Impeller type water suction pump suitable for shallow rivers and easy to clean

An easy-to-clean, impeller-type technology, used in the components of pumping devices for elastic fluids, non-variable-capacity pumps, pumps, etc., can solve the problems of difficult cleaning and easy accumulation of sediment in the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

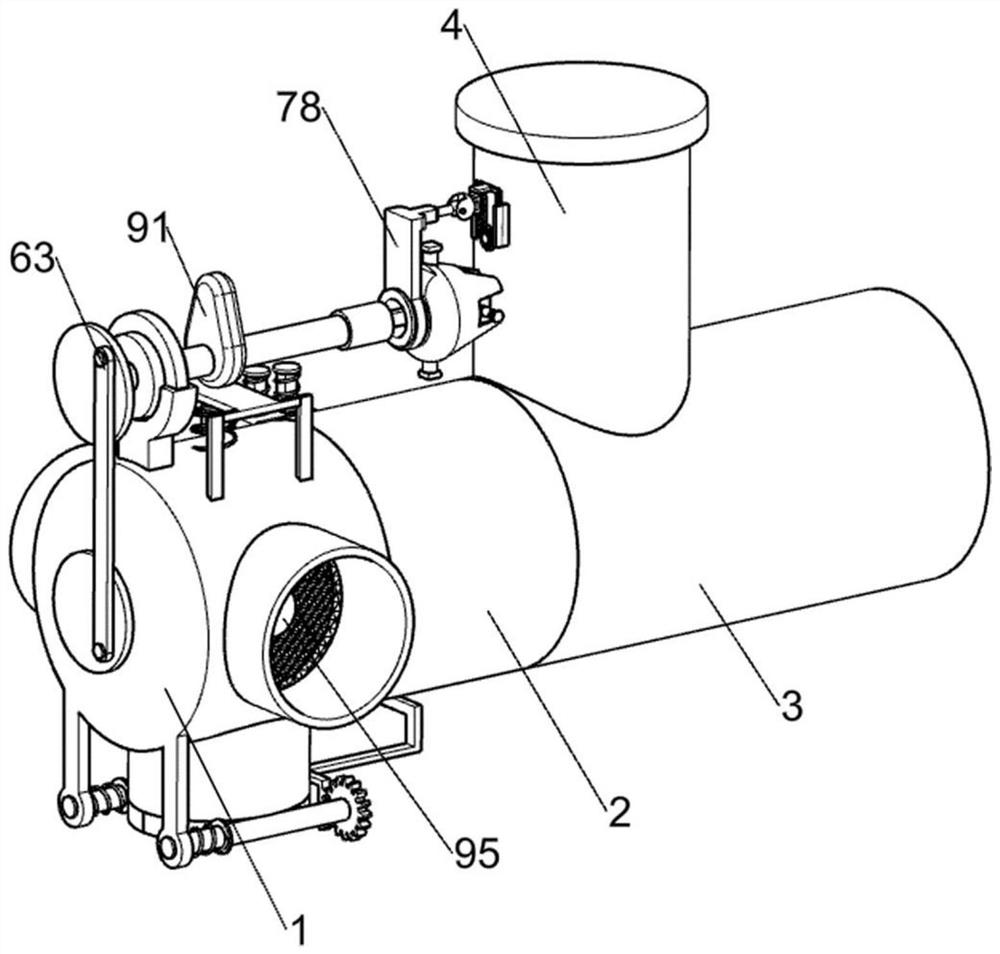

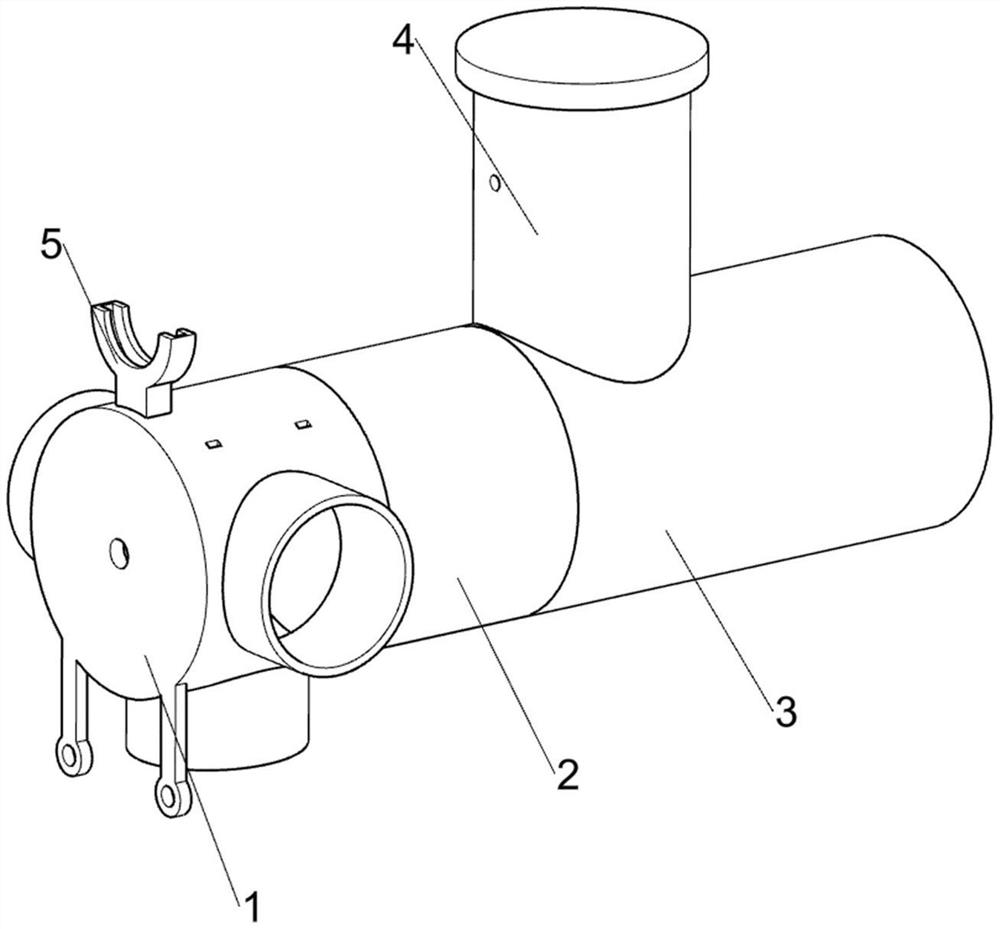

[0028] An impeller type water pump suitable for shallow rivers and easy to clean, such as Figure 1-10As shown, it includes a multi-port water pump pipe 1, a water pump connecting pipe 2, a perforated water pump pipe 3, a perforated cover pipe 4, a motor support frame 5, a pumping mechanism 6, an adjusting swing rotating mechanism 7 and a power supply protection mechanism 8. One end of the multi-port water pump pipe 1 for drainage is fixedly connected with a water pump connection pipe 2, and one end of the water pump connection pipe 2 away from the multi-port water pump pipe 1 is fixedly connected with a perforated water pump pipe 3, and the perforated water pump pipe 3 is fixedly connected with a water pump pipe for collecting fish. The perforated and covered tube 4 of the shrimp, the top surface of the multi-port water pump tube 1 is fixedly connected with the motor support frame 5, the pumping mechanism 6 for pumping water is fixedly installed on the motor support frame 5, a...

