Parts washing system

a washing system and part technology, applied in the field of cleaning, can solve the problems of dermatitis and respiratory problems, inconvenient disposal, and insufficient containment of mineral spirits,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

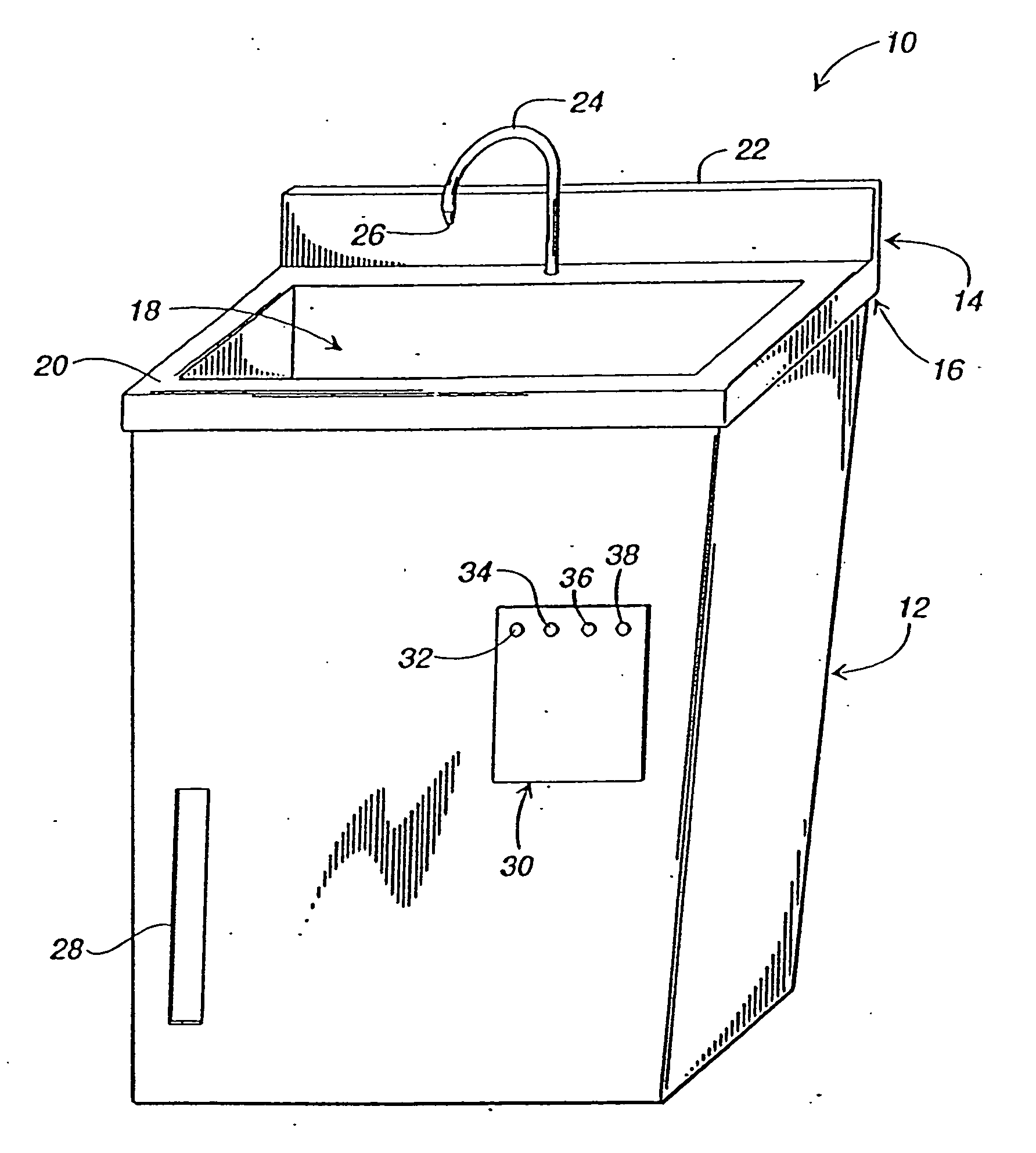

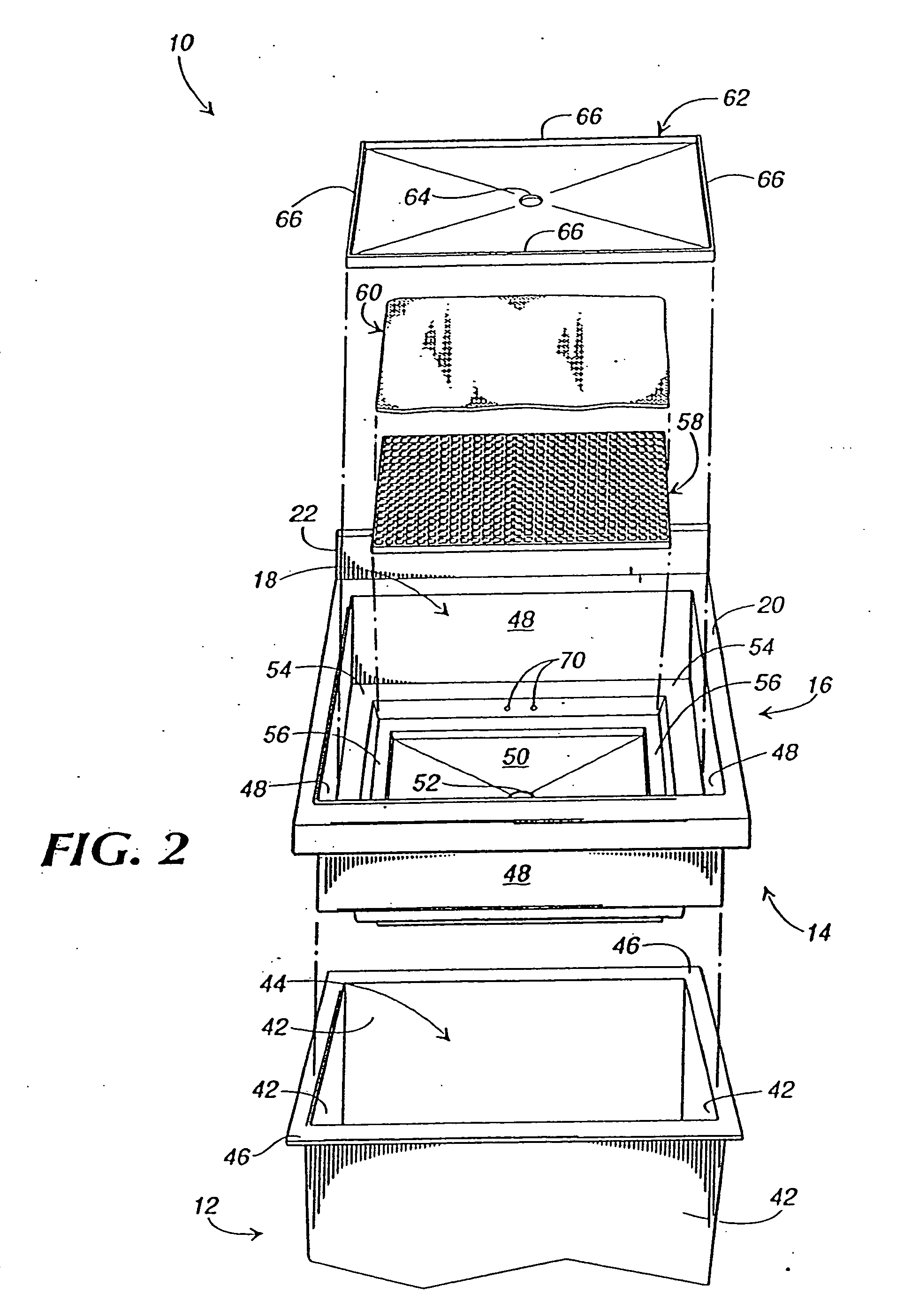

[0027] Referring now in greater detail to the drawings, in which like numerals represent like components throughout the several views, FIG. 1 is an exterior, perspective view of a parts washer apparatus (the “parts washer”) 10, in accordance with the preferred embodiment of the present invention. The parts washer 10 includes a tank 12 and a basin 14. The basin 14 includes a sink member 16 that defines a basin cavity 18. The sink member includes a sink ledge 20 around the periphery of the inlet to the basin cavity 18. A back-splash 22 extends upward from a rear portion of the sink ledge 20, and a flexible faucet 24 penetrates the rear portion of the sink ledge 20 and terminates in the form of a nozzle 26. A optional work light (not shown) extends upward from the basin and illuminates the basin cavity 18. The tank 12 preferably includes a level indicator 28 and a control panel 30. The level indicator 28 is depicted as comprising a temperature sensitive, liquid crystal display. The con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific gravity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com