Patents

Literature

50results about How to "Optimize site selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

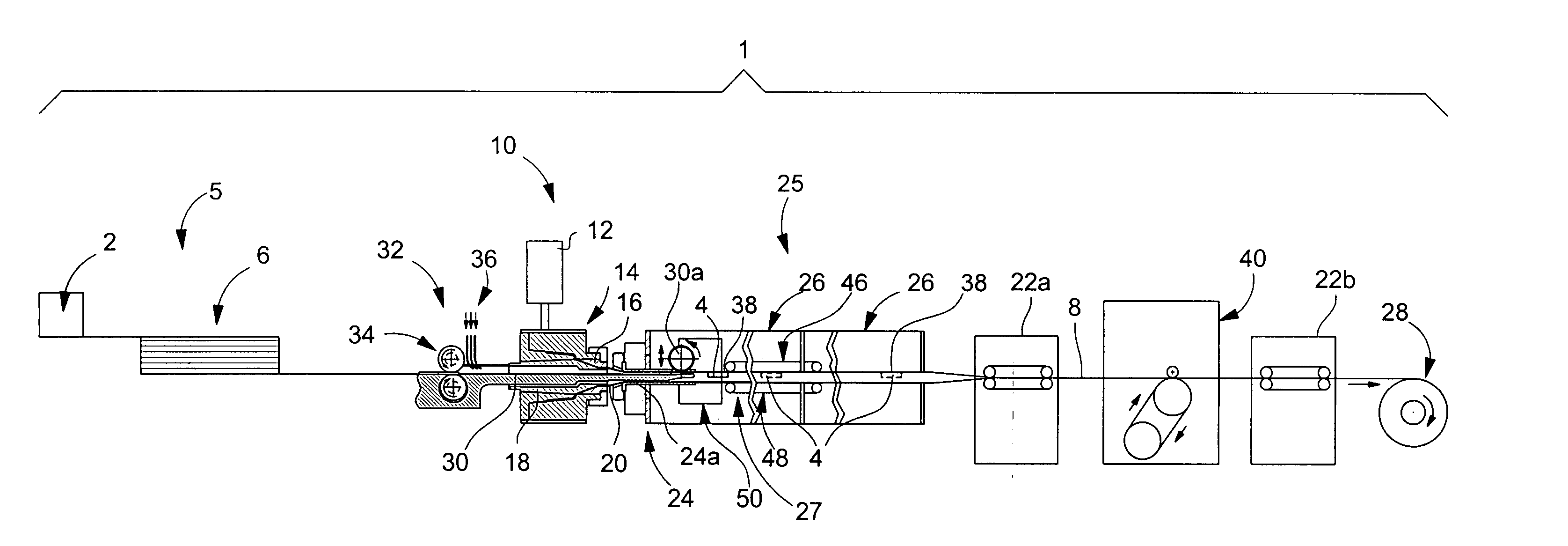

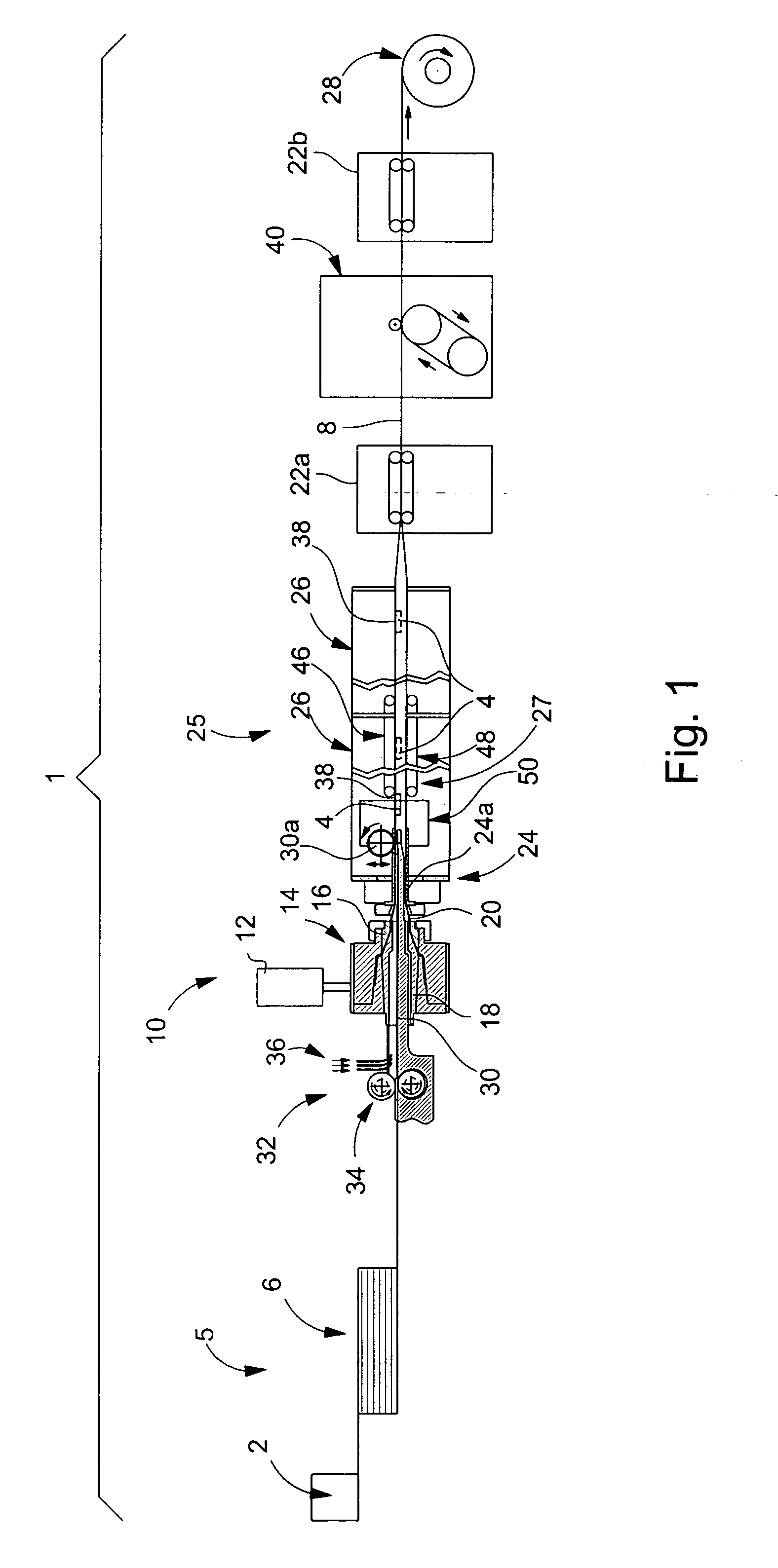

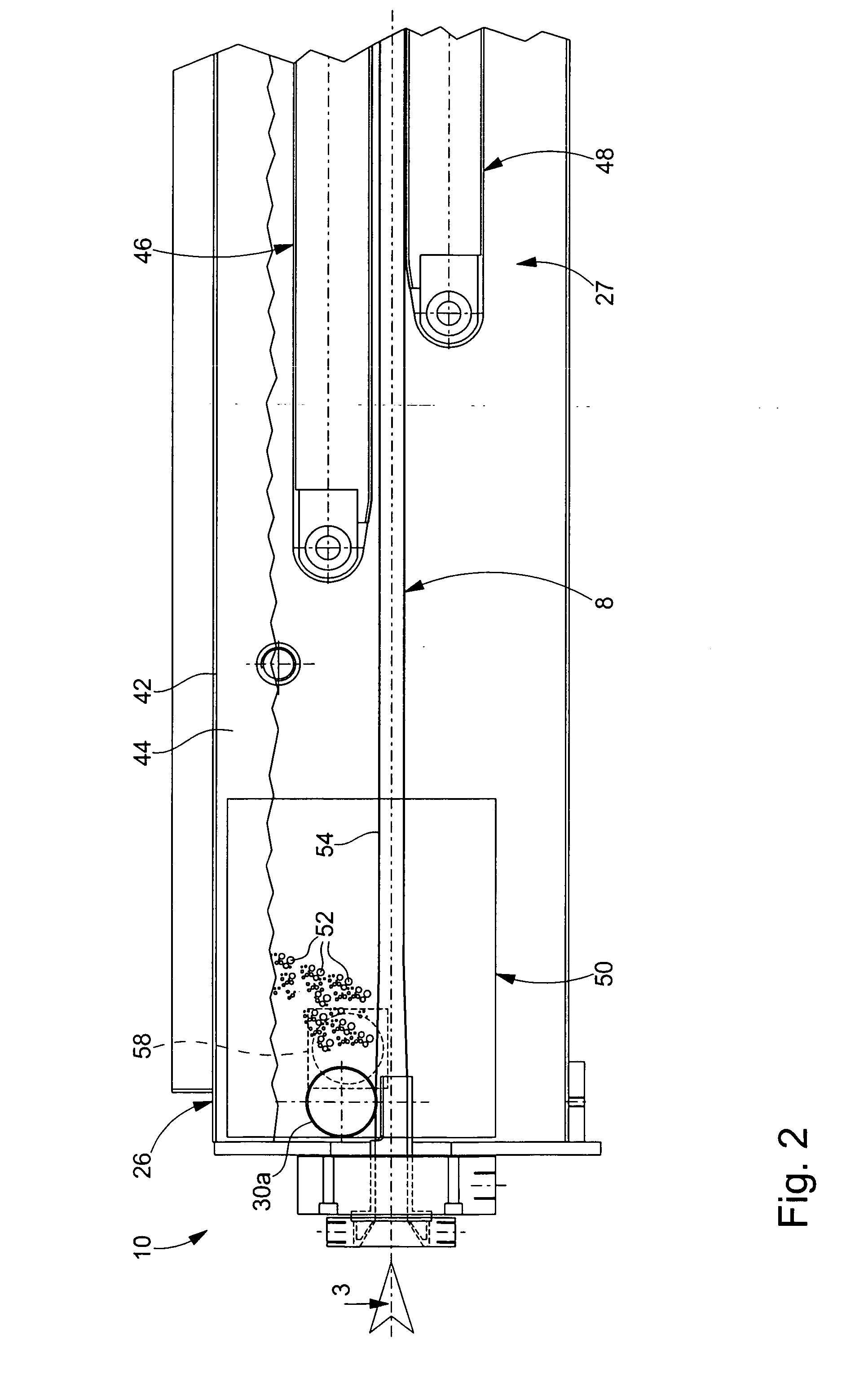

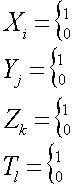

Pipe manufacturing installation and associated defect detection method

InactiveUS20060202381A1Easy to detectOptimize site selectionDetection of fluid at leakage pointCoatingsDrip irrigationEngineering

The invention concerns an installation for manufacturing drip irrigation pipes comprising a dripper feed station followed by an extrusion station comprising extrusion means, means for calibrating the pipe and means for welding the drippers to the inner wall of the pipe, and followed by a cooling station for the pipe, of the type wherein the cooling station includes a cooling tank containing a cooling fluid in which the pipe is immersed, characterized in that a detection device is provided for detecting, in the cooling fluid, the emission of gas bubbles through the wall of the pipe, so as to deduce therefrom the presence of perforations and / or cracks. The invention also concerns a method for detecting perforations and / or cracks.

