Parking device with comb teeth for supporting, storing and withdrawing vehicle

A technology of parking equipment and comb teeth, which is applied in the field of mechanical parking equipment, can solve the problems of reducing the access speed of parking garage vehicles, increasing the necessary time for accessing vehicles, etc., and achieve the effect of increasing flexibility and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

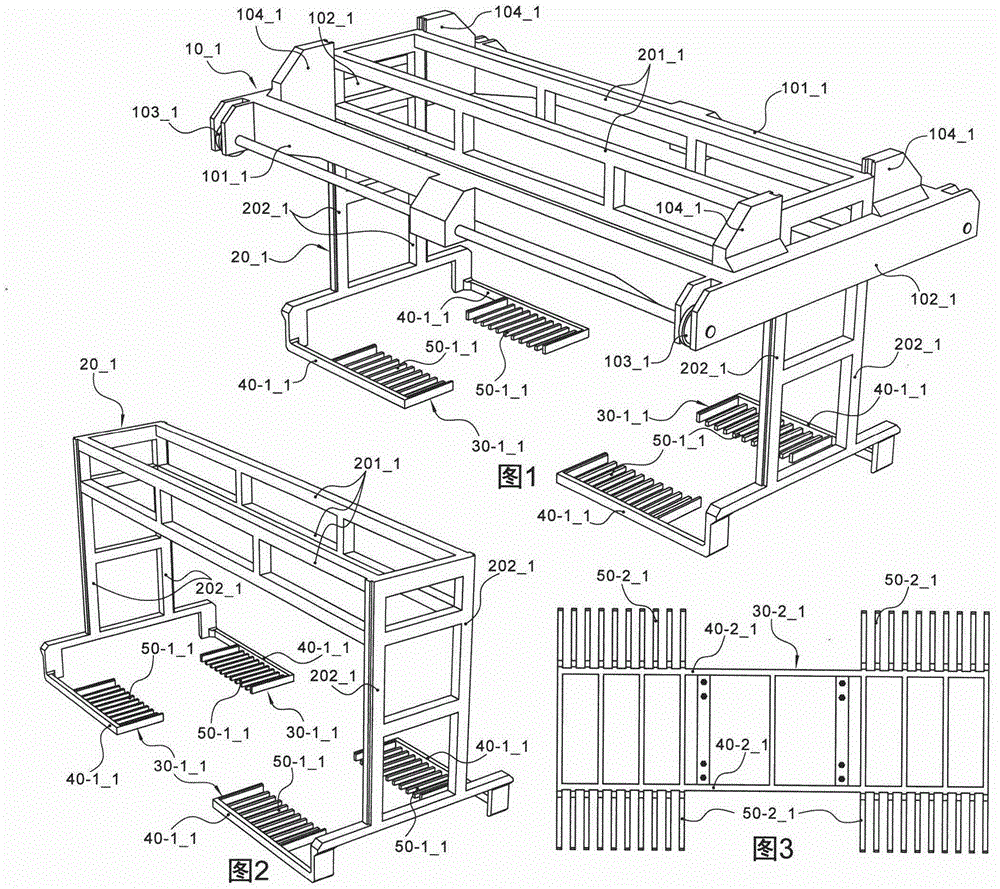

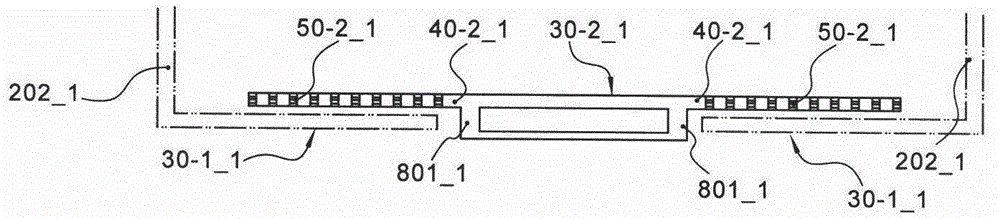

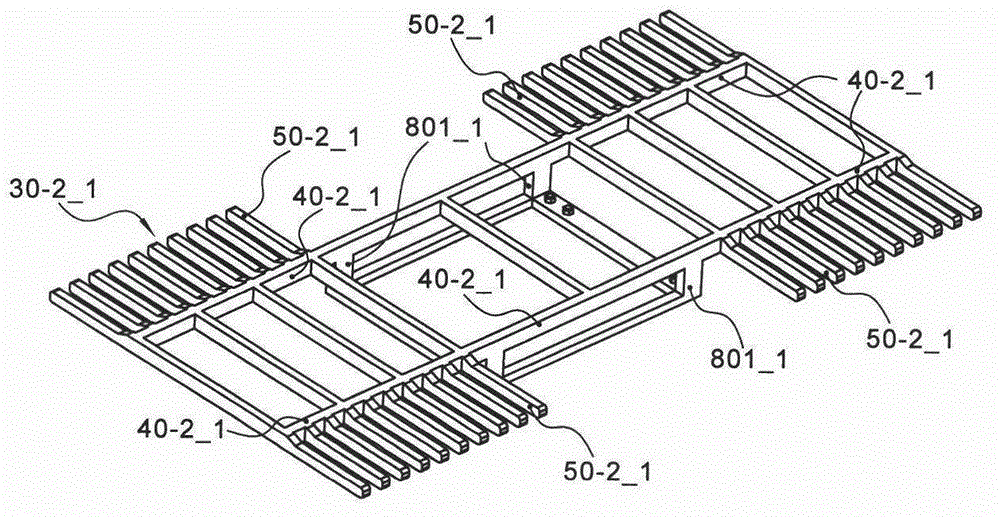

[0102] Embodiment 1 of the present invention is as Figure 1 to Figure 7 shown. see figure 1 The frame of the transport vehicle 10_1 of the present embodiment is a rectangular frame surrounded by two front and rear end beams 102_1 and two left and right side beams 101_1, and guide wheels 103_1 axially parallel to the side beams are installed below the four corners of the frame. Two pairs of lifting guide columns 104_1 are respectively installed inside the front and rear end beams 102_1 of the truck, and a door-shaped lifting frame 20_1 is arranged between the four lifting guide columns 104_1. see figure 2 , the beam 201_1 of the door-shaped lifting frame 20_1 is connected to four booms 202_1 at both ends and four corners. The lower ends of four booms 202_1 are respectively connected with four comb beams 40-1_1 of a comb-shaped access frame 30-1_1 that are divided into four parts, and four comb beams 40-1_1 of the comb-shaped access frame. A group of comb teeth 50-1_1 over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com