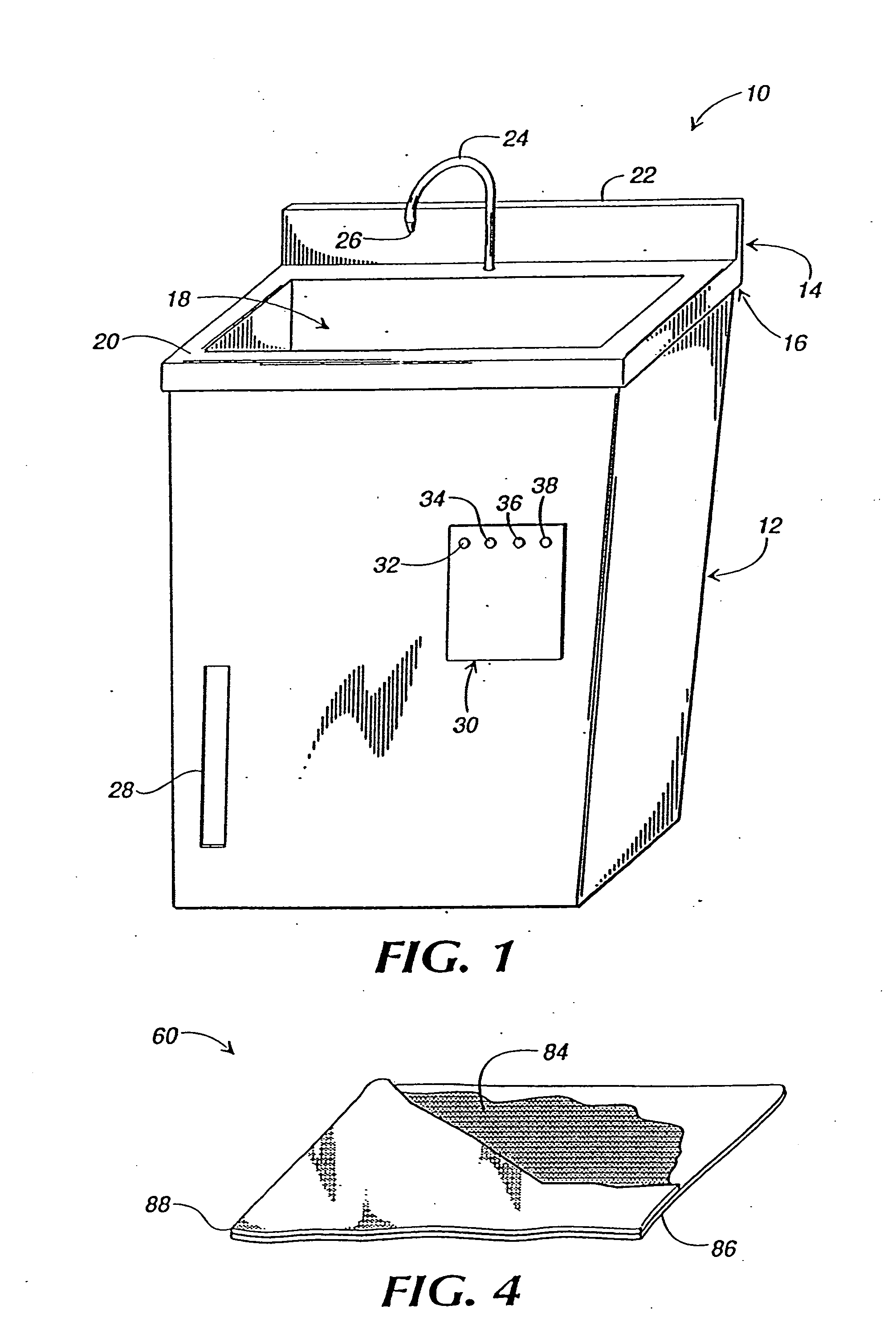

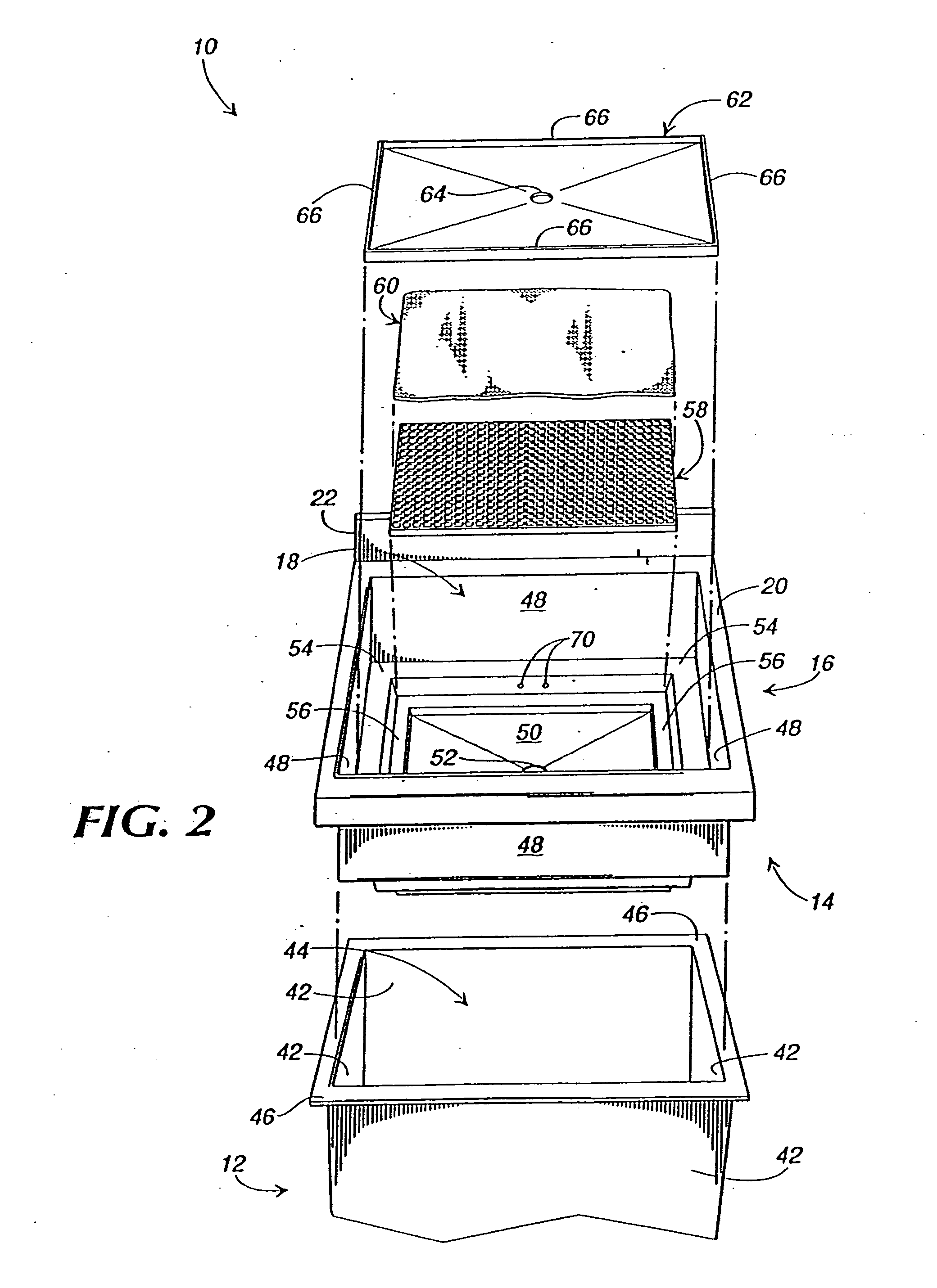

InactiveUS20050224095A1Reduce productionReadily accessible and replaceable filterTreatment using aerobic processesMicroorganismsThermostatSURFACTANT BLEND

Provided is a parts washer that includes a multi-tiered basin, a cleaning fluid and a biological component, living within the fluid, that breaks down organic waste. The multi-tiered basin includes a sink member with a false bottom, and a support grid and filter are interposed between the false bottom and a bottom panel of the sink member. The false bottom support grid, and filler are readily removable from the sink member. The tank is partially filled with the cleaning fluid and a pump and conduit assembly direct a flow of the cleaning fluid to the basin. The cleaning fluid discharged into the basin flows through a drain hole in the false bottom, through the filter and support grid, and then through a drain hole in the bottom panel of the sink member back into the tank for reuse. The cleaning fluid includes, at least, a surfactant that functions to remove organic waste from the parts being washed. The biological component within the cleaning fluid includes nonpathogenic microorganisms that break down the organic waste. The cleaning fluid is not toxic to the microorganisms. The pump and conduit assembly, in addition to aiding in the removal of organic waste, functions to aerate the cleaning fluid to maintain a proper environment for the microorganisms. A heater, thermostat, and level control assembly function to maintain:the cleaning fluid within a certain temperature range so as to aid in the removal of organic waste and maintain a proper environment for the microorganisms.