Owner:THE MACHINES YVONAND

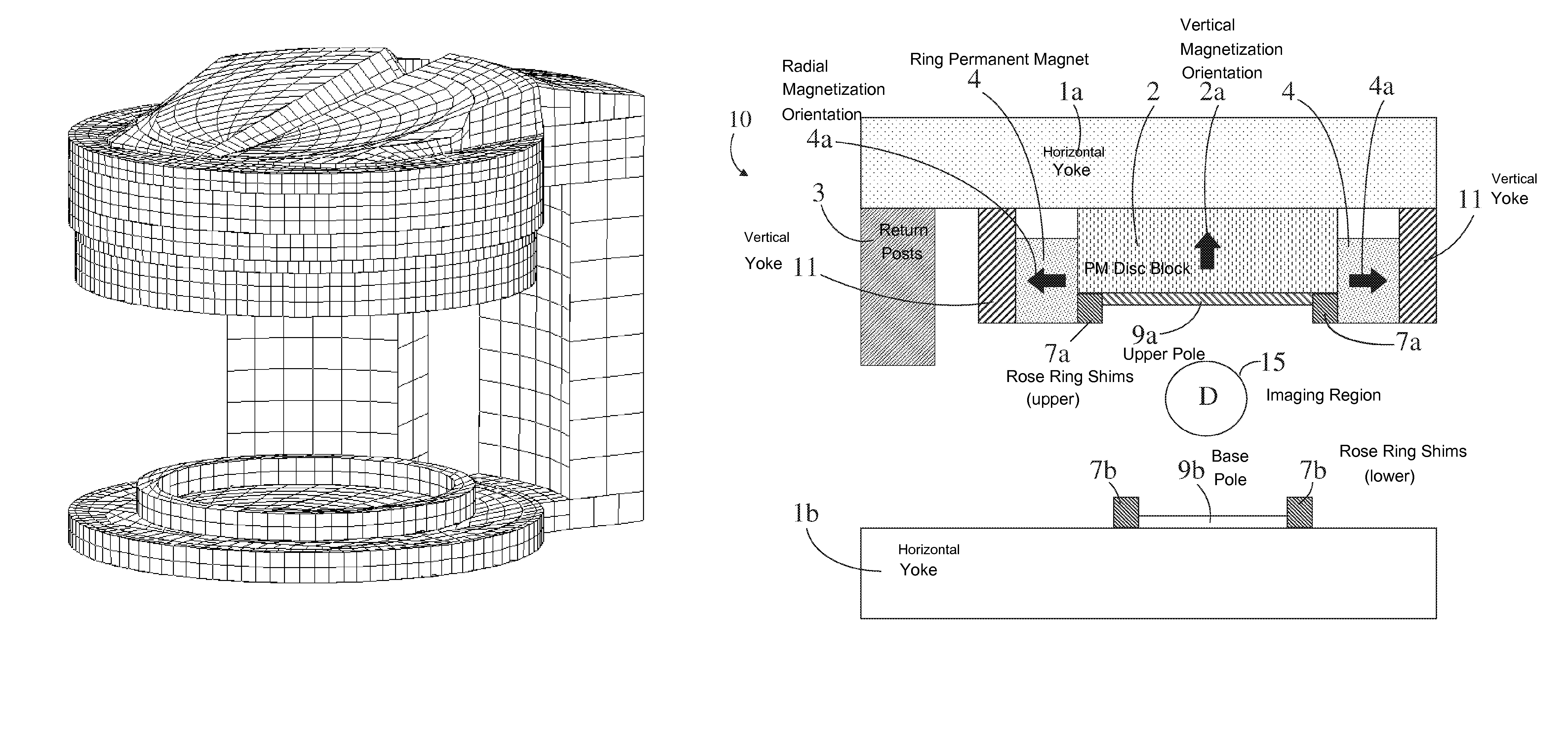

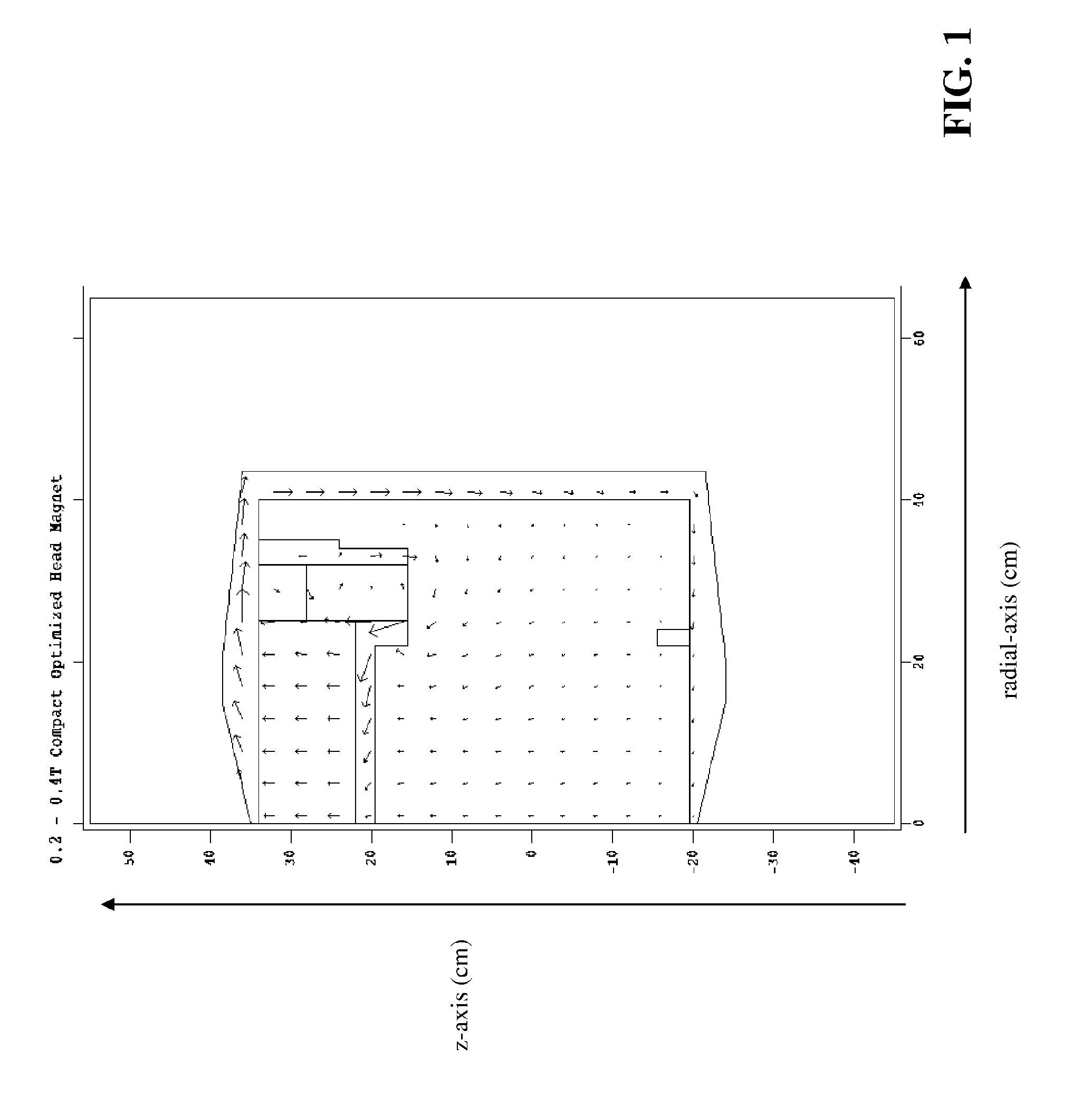

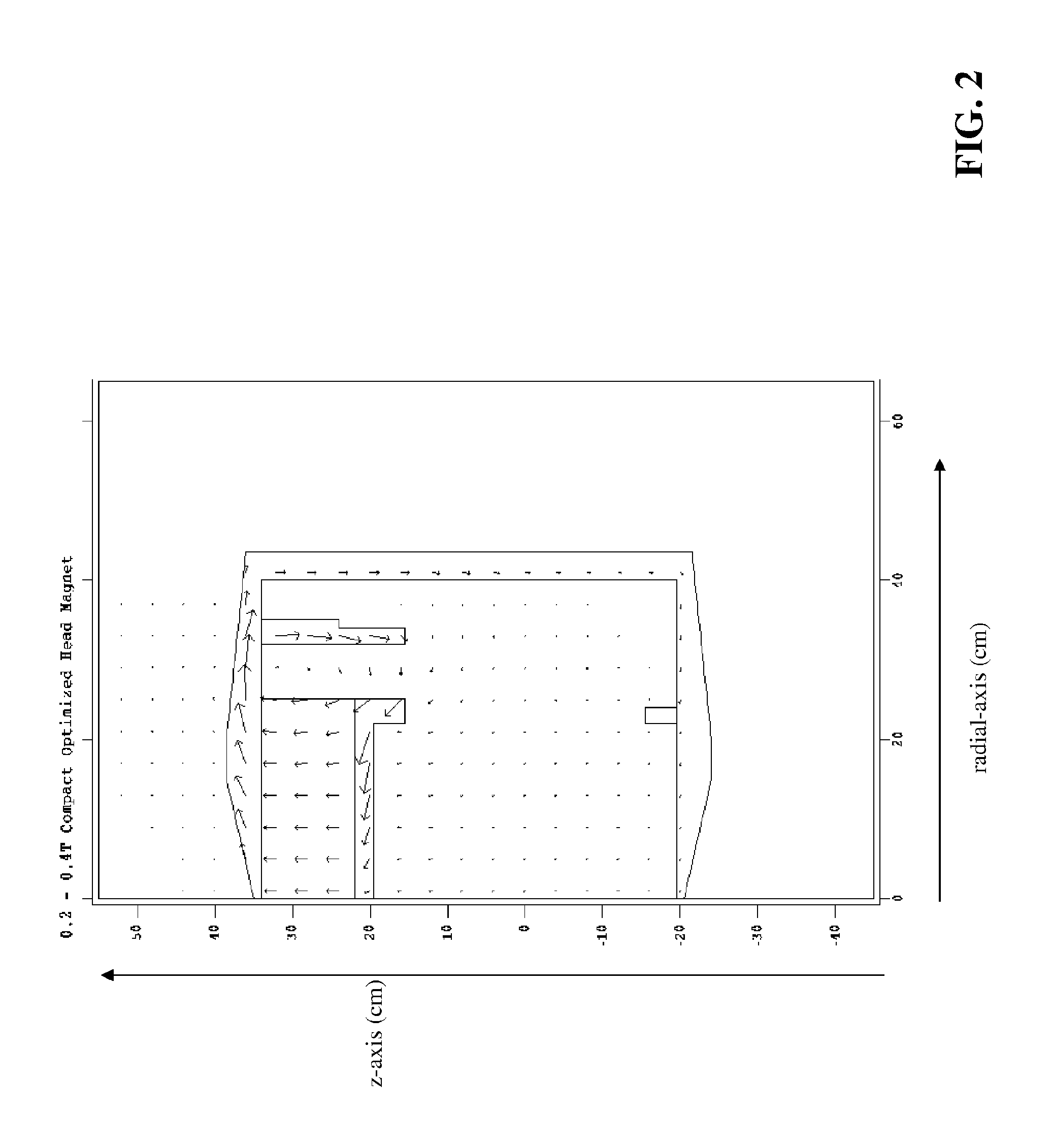

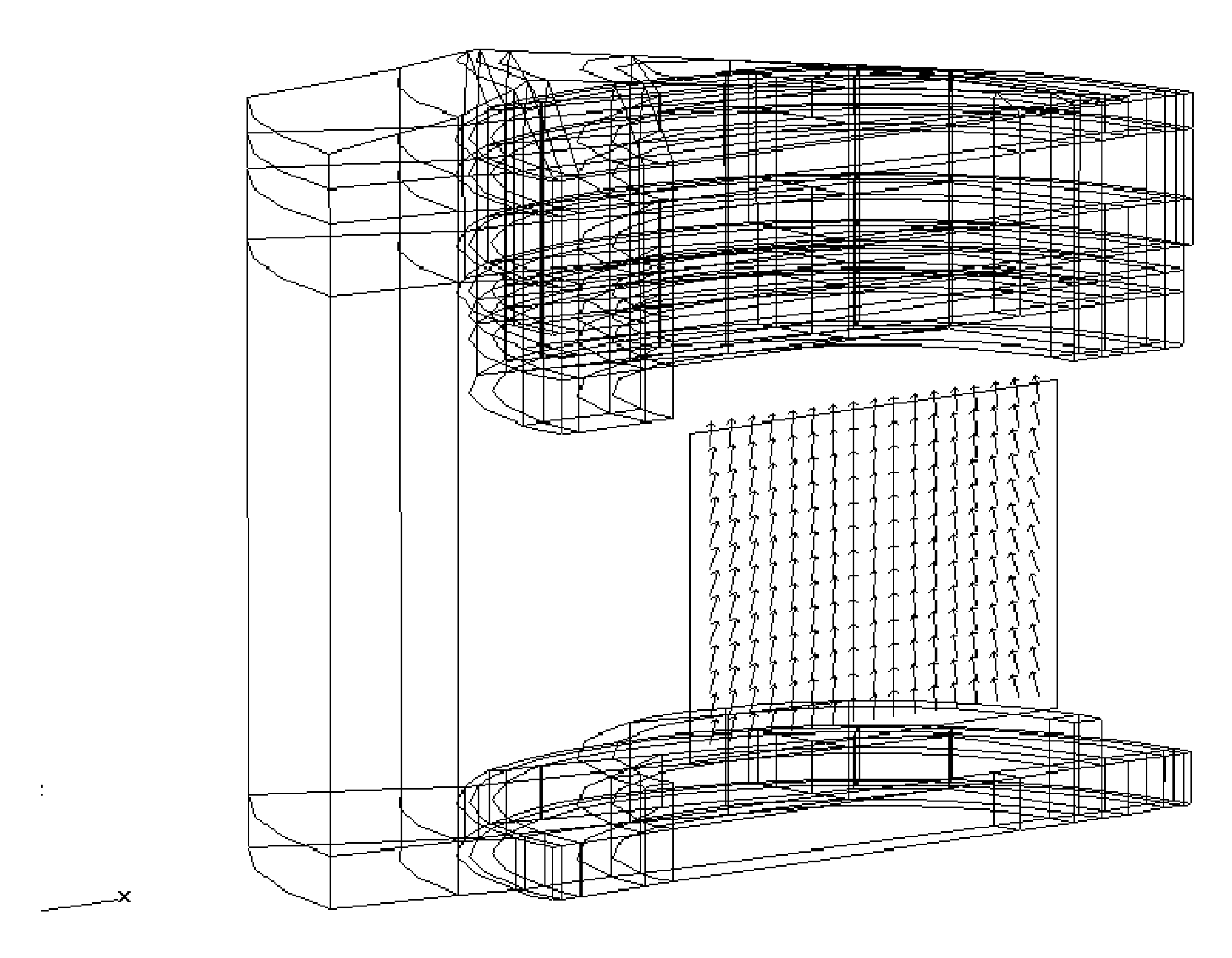

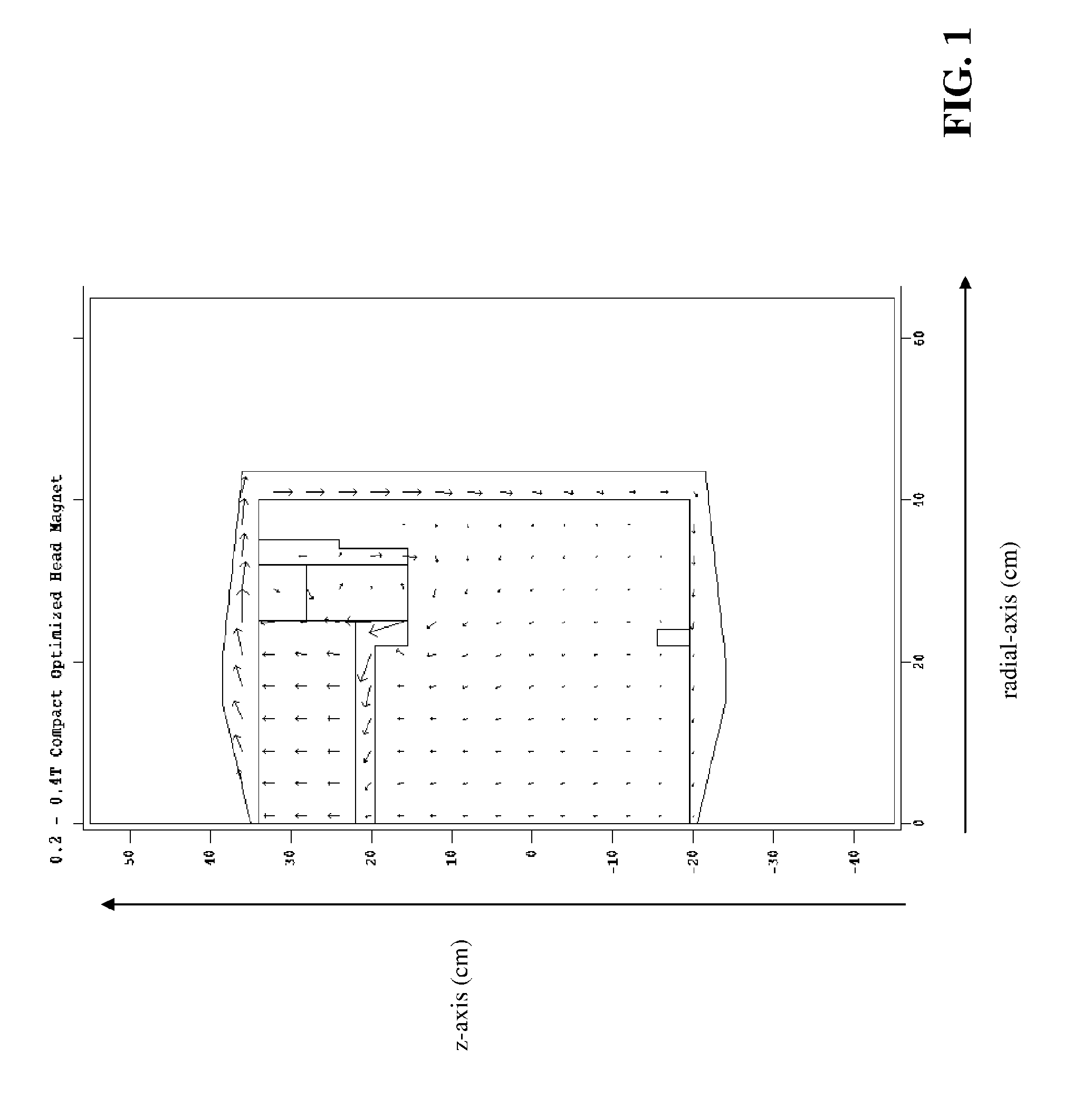

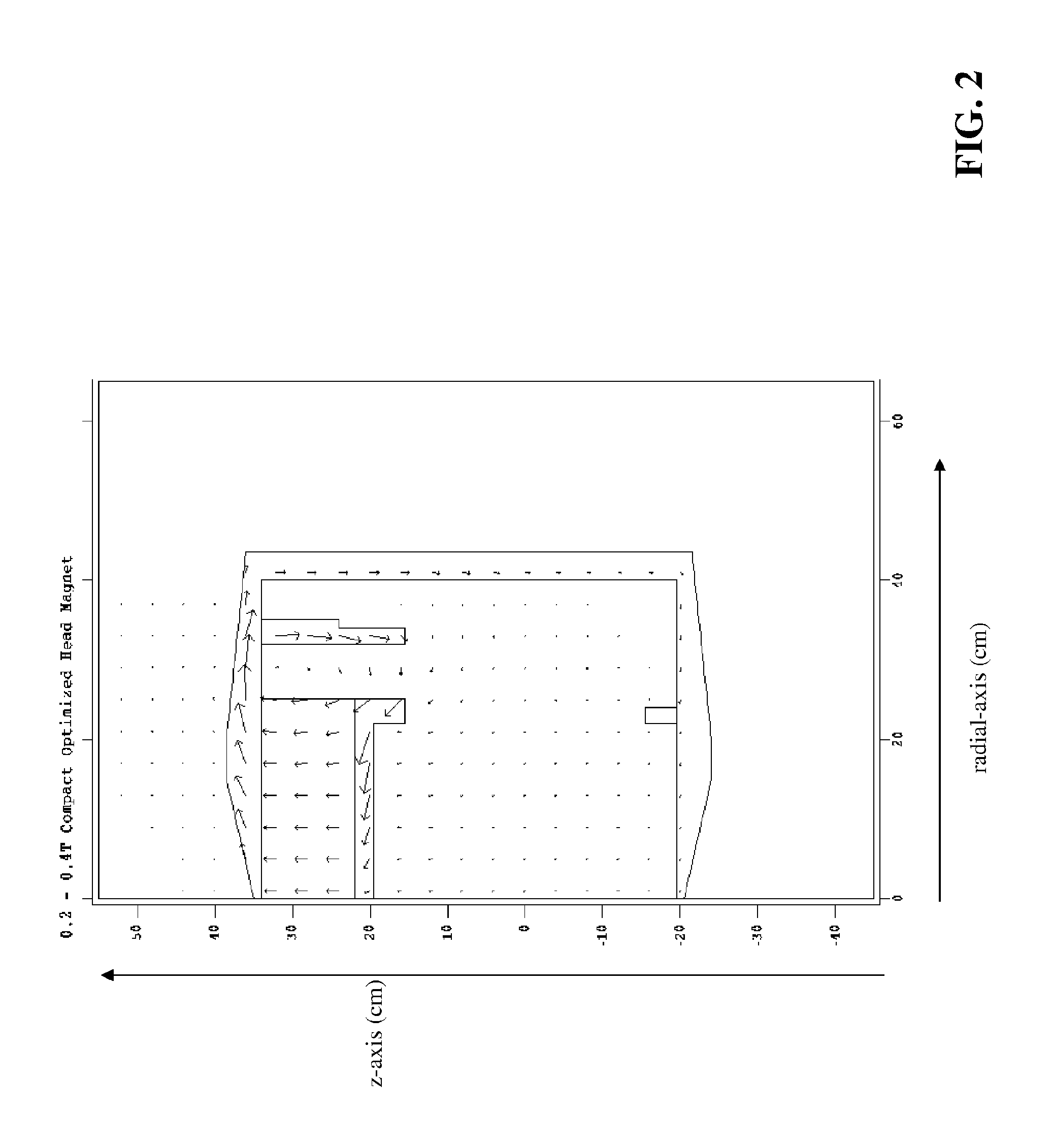

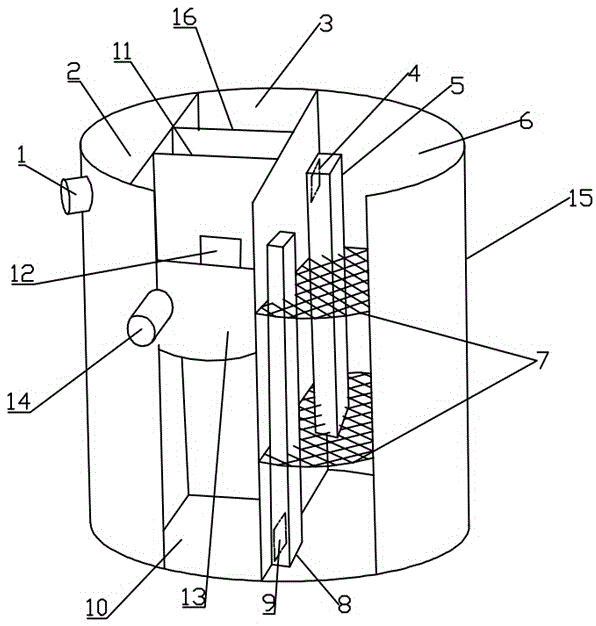

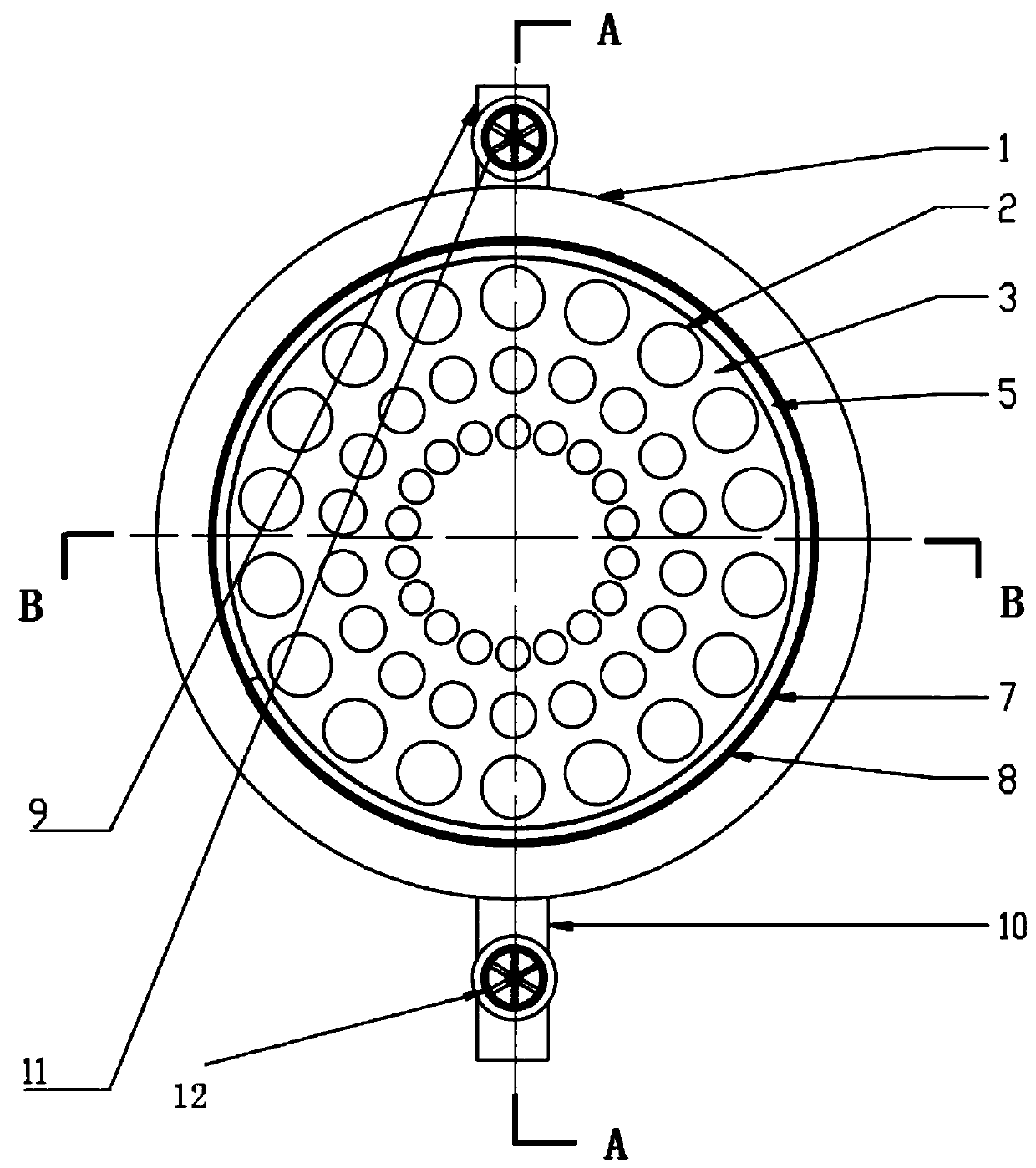

Compact inhomogeneous permanent magnetic field generator for magnetic resonance imaging

InactiveUS9222998B2Large static gradientOptimize site selectionElectric/magnetic detectionMeasurements using magnetic resonanceCircular discDiffusion

A magnet assembly primarily for use in MRI applications is disclosed. The magnet assembly is composed of a single disk and ring permanent magnet set connected to a C-type magnet yoke and return fixture with asymmetrically arranged poles. Together, the permanent magnets create a strong magnetic field that has a large static gradient in the central enclosure. The magnet assembly is primarily designed for diffusion based MRI scanning but can perform routine MRI scanning as well.

Owner:TEKLEMARIAM GRUM +2

Compact Inhomogeneous Permanent Magnetic Field Generator for Magnetic Resonance Imaging

InactiveUS20110248715A1Large static gradientOptimize site selectionElectric/magnetic detectionMeasurements using magnetic resonanceDiffusionCircular disc

A magnet assembly primarily for use in MRI applications is disclosed. The magnet assembly is composed of a single disk and ring permanent magnet set connected to a C-type magnet yoke and return fixture with asymmetrically arranged poles. Together, the permanent magnets create a strong magnetic field that has a large static gradient in the central enclosure. The magnet assembly is primarily designed for diffusion based MRI scanning but can perform routine MRI scanning as well.

Owner:TEKLEMARIAM GRUM +2

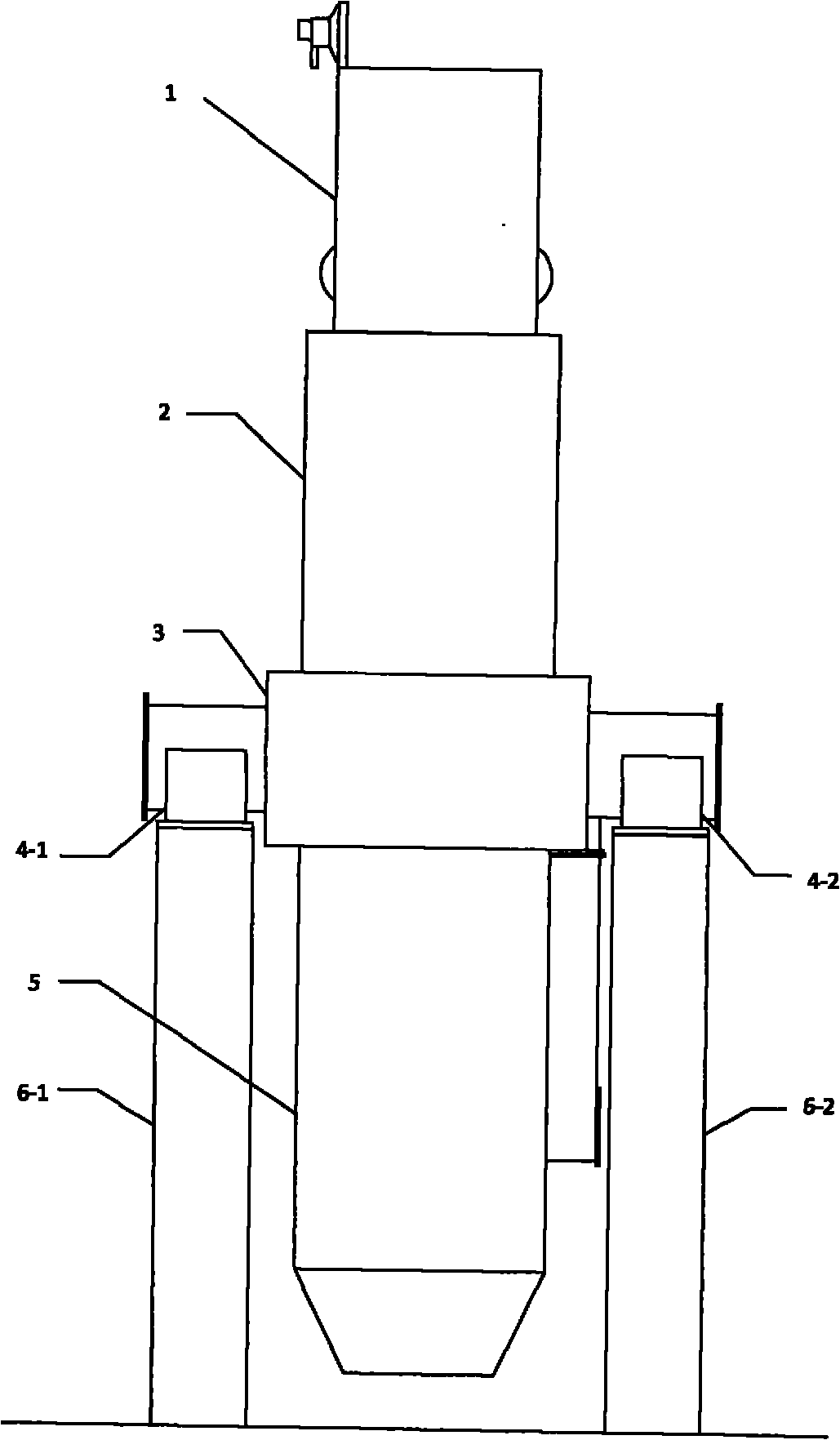

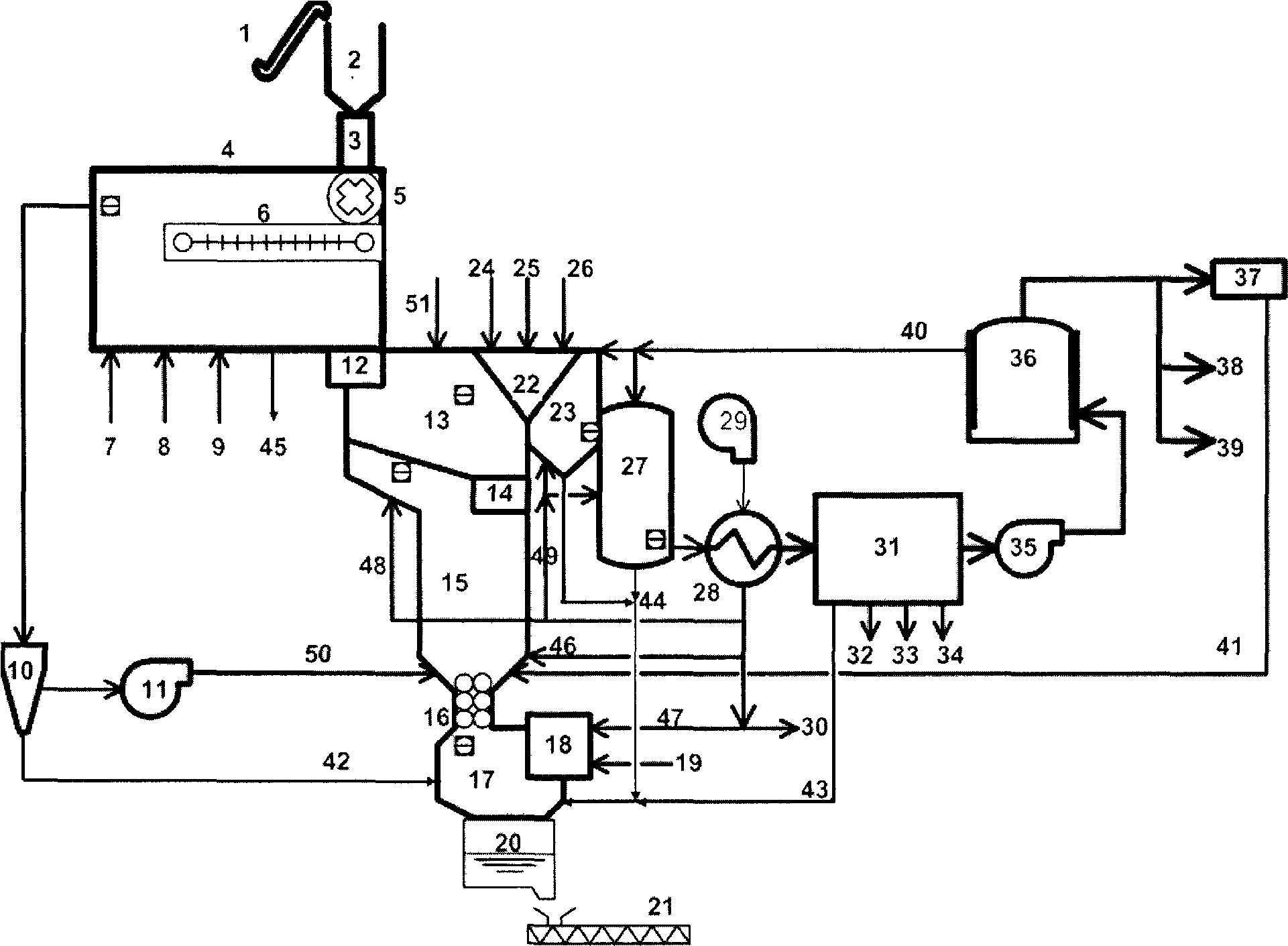

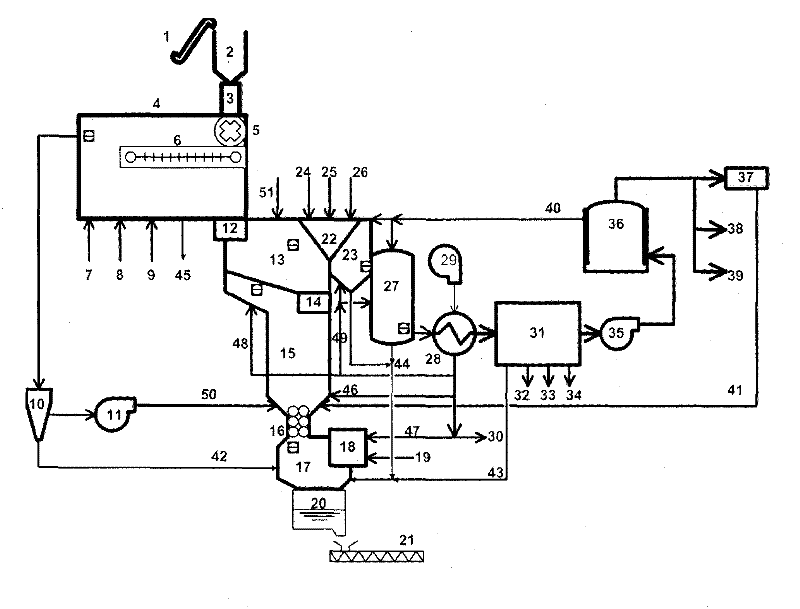

Two-stage plasma gasifying, melting and cracking method and device of waste containing organic matters

ActiveCN102000691ANo emissionsComplete gasificationSolid waste disposalGlass furnace apparatusGeneration rateHigh energy

The invention relates to a treatment method of waste containing organic matters, in particular to two-stage plasma gasifying, melting and cracking method and device of the waste containing organic matters, belonging to the field of gasifying, melting and cracking techniques. In the invention, the serious defects of high energy consumption of the waste containing organic matters and more flying ash during the plasma arc melting and cracking are solved, thereby thoroughly utilizing the energy of the organic matters and maximizing the treating efficiency, thoroughly cracking the tar, reducing the generation rate of Dioxin, obtaining synthesis gas with high quality and high heat value as much as possible, providing guarantee for the subsequent gasification power generation, the hydrogen energy recovery or the production of green liquid fuel, simultaneously finishing one-step recovery of noble metals and direct utilization of glass bodies in the field of building materials, laying foundation for the large-scale commercial development and application of the energy of the waste containing organic matters, and thoroughly solving the possible pollutant discharging problem in the gasifying process of the organic matters, particularly the dangerous waste.

Owner:HOOTECH

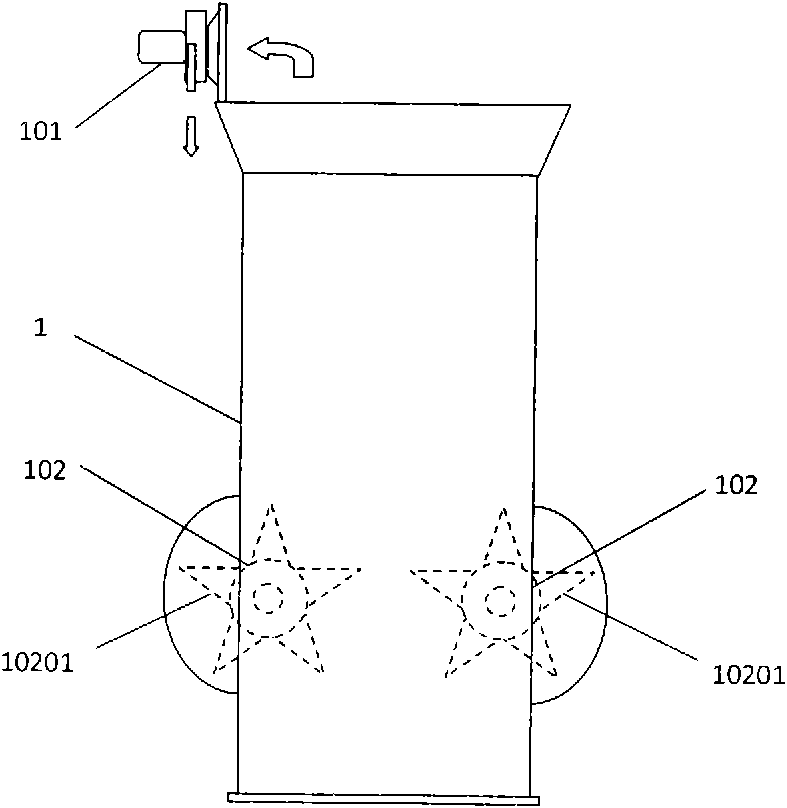

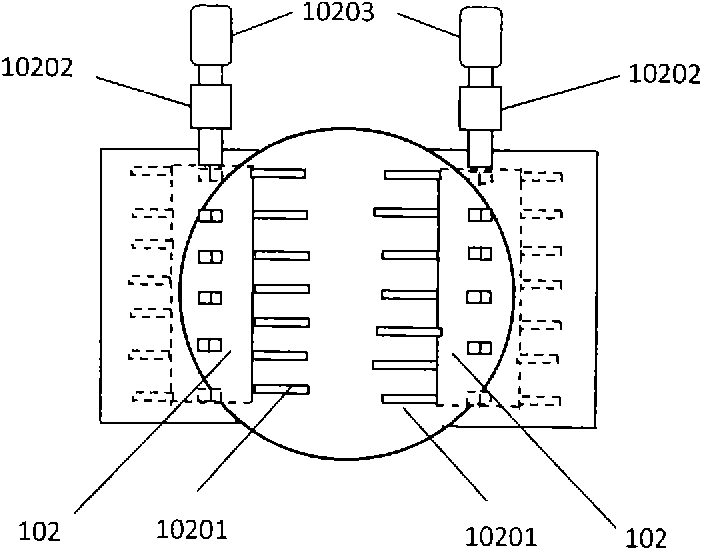

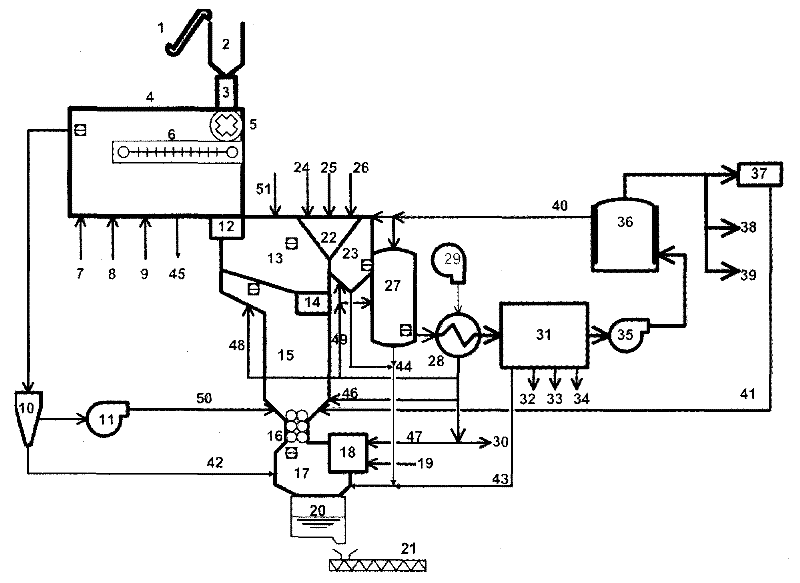

Multilevel-control polyradical biomass-gasification energy regeneration system

ActiveCN101519604AImprove gasification efficiencyHigh reforming efficiencyBiofuelsEnergy inputOxygenMoisture

The invention provides a multilevel-control free-polyradical biomass-gasification energy regeneration system, which can transform extensive biomass and carbon-containing raw materials, including energy crops, agriculture-forestry byproducts, organic waste, industrial and dangerous waste and the like, into high-grade energy. The system is designed for continuous operation. Gasification comprises the following steps of performing pretreatment, performing pyrolysis, transforming carbon, fusing ash, cracking tar, reforming syngas and utilizing waste heat, wherein the steps are precisely controlled one by one and integrated so as to achieve optimum; moisture from the pretreatment of the materials is led into a carbon-transforming unit so as to realize oxygen-free pyrolysis; gasification gas is in contact with a large number of free polyradicals in a free-polyradical reaction-accelerating unit; and the obtained product is purified and then enters downstream application, such as power generation, hydrogen production and biomass methanol / ethanol production. The system has the advantages of needing no auxiliary fuel, maximizing gasification efficiency and thoroughly cracking tar and clearing pollutants, and is an upstream technique for the application of biomass renewable energy. As energy utilization meets all strict environmental protection standards, the system is also an energy-saving environment-friendly technique for non-incineration harmless treatment.

