Polishing device and method of sapphire

A polishing device, sapphire technology, applied in grinding/polishing equipment, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problems of difficult to obtain high-quality optical surfaces, low polishing efficiency and yield, subsurface cracks, etc. problems, to achieve low surface roughness, small thermal impact, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

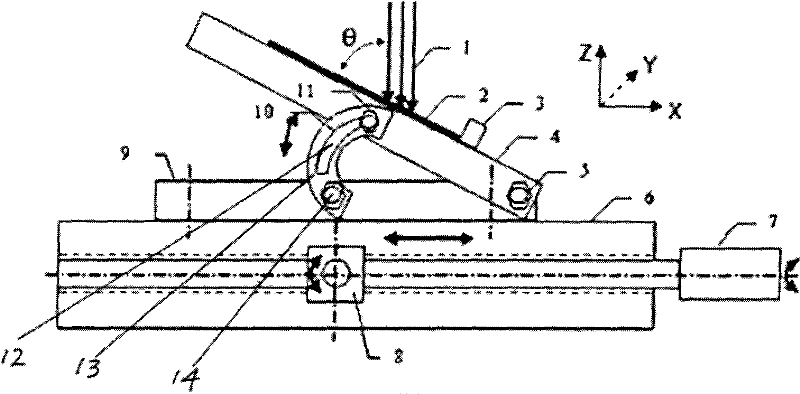

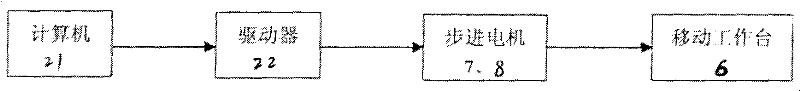

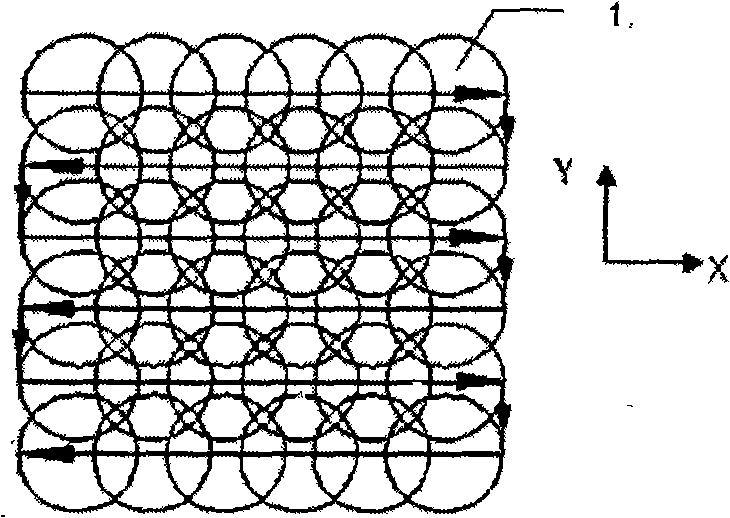

[0023] The structural representation of the sapphire polishing device of the present invention is as figure 1 As shown, it includes a laser beam 1, a support plate 4, a workbench 6, a stepper motor 7 that drives the workbench 6 to move in the X direction, a stepper motor 8 that drives the workbench 6 to move in the Y direction, and a connecting piece 9, wherein The workbench 6 is equipped with a stepper motor 7 for driving it to move in the X direction and a stepper motor 8 for driving it to move in the Y direction, the connecting piece 9 is fixed on the workbench 6, and the support plate 4 is installed on the connecting piece 9 , the sapphire wafer 2 to be polished is fixed on the support plate 4, the laser beam 1 is radiated from the top of the sapphire wafer 2 to be polished to the sapphire wafer 2, and the stepping motor 7 and the drive worktable are driven by the workbench 6 to move in the X direction 6 The stepping motors 8 moving in the Y direction are all connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com