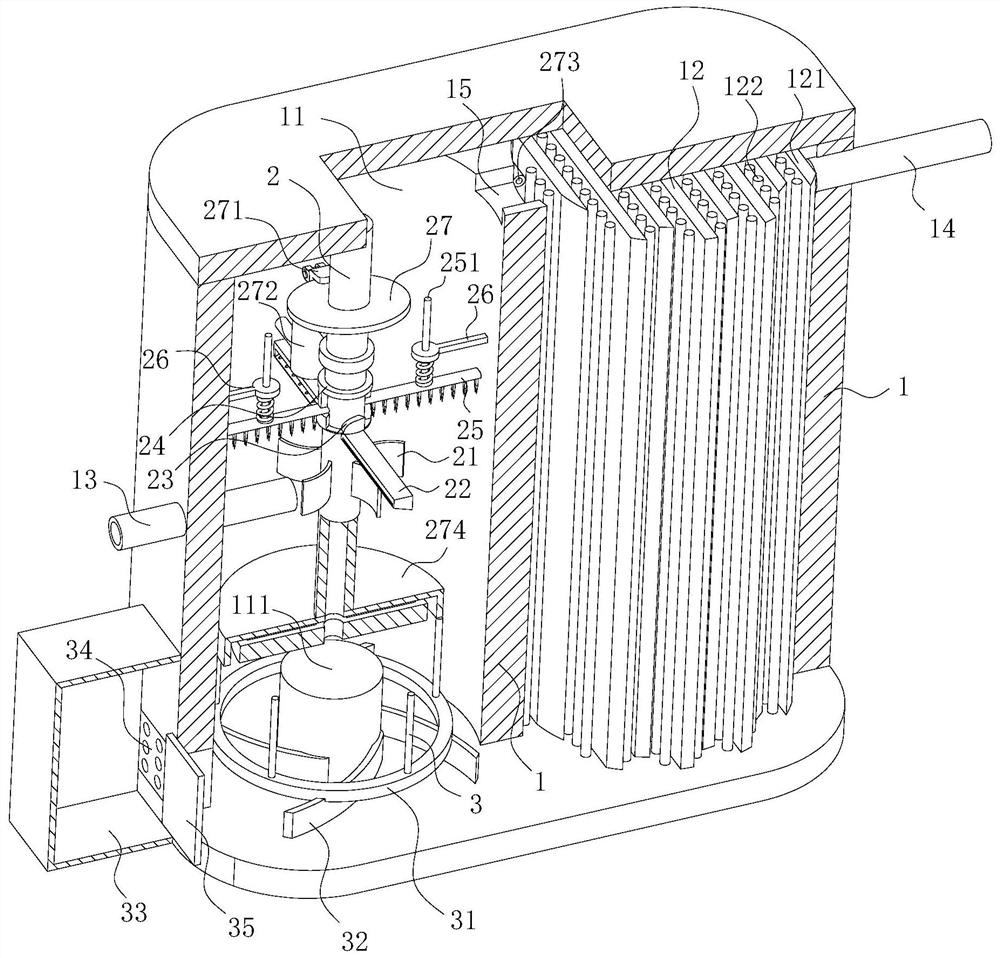

Treatment device for concentrated landfill leachate

A landfill leachate and treatment device technology, which is applied in the direction of contaminated groundwater/leachate treatment, special treatment targets, water/sewage treatment, etc., can solve the problems of difficult treatment, high salt content, poor biodegradability, etc. To achieve the effect of improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

