Five-coordinate locating mechanism

A positioning mechanism and five-coordinate technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of limited range of work surface attitude adjustment, inability to meet processing and assembly needs, complex control process, etc. Simple design, simple structure, simple kinematic analysis and solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

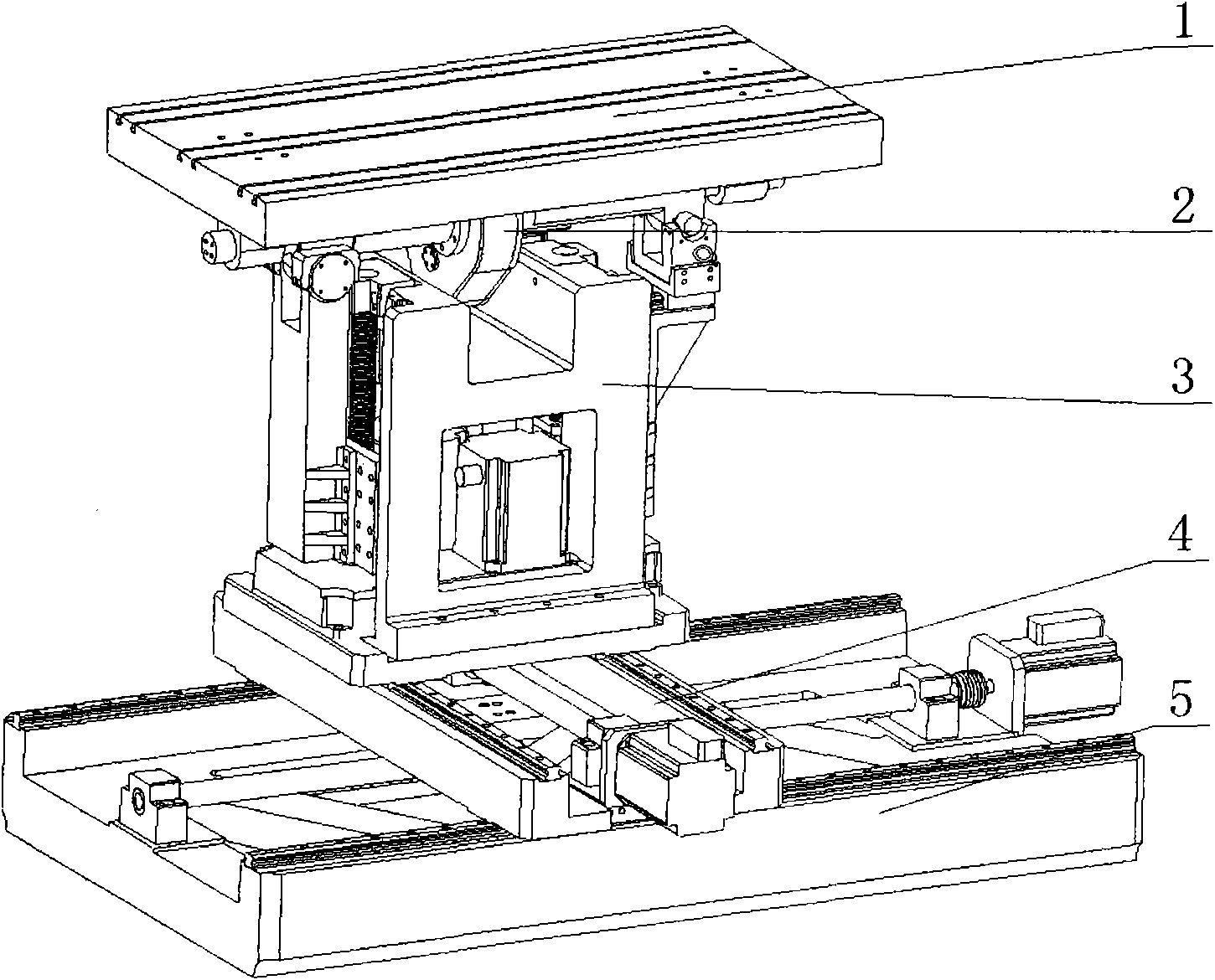

[0027] The five-coordinate positioning mechanism described in this embodiment includes an X-direction guiding part 5 , a Y-direction guiding part 4 , a Z-direction guiding part 3 , an A-direction rotating part 2 and a working platform 1 .