Owner:CHEMFREE CORP +1

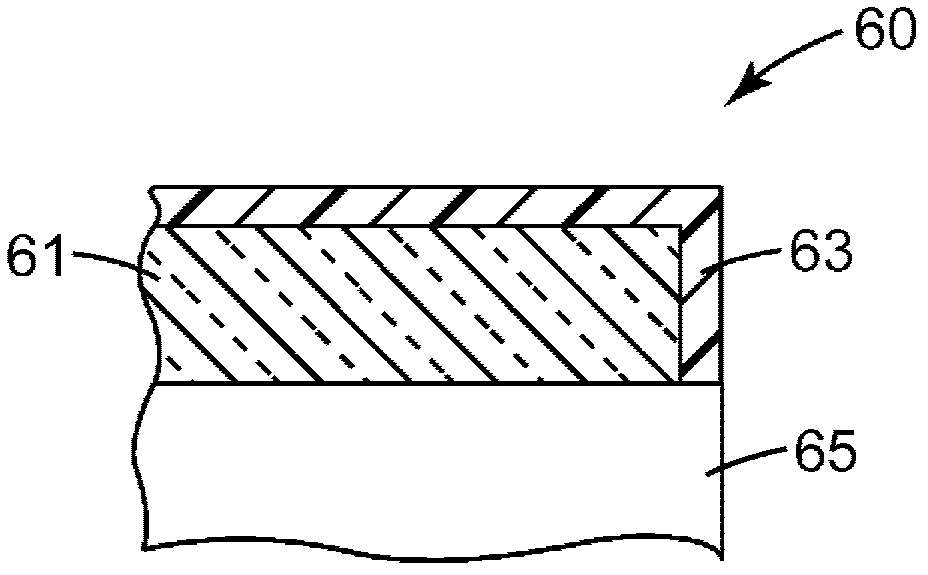

Metal coated with a radiation curable outdoor durable coating

InactiveCN101052518AReduce or eliminate the use ofReduce or eliminateVacuum evaporation coatingSputtering coatingUltravioletPolymer chemistry

Owner:ALUMINUM CO OF AMERICA

Treatment device for concentrated landfill leachate

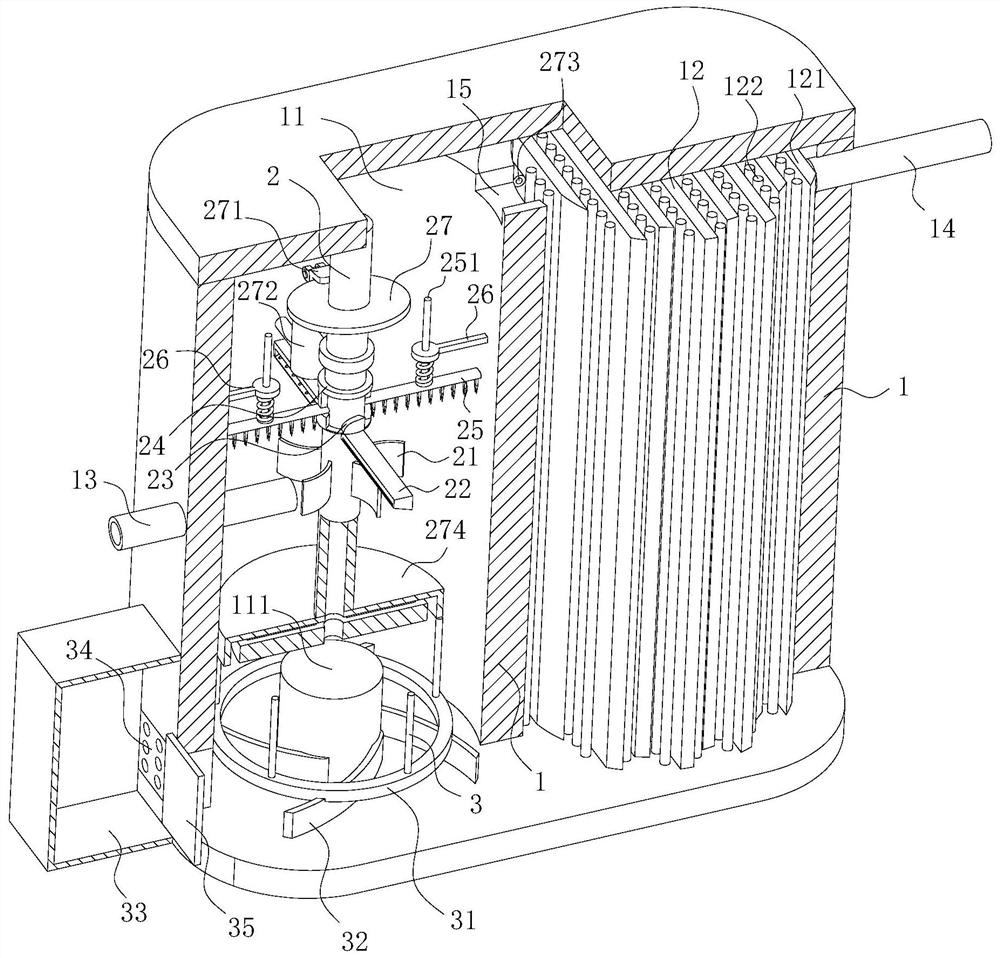

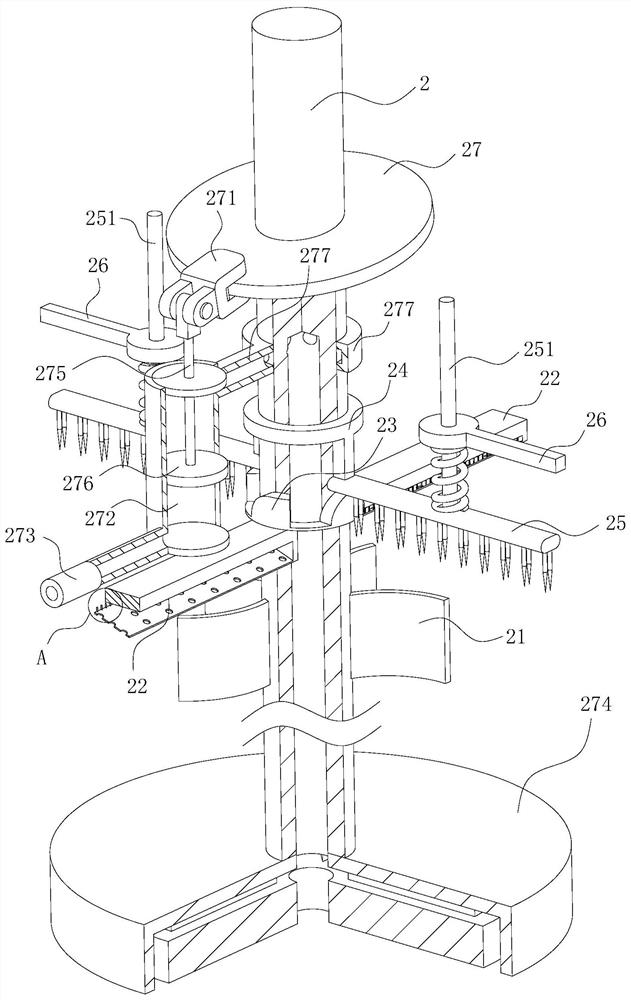

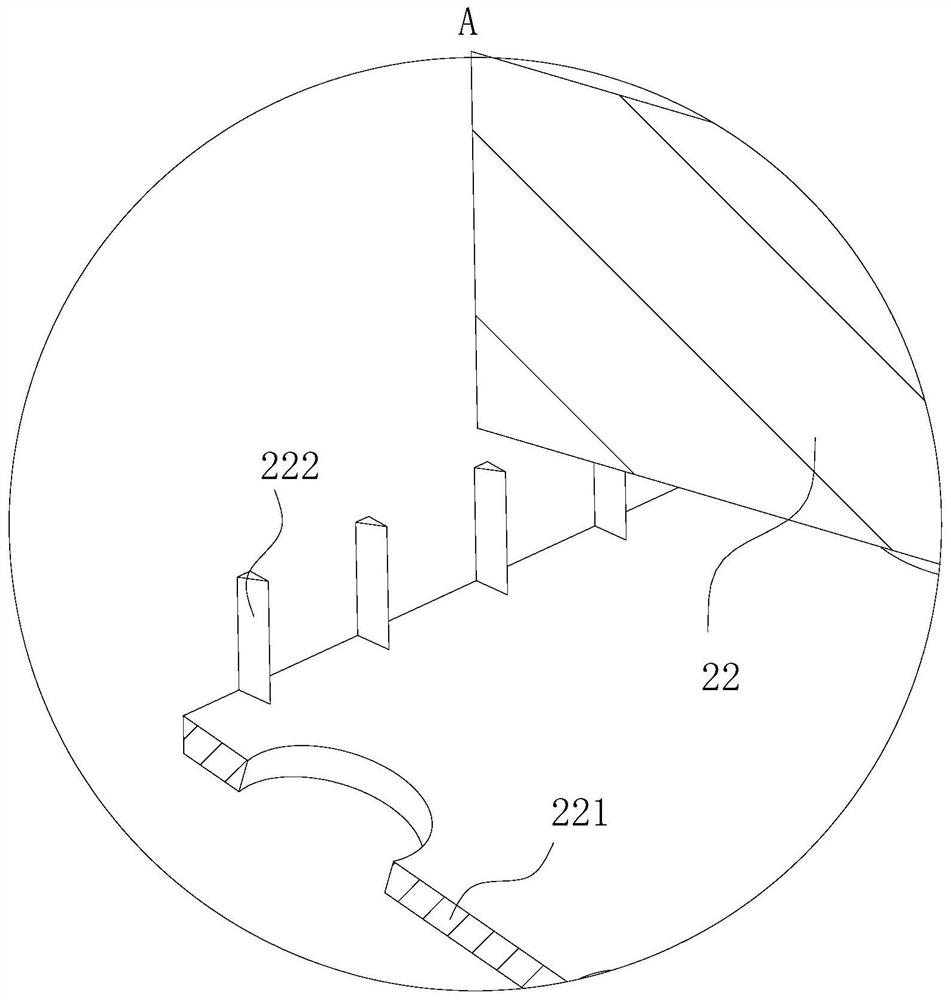

ActiveCN112028349AFully clearAffect normal workSpecific water treatment objectivesWater/sewage treatment with mechanical oscillationsSewage treatmentElectrochemistry

The invention belongs to the technical field of sewage treatment equipment, and particularly relates to a treatment device for concentrated landfill leachate. The treatment device comprises a tank body, wherein the tank body is provided with an ultrasonic treatment tank and an electrochemical treatment tank; a liquid inlet pipe and a liquid outlet pipe are mounted on the tank body; an ultrasonic generator is mounted on the bottom surface of the ultrasonic treatment tank; a rotating shaft is mounted in the ultrasonic treatment tank; a pushing blade is mounted on the rotating shaft; the pushingblade is just over the outlet, in the ultrasonic treatment tank, of the liquid inlet pipe; a defoaming plate is mounted on the rotating shaft; polar plates are mounted in the electrochemical treatmenttank; and the polar plates are composed of a negative plate and a positive plate which are respectively communicated with the positive electrode and the negative electrode of a power supply. The device is simple in structure, convenient to use, good in treatment effect and high in treatment efficiency.