Owner:浙江瑞拓展泰再生能源有限公司

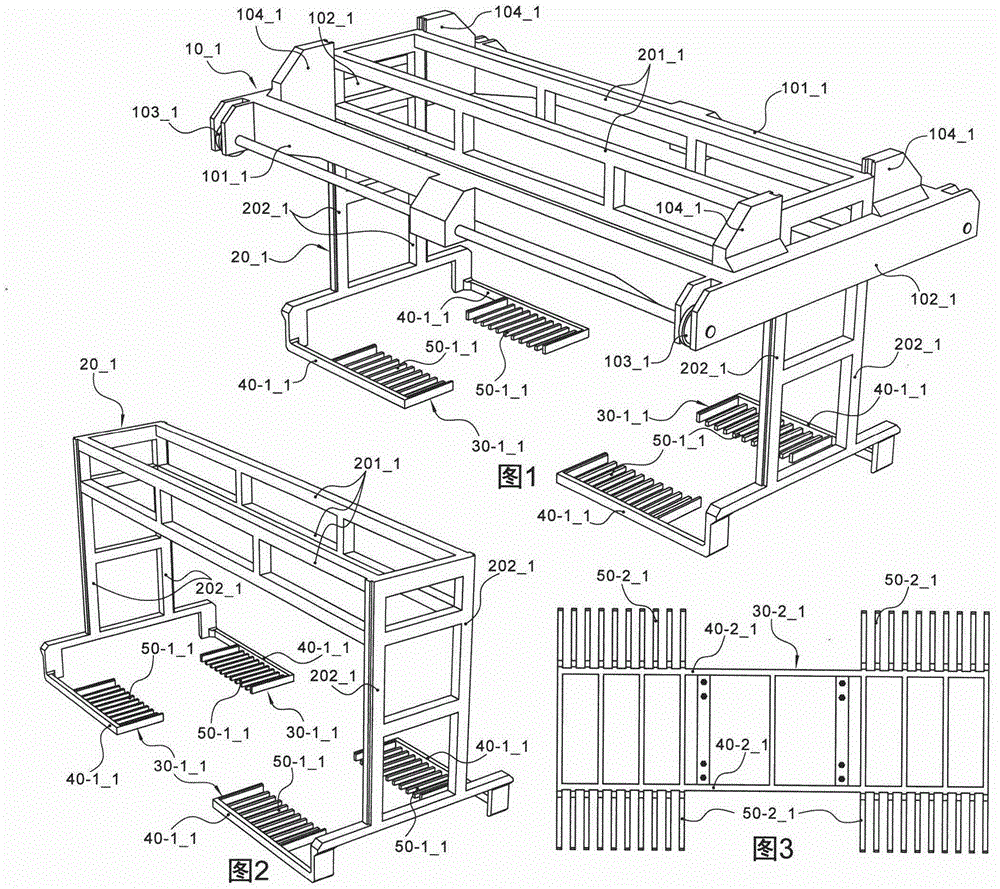

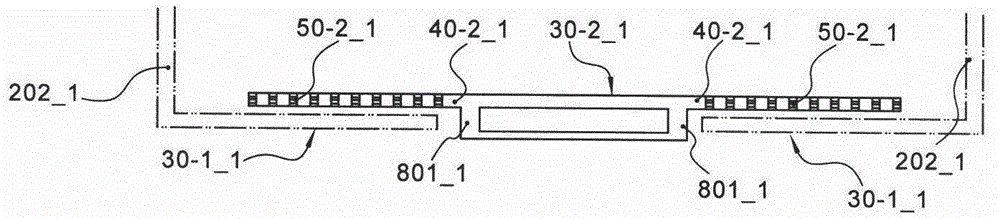

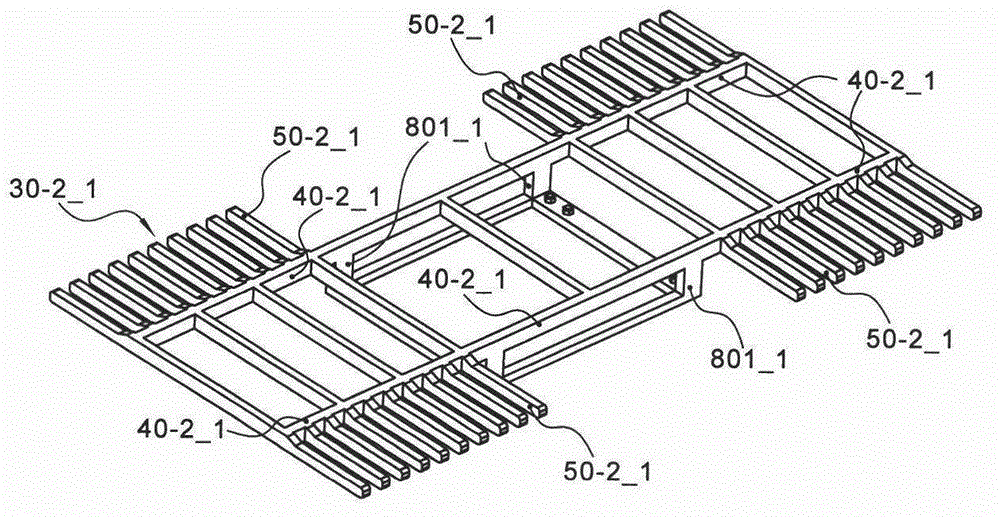

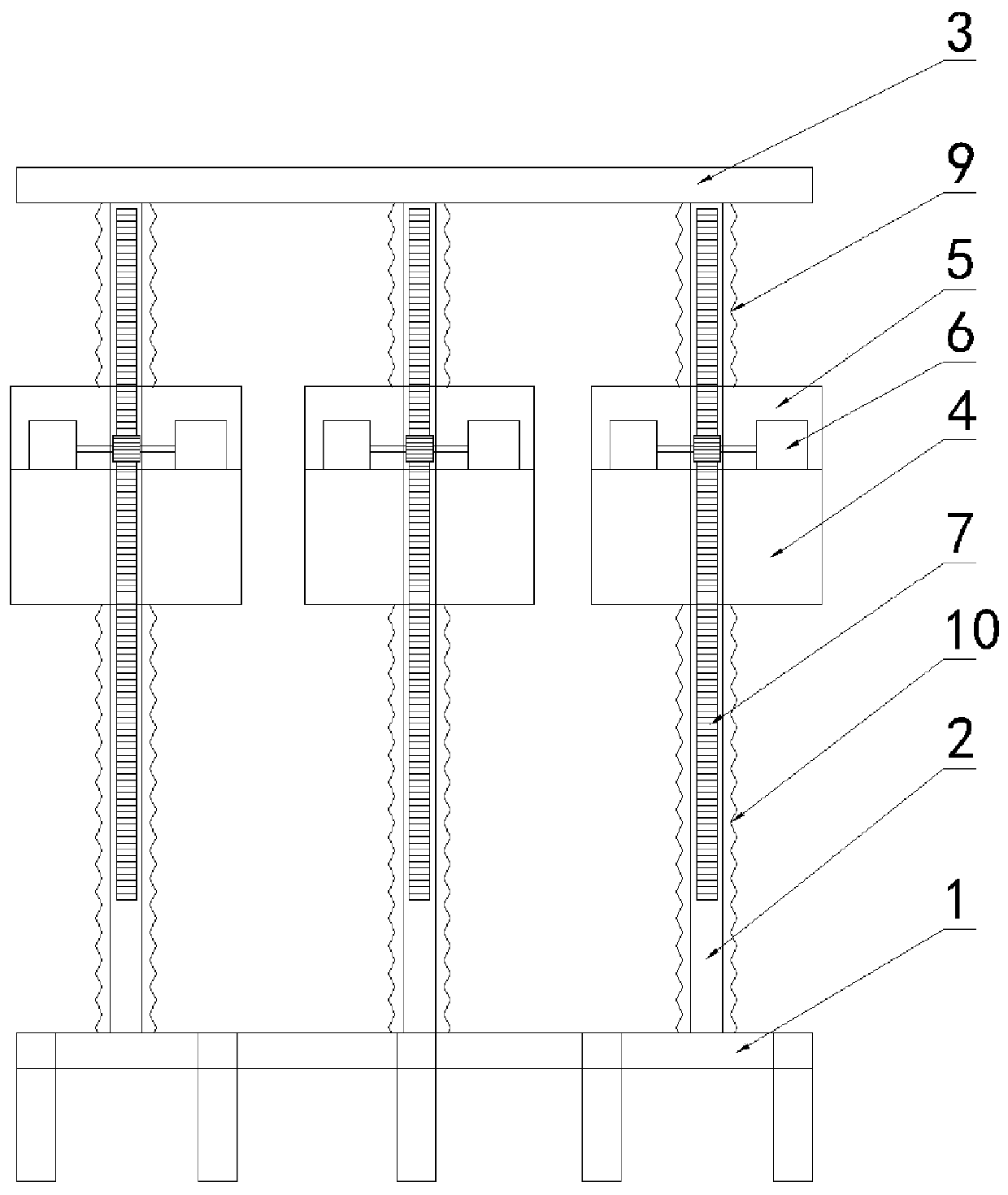

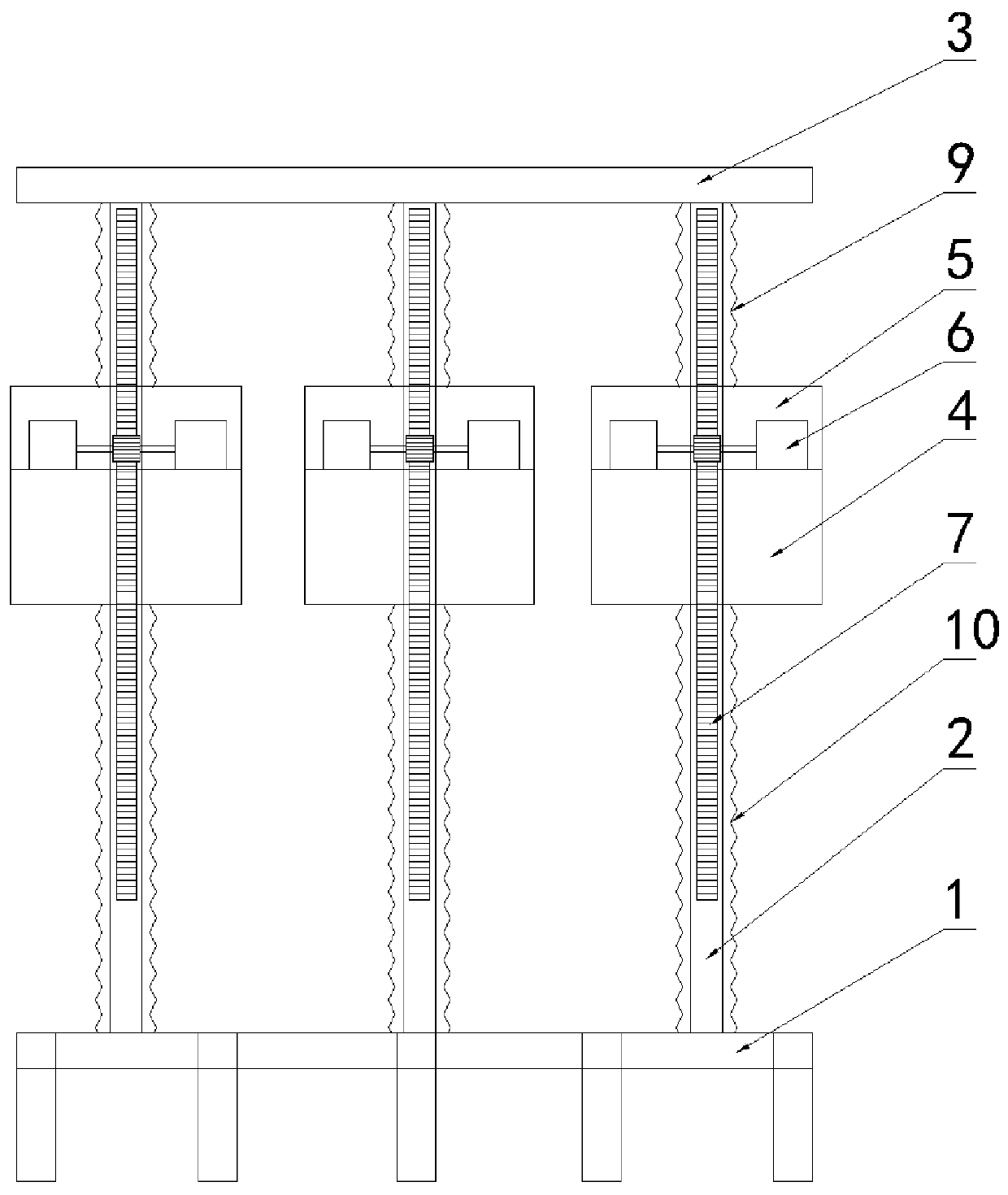

Parking device with comb teeth for supporting, storing and withdrawing vehicle

The invention provides a vehicle carrying scheme that lifting racks are used for lifting a vehicle above a vehicle top so as to perform leap-type translation in order to solve the problems that existing parking devices with the comb teeth for supporting, storing and withdrawing the vehicle are low in using ratio of the ground, inflexible in application, poor in storing and withdrawing efficiency and the like. Besides, by means of mutually communicated storing and withdrawing rack channels which are distributed below all comb-shaped parking racks of a parking queue, comb-shaped storing and withdrawing racks of carriers can directly and rapidly move and operate between each comb-shaped parking rack and vehicle storing and withdrawing port, the process of lifting and putting the road vehicle to a garage can be simply finished by the aid of comb-shaped lifting racks which are arranged at positions of the vehicle storing and withdrawing ports, a system is effectively simplified, and the efficiency is increased.

Owner:于君

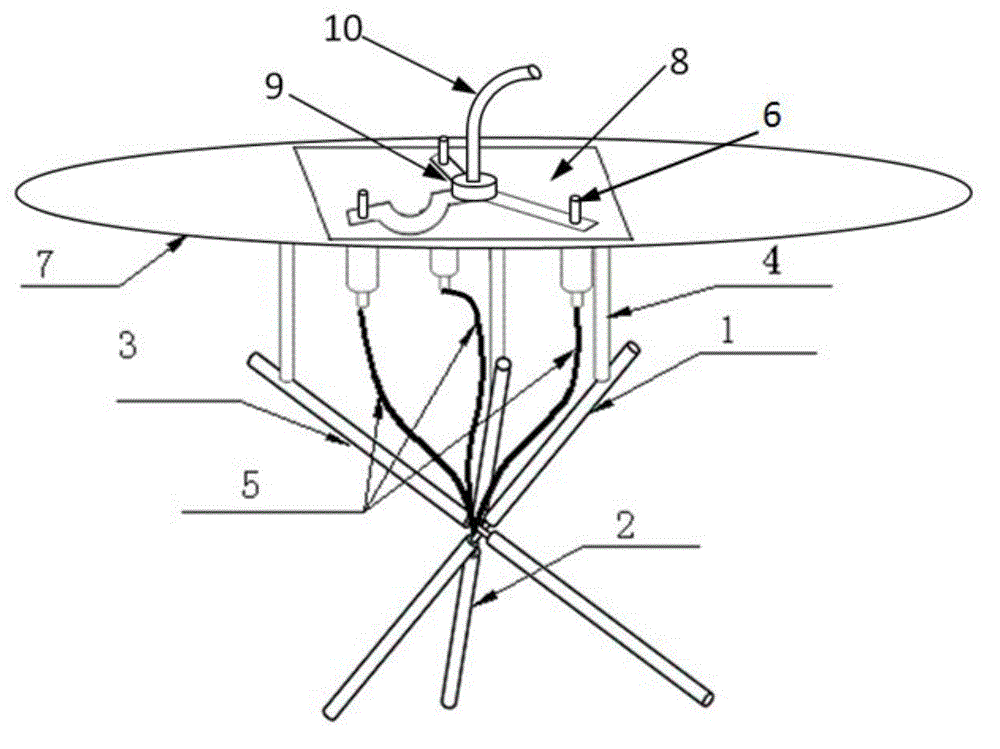

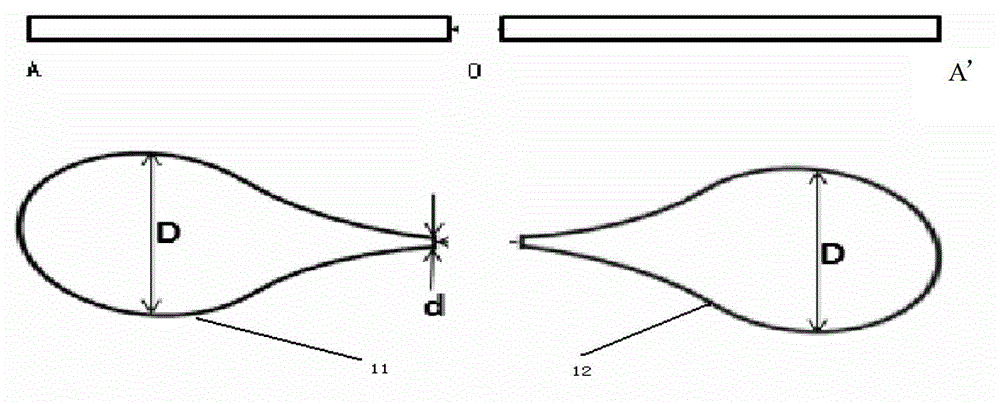

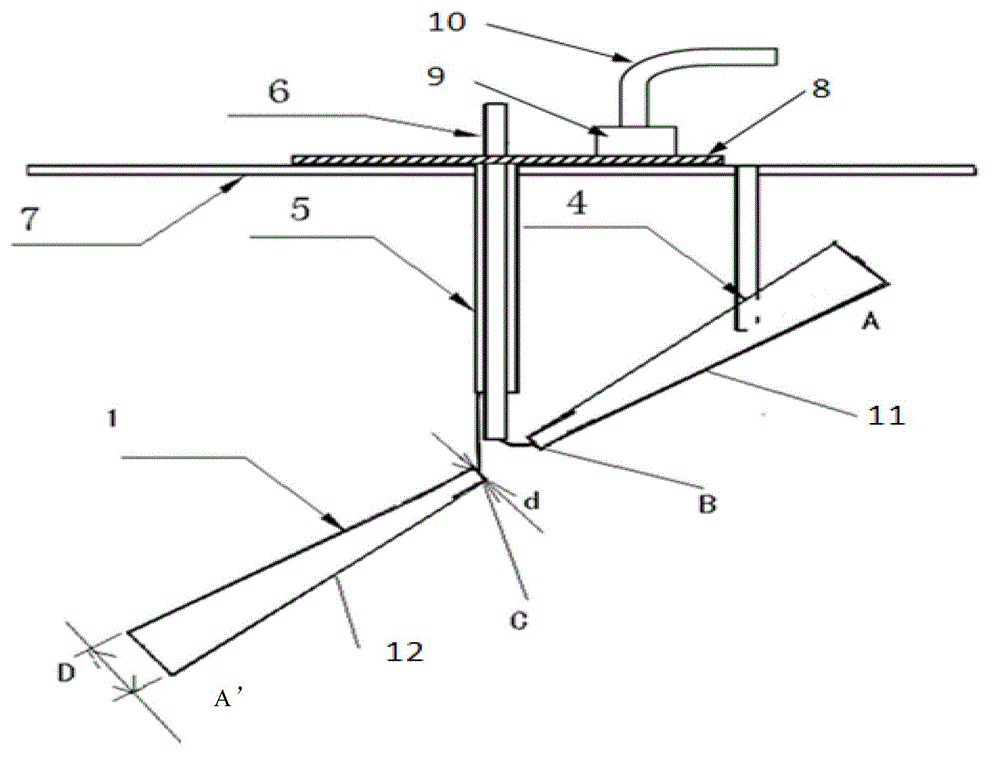

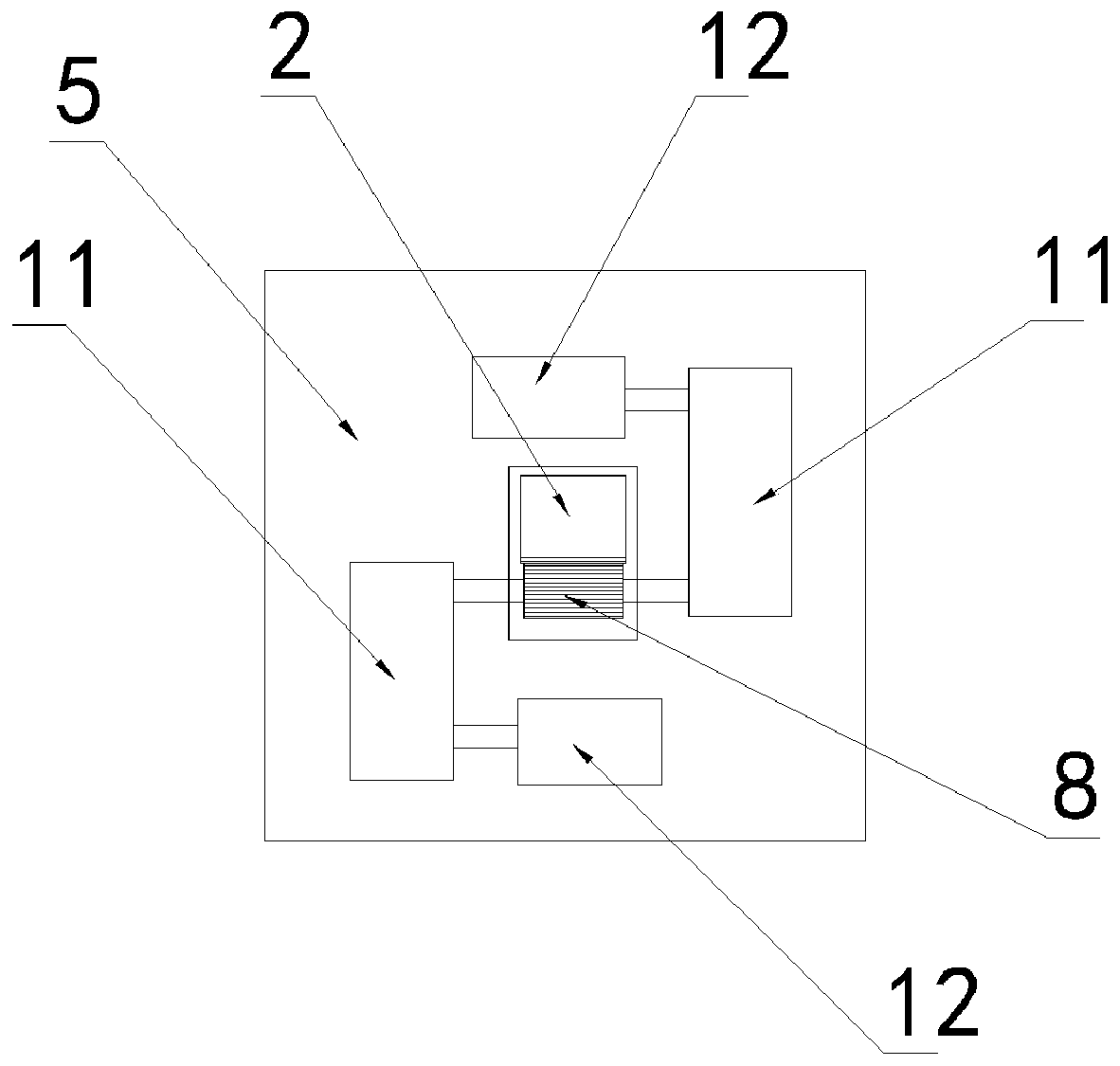

Antenna device and antenna array

ActiveCN104009277AUniform coverageFlexible coverageAntenna supports/mountingsRadiating elements structural formsPhysicsSignal on

The invention discloses an antenna device and an antenna array. The main content is that the antenna device includes three antenna oscillators fixed onto a supporting part, wherein a vertical distance between the radiation center of each antenna oscillator fixed onto the supporting part and a mirroring reflection ground plate is 1 / 5[lambda] to 2[lambda]; any two antenna oscillators fixed onto the supporting part mutually intersect at right angles; and an angle value of an included angle formed by a polarization direction and a horizontal direction of any different antenna oscillator is identical. Each antenna oscillator is connected with a feed network board through a core wire of a coaxial cable. The feed network board is used for independently adjusting amplitude and phase of a transceiving signal on each antenna oscillator. The three-polarization antenna device is applied to a communication network built by using MIMO technology, is convenient for address site selection and installation, and can help to improve the covering capability of network signals, raise broadband data service processing level and increase spectrum resource utilization rate.

Owner:CHINA MOBILE GROUP DESIGN INST

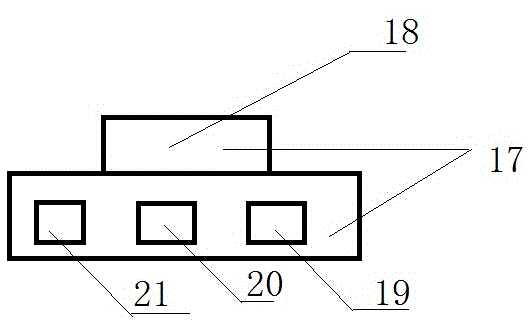

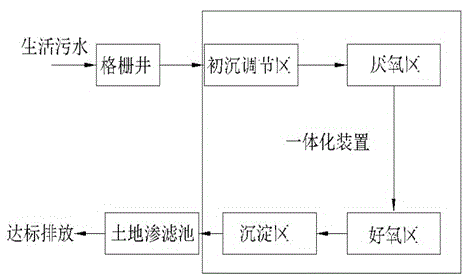

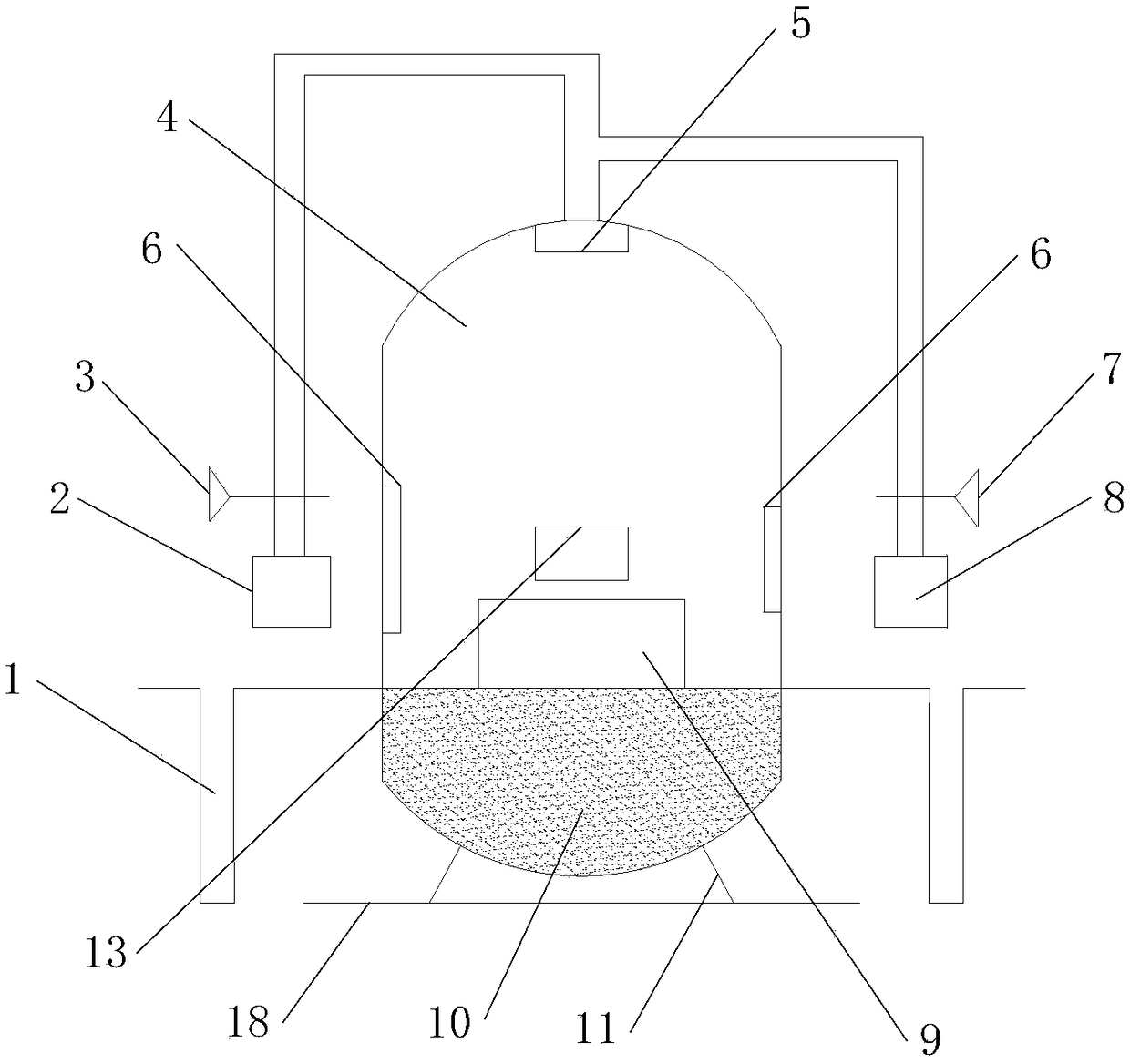

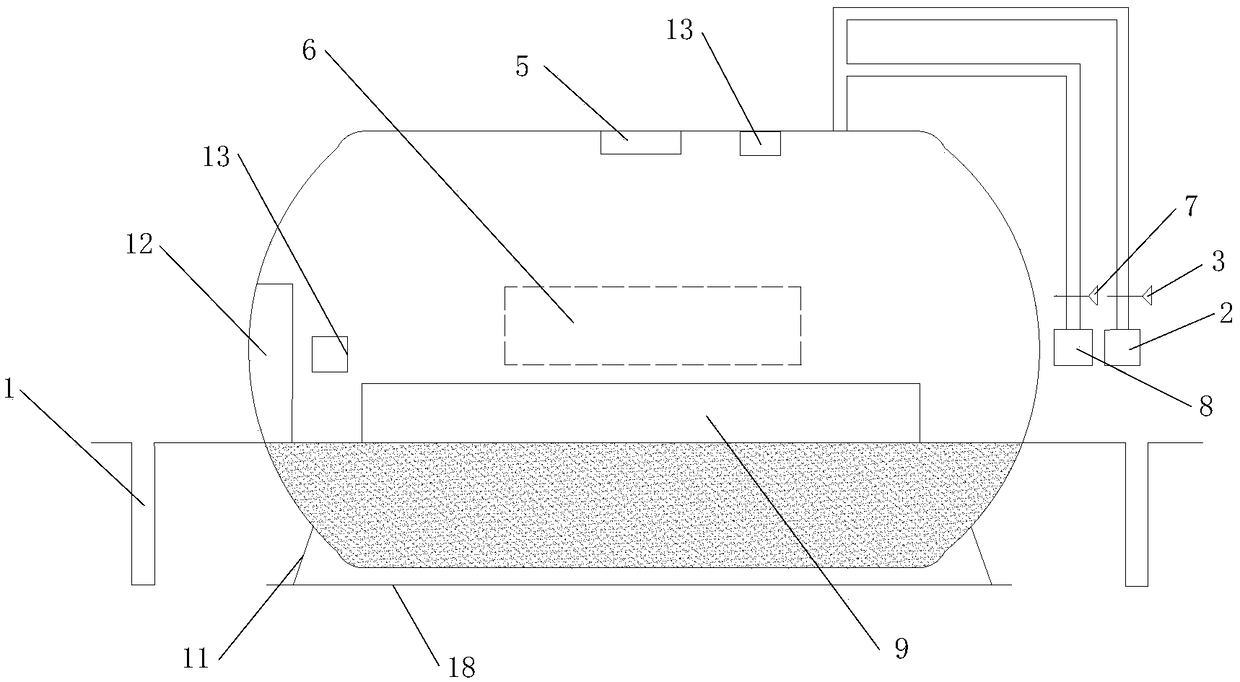

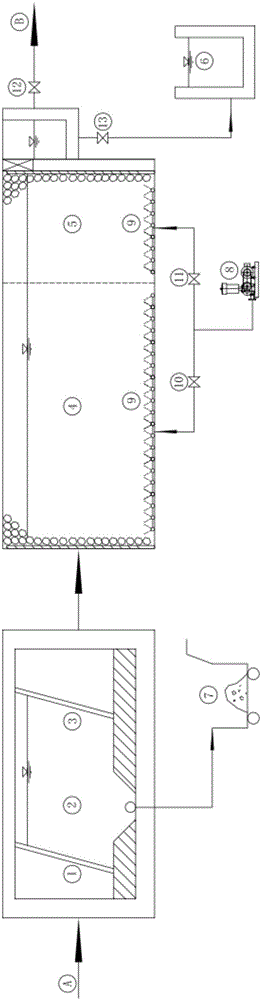

Scattered small integrated sewage processing device for rural areas

PendingCN104671408ASmall footprintOptimize site selectionTreatment with aerobic and anaerobic processesEnergy based wastewater treatmentRural areaControl system

The invention discloses a scattered small integrated sewage processing device for rural areas and aims at the characteristics and problems that the rural inhabitants are live scattered, the domestic sewage point source with small sewage quantity is randomly distributed and the position is remote, the power intervention is inconvenient and the centralized disposal investment cost is high. According to the device, a high-tech practical technology is highly integrated, the device is under automatic photovoltaic operation, and a centralized disposal is substituted by a distributed disposal. The device saves the place, has a short pipe and is conveniently installed. The device mainly comprises a solar driving and controlling system, a first anaerobic pond, a second anaerobic pond, a contact aeration pond, a settling pond and a disinfecting canal; and a small soil percolation system can be added on demand as a deep processing unit.