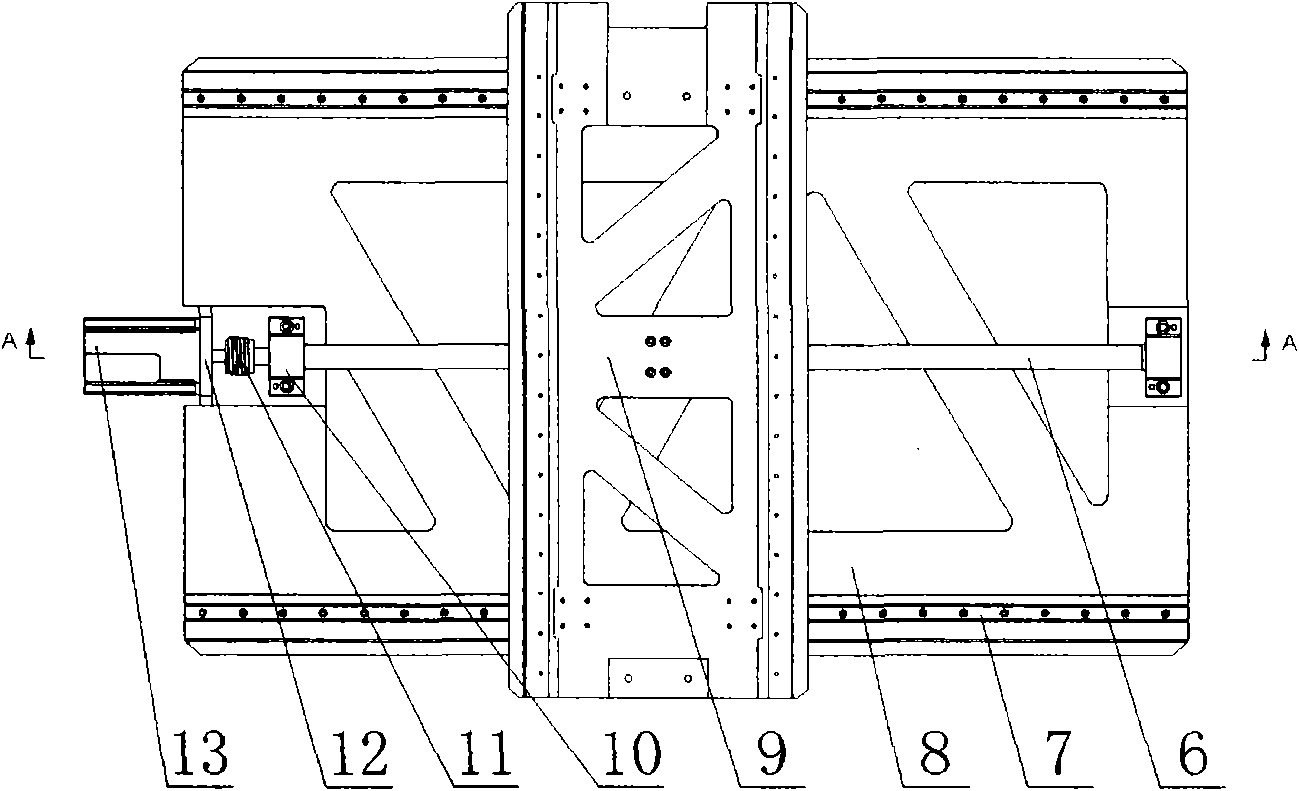

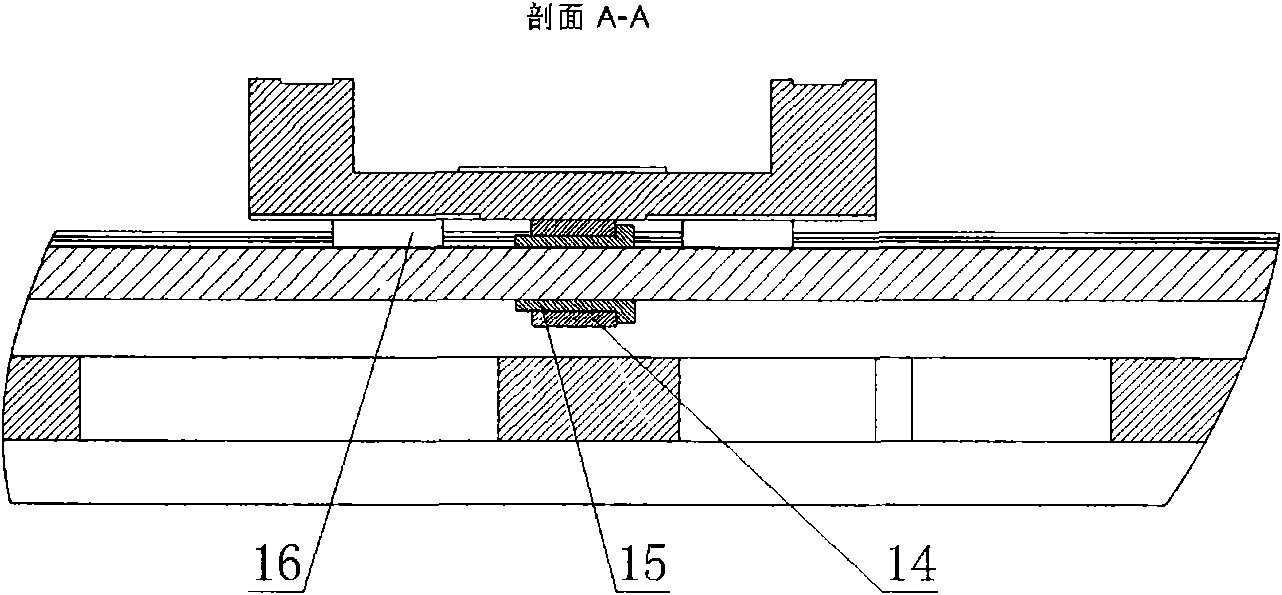

[0028] Refer to attached figure 2 , the X-direction guide component 5 includes an X-direction base plate 8, X-direction guide slide rails 7 along the length direction on both sides of the front side of the X-direction base plate 8, and an X-direction guide screw 6 along the length direction in the middle of the front side of the X-direction base plate 8 , The X-direction guide rail 7 is parallel to the X-direction guide screw 6. A support block 10 is screw-fixed in the middle of both ends of the front of the X-direction base plate 8 in the longitudinal direction, and the X-direction guide screw 6 is inserted into the through hole of the support block 10 and connected with the support block 10 bearings. One end of the X-direction guide scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com