Owner:ANHUI QINGYANG WATER TREATMENT EQUIP TECH CO LTD

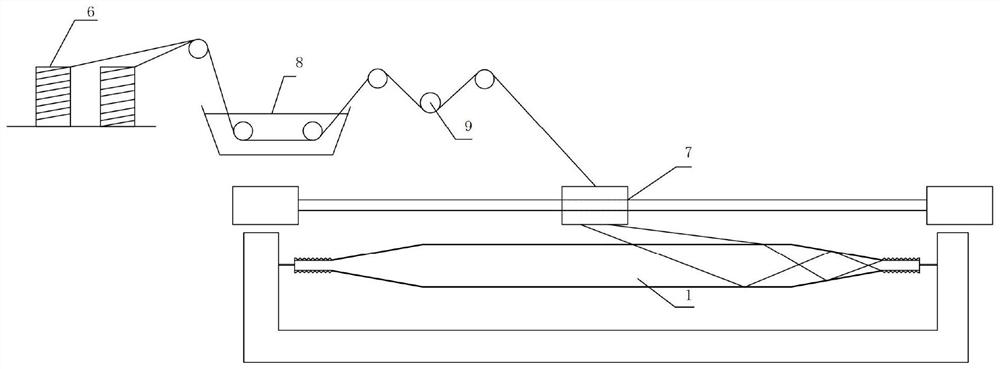

Variable cross-section fiber reinforced composite pipe and pipe-die integrated forming method

PendingCN112009001AHigh strengthImprove stabilityTubular articlesConical tubeFiber-reinforced composite

The invention discloses a variable cross-section fiber reinforced composite pipe and a pipe-die integrated forming method. The method includes the steps of step 1, steel core die manufacturing and installation in which a steel core die is manufactured and installed, and a metal die is made of thin-wall steel into the shape of the interior of the composite pipe; step 2, steel core die winding in which the steel core die is wound with long fibers to form a fiber composite laying layer; step 3, fiber composite laying layer curing in which an external installed metal outer die integrally wraps thefiber composite laying layer, and the fiber composite laying layer is placed into a curing box for curing; and step 4, machining in which the metal outer die is taken down after curing and machined and installed according to needs. The variable cross-section fiber reinforced composite pipe comprises a middle linear round pipe, transition section conical pipes at the two sides, and end connector parts. The process is free of demolding and the die directly serves as a combined component to be integrally stressed with the composite pipe, so that the overall strength and stability of the composite pipe are improved, a complex demolding process is avoided; and the transition between the composite pipe and a metal structure is provided by the connector parts at the ends, and the composite pipecan be more easily applied to the field of high-performance works.

Owner:NANJING INST OF TECH

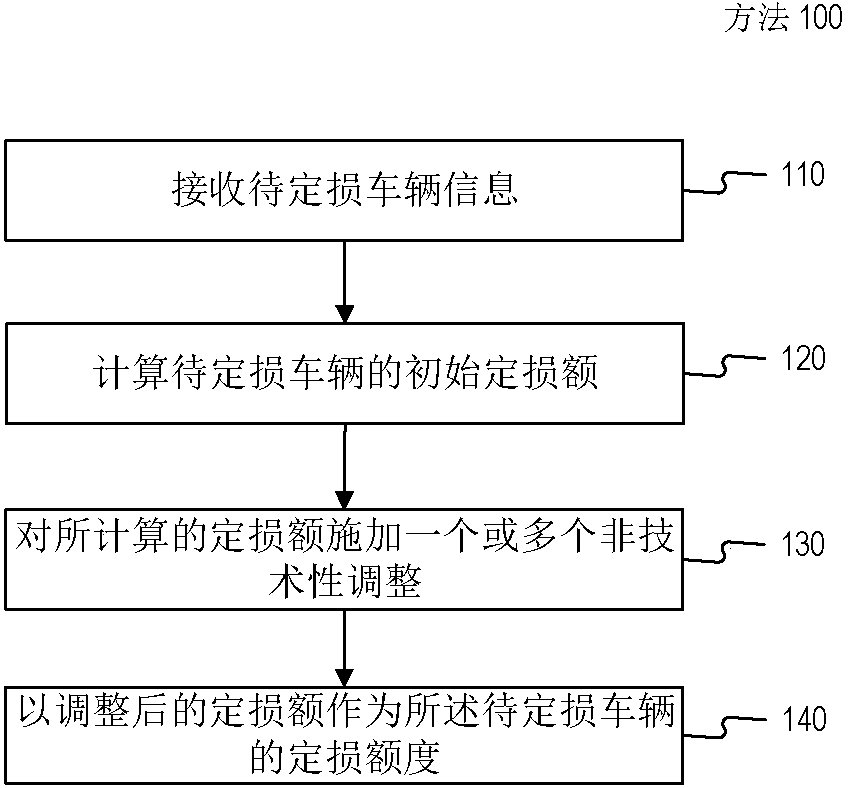

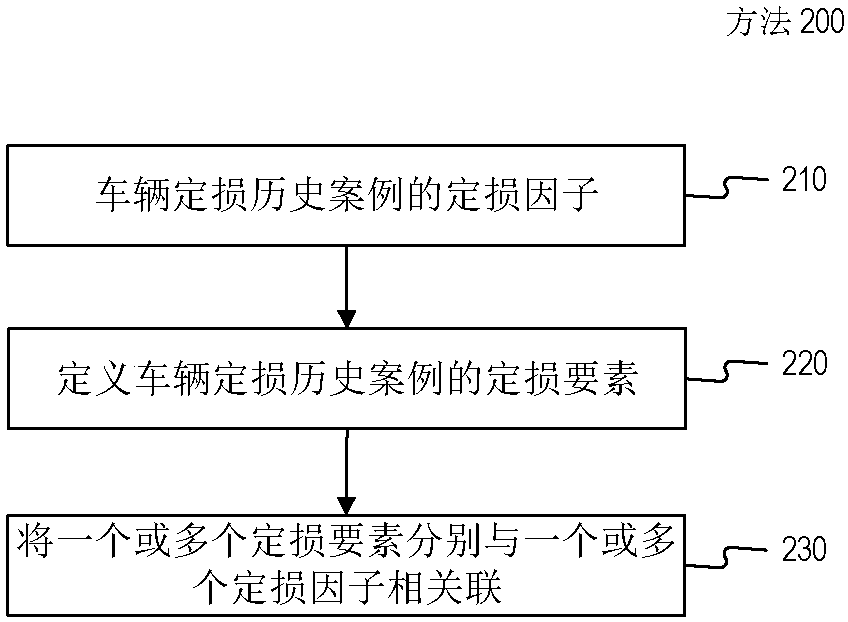

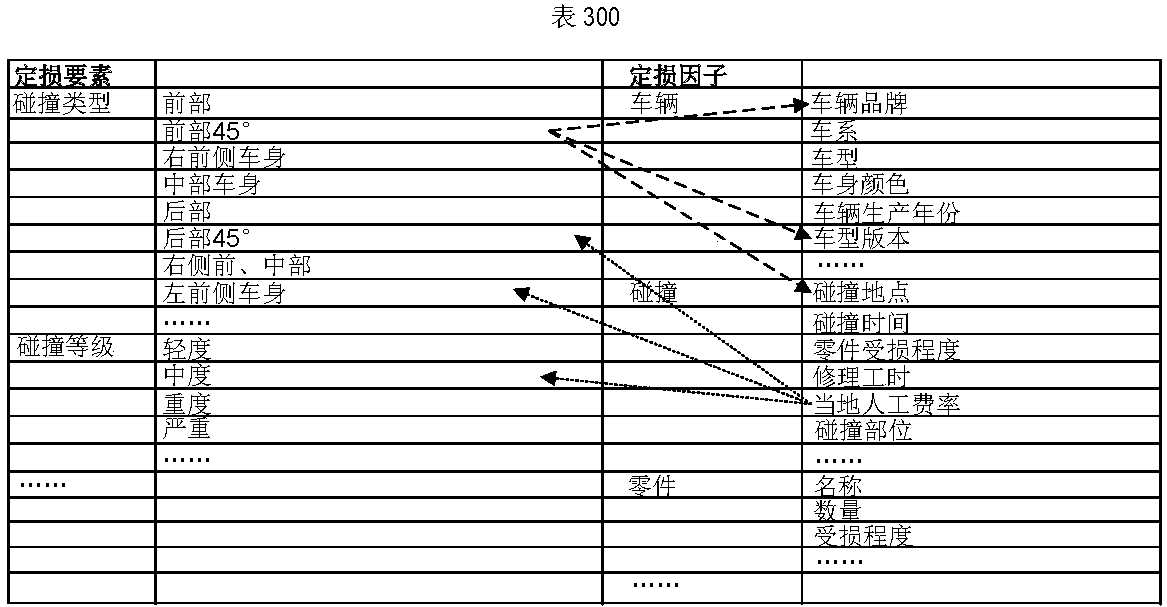

Vehicle collision automatic loss assessment method and system based on non-technical factors

InactiveCN110363669AReduce or eliminateFast loss assessmentFinancePersonalizationIndustrial engineering

Owner:MR T INFORMATION&TECH LTD

Polishing device and method of sapphire

InactiveCN101664894BReduce or even eliminate the impactEliminate the effects ofEdge grinding machinesSurface roughnessEngineering

The invention relates to polishing device and method of sapphire. The polishing device comprises a laser beam, a shoe plate, a worktable and a connecting piece, wherein the worktable is provided with a stepper motor driving the worktable to make X-direction movement and a stepper motor driving the worktable to make Y-direction movement, the connecting piece is fixed on the worktable, the shoe plate is arranged on the connecting piece, and a sapphire wafer to be polished is fixed on the shoe plate; the laser beam radiates to the sapphire wafer from the upward side of the sapphire wafer to be polished, and the stepper motor driving the worktable to make the X-direction movement and the stepper motor driving the worktable to make the Y-direction movement are respectively connected with a control device. The invention controls the X-direction movement and the Y-direction movement of a workpiece and the movement track of the workpiece relative to the laser beam by regulating the incident angle of the laser beam and controlling the worktable, thereby realizing the comprehensive scanning and polishing on the surface of the sapphire wafer. The invention can remove very little material, reduce and even eliminate the influence of heat on the sapphire material, thereby obtaining a polished surface with low surface roughness and low subsurface injury degree.