Owner:广西汇泰环保科技有限公司

Vacuum explosion effect testing device

The invention discloses a vacuum explosion effect testing device, which comprises a tank body; the upper end of the tank body is respectively connected to a vacuuming device and a smoke exhausting andgas exchanging device through pipelines; a spray device is arranged at the top of the tank body; a toxic and harmful gas monitoring device is also arranged in the tank body; a wiring sealing window and an observable window are arranged on both sides of the tank body; a double-layer sealing door is arranged at one end of the tank body; a detachable device table and a replaceable cushion are arranged at the bottom of the tank body. Due to the arrangement of a spray dust reduction system, a purification system, and the toxic and harmful gas monitoring device, toxic and harmful substances generated in explosion are monitored, prescribed, removed and absorbed, thereby ensuring the safety of operation personnel performing an explosion effect test in a vacuum environment to the greatest extent.In addition, a damping groove is formed outside the device, and a surface, connected with a base, of the device is filled with a vibration damping material, so that vibration hazards caused by an explosion effect are reduced.

Owner:ANHUI UNIV OF SCI & TECH

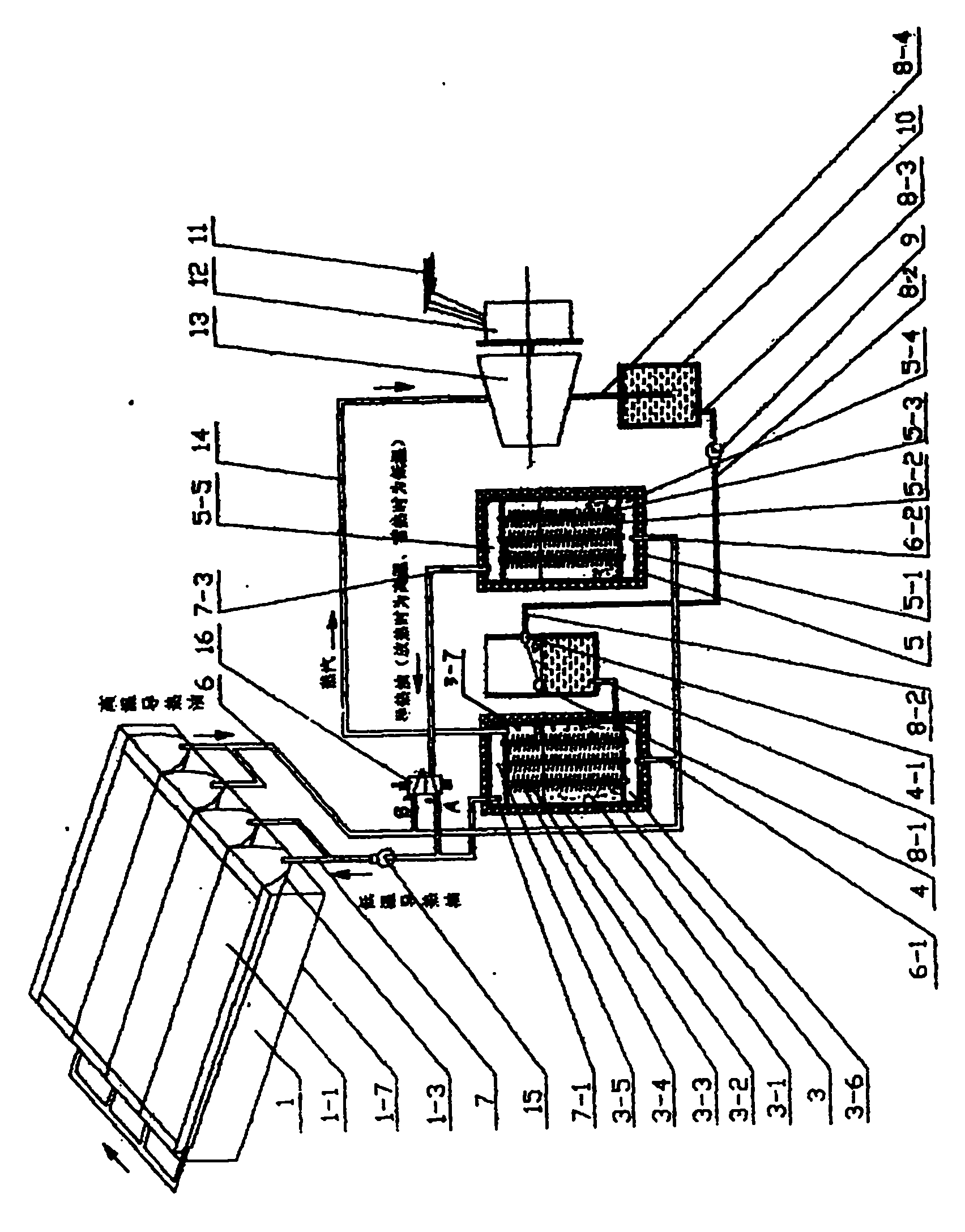

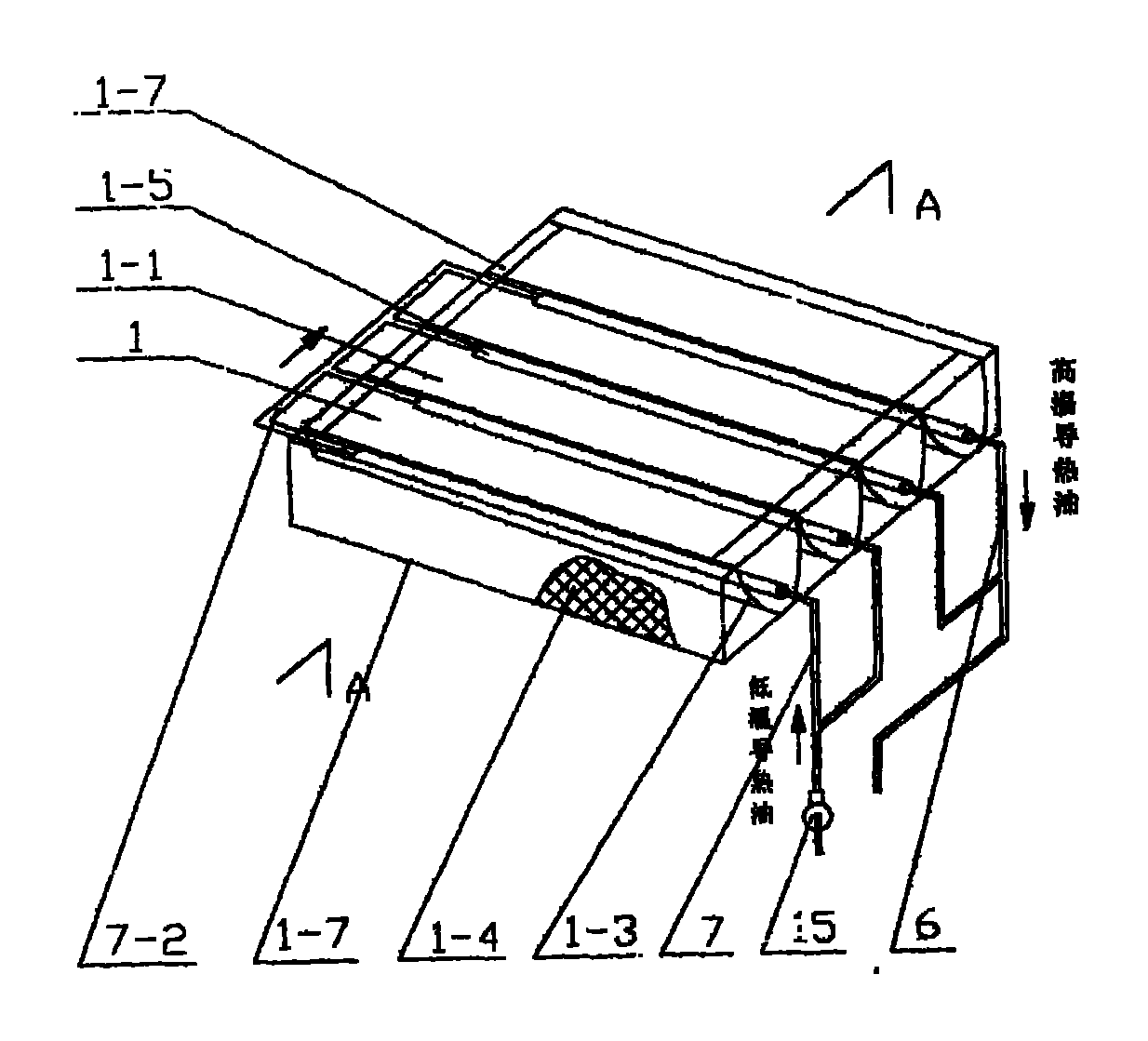

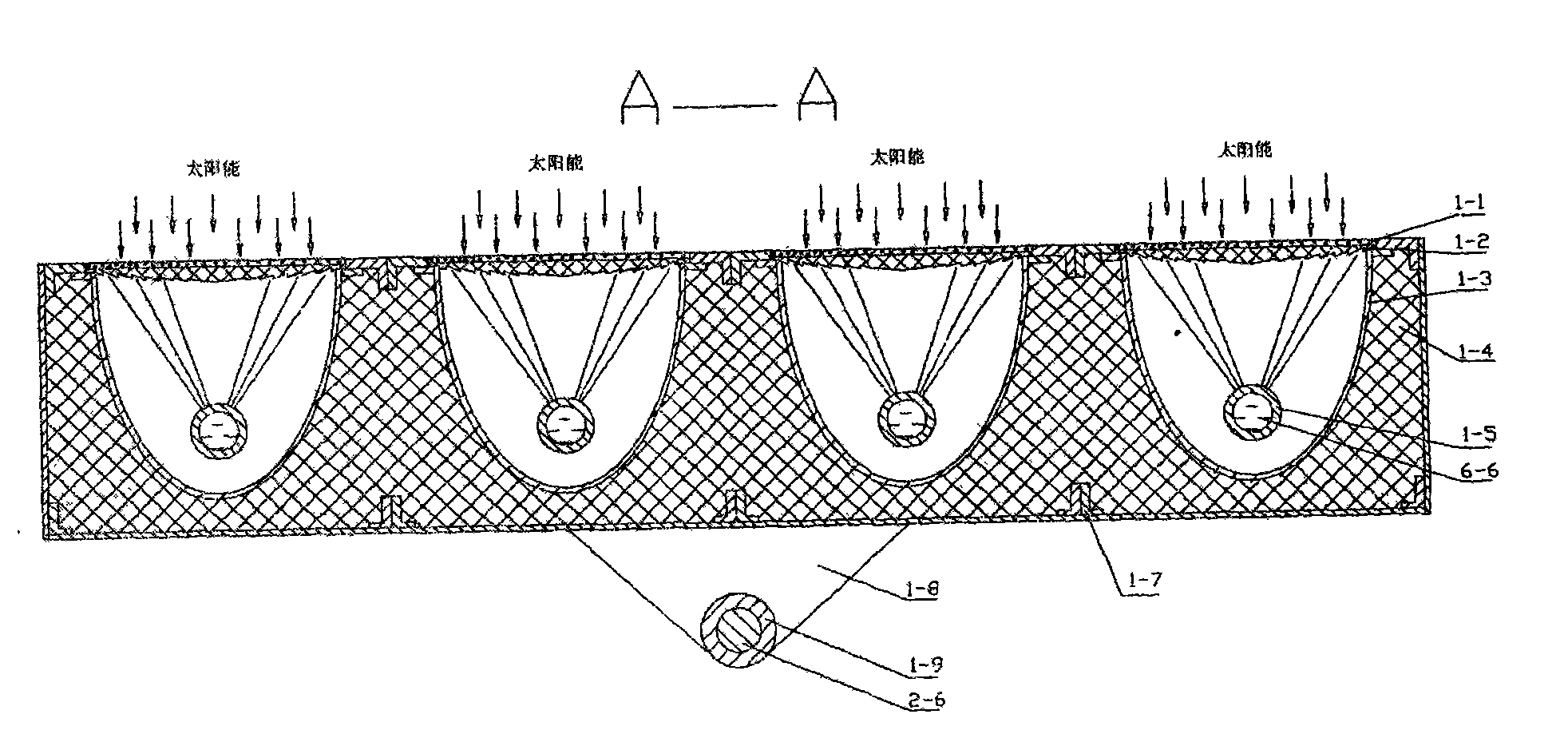

High temperature efficient ground solar steam generating set

InactiveCN101985918AHigh solar energy conversion efficiencyImprove conversion efficiencyFrom solar energyMachines/enginesTemperature controlProcess engineering

The invention discloses a high temperature efficient ground solar steam generating set, comprising a water pump, a water tank component, a steam turbine, a generator and a system control circuit. The generating set is characterized by also comprising a condenser component, a heat exchanger component, a thermal storage box component, an oil pump, a temperature control valve, a water level control water tank component and a base component. The generating set in the invention has the advantages of reasonable structure, low carbon, environment protection, high temperature and high efficiency, low cost, convenient installation and maintenance, safety and reliability, greatly saves land resources, and can be built in the areas at the classes of 1-5 in which national solar resources are distributed.

Owner:郭绍浩

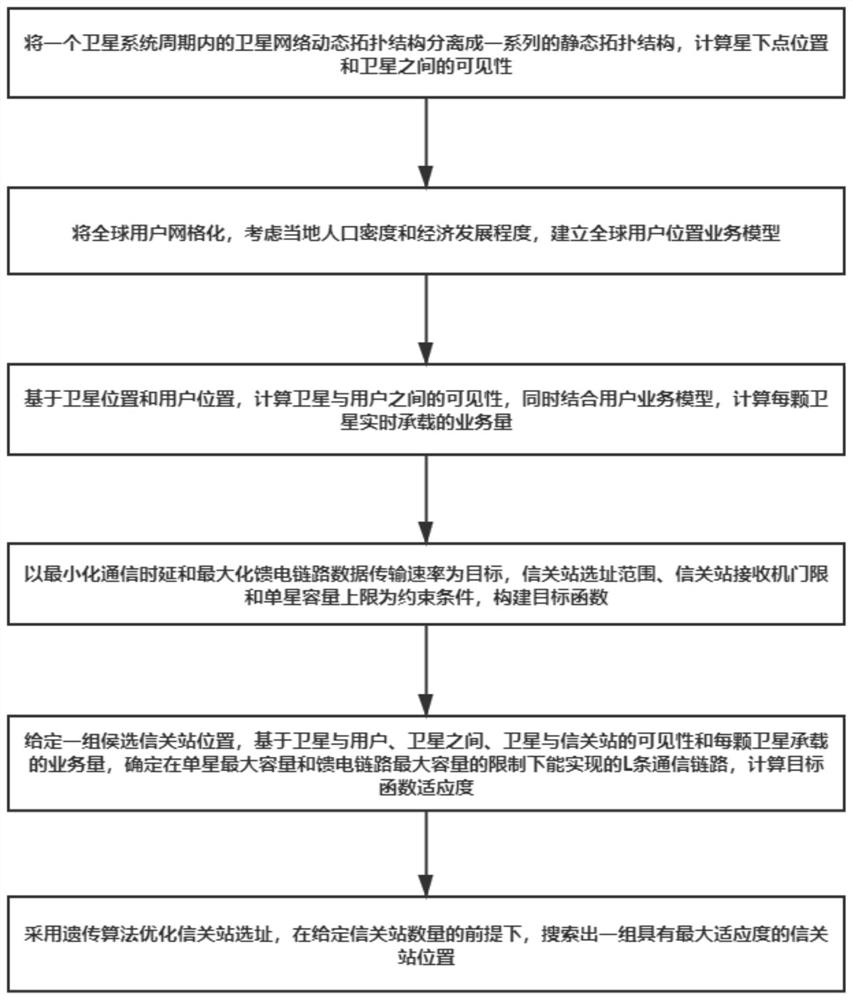

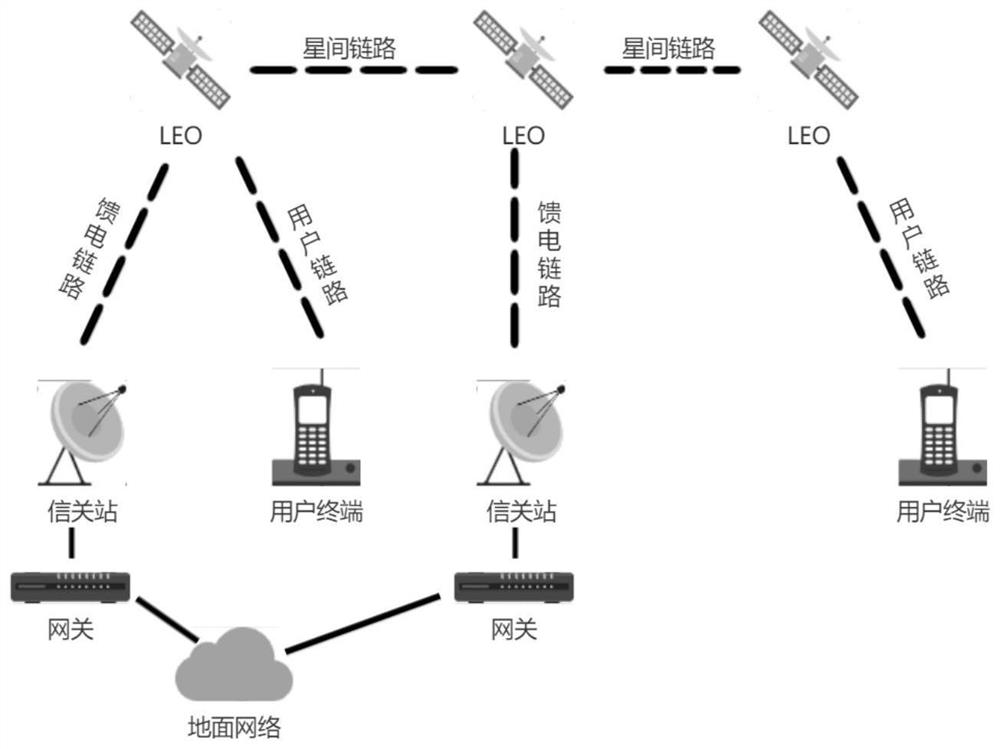

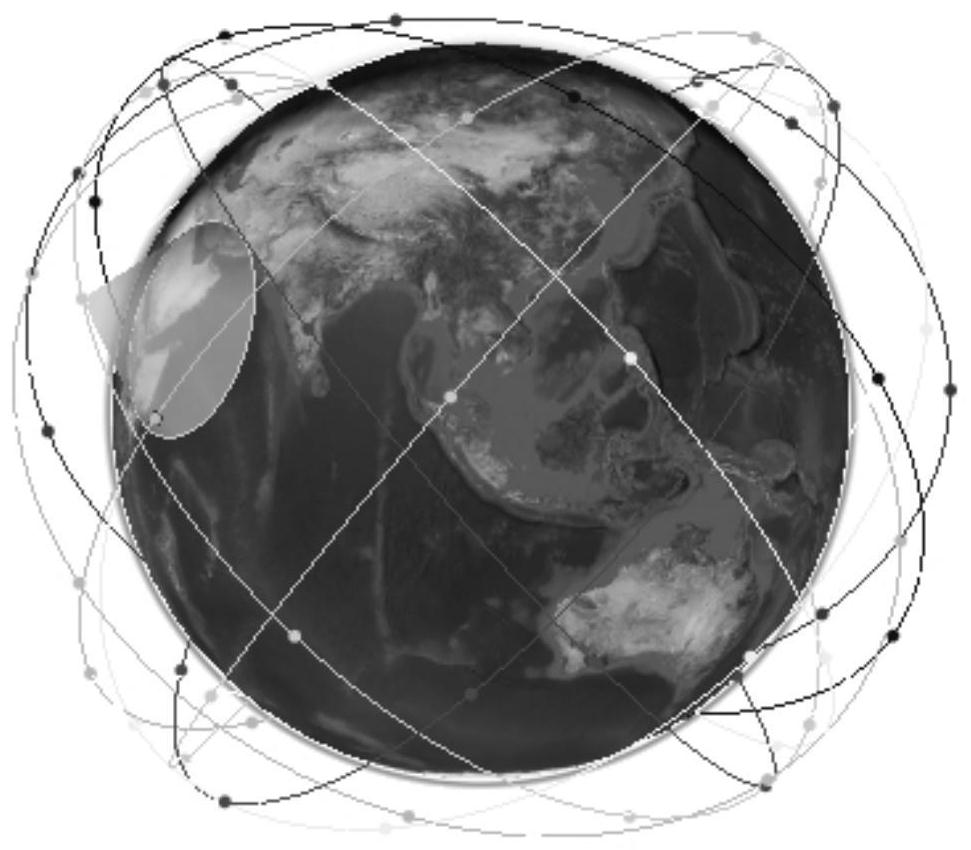

Gateway station site selection method and system of broadband low-orbit satellite communication system

The invention discloses a gateway station site selection method and system for a broadband low-orbit satellite communication system. The method comprises the following steps: generating a satellite network static topology; constructing a global user location service model to obtain the service volume borne by all satellites; establishing a target function by taking minimization of communication time delay and maximization of data transmission rate as targets and taking a gateway station site selection range, a gateway station receiver threshold and a single-satellite capacity upper limit as constraint conditions; calculating the target function fitness of a group of candidate gateway stations; and optimizing the site selection of the gateway station by adopting a genetic algorithm. The system comprises a satellite, a gateway station and a user terminal. According to the method, the influence of single-satellite capacity limitation and global service distribution on the site selection of the gateway station is considered, and an effective reference method is provided for the site selection of the gateway station of the broadband low-orbit satellite communication system. The gateway station site selection method and system for the broadband low-orbit satellite communication system can be widely applied to the technical field of satellite communication.

Owner:SUN YAT SEN UNIV

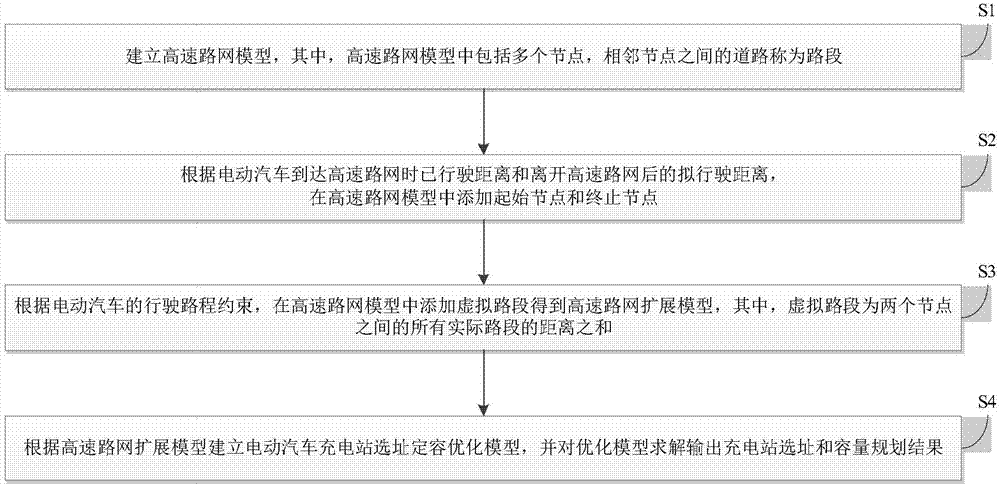

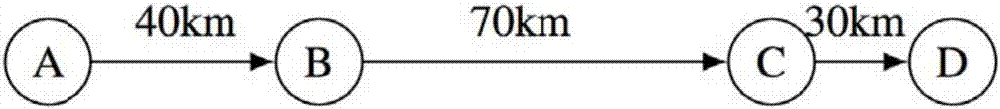

Method for planning electric vehicle charging stations in highway networks

InactiveCN107403267AOptimizing Site Selection and CapacityLow investment costInternal combustion piston enginesResourcesAutomotive engineeringNetwork model

The invention discloses a method for planning electric vehicle charging stations in highway networks. The method comprises the following steps of: establishing a highway network model, wherein the highway network mode comprises a plurality of nodes and roads between adjacent nodes are called as sections; adding an initial node and a termination node in the highway network model according to an actual running distance of an electric vehicle when the electric vehicle reaches a highway network and a planned running distance of the electric vehicle when the electric vehicle leaves the highway network; adding a virtual section in the highway network model according to running journey constraint of the electric vehicle so as to obtain a highway network extended model, wherein the virtual section is the sum of distances of all the actual sections between two nodes; and establishing an electric vehicle charging station site selection and constant volume optimization model according to the highway network extended model, and solving the optimization model to output a charging station site selection and volume planning result. The method has the following advantages of optimizing the site selection and volumes of electric vehicle charging stations and reducing the investment cost of the electric vehicle charging stations under the premise of satisfying the charging demands of electric vehicles.

