Low-energy consumption pressure spray desalination device and method thereof

A pressure spraying and desalination device technology, applied in chemical instruments and methods, energy wastewater treatment, water/sewage treatment, etc., can solve the problems of high-grade energy consumption, environmental pollution, low recovery rate, etc., to reduce energy consumption, reduce Investment, reduce the effect of high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Embodiments of the present invention are further described below in conjunction with accompanying drawings:

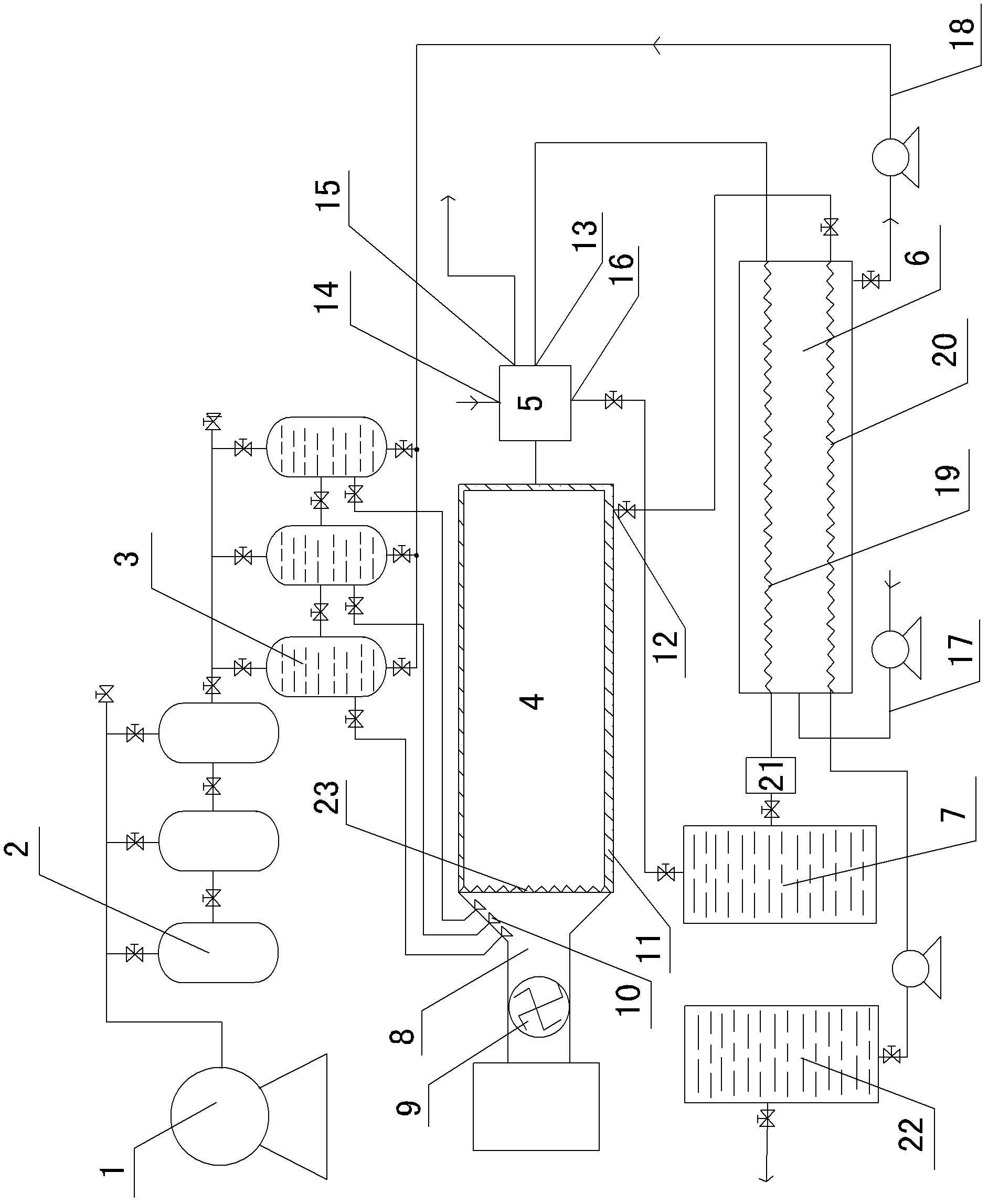

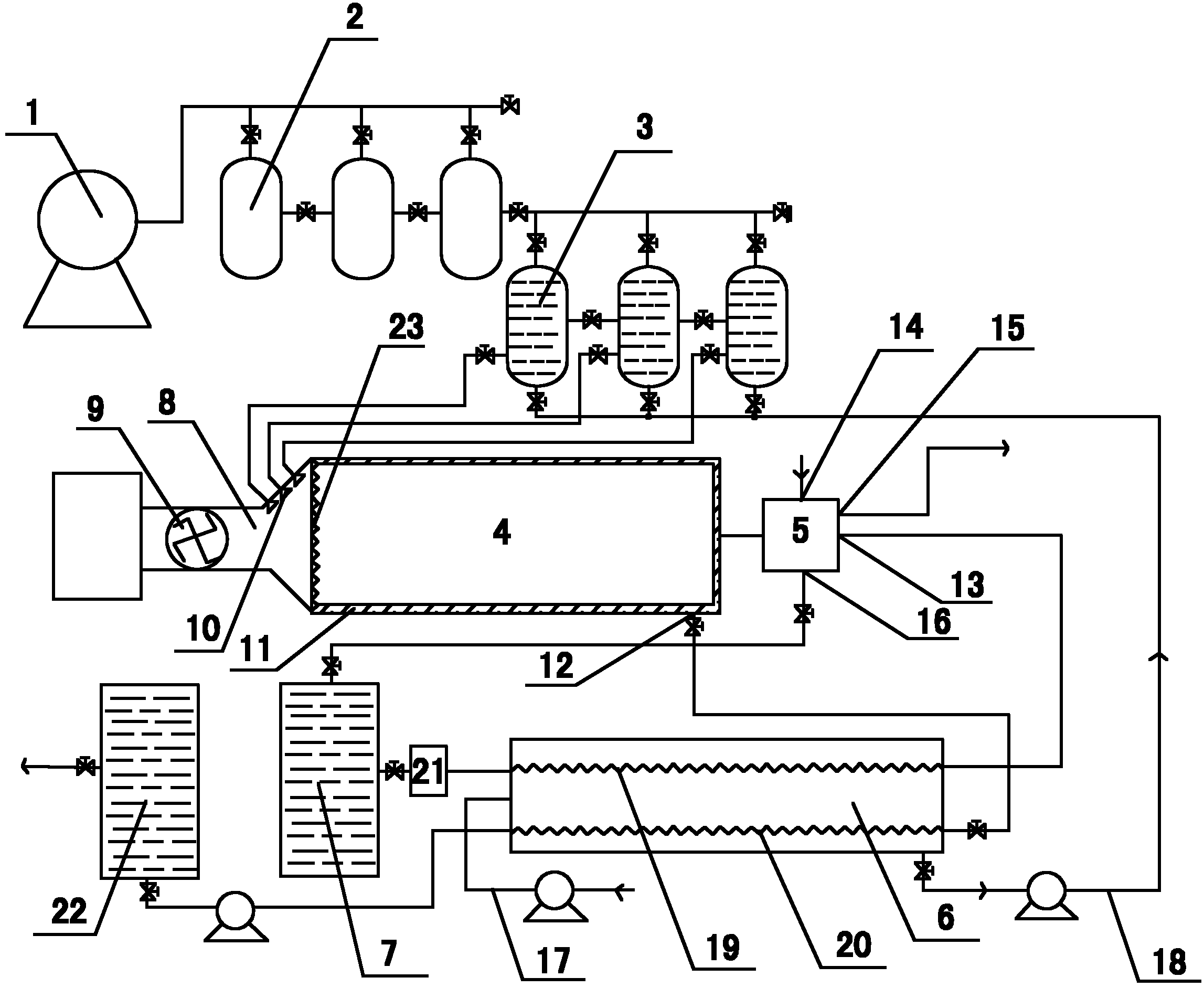

[0044] Such as figure 1 As shown, the low-energy pressure spray desalination device includes an air compressor unit 1, a high-pressure air tank 2, a high-pressure hot seawater tank 3, a desalination separation chamber 4, a hot air recovery device 5, a seawater heat exchange pool 6 and a fresh water pool 7, The tops of the air compressor unit 1, the high-pressure air tank 2 and the high-pressure hot sea water tank 3 are connected through pipelines in turn, one end of the desalination separation chamber 4 is connected to the hot air pipeline 8, and the other end is connected to the hot air recovery device 5, and the hot air A hot air blower 9 is installed in the pipeline 8, and a high-pressure spray head 10 is provided at a position close to the desalination and separation chamber 4 of the hot air pipeline 8. A far-infrared radiation emitting element 11 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com