Owner:GUANGDONG UNIV OF TECH

Parts washing system

InactiveUS20050056304A1No toxicityReduce productionTreatment using aerobic processesMicroorganismsThermostatSURFACTANT BLEND

Provided is a parts washer that includes a multi-tiered basin, a cleaning fluid and a biological component, living within the fluid, that breaks down organic waste. The multi-tiered basin includes a sink member with a false bottom, and a support grid and filter are interposed between the false bottom and a bottom panel of the sink member. The false bottom, support grid, and filter are readily removable from the sink member. The tank is partially filled with the cleaning fluid and a pump and conduit assembly direct a flow of the cleaning fluid to the basin. The cleaning fluid discharged into the basin flows through a drain hole in the false bottom, through the filter and support grid, and then through a drain hole in the bottom panel of the sink member back into the tank for reuse. The cleaning fluid includes, at least, a surfactant that functions to remove organic waste from the parts being washed. The biological component within the cleaning fluid includes nonpathogenic microorganisms that break down the organic waste. The cleaning fluid is not toxic to the microorganisms. The pump and conduit assembly, in addition to aiding in the removal of organic waste, functions to aerate the cleaning fluid to maintain a proper environment for the microorganisms. A heater, thermostat, and level control assembly function to maintain the cleaning fluid within ascertain temperature range so as to aid in the removal of organic waste and maintain a proper environment for the microorganisms.

Owner:ZYMO INT +1

Filter drier

InactiveCN105705887AReduce or eliminateEfficient removalGas treatmentDispersed particle separationEngineeringFixed position

A spherical filter drier for an HVACR system includes a generally spherical shell and a core that is fixed position relative to the shell. The shell has a first opening and a second opening in fluid communication with one another across the core. The core includes a media that removes contaminants from fluid flowing from the first opening through the core to the second opening. The spherical shell may be a monolithic shell, or formed from a pair of generally hemispherical shells.

Owner:PARKER HANNIFIN CORP

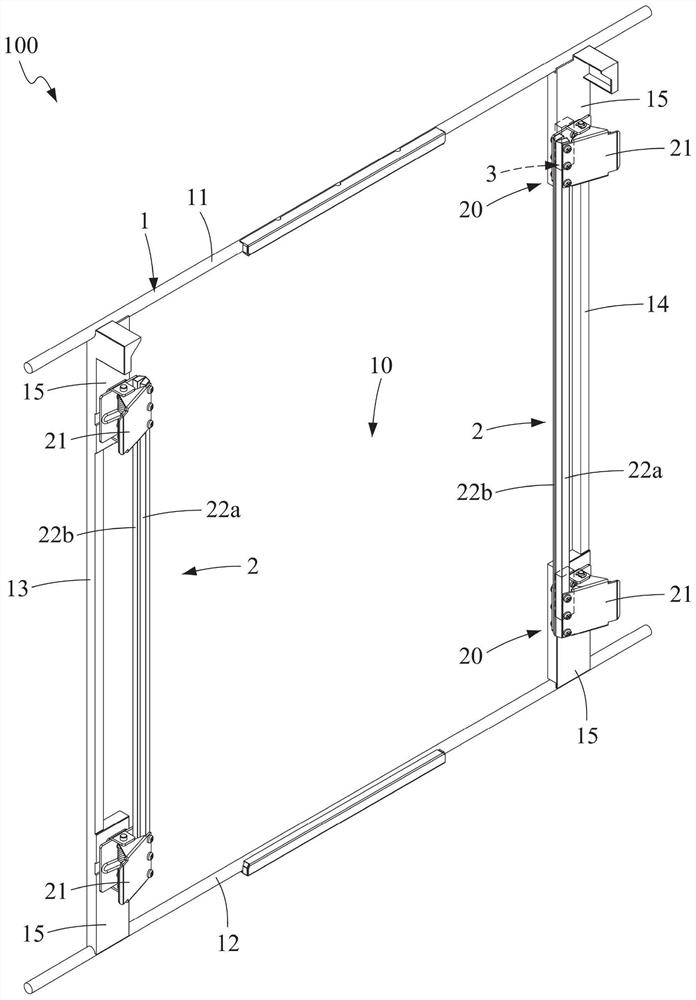

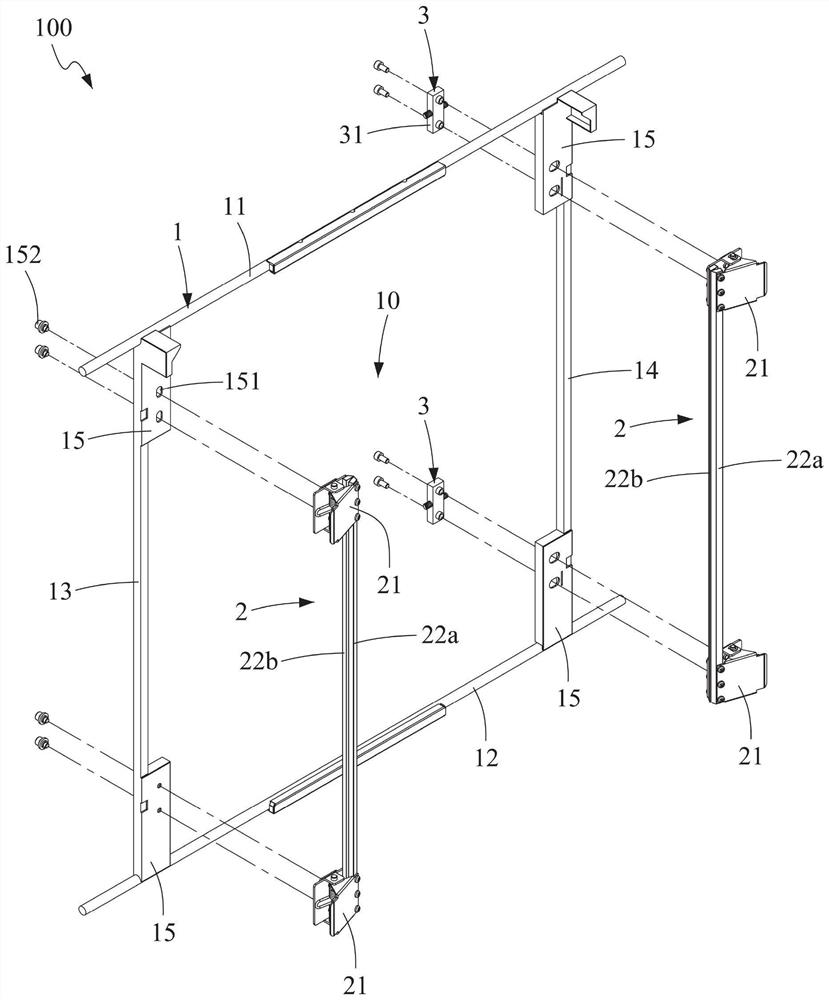

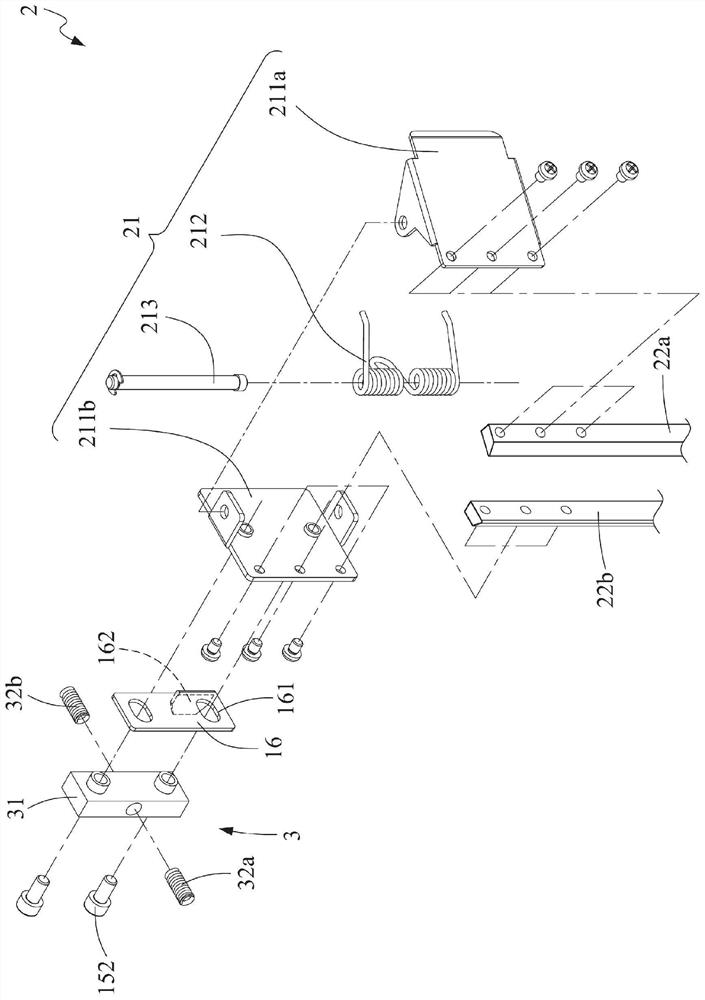

Anti-arching circuit board rack

PendingCN114193412AReduce or eliminateAvoid breakingWork benchesClassical mechanicsStructural engineering