Owner:TSINGHUA UNIV +2

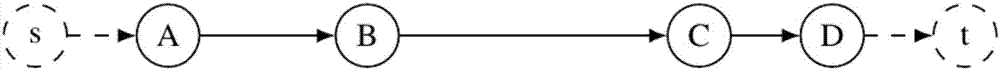

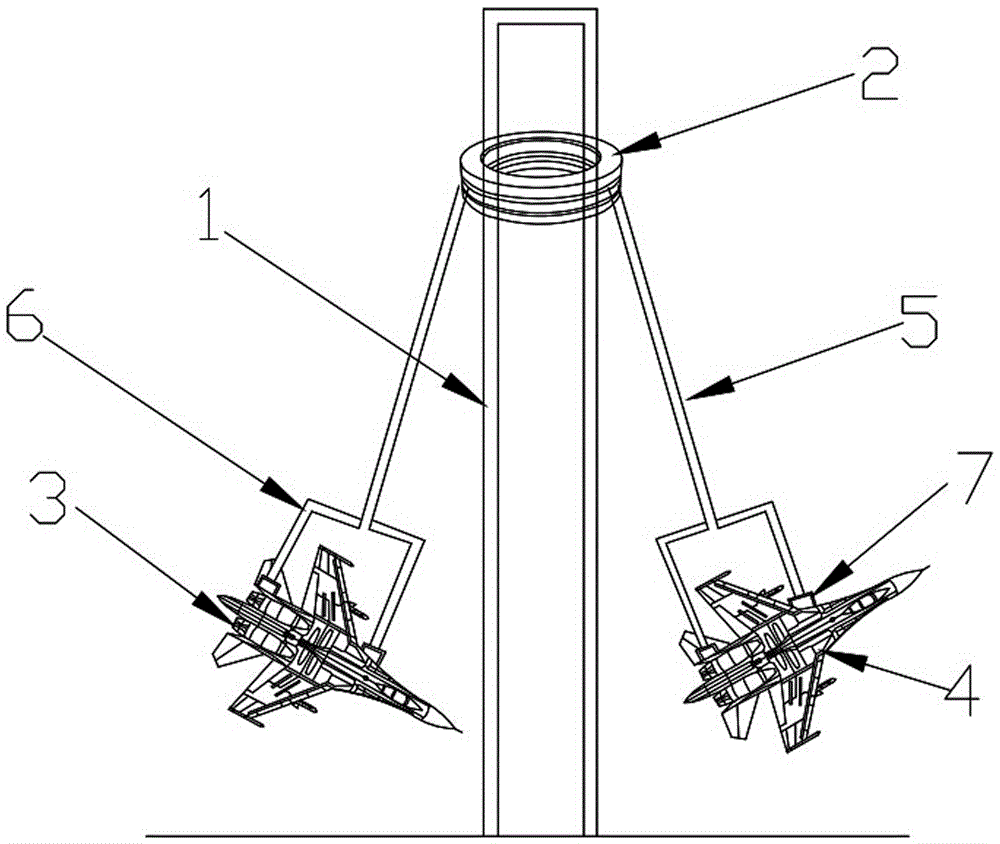

Ultra-short-range airplane takeoff method

The invention relates to an ultra-short-range airplane takeoff method in the field of flight methods. The ultra-short-range airplane takeoff method comprises following steps: step one, a flight column is established; step two, a rotational stand is mounted; step three, airplanes are dragged; step four, counterweights are set; step five, circumferential type takeoff is performed; step six, connection points are loosened. Not only can the length of a runway used during takeoff of each airplane be shortened, but also the dead weight capacity of the airplane during takeoff can be increased; the airplane takeoff method is more suitable for takeoff of military airplanes, the requirement for an aviator is higher, the occupied space is smaller, the concealment performance is good, and site selection is convenient; furthermore, flight buildings such as the flight column and the like are simple and convenient to manufacture and lower in cost, can be wholly moved after dismounting, has strong adaptability and is suitable for massive popularization in a small range, thereby accelerating development of the aviation industry.

Owner:刘可平

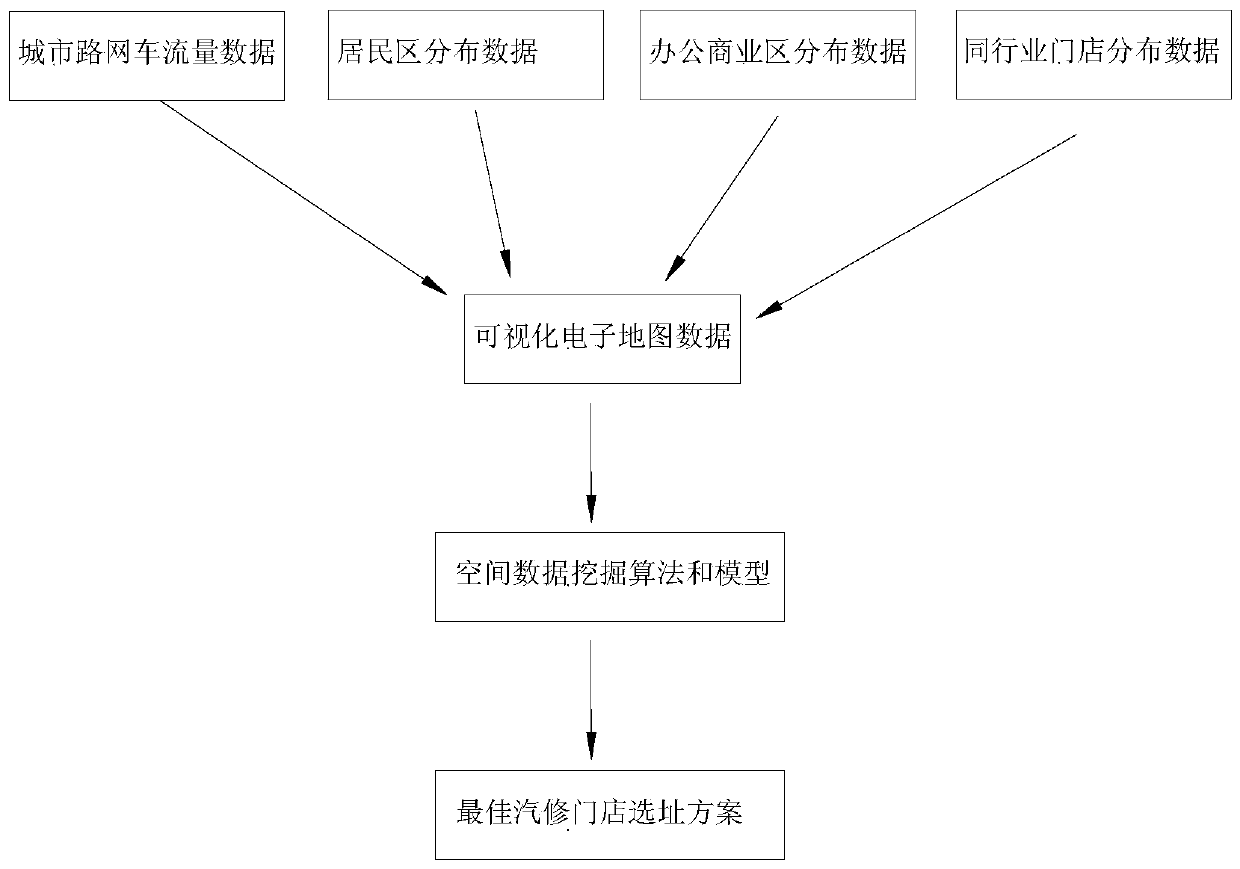

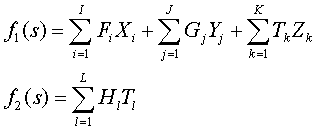

Automobile repair store site selection method based on vehicle space-time distribution

ActiveCN110674976AEliminate negative effectsOptimize site selectionForecastingGeographical information databasesAutomotive engineeringData processing

The invention discloses an automobile repair store site selection method based on vehicle space-time distribution, and belongs to the technical field of data processing. On the basis of comprehensivefactors of an urban road network, a residential area and an office and commercial area, the condition of the vehicle ownership in the area is analyzed through visual map display, the corresponding weight level is formulated according to the corresponding rating, and the comprehensive score of the area is calculated; negative effects caused by competition in the area are eliminated; and the optimalsite selection scheme of the automobile repair store is comprehensively analyzed, and theoretical support is provided for site selection of the automobile repair store. By optimizing site selection,the passenger flow volume of the store is improved, and more profit points are brought.

Owner:爱易优(上海)信息科技有限公司

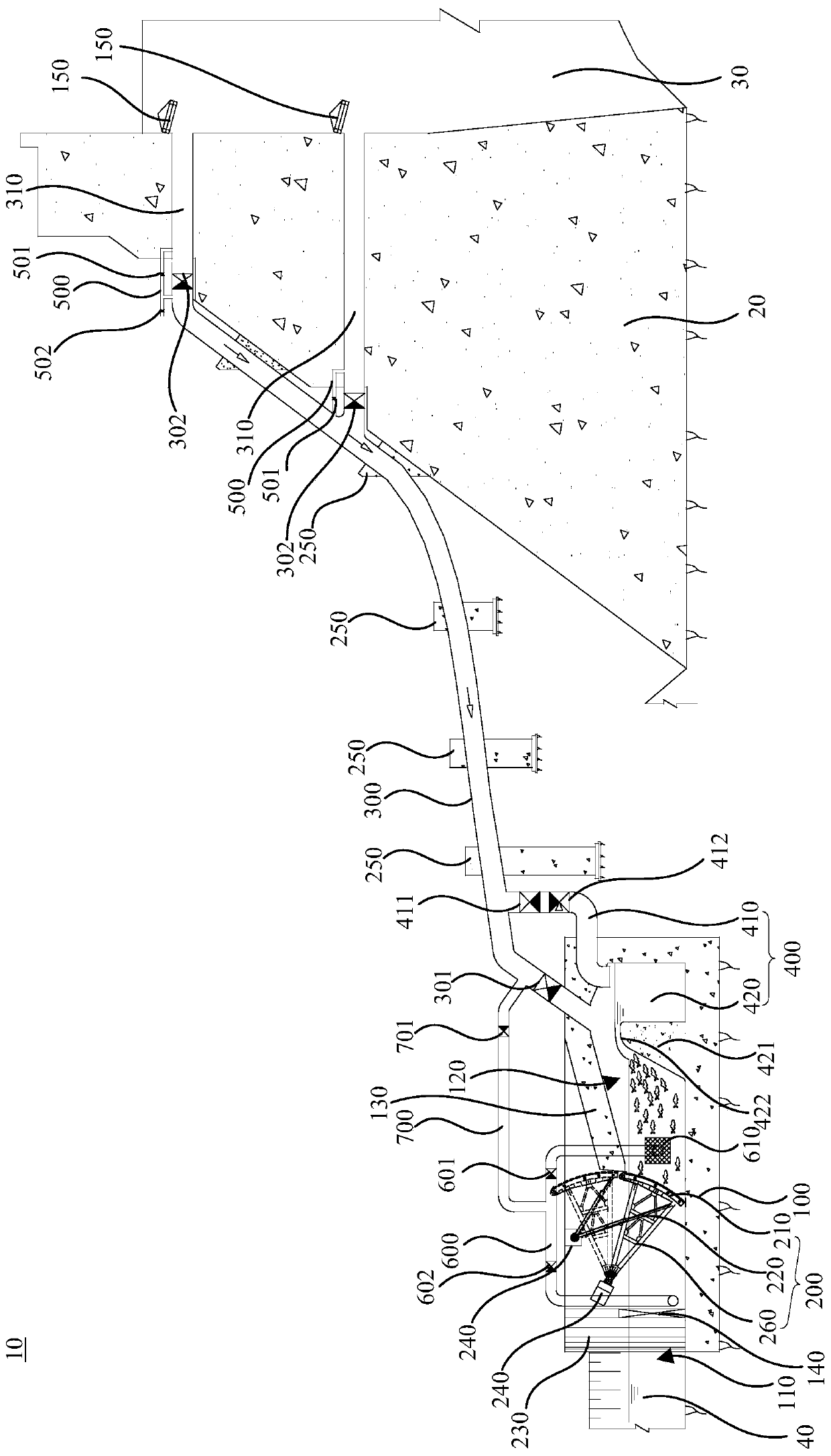

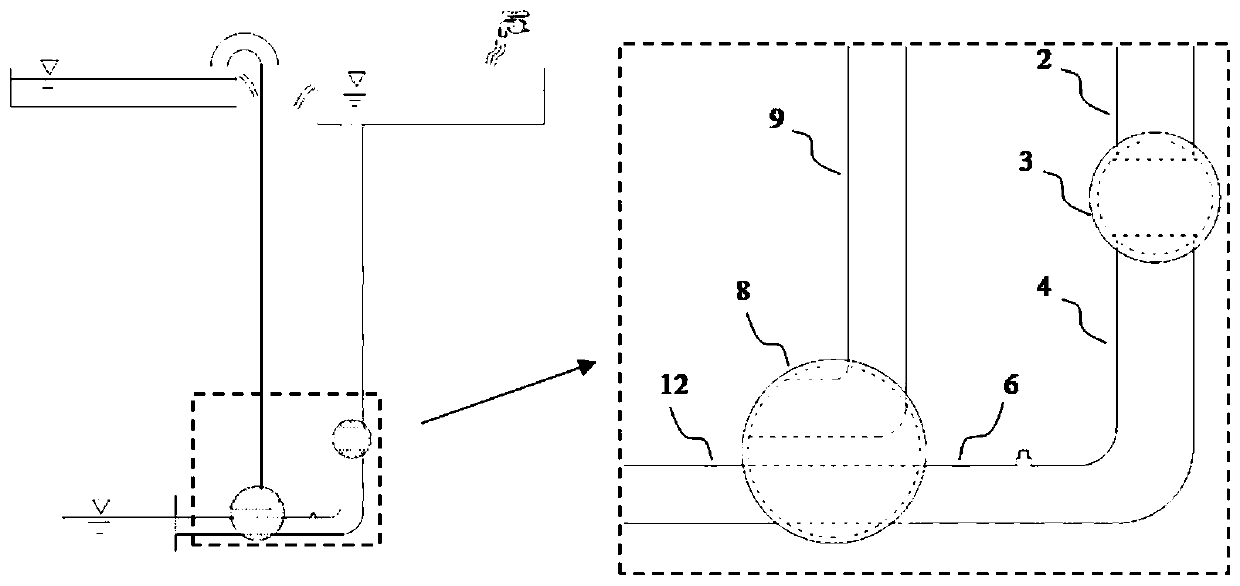

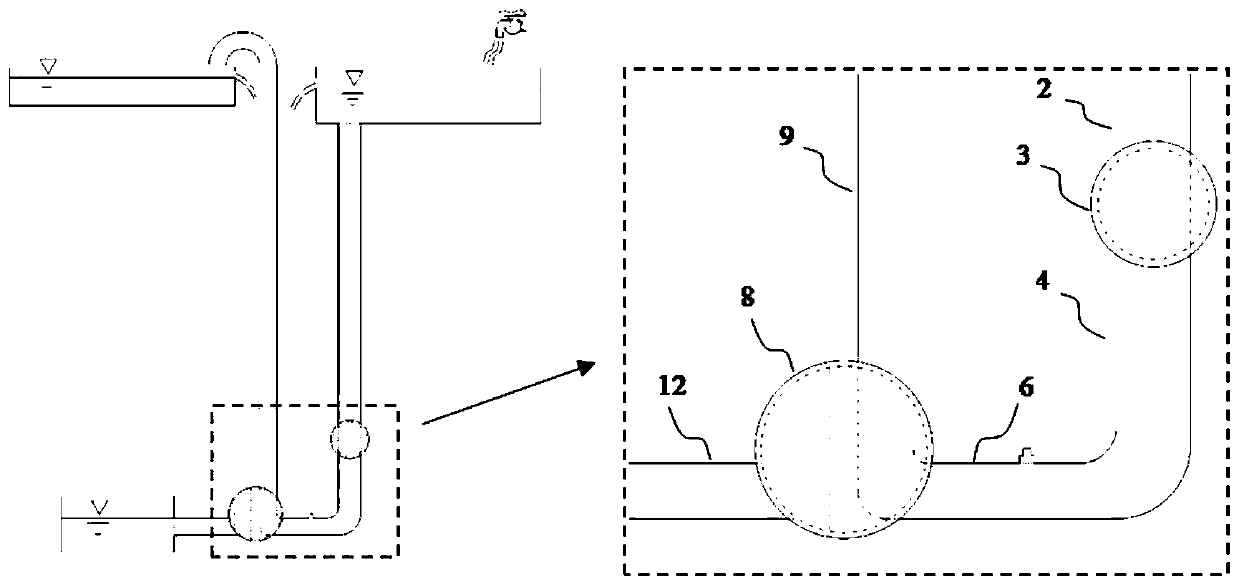

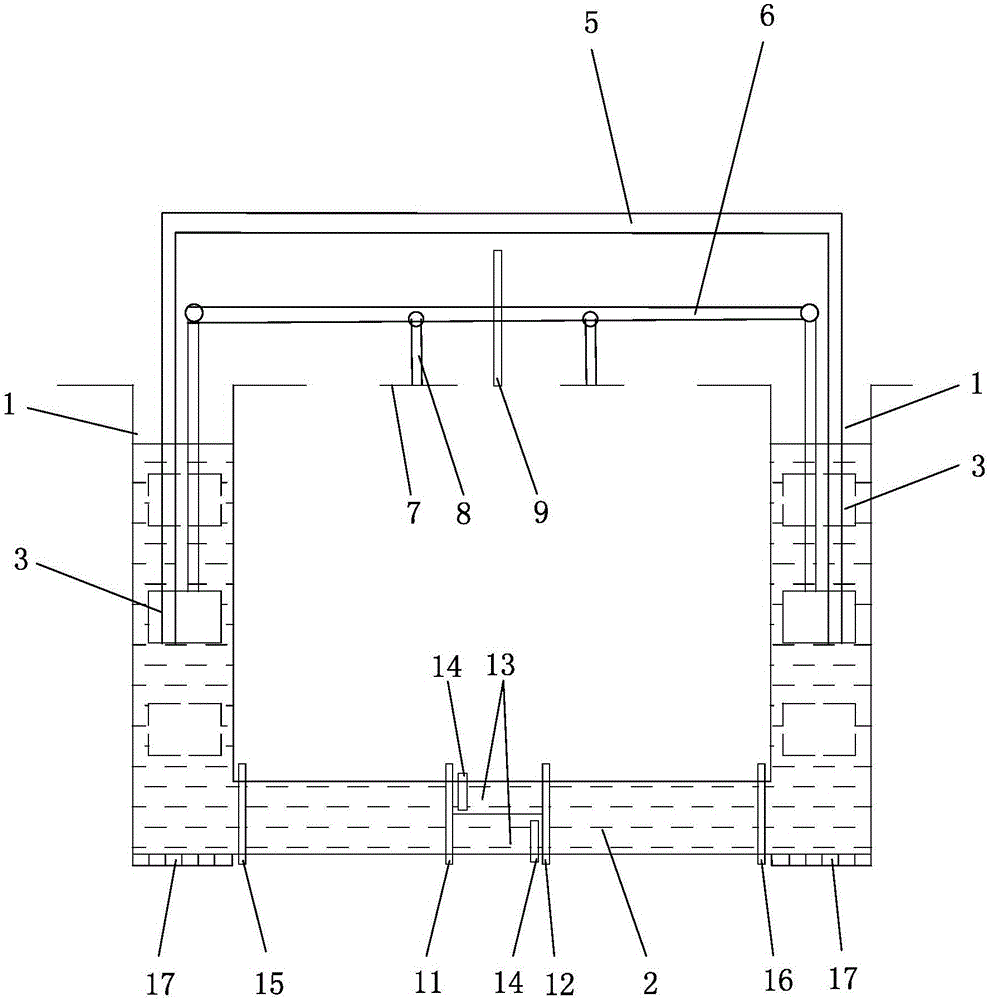

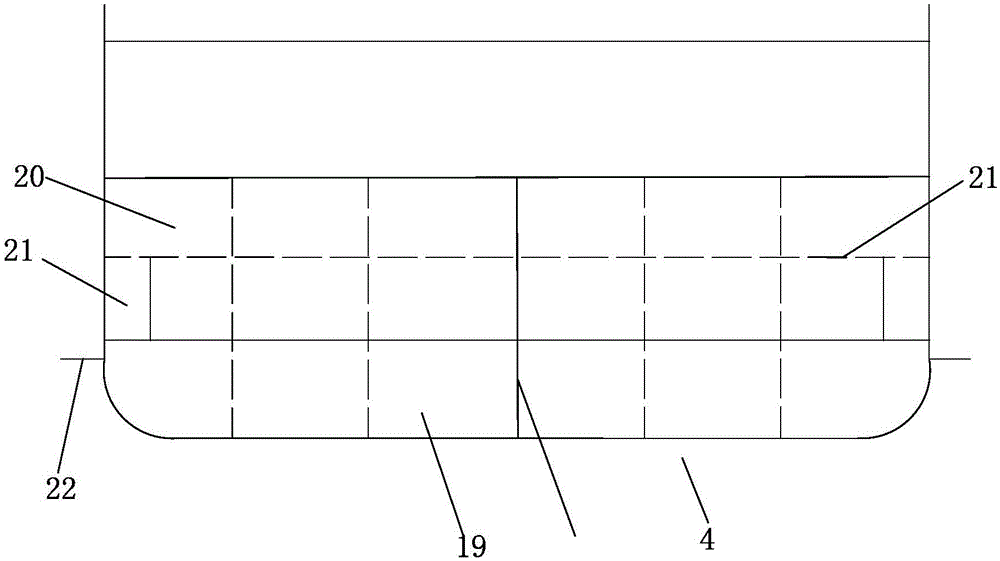

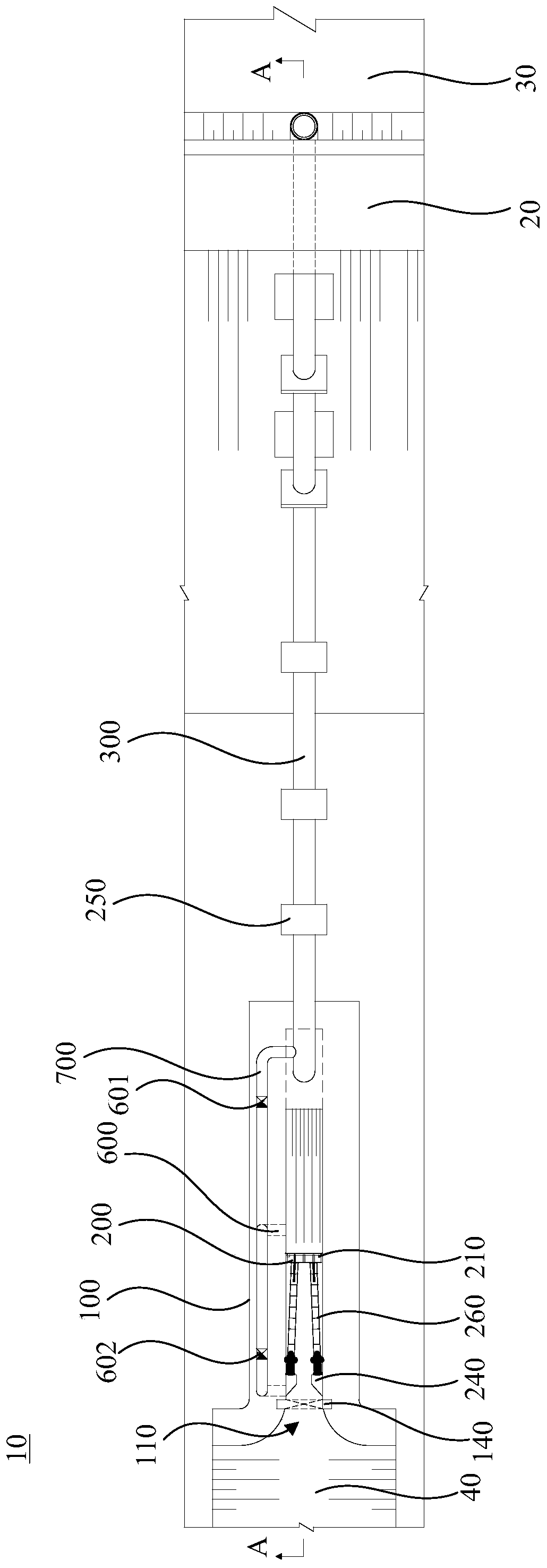

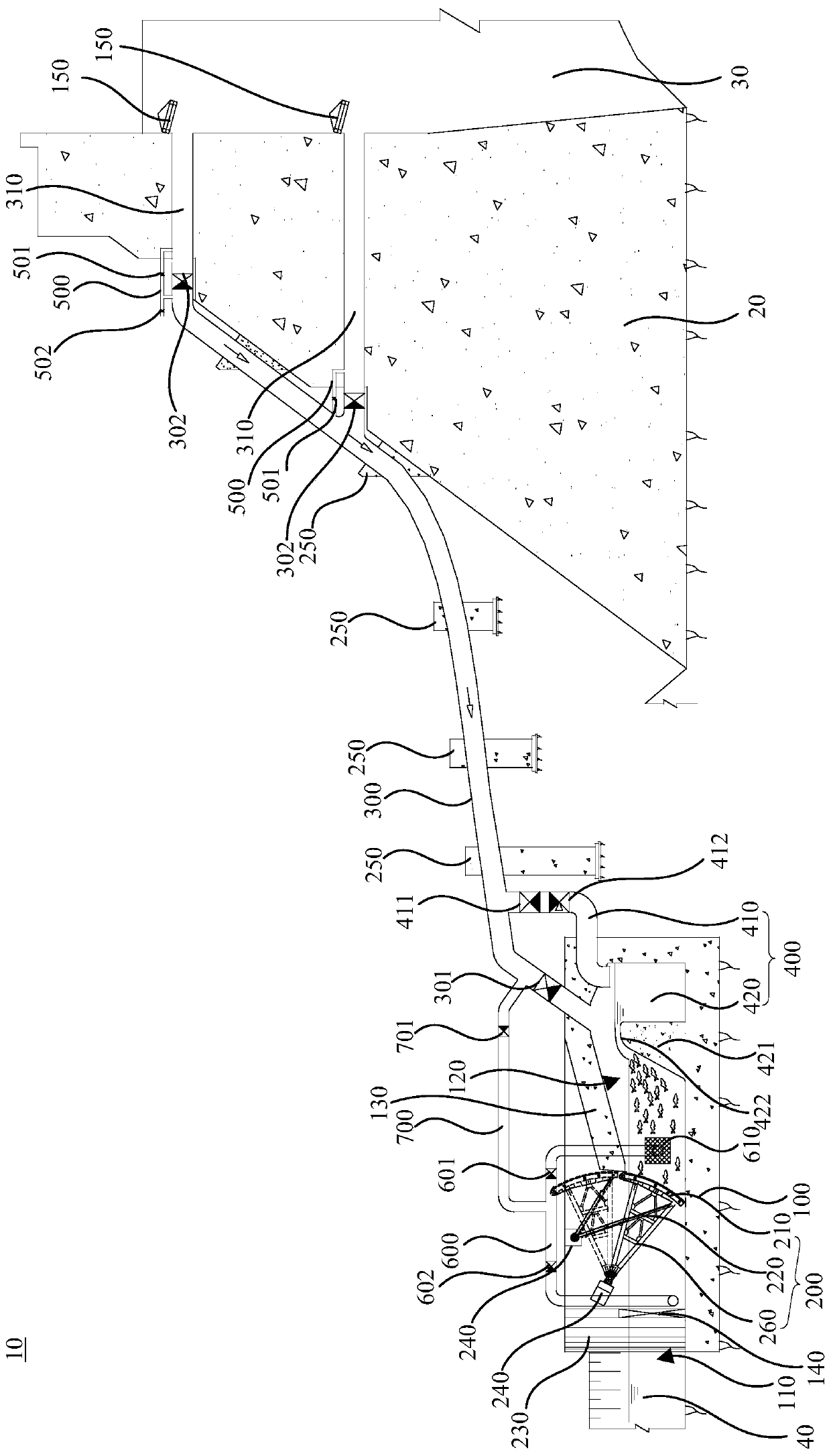

Gate valve pipeline type fish passing facility

PendingCN109853491AIncrease pressureRealize hydraulic fish passingBarrages/weirsClimate change adaptationTerrainPipeflow

The invention relates to a gate valve pipeline type fish passing facility. The gate valve pipeline type fish passing facility comprises a fish collecting cabin, a gate, a fish passing pipeline, a fishattracting structure, a water injecting pipeline and a discharge pipeline, the body type of the fish collecting cabin is small, fish passing is performed by adopting the pipelines, the pipelines canbe laid underground and on the ground, land occupation is less, the terrain adaptability is high, nearly no terrain restrictions occurs, and engineering site selection and arrangement are facilitated.A long-distance gentle slope channel is not required, a cumbersome water gate and start-stop equipment are not required, complex structural design and expensive lifting equipment are not required, and the engineering cost is reduced. The pipeline water pass fracture surface is small, the flow speed is low, and the flow is small; and fish attracting and fish concentrating are realized through thefish collecting cabin, concentrated fish passing is carried out by cabins and times, continuous discharge required by continuous fish attracting is avoided, and the water consumption is reduced.