Embodiment 2

[0036] On the basis of Example 1, such as Figure 10 As shown, it also includes a filter cleaning mechanism 9, which is located on the multi-port water pump pipe 1, and the filter cleaning mechanism 9 includes a cam 91, a four-corner connecting plate 92, a hair brush 93, and a fifth return spring 94 And the second filter plate 95, the cam 91 is fixedly connected on the rotating shaft 62, the fifth return spring 94 is fixedly connected on the multi-port water pump tube 1, and the fifth return spring 94 far away from the multi-port water pump tube 1 is fixedly connected with a four-corner connection Plate 92, the four-corner connecting plate 92 and the cam 91 are in contact with each other, the cam 91 is used to push the four-corner connecting plate 92 to move downward, and the four-corner connecting plate 92 is distributed and fixed with hair brushes 93, and the hair brush 93 is used for cleaning the second filter plate. 95 for brushing, the brush 93 is slidingly connected with...

Embodiment 3

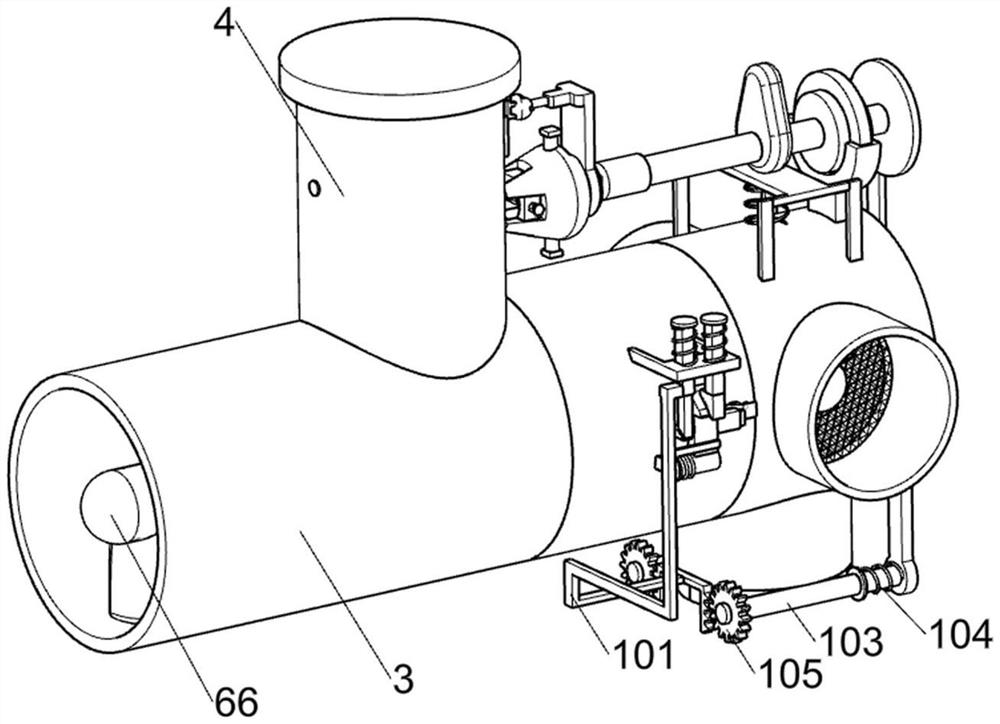

[0039] On the basis of Example 2, such as Figure 11As shown, it also includes a silt clearing mechanism 10, which is arranged on the multi-port water pump pipe 1, and the silt clearing mechanism 10 is used to discharge the silt deposited at the bottom of the multi-port water pump pipe 1. The sand clearing mechanism 10 includes a special-shaped connecting bar 101, a rack two 102, a drive shaft four 103, a second torsion spring 104, a gear two 105 and an elliptical valve 106, and the special-shaped connecting bar 101 is fixedly connected to a switch pressing bar 86 Rack 2 102 is fixedly connected to the special-shaped connection bar 101 away from the switch pressing bar 86, and the transmission shaft 4 103 is connected to the multi-port water pump tube 1 in a symmetrical rotational manner, and the multi-port water pump tube 1 is fixedly connected to the second torsion spring 104 One end of the second torsion spring 104 away from the multi-port water pump tube 1 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com