Owner:GRP UP IND CO LTD

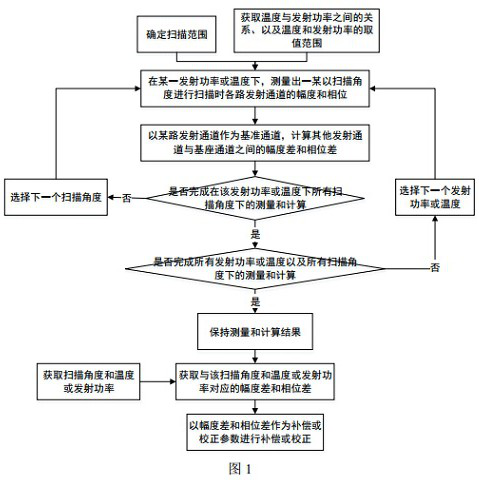

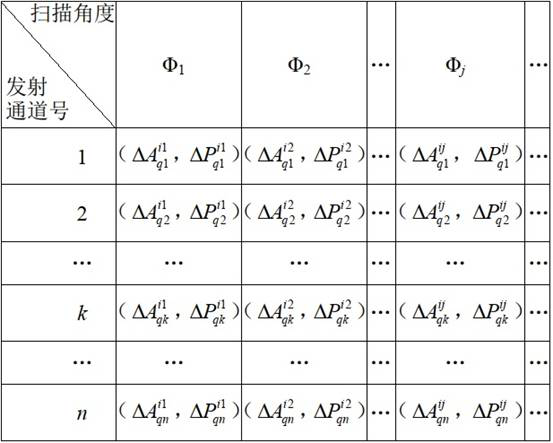

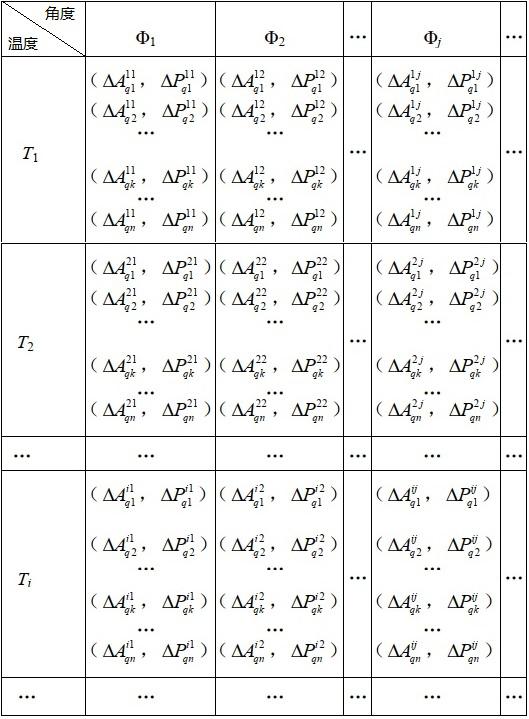

Phased array weather radar and transmitting amplitude and phase correction method and system thereof

InactiveCN113835073AReduce or eliminateReduce or eliminate the effect of phaseICT adaptationRadio wave reradiation/reflectionPhase correctionWeather radar

The invention discloses a phased array weather radar and a transmitting amplitude and phase correction method and system thereof, and the method comprises the steps: measuring the amplitude and phase of each transmitting channel at different scanning angles and different transmitting powers or temperatures, and taking a certain transmitting channel as a reference channel; and calculating amplitude differences and phase differences between other transmitting channels and the reference channel, and correcting the amplitude and the phase of each transmitting channel by taking the amplitude differences and the phase differences as compensation or correction parameters. Therefore, the influence of active standing wave changes and temperature on the amplitude and the phase of each transmitting channel is reduced or eliminated.

Owner:HUNAN EASTONE WASHON TECH CO LTD

Method for reducing formation of electrically resistive layer on ferritic stainless steels

ActiveUS8529709B2Reduce or eliminate)Trend downFinal product manufactureSolid state diffusion coatingElectrical resistance and conductanceFerrosilicon

A method of reducing the formation of electrically resistive scale on a an article comprising a silicon-containing ferritic stainless subjected to oxidizing conditions in service includes, prior to placing the article in service, subjecting the article to conditions under which silica, which includes silicon derived from the steel, forms on a surface of the steel. Optionally, at least a portion of the silica is removed from the surface to placing the article in service. A ferritic stainless steel alloy having a reduced tendency to form silica on at least a surface thereof also is provided. The steel includes a near-surface region that has been depleted of silicon relative to a remainder of the steel.

Owner:ATI PROPERTIES

A high-efficiency treatment method for oilfield complex oil-water emulsion

ActiveCN106701156BReduce or eliminateChange stabilityDewatering/demulsification with chemical meansAlkaneDemulsifier

Owner:CHINA NAT OFFSHORE OIL CORP +1

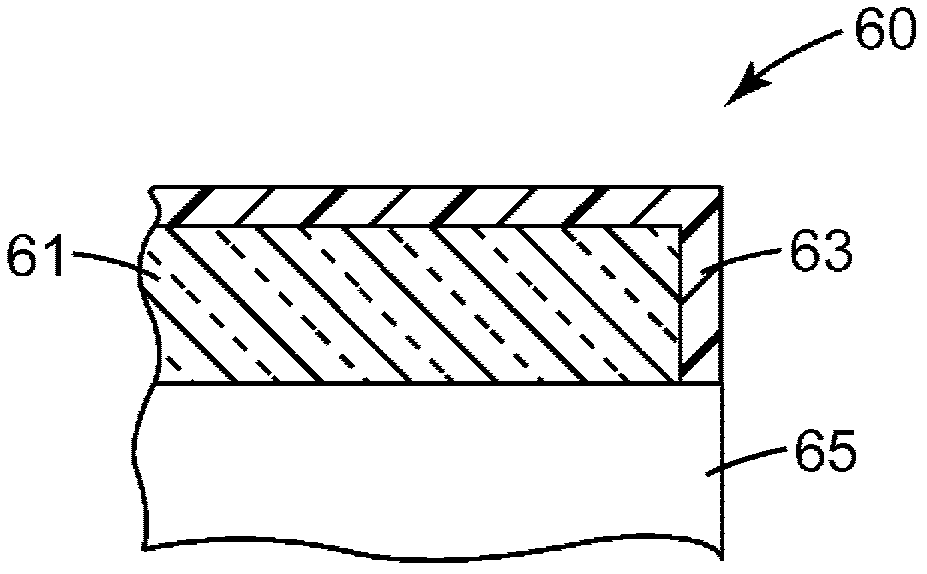

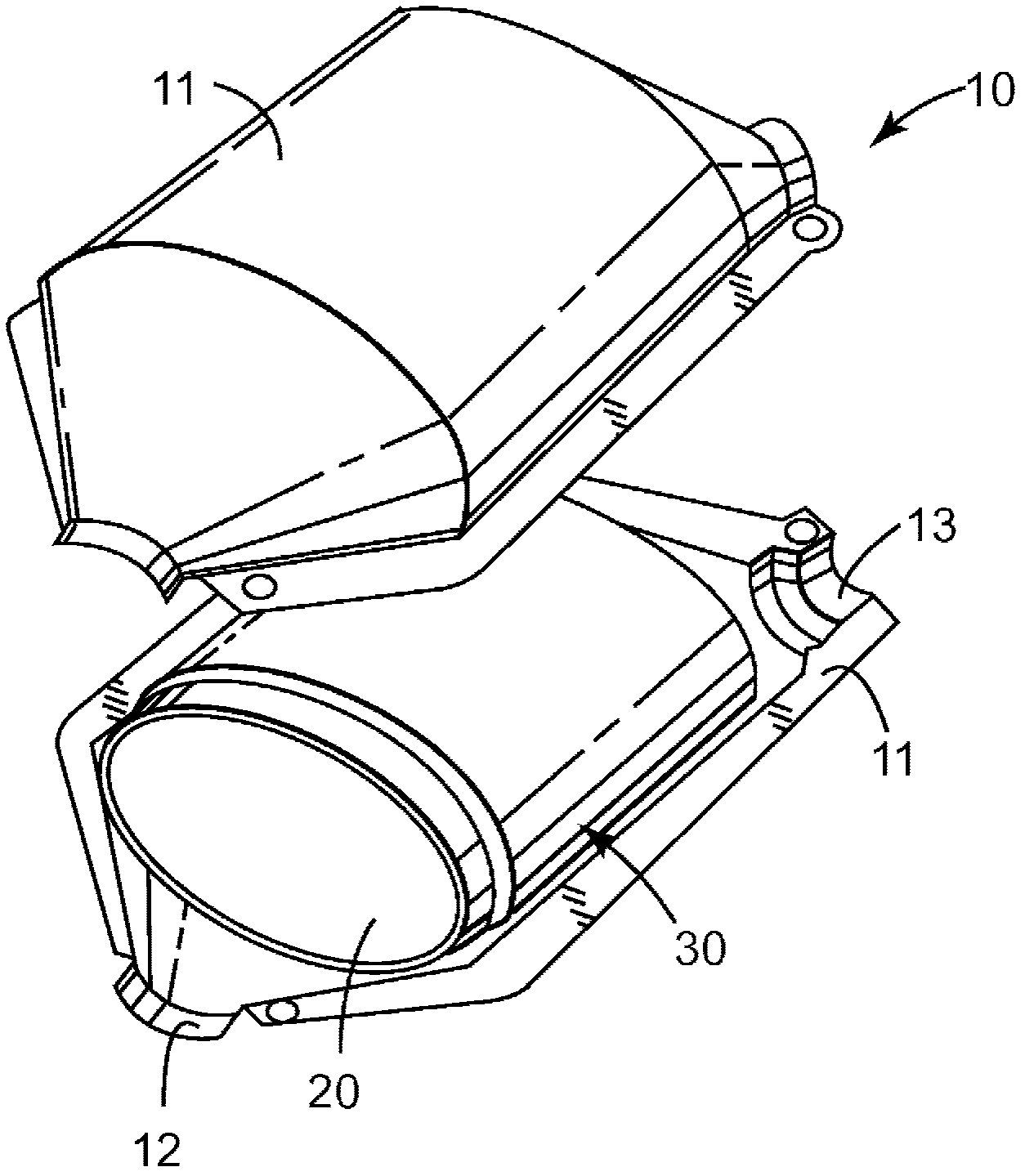

Tubular, continuous, seamless, compressible, resilient installation article and pollution control device comprising said installation article