Owner:CHINA WATER RESOURCES PEARL RIVER PLANNING SURVERYING & DESIGNING

Buried ecological sewage treatment system and method using gravel as medium

ActiveCN105692876ASimple processSave engineering investmentTreatment using aerobic processesSustainable biological treatmentSludgeWater quality

The invention discloses a buried ecological sewage treatment system using gravel as a medium. The system comprises a pretreatment unit and an inter-gravel contact oxidation unit which are sequentially connected, wherein the inter-gravel contact oxidation unit comprises a gravel-filled inter-gravel aeration region, an inter-gravel non-aeration region and a sludge storage tank; the inter-gravel aeration region communicates with the inter-gravel non-aeration region through an aeration pipe; the aeration pipe is connected with a blast blower; the aeration pipe is provided with an aeration region valve and a non-aeration region valve; the inter-gravel non-aeration region communicates with the sludge storage tank through a water outlet pipe; and the water outlet pipe is provided with a water outlet valve and a sludge discharge valve. The invention also discloses a sewage treatment method. The system has the advantages of simple technical process and low engineering investment (only 2 / 3 of the investment of the traditional sewage treatment method). The system also has the advantages of strong adaptability to sewage quality / quantity fluctuations, and high pollutant removal efficiency (the removal rate for ammonia nitrogen, BOD (biochemical oxygen demand) and SS (suspended sediment)) can reach 90%. By adopting the inter-gravel buried type, the system reduces the land occupation, and is ecological and environment-friendly.

Owner:华美环境工程(上海)有限公司 +2

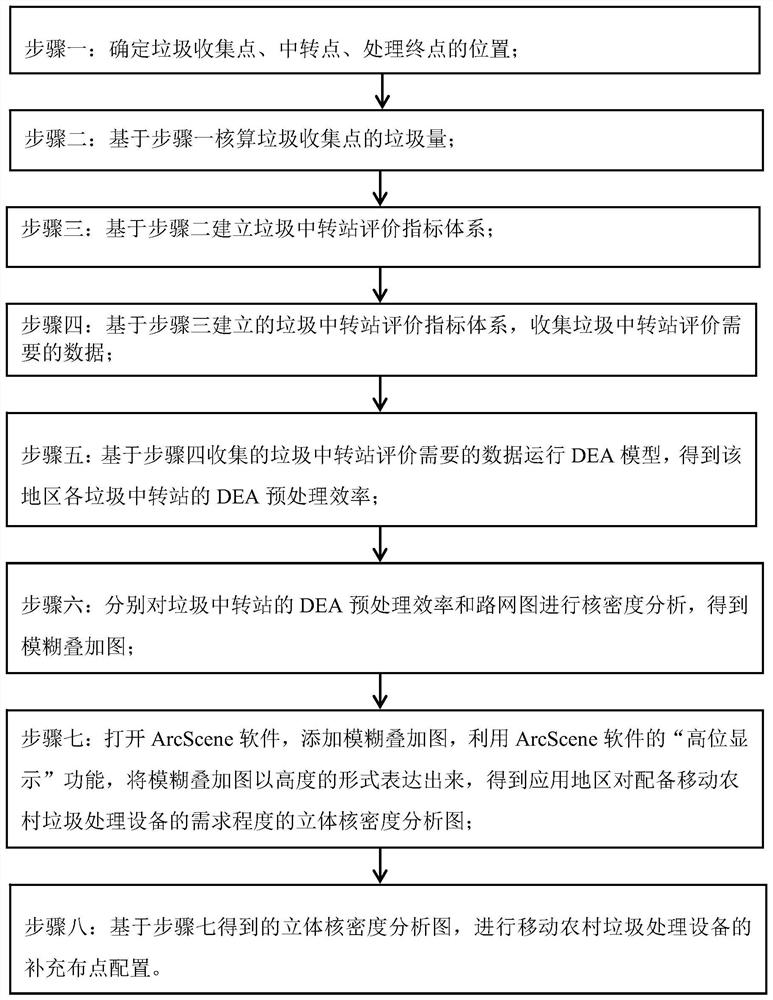

Mobile rural garbage treatment equipment distribution method based on DEA and nuclear density

PendingCN113762793AInclusiveImprove the environmentGeometric CADRefuse transferringNuclear physicsGarbage collection

The invention relates to a mobile rural garbage treatment equipment distribution method based on DEA and nuclear density, in particular to the mobile rural garbage treatment equipment distribution method. The invention aims to solve the problem of low garbage collection efficiency and treatment efficiency caused by non-uniform distribution of garbage transfer stations in the existing method. The method comprises the following steps: 1, determining the positions of a garbage collection point, a transfer point and a treatment end point; 2, calculating the garbage amount of the garbage collection point; 3, establishing a waste transfer station evaluation index system; 4, collecting data required by evaluation of the garbage transfer station; 5, operating the DEA model to obtain the DEA pretreatment efficiency of each garbage transfer station in the region; 6, obtaining a fuzzy superposition graph; 7, opening ArcScene software, and adding the fuzzy superposition graph to obtain a three-dimensional kernel density analysis graph; and 8, on the basis of the three-dimensional kernel density analysis chart, carrying out supplementary stationing configuration on the mobile rural garbage treatment equipment. The method is applied to the field of garbage treatment equipment distribution.

Owner:HARBIN INST OF TECH

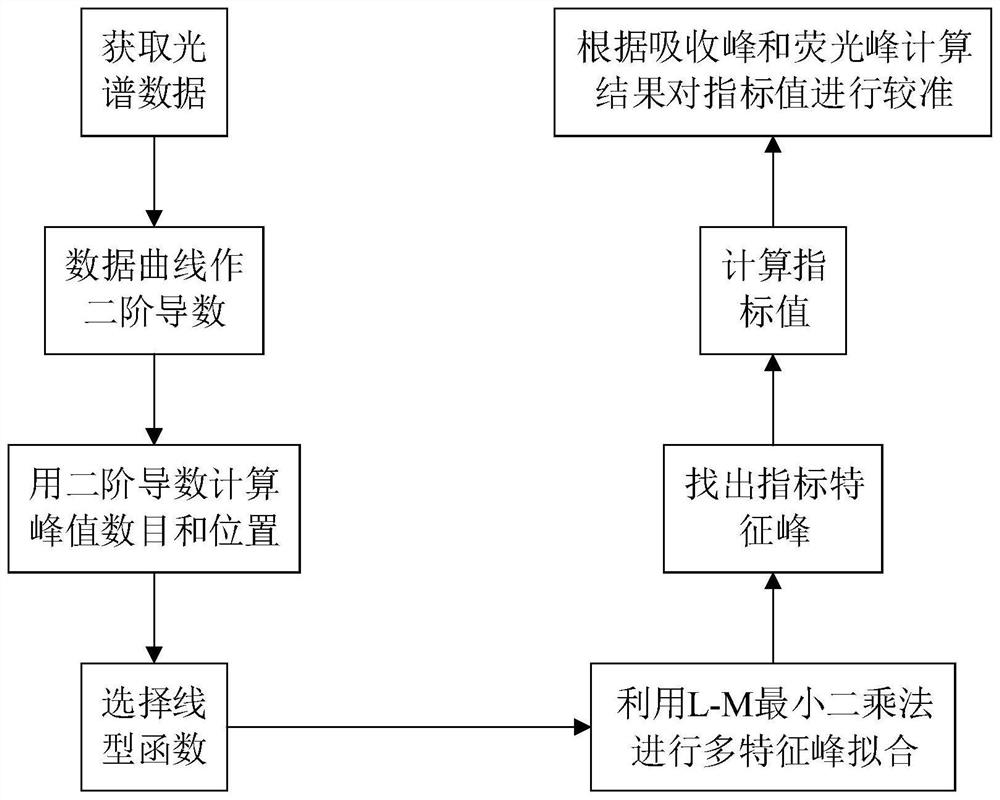

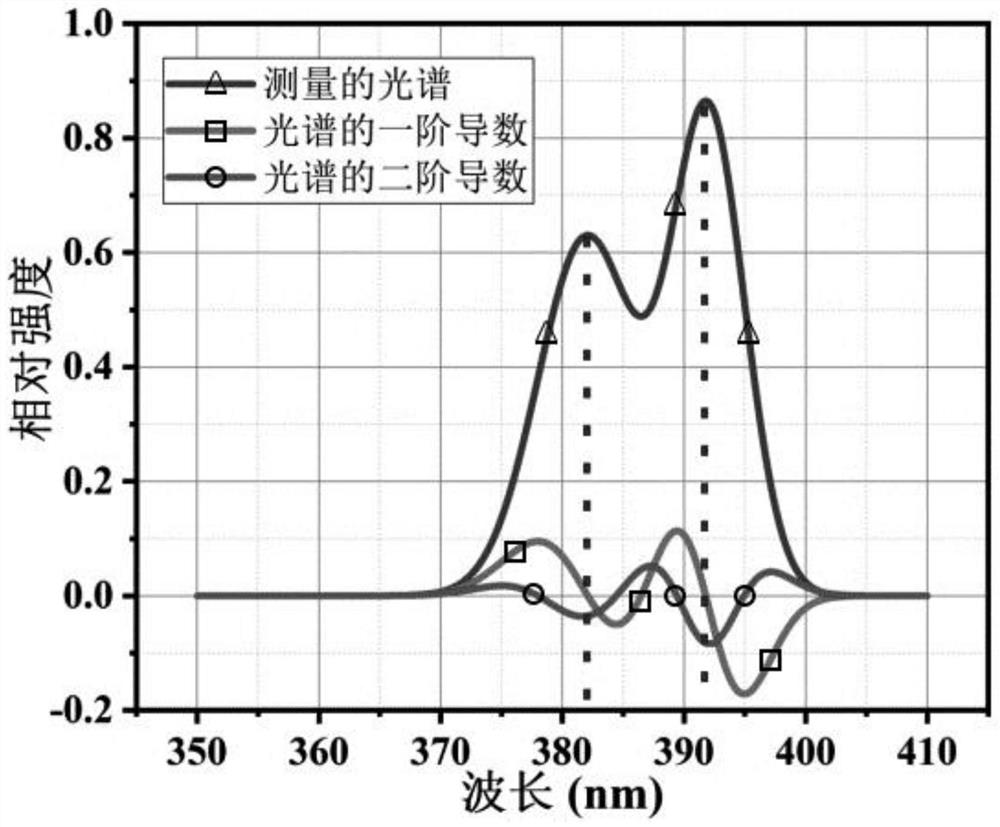

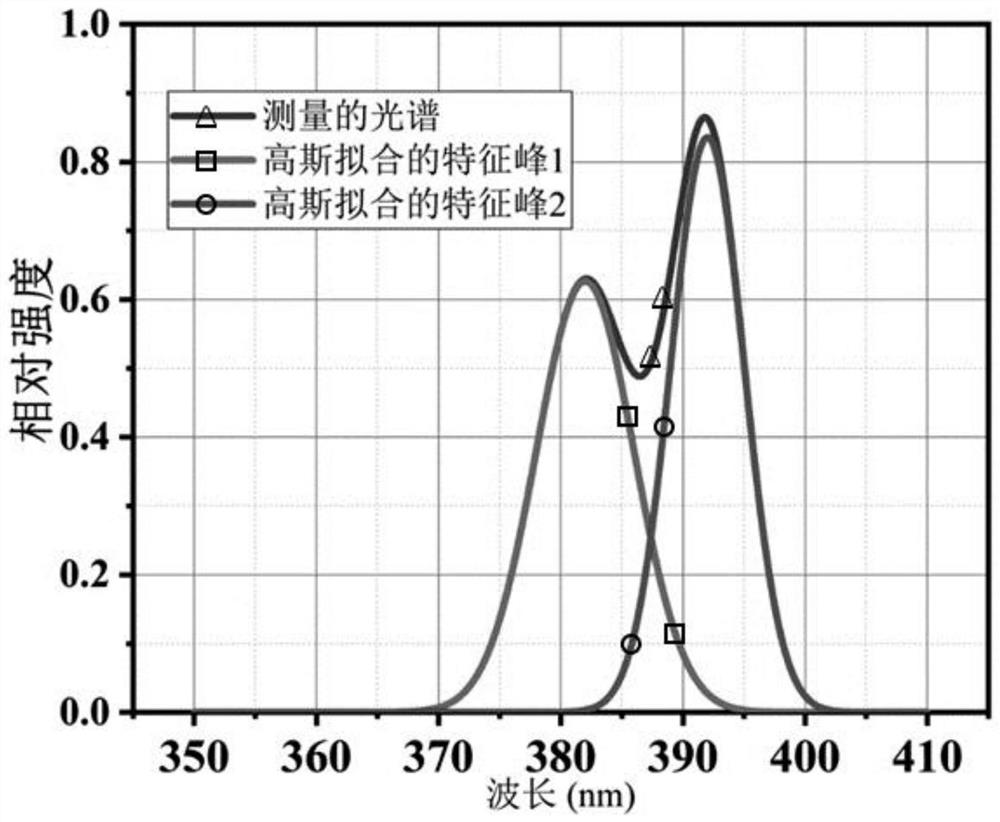

Method for monitoring water quality on line as well as device and system applied by method

ActiveCN113607710AOptimize site selectionEasy to installGeneral water supply conservationColor/spectral properties measurementsFluorescence spectraWater quality

The invention discloses a method for monitoring water quality on line as well as a device and a system applied by the method, and relates to a water body detection technology. In order to solve the problem of inconvenience in detection in the prior art, the method comprises the step of finding out a characteristic peak and a height corresponding to an index by utilizing a curve formed by two kinds of spectral data so as to confirm the specific size of the index in a detected water body. The device is placed in a water body by using a buoy, and water body detection is carried out by using the method. On the basis of comprising the device, the system is also provided with a background server for deep processing. The system has the advantages that detection, communication, power supply and installation fixation are integrated, and site selection and arrangement of water quality monitoring points can be conveniently and effectively carried out. The water quality index is automatically analyzed by directly utilizing a water body fluorescence spectrum, an absorption spectrum and a self-adaptive algorithm, so that the effectiveness of a test index value is enhanced.

Owner:GUANGZHOU XINGBO SCI INSTR +1

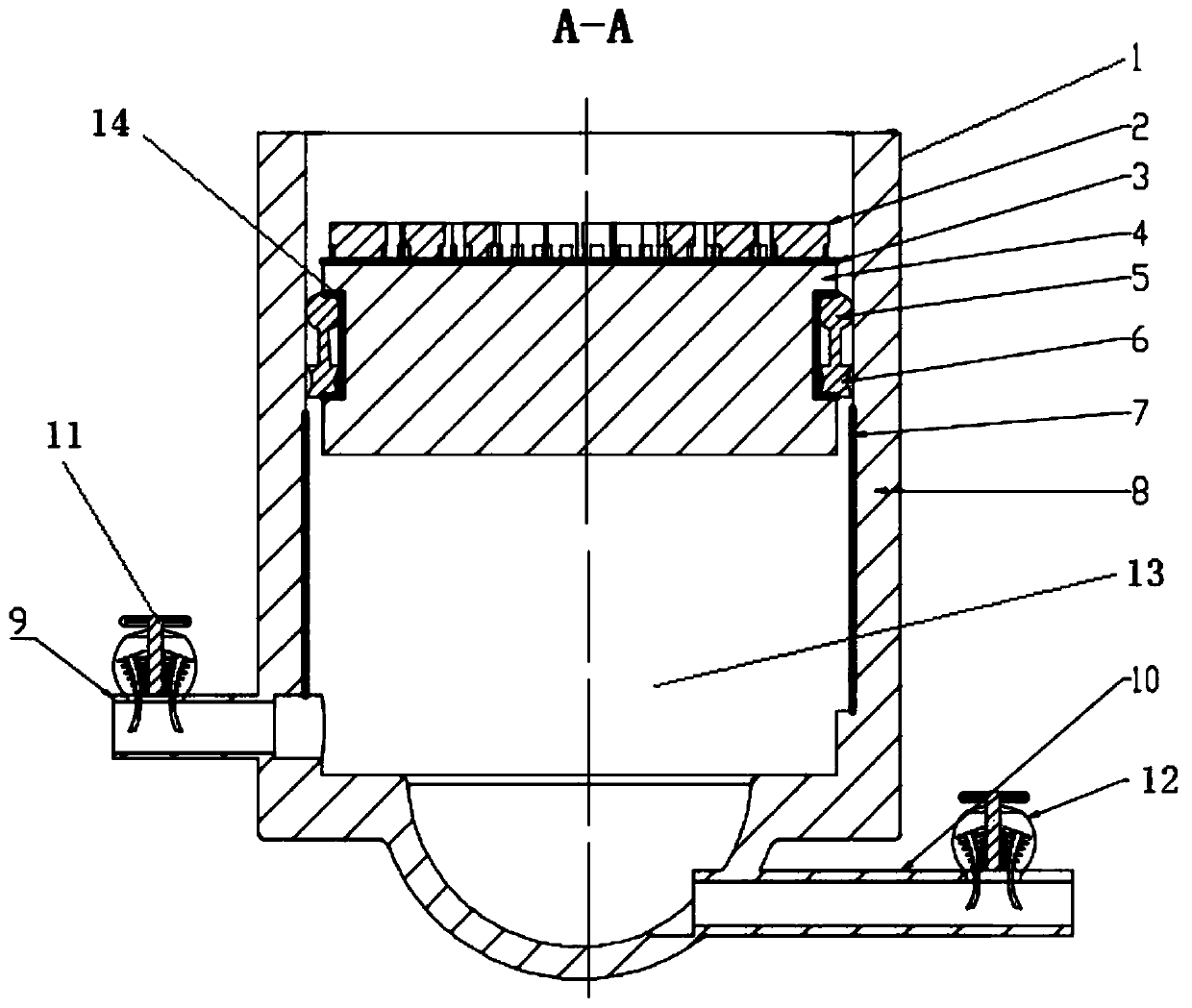

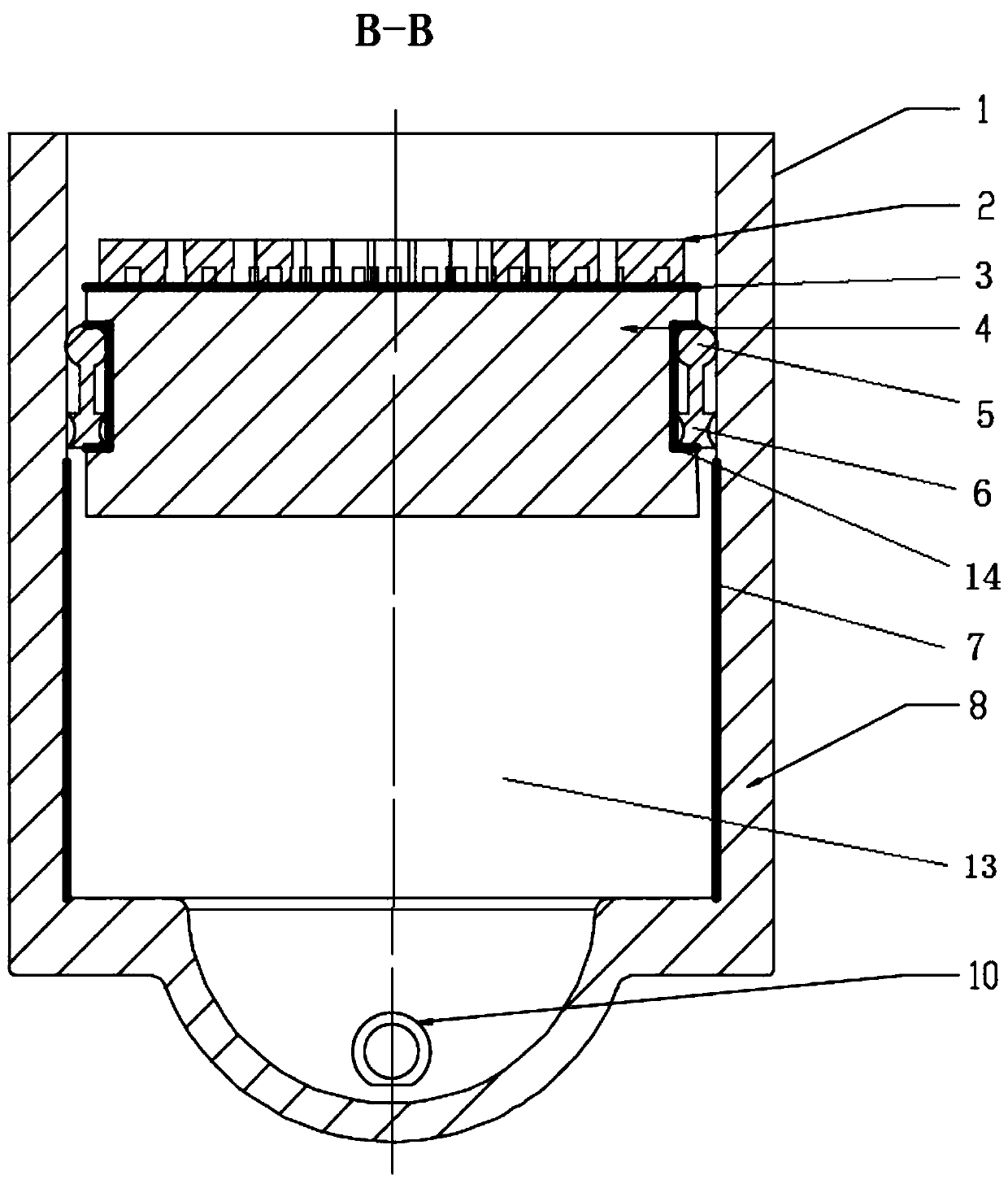

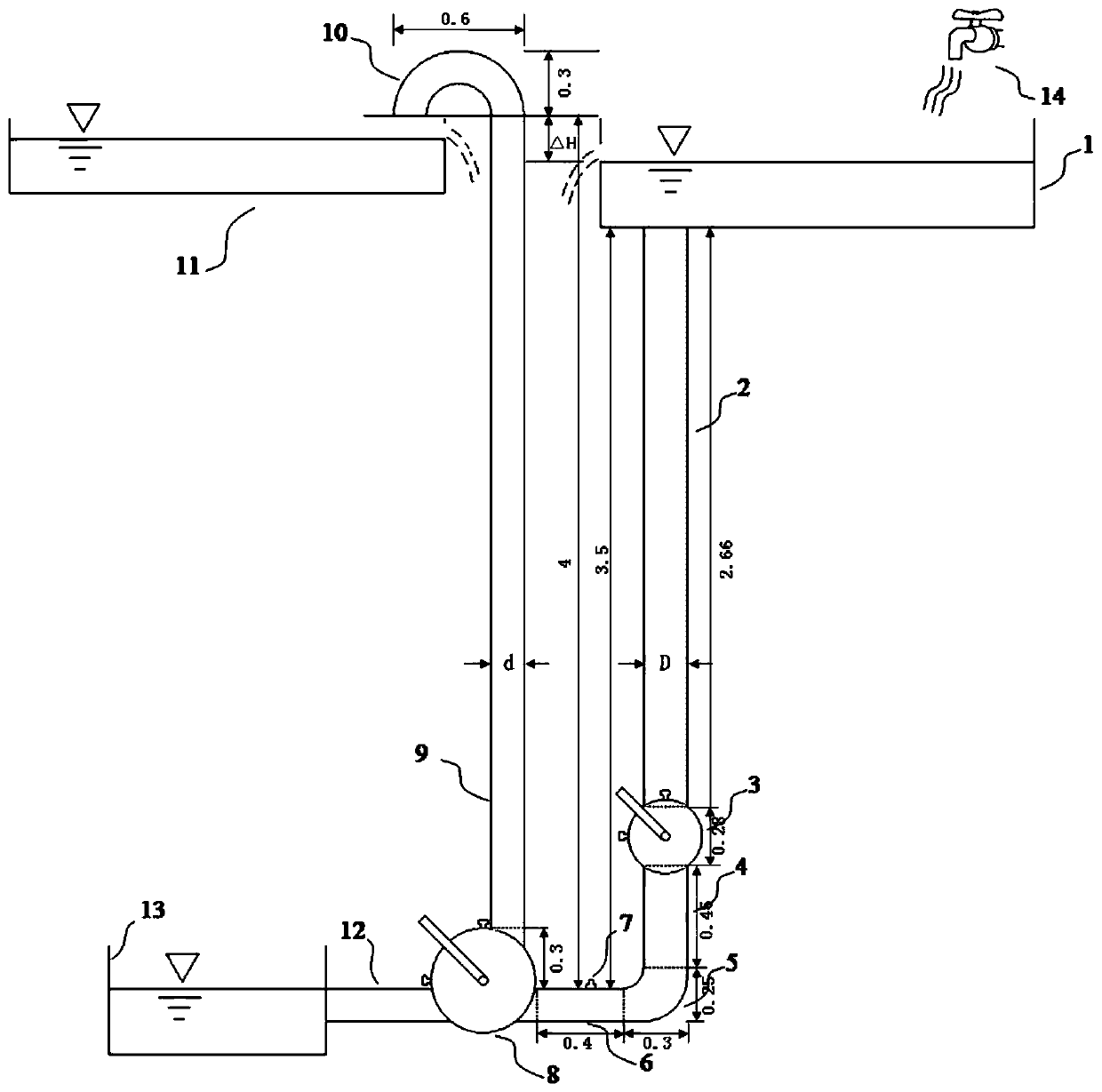

Novel water pumping energy storage device

ActiveCN109881956ASmall footprintOptimize site selectionHydro energy generationMachines/enginesPipingAutomotive engineering

The invention relates to a novel water pumping energy storage device which comprises a container wall, an additional counterweight, a large piston, an O-shaped piston sealing ring, a waterproof wall,a water inlet pipe end opening, a water outlet pipe end opening, a first valve and a second valve. When the power consumption is low, off-peak electric energy drives a hydraulic pump through a motor,filtered water is added into an energy storage pool from the water inlet pipe end opening, the filtered water lifts the large piston to store potential energy in the energy storage pool, and the stored potential energy is adjusted through the additional counterweight; during peak power consumption, the large piston and the additional counterweight press the water in the energy storage pool out offrom the outlet pipe end opening under the action of gravity, and the pressed water flow drives a water turbine to generate electricity, the potential energy is converted into electric energy, and theproblem that a water pumping energy storage power station cannot be built due to the restriction of geographical conditions is thus solved.