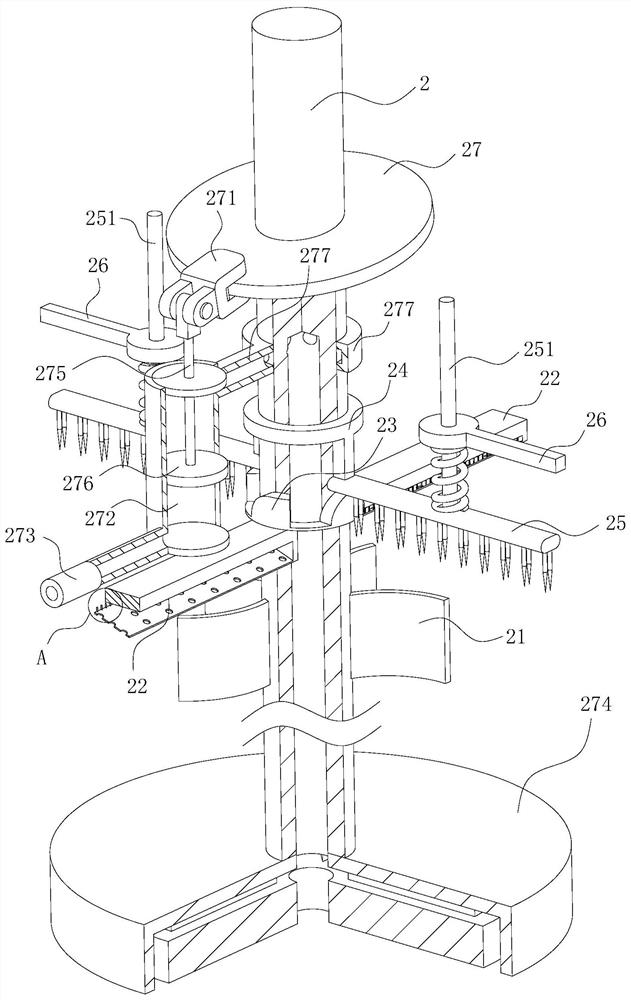

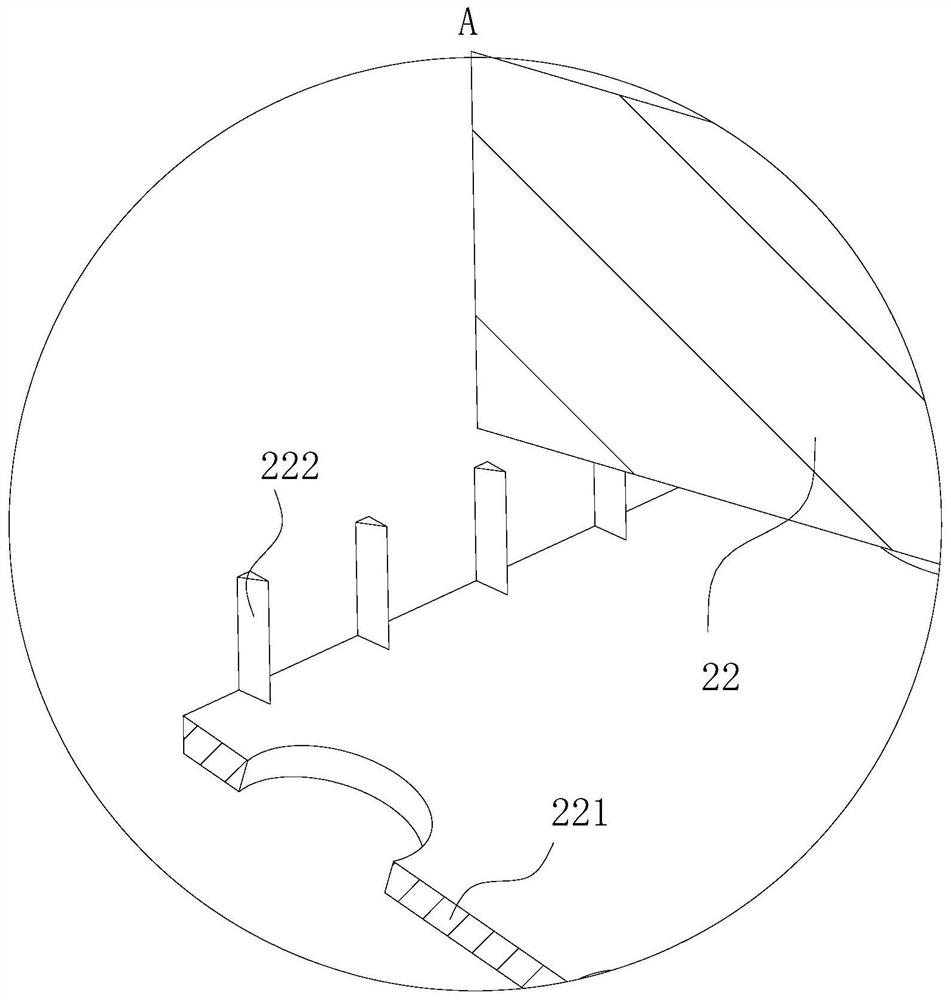

[0030] As an embodiment of the present invention, a cam ring 23 is fixedly installed on the rotating shaft 2; the cam ring 23 is located above the defoaming plate 22; a fixing frame 26 is installed on the side wall of the ultrasonic treatment tank 11; A guide rod 251 is slidably installed on the fixed mount 26; a mounting rod 25 is installed on the lower end of the guide rod 251; a spring is installed on the guide rod 251, and the spring is located between the fixed mount 26 and the mounting rod 25; One end of the mounting rod 25 near the rotating shaft 2 is in contact with the cam ring 23; the lower surface of the mounting rod 25 is evenly equipped with defoaming needles; The lower end of the defoaming needle is just inserted into the liquid phase; there are two mounting rods 25, which are symmetrically distributed around the rotating shaft 2 in the ultrasonic treatment tank 11; a fixed ring 24 is installed on the rotating shaft 2; the two mounting rods 25, one end close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com