InactiveCN102481750BReduce or eliminateEasy to slideExhaust apparatusSynthetic resin layered productsFiberEngineering

The present invention discloses a tubular, continuous, seamless, compressible, resilient mounting article comprising inorganic fibers and having an interior curved surface, a central longitudinal axis, and a consistent internal cross-section along said central longitudinal axis . The mounting articles are useful, for example, for mounting pollution control elements in pollution control devices.

Owner:3M INNOVATIVE PROPERTIES CO

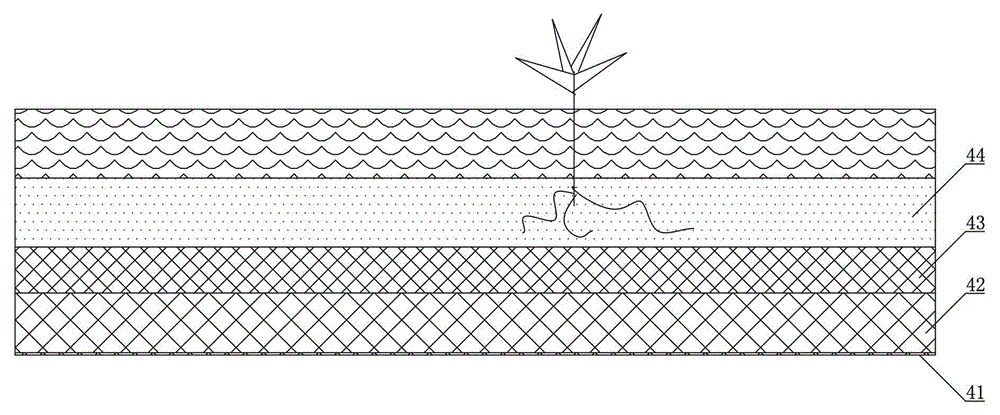

Preparation method of radix astragali health-care tea

The present invention relates to a preparation method of radix astragali health-care tea. The preparation method comprises the following steps: (1) the radix astragali health-care tea consists of the following raw materials in parts by weight: 18-24 parts of tea leaves, 4-7 parts of bitter gourds, 5-8 parts of radix astragali and 3-6 parts of buckwheat sprouts; (2) the bitter gourds are extracted with ethanol with a concentration of 55%-91%, and the extract is concentrated to a density of 1.24 + / - 0.06 g / ml, thereby obtaining the bitter gourd extract; (3) the radix astragali and the buckwheat sprouts are separately extracted with ethanol with a concentration of 53%-83%, and the extract is separately concentrated to a density of 1.24 + / - 0.06 g / ml, thereby obtaining the radix astragali extract and the buckwheat sprout extract, respectively; (4) the bitter gourd extract, the radix astragali extract and the buckwheat sprout extract are mixed, the mixture is dissolved with 8-23 parts of pure water, and then the dissolved mixture is fully mixed with the tea leaves; and (5) the tea leaves absorbing the mixed medicine liquid are fermented, and then the fermented tea leaves are dried and packaged, thereby obtaining the finished products of the radix astragali health-care tea. The preparation method is simple in production process, and is suitable for industrial production.