Owner:NORTHEAST DIANLI UNIVERSITY

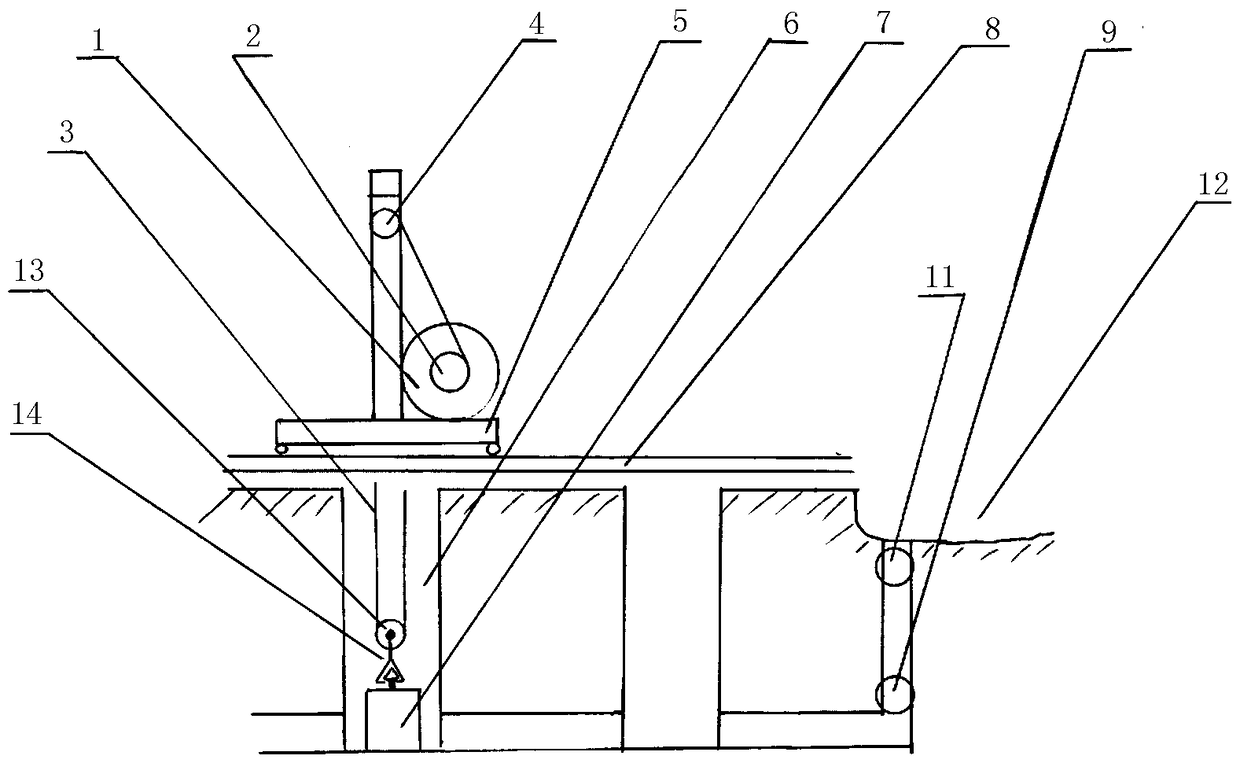

Gravity energy storage system

InactiveCN109185082AReduce energy storage capacityPower stabilityMachines/enginesMotorsNew energyBlock and tackle

The invention relates to a gravity energy storage system. According to the structure of the gravity energy storage system, at least two vertical shafts are built underground, and the bottoms of the vertical shafts mutually communicate; a bidirectional water pump is arranged on a channel at the bottom of each vertical shaft, and each bidirectional water pump is connected with an upper water tank onthe ground through a water pipe and a water valve; rails are arranged above each vertical shaft, a gantry crane is arranged on the rails, and a lifting motor is installed on a base at the lower partof the gantry crane; the lifting motor is connected with a winding drum and drives the winding drum to rotate, and a steel wire rope is wound on the winding drum; and the steel wire rope penetrates through a fixed pulley set on the gantry crane and the rear tail end of a movable pulley set to be fixed on a gantry crane main beam on the upper portion of the gantry crane, a lifting appliance is arranged below the movable pulley set, and an energy storage block is hooked through the lifting appliance. According to the gravity energy storage system, electric power can be smoothly output, the occupied area is small, site selection is easy to achieve, no emission exists, pollution is avoided, the storage power is high, the efficiency is high, the service life is long, the problem of new energy grid connection can be effectively solved, and power fluctuation reduction can be effectively reduced.

Owner:张智蓬

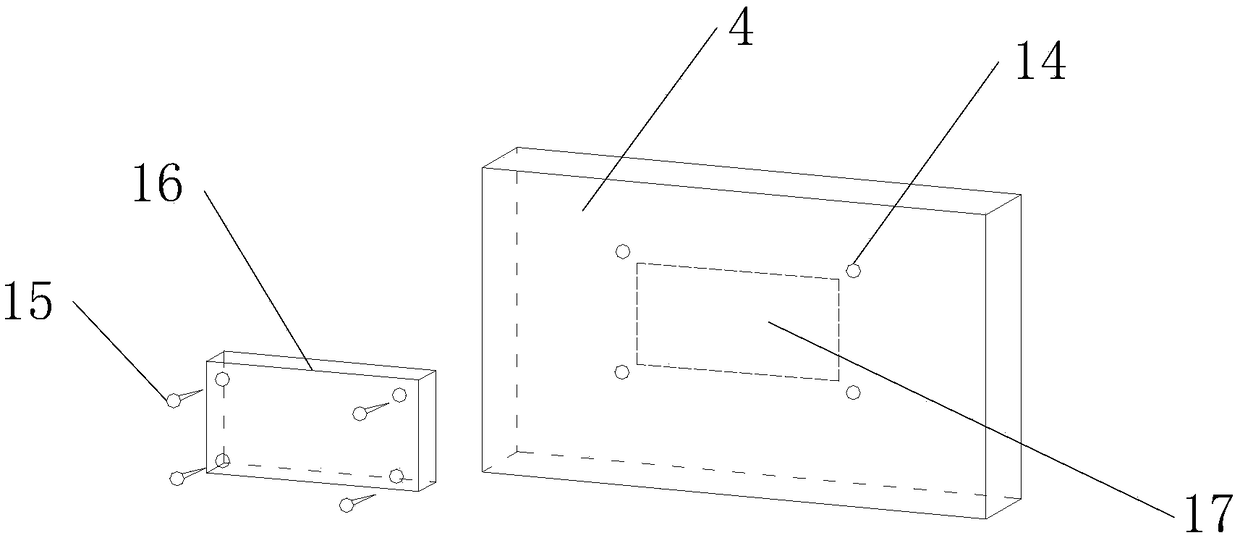

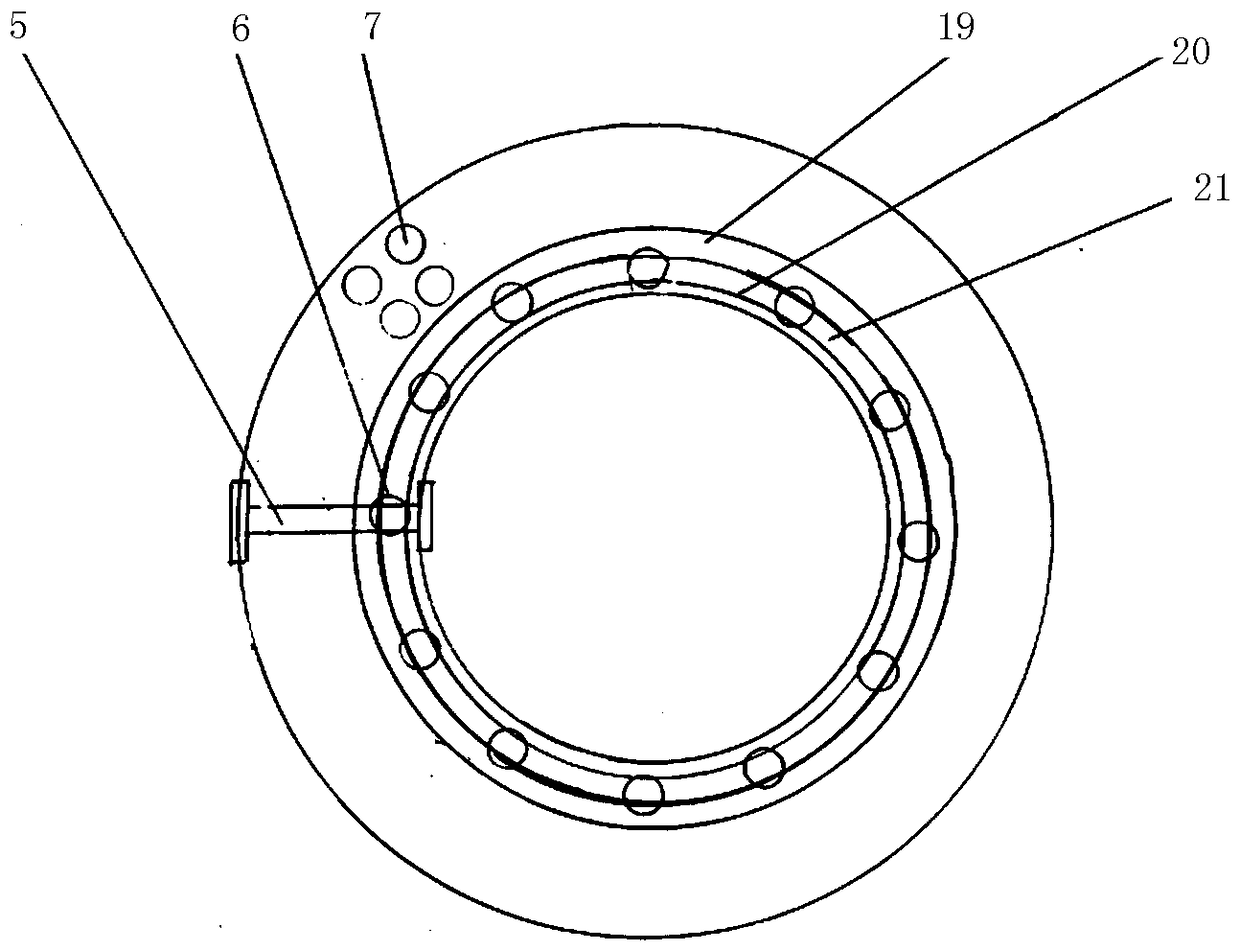

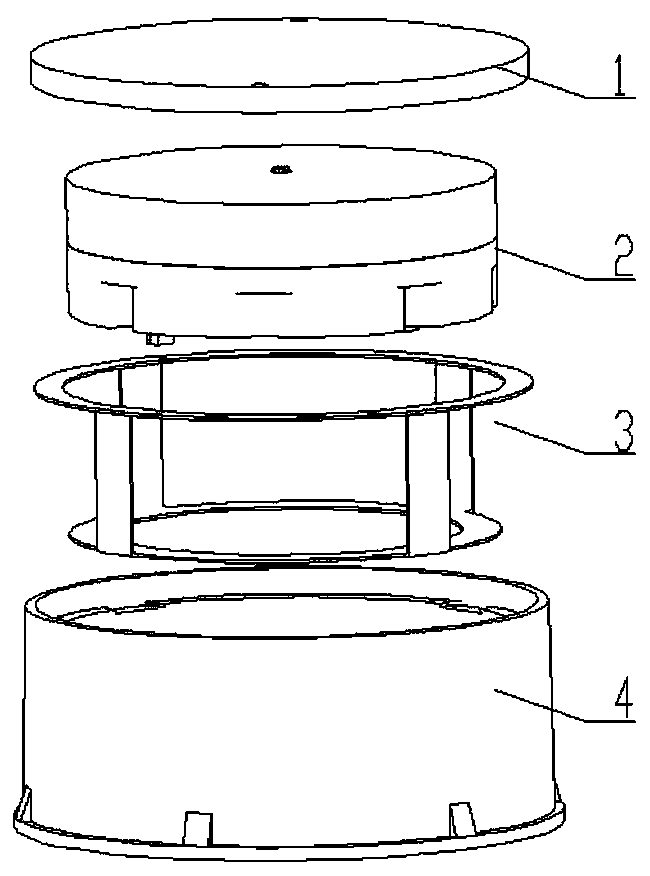

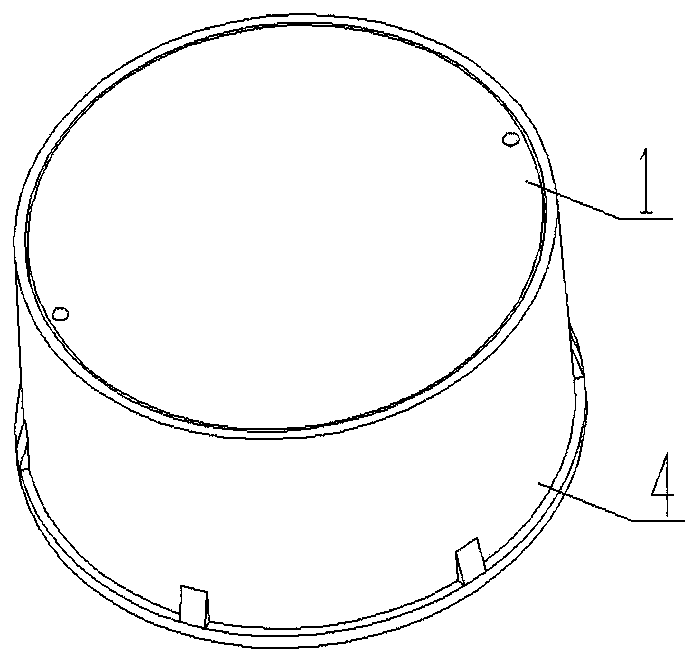

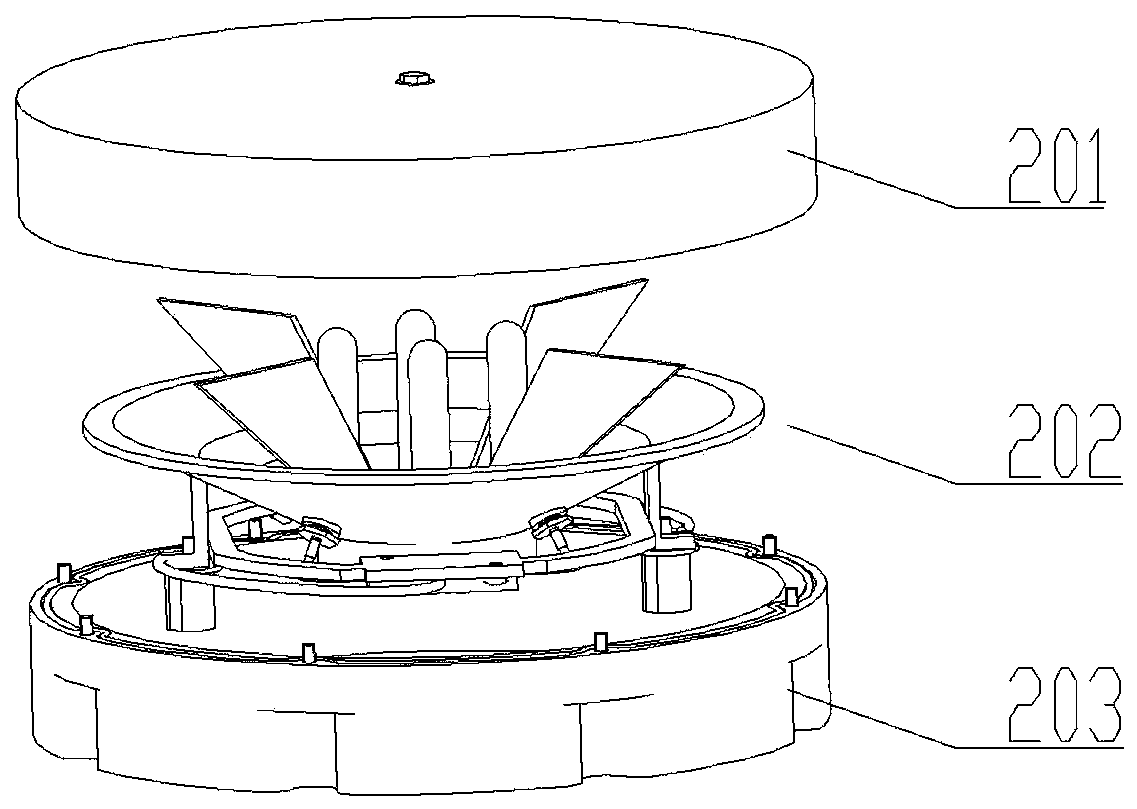

Well lid type ground antenna device

InactiveCN111244602AFacilitate step-by-step processing and fixationSimple structureAntenna supports/mountingsRadiating element housingsRadomeElectric cables

The invention discloses a well lid type ground antenna device. The well lid type ground antenna device comprises a cover plate, an antenna body, a supporting frame and a base, an upper mounting cavityis formed in the base, the supporting frame is arranged in the mounting cavity, the antenna body is mounted in the mounting cavity through the supporting frame, and the cover plate is mounted at theupper end in the base. According to the invention, the antenna bodies are integrally integrated and separated from the fixing device; the well lid type ground antenna device has the advantages of simple structure, small size and light weight, and workers can conveniently machine and fix step by step; and mass production is convenient, and meanwhile, the interchangeability of the antenna device isgood, wherein the antenna body is the core part of the whole device, only two cables are connected with the outside, if the antenna body needs to be replaced, only the antenna body needs to be replaced, installation is convenient, the upper antenna cover, the lower antenna cover and the connector of the antenna body are each of a waterproof structure, the cover plate is covered with the antenna body, only the cover plate is exposed out of the whole antenna device, the cover plate is in the well lid shape and style, and good concealment is achieved.

Owner:安徽泊仙科技有限公司

Offshore wind plant site selection method and device

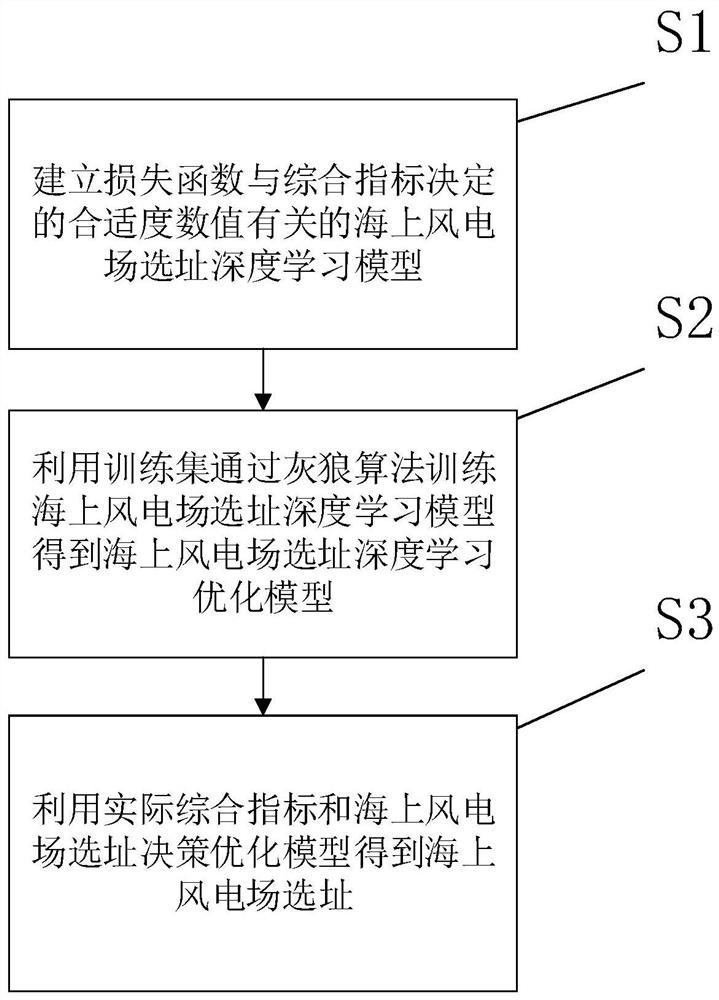

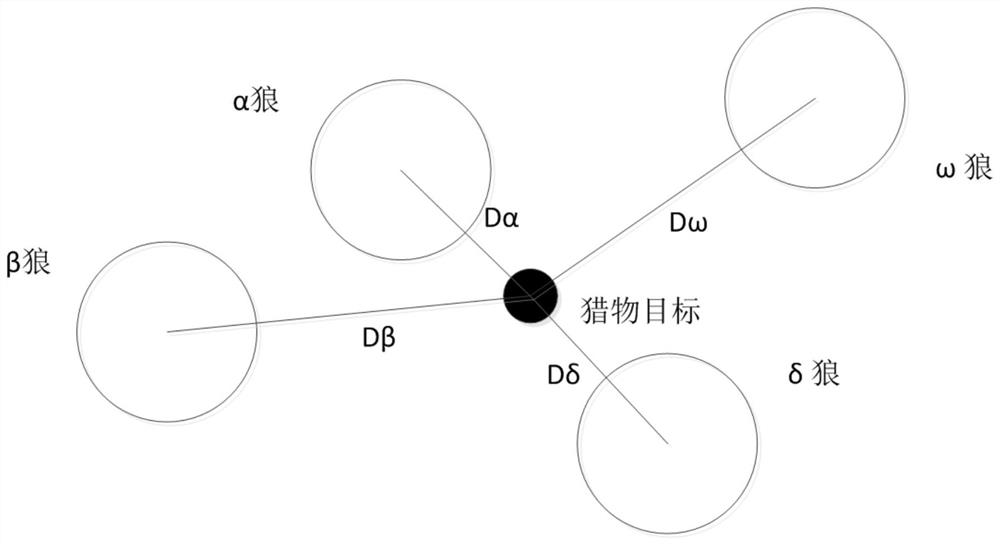

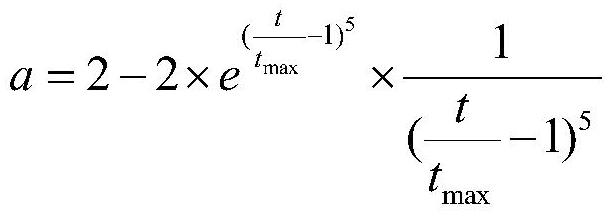

PendingCN112101608AImprove accuracyImprove efficiencyForecastingFinancial managementMarine engineeringNew energy

The invention relates to an offshore wind power plant site selection method and device. The method comprises the steps that S1, creating an offshore wind power plant site selection deep learning modelwith a loss function related to the suitability determined by comprehensive indexes; S2, training an offshore wind power plant site selection deep learning model through a grey wolf algorithm by utilizing the training set to obtain an offshore wind power plant site selection deep learning optimization model; S3, obtaining offshore wind farm site selection by utilizing the actual comprehensive indexes and the offshore wind farm site selection decision optimization model; the device comprises a memory and a processor, and the processor calls a program of the offshore wind farm site selection method stored in the memory to select the offshore wind farm site. Compared with the prior art, the offshore wind farm site selection scheme decision can be better achieved, the wind energy utilizationdegree of the offshore wind farm is improved, benefits brought by the offshore wind farm are improved, and therefore the purpose of increasing effective utilization of new energy of an electric powersystem is achieved.

Owner:SHANGHAI DIANJI UNIV

Regional power grid environment risk assessment method

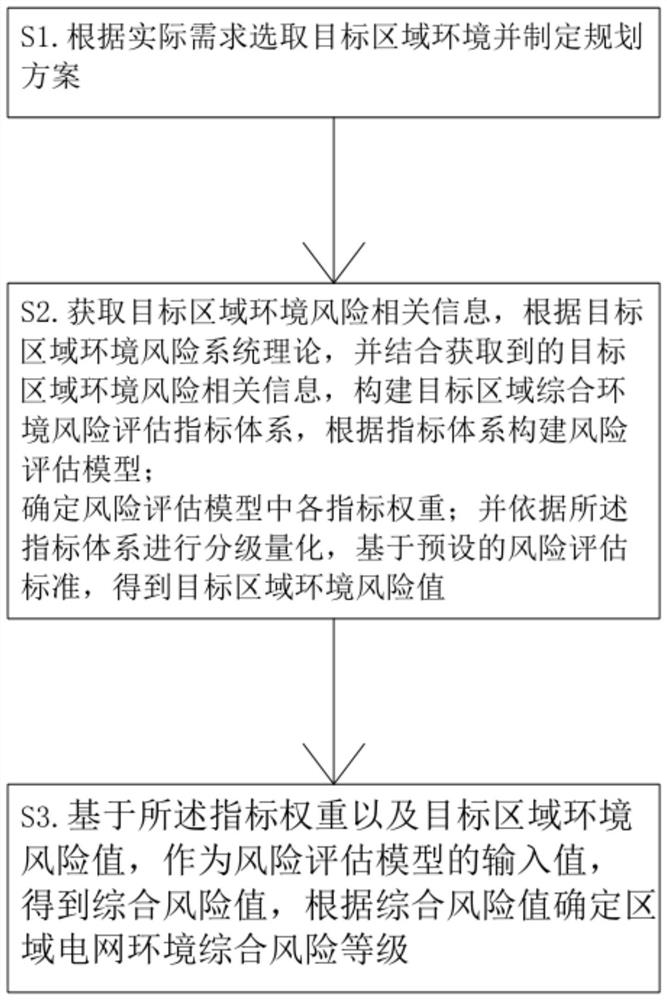

PendingCN114065127AOptimize site selectionOptimize line selectionResourcesSystems intergating technologiesEnvironmental resource managementPower grid

The invention discloses a regional power grid environment risk assessment method, and relates to the technical field of power grid planning, and the method comprises the following steps: selecting a target regional environment according to an actual demand, and making a planning scheme; obtaining environment risk related information of the target area, constructing a comprehensive environment risk assessment index system of the target area, and constructing a risk assessment model according to the index system; determining the weight of each index in the risk assessment model; and carrying out grading quantification according to the indicator system to obtain an environment risk value of the target area. According to the regional power grid environment comprehensive risk assessment method, on the basis of the environment data, the power grid planning environment influence key factors are identified, the corresponding risk levels are assessed, the power grid planning environmental impact evaluation and the power transmission and transformation project are effectively combined, the planned substation site selection and line selection can be optimized, the environmental risk can be fully identified and avoided, and the environmental dispute and emergencies can be prevented and reduced.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +2

