Manufacturing method of semiconductor device

A semiconductor and device technology, which is applied in the field of semiconductor device preparation, can solve the problems of poor wafer yield and affect the electrical performance of the device, and achieve the effect of improving electrical performance, eliminating aluminum residue, and avoiding the formation of aluminum oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

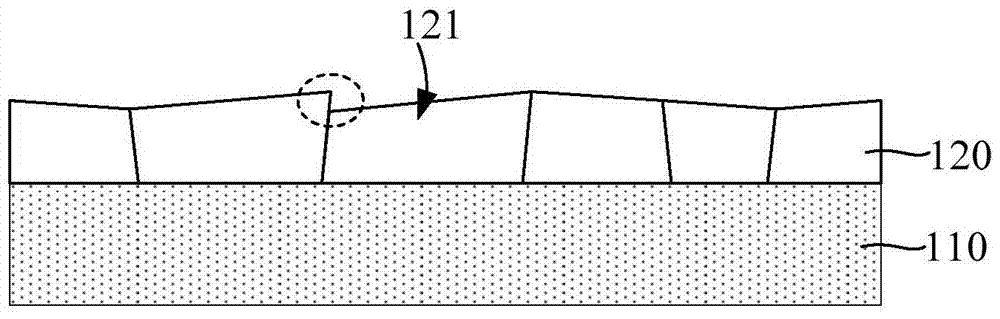

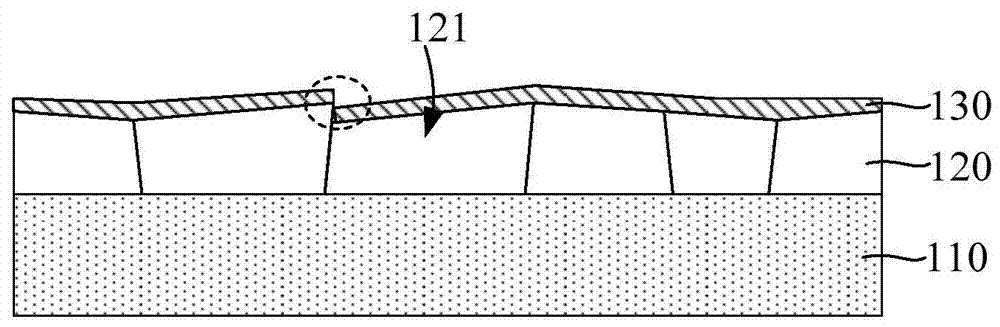

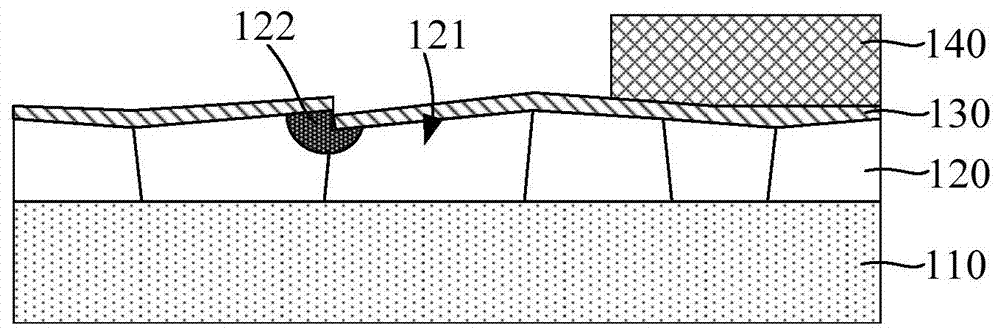

[0032] The core idea of the present invention is to provide a method for preparing a semiconductor device, including:

[0033] Step S11, providing a semiconductor substrate;

[0034] Step S12, preparing a metal layer on the semiconductor substrate;

[0035] Step S13, preparing an oxidation barrier layer on the metal layer;

[0036] Step S14, performing an oxidation process so that a metal oxide layer is formed on the surface of the metal layer where the metal layer is in contact with the oxidation barrier layer;

[0037] Step S15, selectively etching the metal layer, the metal oxide layer will block chemical reagents from oxidizing the metal layer, avoiding the formation of local aluminum oxide, thereby reducing or eliminating the formation of aluminum residues, so as to improve the device electrical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com