Owner:HUNAN FU XIANGTIAN TEA CO LTD

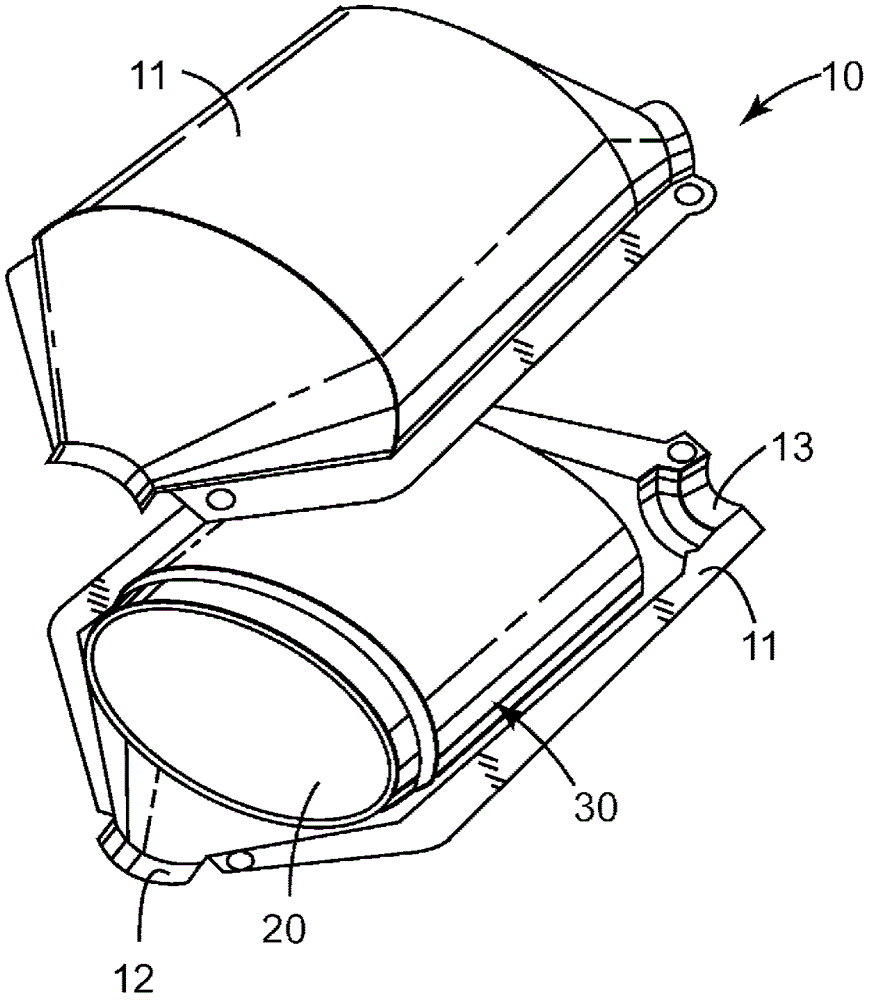

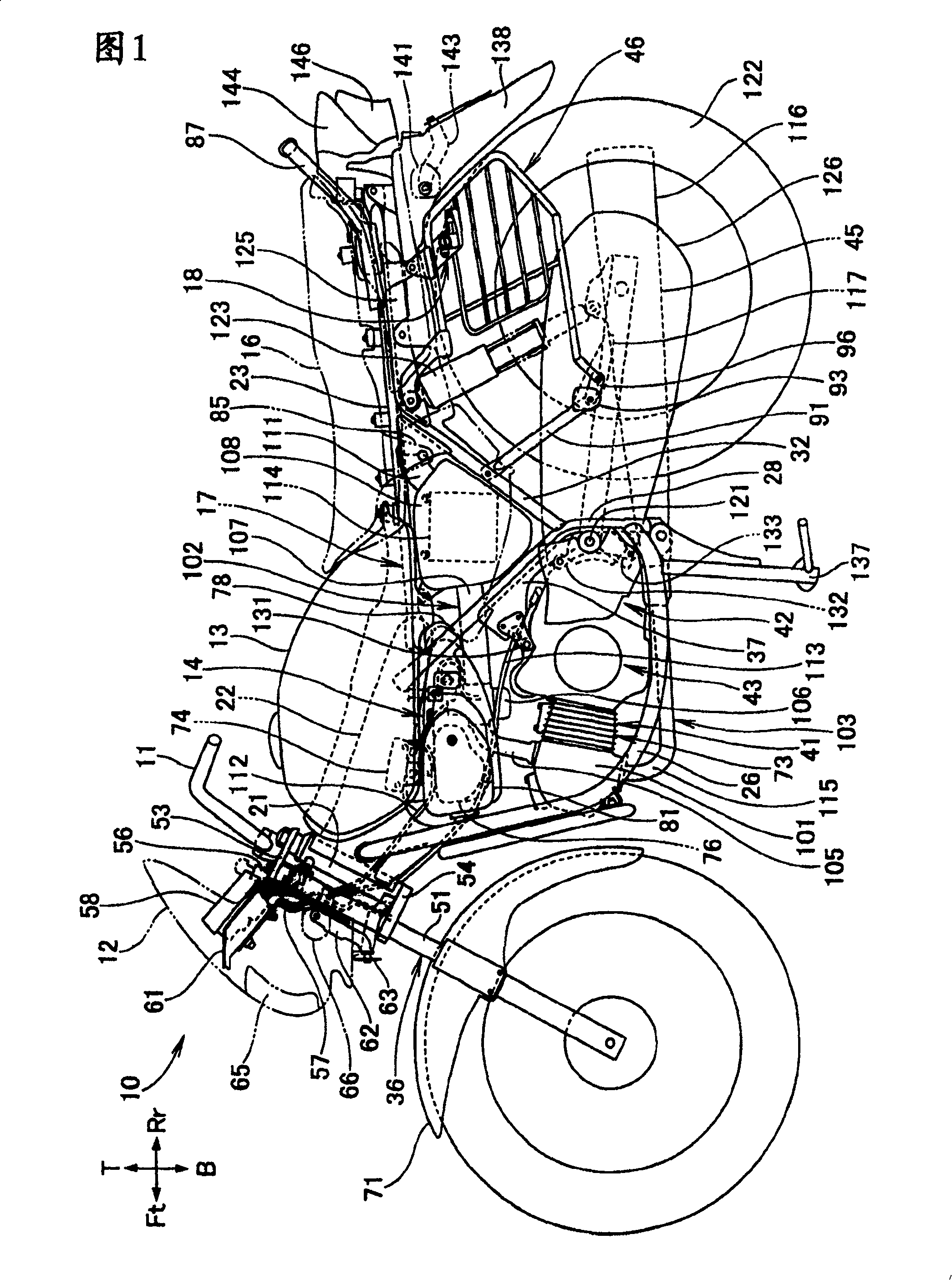

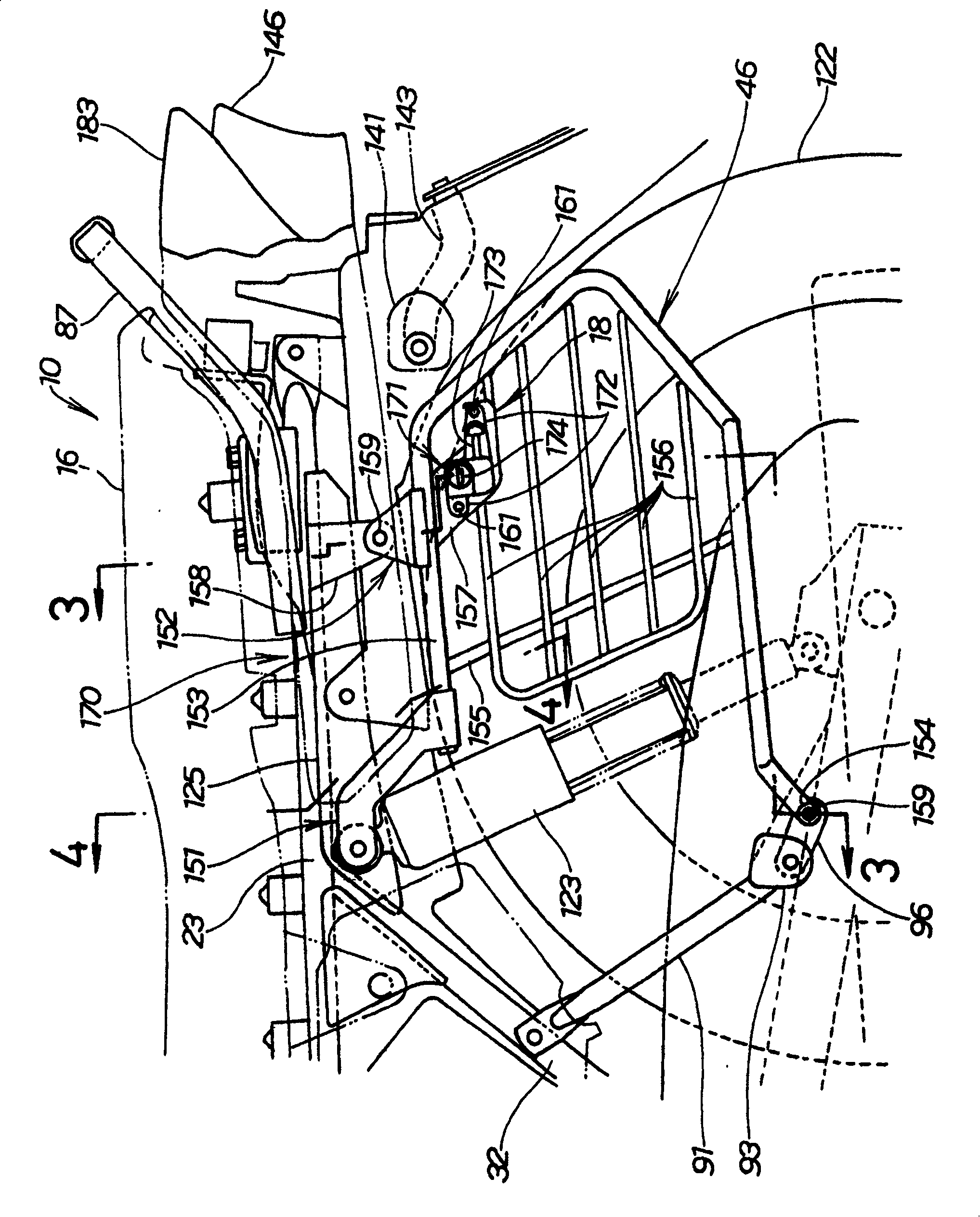

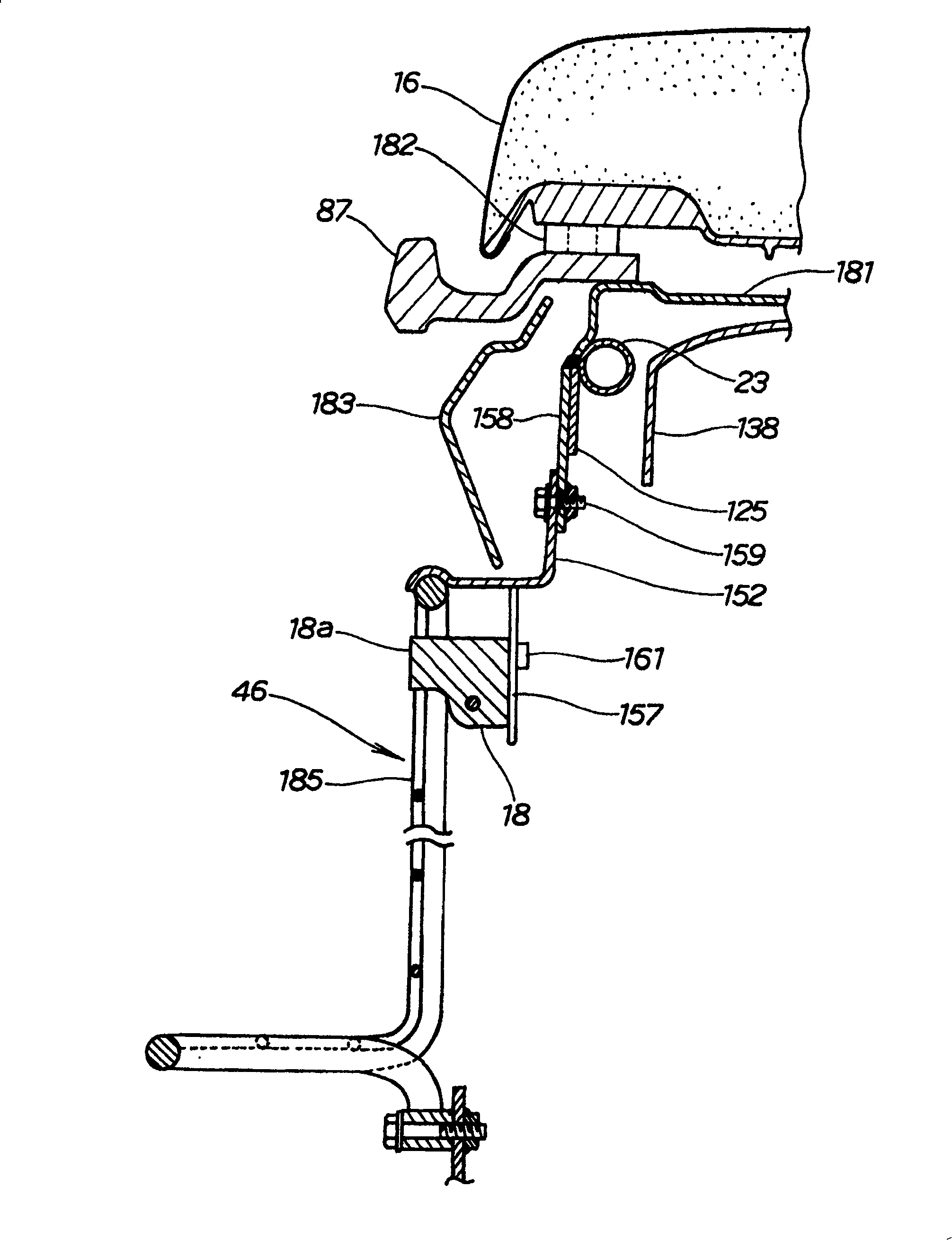

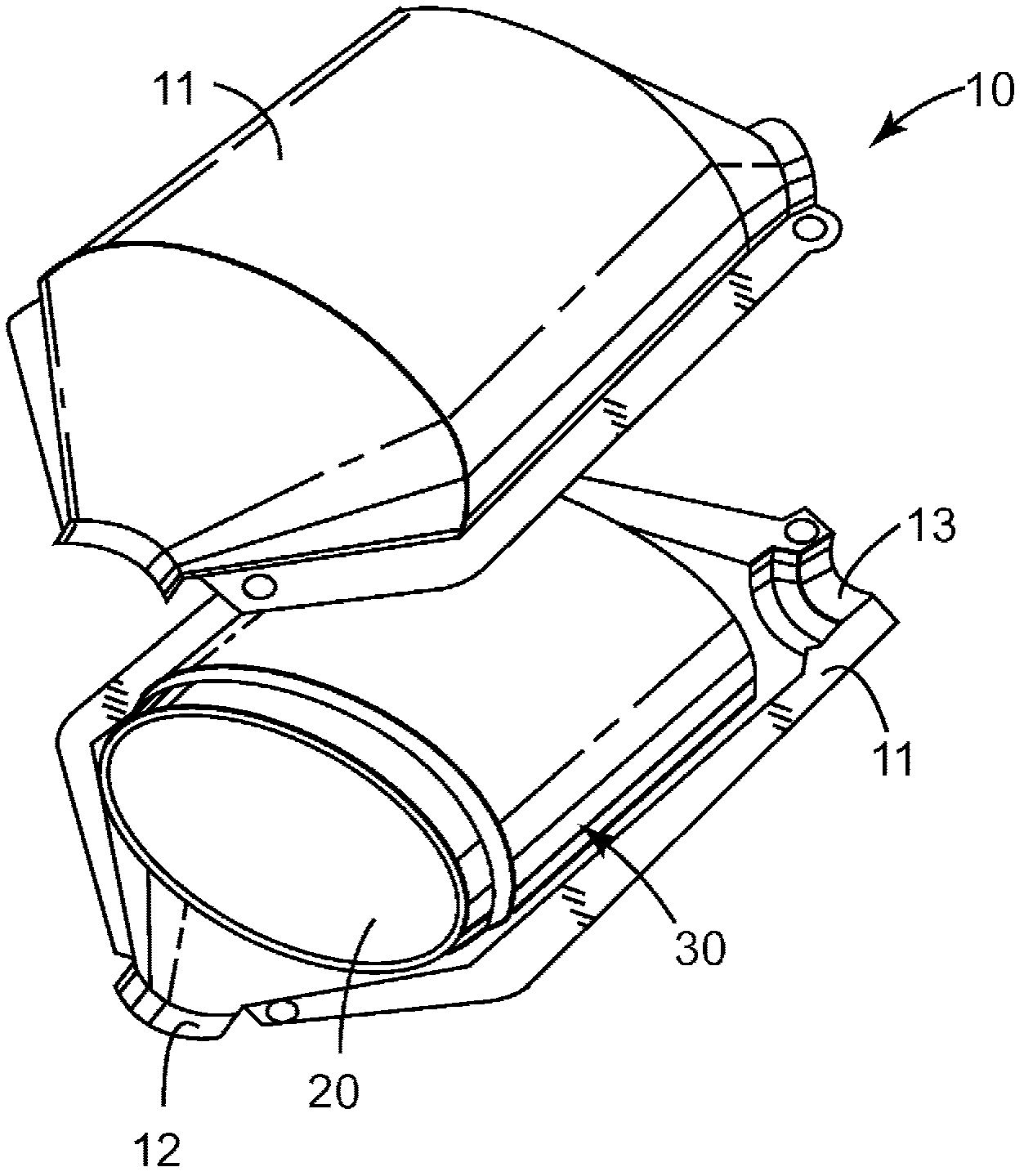

Mounting structure for helmet holder of two-wheeled automobile

InactiveCN100404358CIncrease freedomEasy to seeArticle supporting devicesOther supporting devicesEngineeringBack brace

The topic of present invention is to provide an installation structure of the retainer in the helmet of the motor two-wheeled bicycle, and the helmet retainer can be seen easily even the back of the bicycle is covered by the side cover at the installation structure of the retainer in the helmet of the motor two wheeled bicycle. In the following motor two-wheeled bicycle (10), the motor two-wheeled bicycle (10) is arranged with the protecting component (46) which covers the side of the back wheel (122) at the back side of the bicycle body frame (170), with the protecting component (46) it protects the passenger from the back wheel (122), and the helmet retainer (18) is arranged at the protecting component (46). Concretely speaking, extend the retainer lug support (157) from the brace rod (152) at the side of the bicycle body frame (17) by the protecting component (46) to the lower side, at the retainer lug support (157), arrange the helmet retainer (18) lower than the back brace rod (152) by one level.

Owner:HONDA MOTOR CO LTD

Low-energy consumption pressure spray desalination device and method thereof

InactiveCN102358628BAchieve recyclingIncrease investmentGeneral water supply conservationSeawater treatmentWater desalinationThermal energy

The present invention relates to a low-energy consumption pressure spray desalination device and a method thereof, and belongs to the field of sea-water desalination. The device part mainly comprises an air compressor set, a high pressure air tank, a high pressure hot seawater tank, a desalination and separation chamber, a hot air recoverer, a seawater heat exchanger tank and a freshwater tank. The spray desalination method mainly comprises the following steps: pressing seawater in sprinklers by high pressure, carrying out salt and water separation in the desalination and separation chamber in the high pressure spray manner. According to the present invention, the heat energy recycling and utilizing is realized; the high pressure gas phase power is adopted to transfer the spray, two heat exchanger method of convection and radiation are adopted, and the condensing waste heat is adopted for seawater heat energy recycling, such that the moving parts contacting with the seawater are reduced to the minimum, the system is simple, the operation is safe and stable so as to achieve purposes of low-temperature vaporization, low energy consumption, low investment, high yield, high efficiency and long service life.

Owner:BEIJING YUNTE TECH

Method and device for treating toilet sewage

ActiveCN103693816BAvoid new pollution problemsImplement resourcesMultistage water/sewage treatmentSludgeEmission standard

Owner:王凤蕊

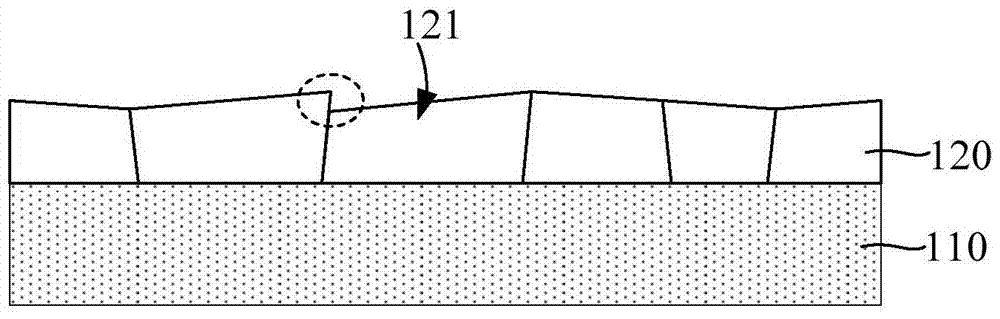

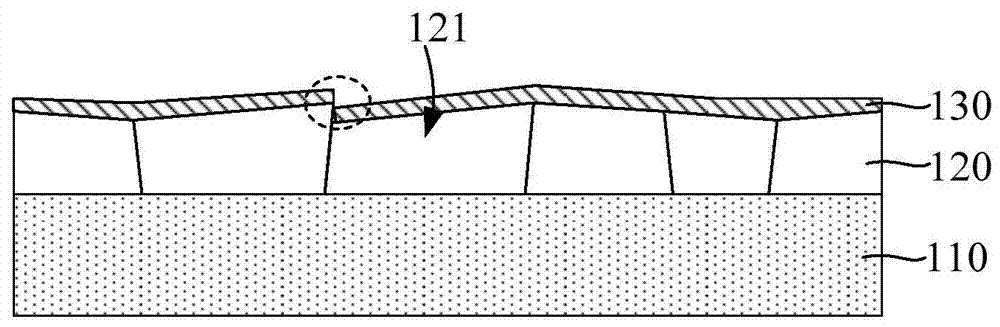

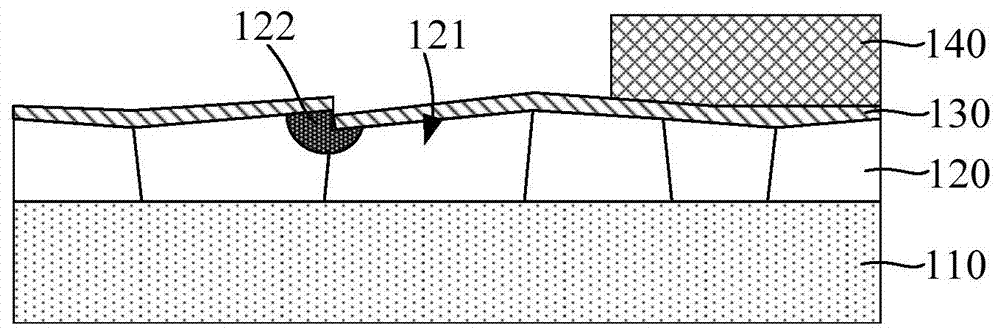

Manufacturing method of semiconductor device

ActiveCN104576514BImprove electrical performanceReduce or eliminateSemiconductor/solid-state device manufacturingPower semiconductor deviceElectrical performance

The invention discloses a method for preparing a semiconductor device, comprising: providing a semiconductor substrate; preparing a metal layer on the semiconductor substrate; preparing an oxidation barrier layer on the metal layer; performing an oxidation process so that the metal layer A metal oxide layer is formed on the surface of the metal layer in contact with the oxidation barrier layer; and the metal layer is selectively etched. The preparation method of the semiconductor device provided by the present invention first performs an oxidation process, so that a metal oxide layer is formed on the surface of the metal layer where the metal layer is in contact with the oxidation barrier layer, and during selective etching of the metal layer, The metal oxide layer can block chemical reagents from oxidizing the metal layer and avoid the formation of local aluminum oxide, thereby reducing or eliminating the formation of aluminum residues to improve the electrical performance of the device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Tubular, continuous, seamless, compressible, resilient mounting articles and pollution control devices comprising the same

InactiveCN102481750AReduce or eliminateEasy to slideExhaust apparatusSynthetic resin layered productsFiberEngineering

Tubular, continuous, seamless, compressible, resilient mounting article comprising inorganic fibers, and having an inner curved surface, a central longitudinal axis, and a uniform internal cross-sectional area along the central longitudinal axis. The mounting articles are useful, for example, in mounting pollution control elements in pollution control devices.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com