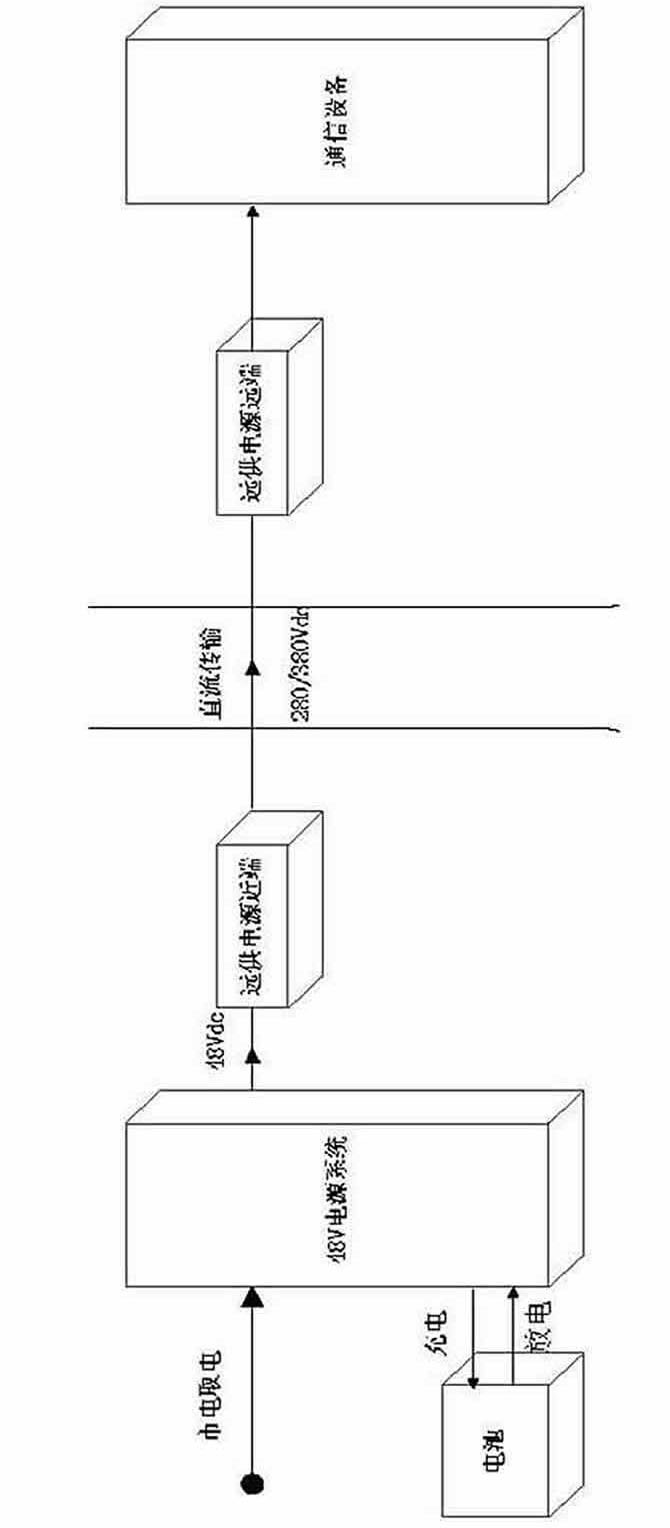

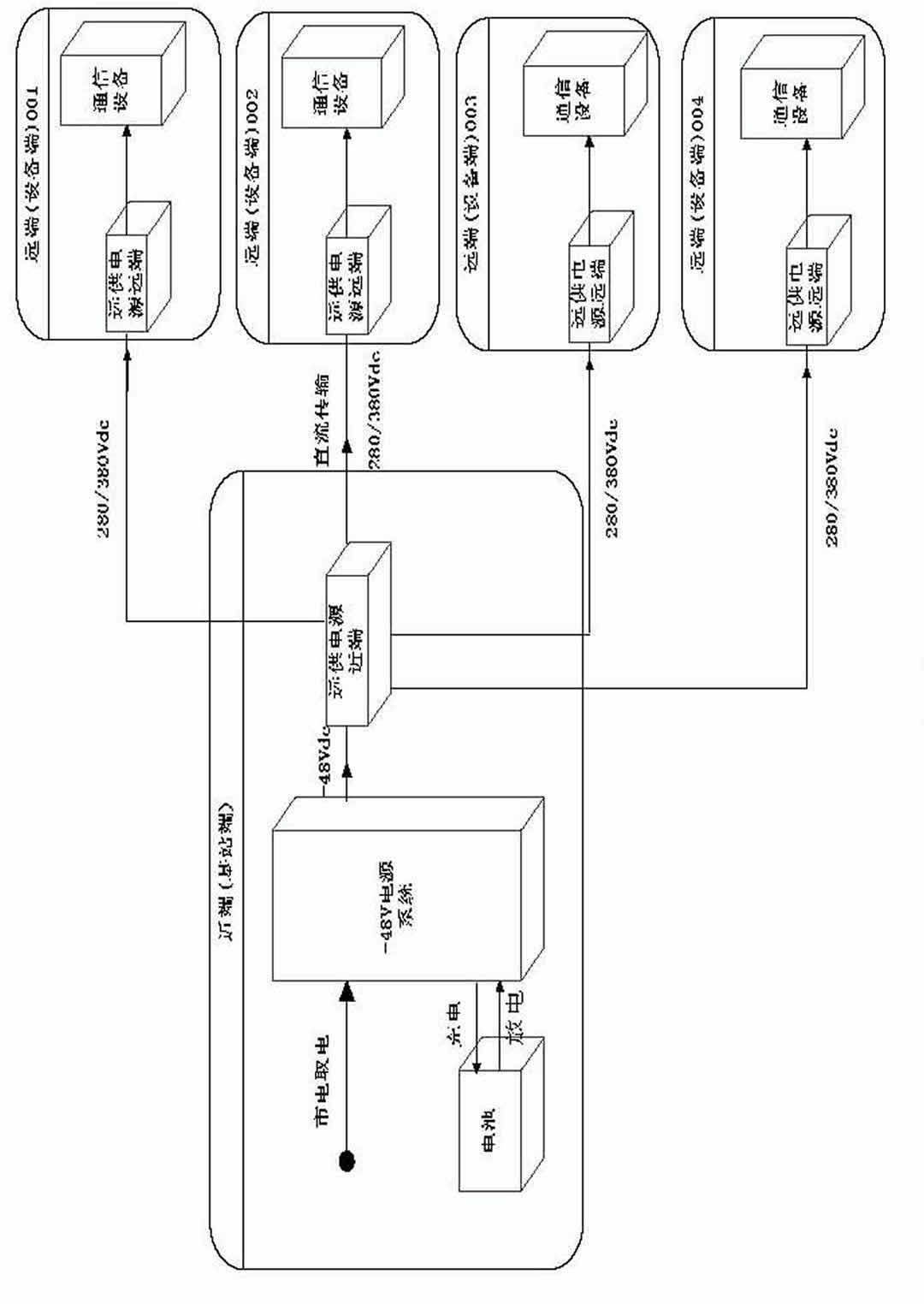

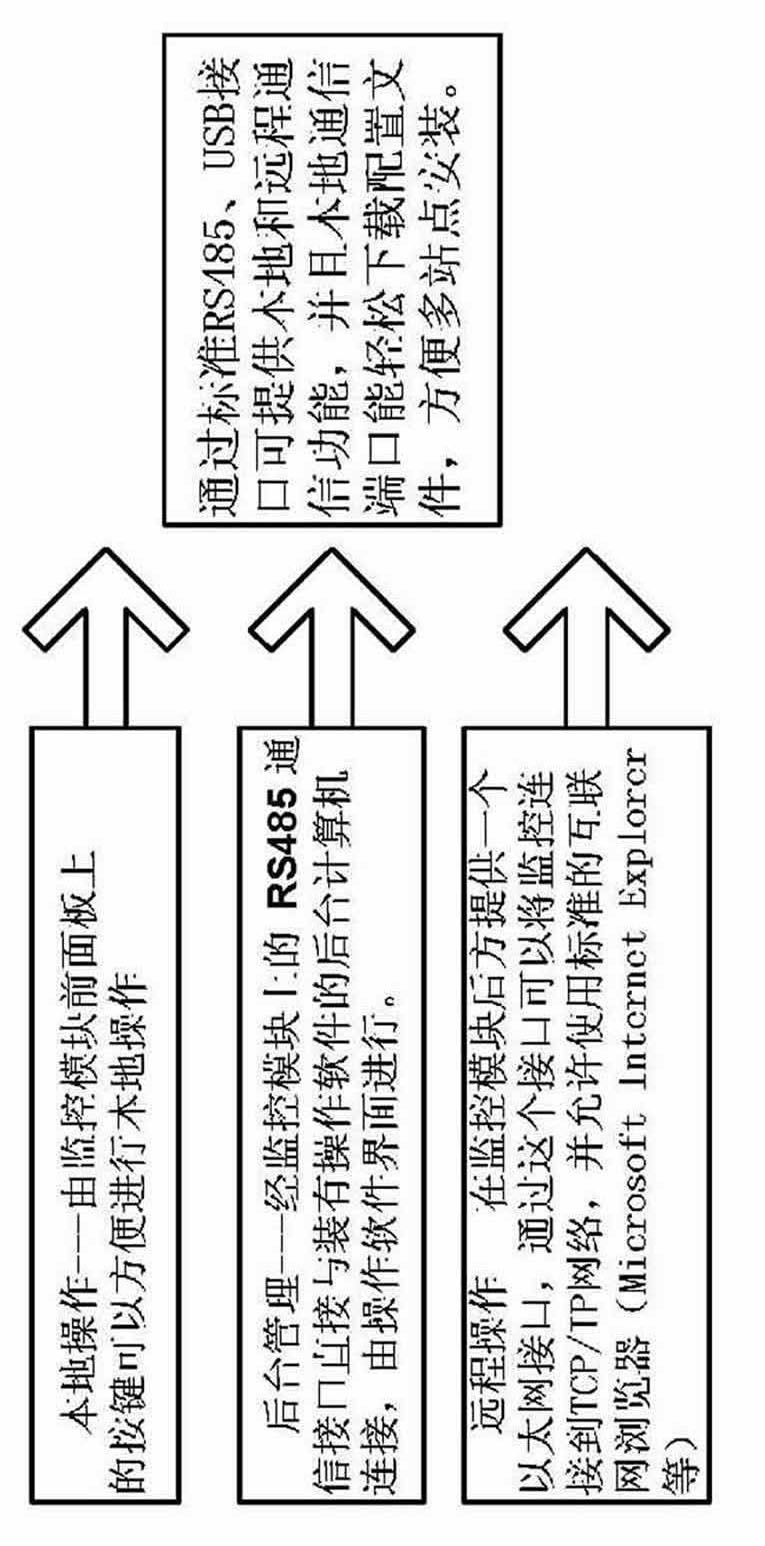

Remote power supply system for repeater

InactiveCN101951284AGood reliabilityGuaranteed reliabilityBatteries circuit arrangementsElectric powerEngineeringPower flow

The invention belongs to the technical field of mobile communication, and in particular relates to a power supply system for a repeater. The system comprises a near-end part and a far-end part, wherein the near-end part comprises a base station direct-current power supply cabinet and a near-end machine; the far-end part comprises a far-end machine; the transmission port of the base station direct-current power supply cabinet is connected with the transmission port of the near-end machine; and the output end of the near-end machine is connected with the input end of the far-end machine. The near-end part is also provided with a storage battery; the port of the storage battery is connected with the port of the base station direct-current power supply cabinet; the near-end machine comprises a rectifying module and a monitoring module; the port of the rectifying module is connected with the port of the monitoring module; the monitoring module monitors and controls voltage and current of the rectifying module and transmits the voltage and current to a terminal control computer through 485 communication; and the rectifying module is used for adjusting and stabilizing the voltage and current and supplying power to the terminal repeater. The power supply system has the advantages of high safety and reliability, convenient daily maintenance and management, wide environmental adaptation range and high efficiency.

Owner:ALLWIN TELECOMM

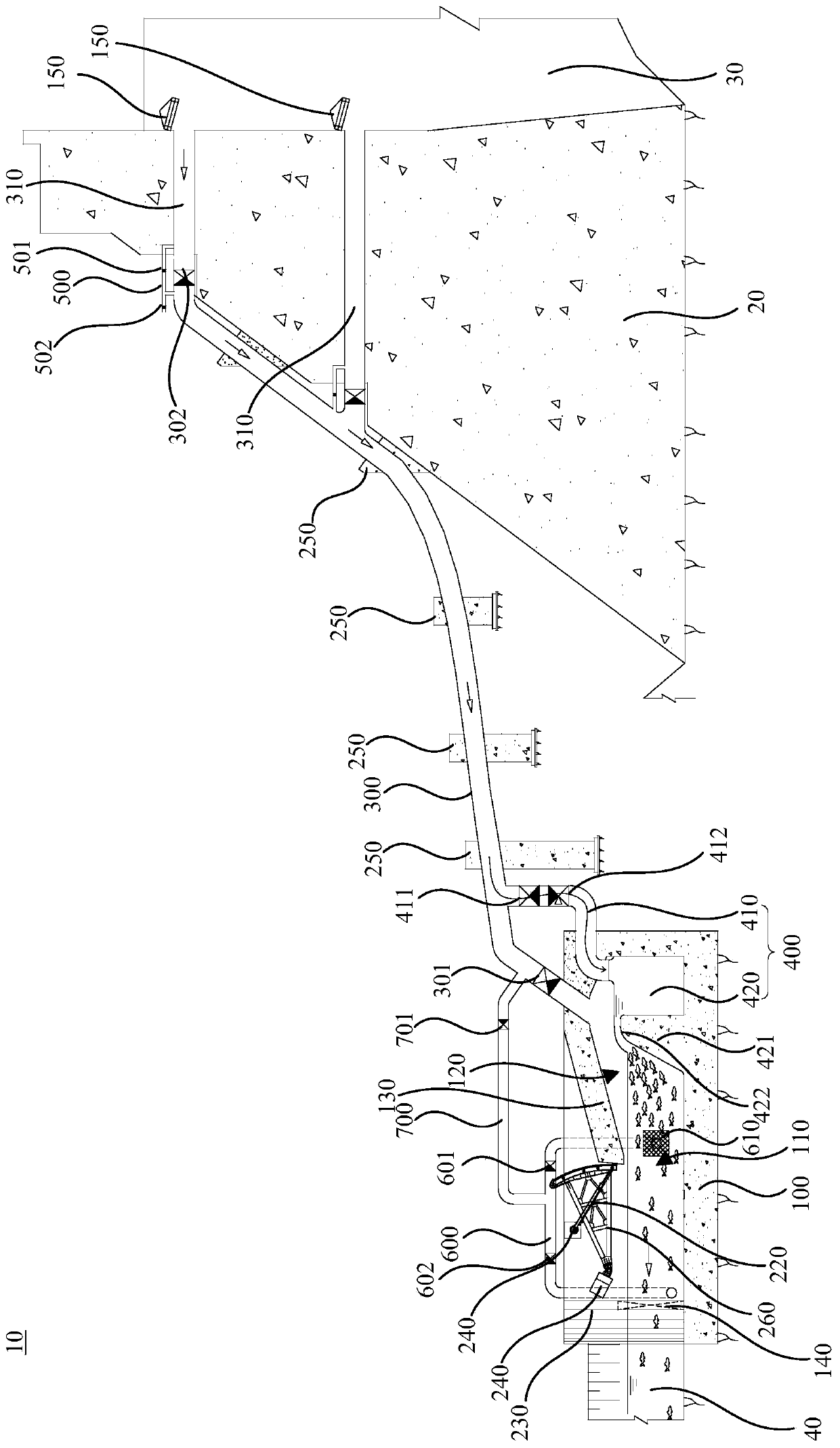

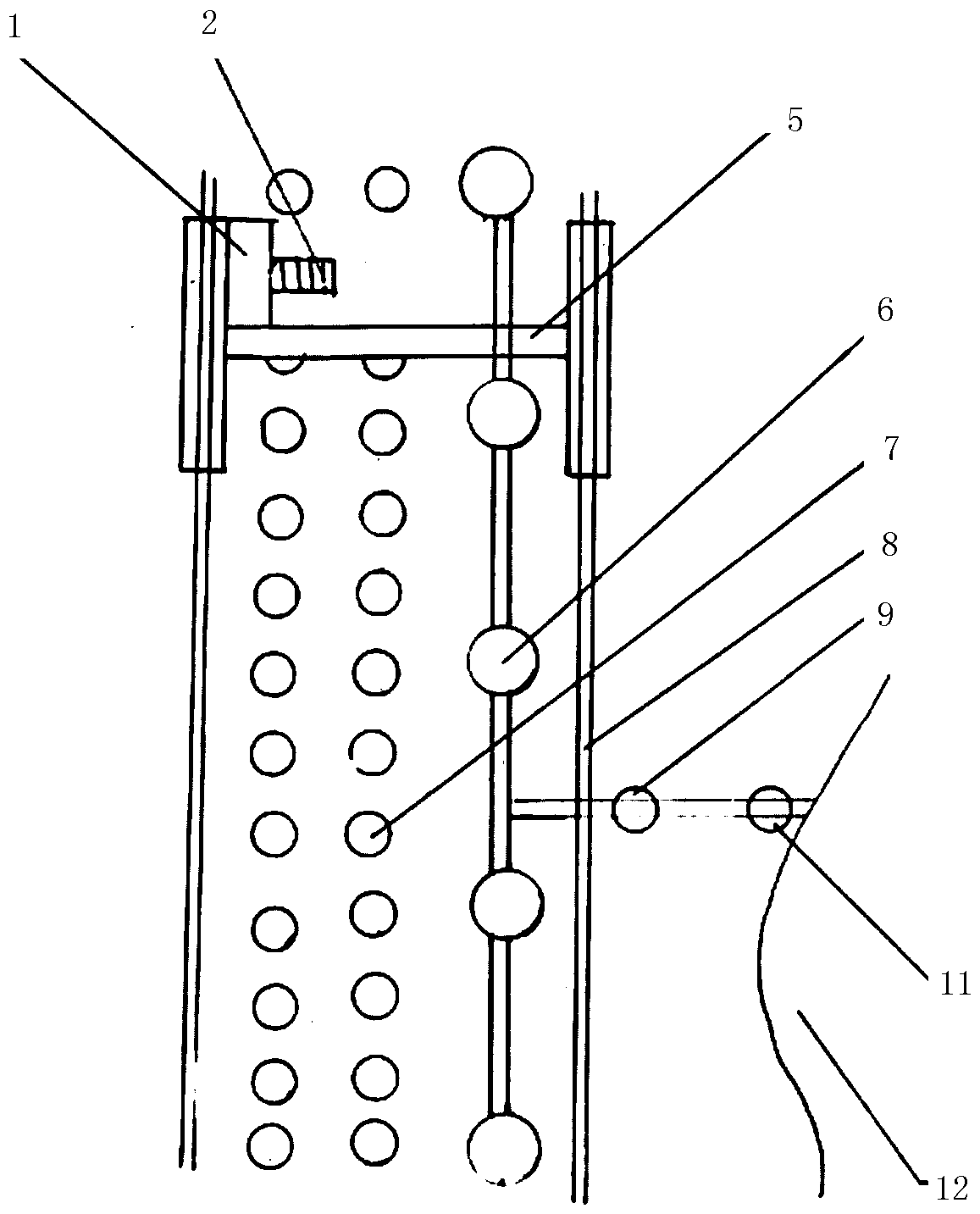

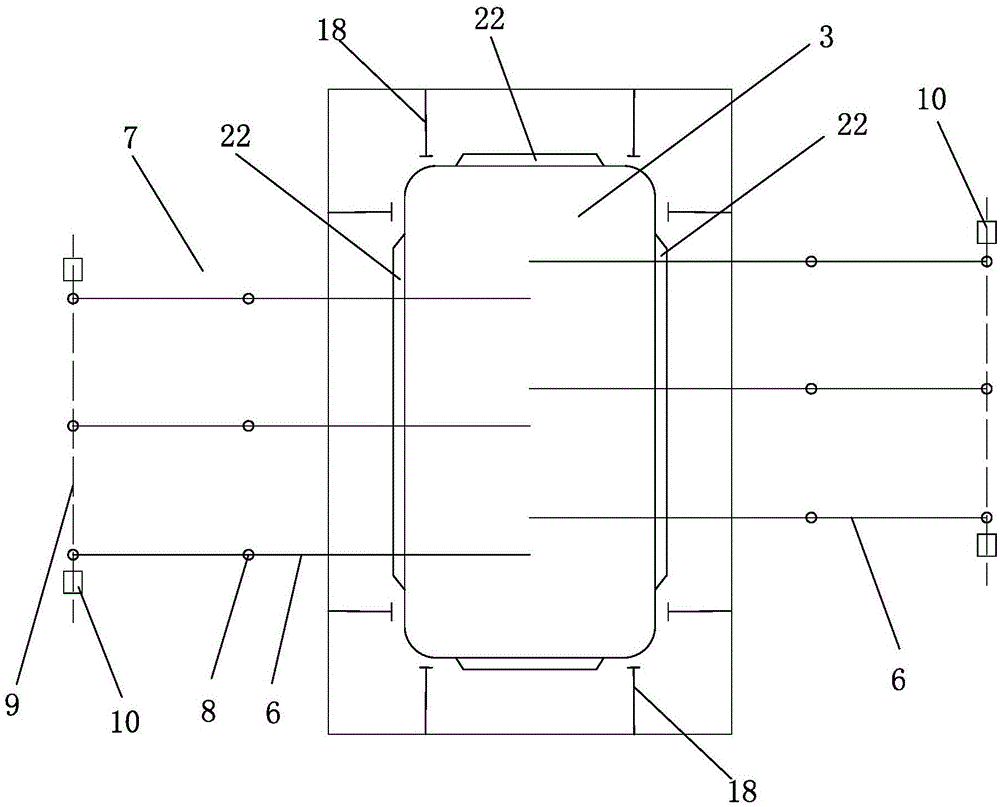

De-mechanized tubular fishway device

ActiveCN111236181AAvoid direct damageLess likely to cause deathBarrages/weirsClimate change adaptationWater storageWater storage tank

The invention discloses a de-mechanized tubular fishway device. The de-mechanized tubular fishway device comprises a water storage mechanism for providing a stable water flow for transporting fishes,a fish collecting mechanism for gathering the fishes in a downstream reservoir, and a transportation mechanism for lifting and transporting the fishes in the fish collecting mechanism to an upstream reservoir; the water storage mechanism comprises a water storage tank with the stable water level and a first water feeding tube communicating with the water storage tank; the fish collecting mechanismcomprises a fish collecting tank used for gathering the fishes in the downstream reservoir, a second transportation tube communicating with the fish collecting tank, a fish collecting tube communicating with the first water feeding tube through a double-way valve, and a fish luring facility; and the transportation mechanism comprises a first transportation tube communicating with the second transportation tube and the fish collecting tube through a three-way valve, a water outlet of the first transportation tube corresponds to the upstream reservoir, and the elevation of the water outlet is larger than the water level in the water storage tank. A system operates through the inertia of water, then the fishes are transported into the upstream reservoir, a school of fishes is taken away at atime, thus the water consumption is greatly saved, and the water consumption efficiency of fish passing is improved.

Owner:毛熹

Pumped storage power station

ActiveCN105134474AImprove efficiencyEasy to operateHydro energy generationMachines/enginesElectric power transmissionPower station

The invention belongs to the technical field of generating sets, in particular to a pumped storage power station. The pumped storage power station adopts the structure that two power transmission floating body water tanks are communicated with each other through two or more water flow passages; power transmission floating bodies are arranged in both the power transmission floating body water tanks; liquid ballast chambers are arranged in the power transmission floating bodies, and are communicated with one another through water feed / drainage pipelines; an on-off valve is arranged on each water flow passage; water is fed into and drained from the power transmission floating body water tanks through a feed pump and a drainage pump; two power transmission floating bodies are connected with one end of a corresponding lever; the other ends of the levers are connected with a connecting rod; one end of the connecting rod is connected with a generator through a booster engine, or two ends of the connecting rod are connected with generators through booster engines respectively; water level variation in the power transmission floating body water tanks drives the levers to swing around a fulcrum, so as to drive the connecting rod to work and further drive the generator(s) to generate power. The pumped storage power station has the advantages that the efficiency is high; the operation is simple; the application is wide in range and free from limitation of districts; the operation is safe and reliable.

Owner:张文庆

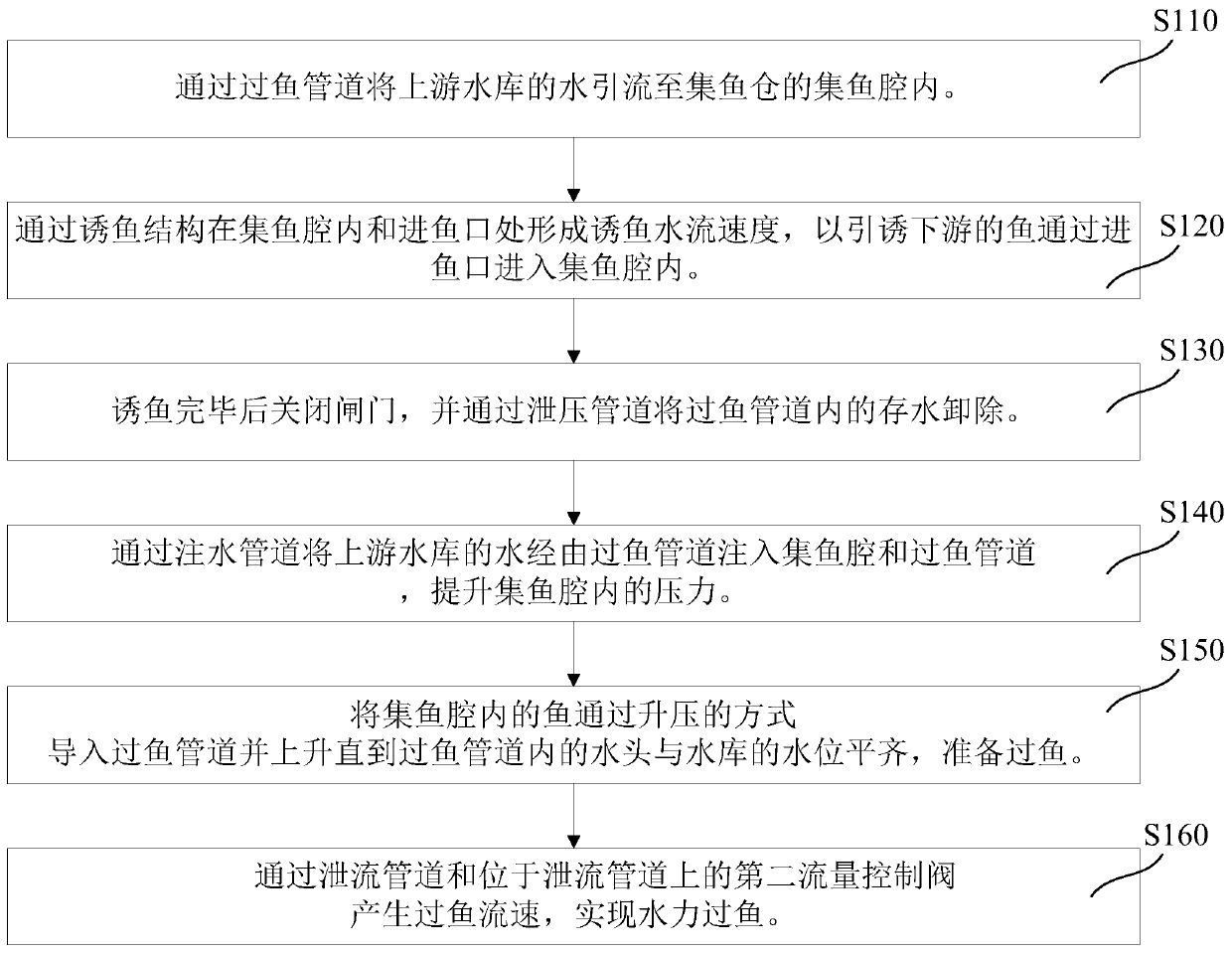

Gate valve pipe-type fish passing method

ActiveCN109853492AReduce sizeOptimize site selectionBarrages/weirsClimate change adaptationPressure riseFishery

The invention relates to a gate valve pipe-type fish passing method. Water of an upstream reservoir is diverted into a fish gathering cavity of a fish gathering storehouse through a fish passing pipeline, and a fish attracting velocity is formed in the fish gathering cavity and at a fish inlet through a fish-attracting structure to induce fishes from downstream to enter the fish gathering cavity through the fish inlet; after the fish attracting is completed, the gate is closed, water stored in the fish passing pipeline is discharged through a pressure release pipeline; the water of the upstream reservoir is injected into the fish gathering cavity and the fish-passing pipeline through a water injecting pipeline to boost the pressure in the fish gathering cavity; the fishes gathered in the fish gathering cavity are introduced into the fish passing pipeline by means of boosting the pressure, and the pressure rises until a water head in the fish passing pipeline is flush with a water levelof the reservoir to prepare the fish passing; and a fish passing velocity is generated through a discharge pipeline and a second flow control valve on the discharge pipeline, and the hydraulic fish passing is realized. According to the gate valve pipe-type fish passing method, the occupied area is small, the project cost is low, and the water consumption is low.

Owner:CHINA WATER RESOURCES PEARL RIVER PLANNING SURVERYING & DESIGNING

Multilevel-control polyradical biomass-gasification energy regeneration system

ActiveCN101519604BImprove gasification efficiencyHigh reforming efficiencyBiofuelsEnergy inputOxygenMoisture

The invention provides a multilevel-control free-polyradical biomass-gasification energy regeneration system, which can transform extensive biomass and carbon-containing raw materials, including energThe invention provides a multilevel-control free-polyradical biomass-gasification energy regeneration system, which can transform extensive biomass and carbon-containing raw materials, including energy crops, agriculture-forestry byproducts, organic waste, industrial and dangerous waste and the like, into high-grade energy. The system is designed for continuous operation. Gasification comprises thy crops, agriculture-forestry byproducts, organic waste, industrial and dangerous waste and the like, into high-grade energy. The system is designed for continuous operation. Gasification comprises the following steps of performing pretreatment, performing pyrolysis, transforming carbon, fusing ash, cracking tar, reforming syngas and utilizing waste heat, wherein the steps are precisely controllede following steps of performing pretreatment, performing pyrolysis, transforming carbon, fusing ash, cracking tar, reforming syngas and utilizing waste heat, wherein the steps are precisely controlled one by one and integrated so as to achieve optimum; moisture from the pretreatment of the materials is led into a carbon-transforming unit so as to realize oxygen-free pyrolysis; gasification gas isone by one and integrated so as to achieve optimum; moisture from the pretreatment of the materials is led into a carbon-transforming unit so as to realize oxygen-free pyrolysis; gasification gas isin contact with a large number of free polyradicals in a free-polyradical reaction-accelerating unit; and the obtained product is purified and then enters downstream application, such as power generatin contact with a large number of free polyradicals in a free-polyradical reaction-accelerating unit; and the obtained product is purified and then enters downstream application, such as power generation, hydrogen production and biomass methanol / ethanol production. The system has the advantages of needing no auxiliary fuel, maximizing gasification efficiency and thoroughly cracking tar and clearinion, hydrogen production and biomass methanol / ethanol production. The system has the advantages of needing no auxiliary fuel, maximizing gasification efficiency and thoroughly cracking tar and clearing pollutants, and is an upstream technique for the application of biomass renewable energy. As energy utilization meets all strict environmental protection standards, the system is also an energy-savig pollutants, and is an upstream technique for the application of biomass renewable energy. As energy utilization meets all strict environmental protection standards, the system is also an energy-saving environment-friendly technique for non-incineration harmless treatment.ng environment-friendly technique for non-incineration harmless treatment.

Owner:浙江瑞拓展泰再生能源有限公司

Tidal power generation system

PendingCN109989874AOptimize site selectionSimple structureMachines/enginesEngine componentsEngineeringGenerating unit

The invention relates to the technical field of tidal power generation, in particular to a tidal power generation system. The tidal power generation system comprises a substrate fixed to the seabed, avertical column fixed to the substrate and extending out of the sea level and a floating unit slidably arranged along the vertical column, wherein the floating unit comprises a floating silo capableof suspending on the sea level and a unit silo located on the floating silo, a generator unit is arranged in the unit silo, and the buoyancy generated by the floating silo is greater than the gravityof the floating unit; the vertical column is provided with a gear rack along the extension direction, the floating unit is provided with a gear wheel matched with the gear rack and capable of rollingalong the gear rack, and the gear wheel is connected with the generator unit through a transmission shaft. Through the arrangement, the tidal power generation system has a simple and reliable structure, is easy to select a site, and conductive to large-scale construction, moreover, the tidal power generation system has the advantages of low cost and energy consumption, high power generation efficiency and stability.

Owner:张建杰

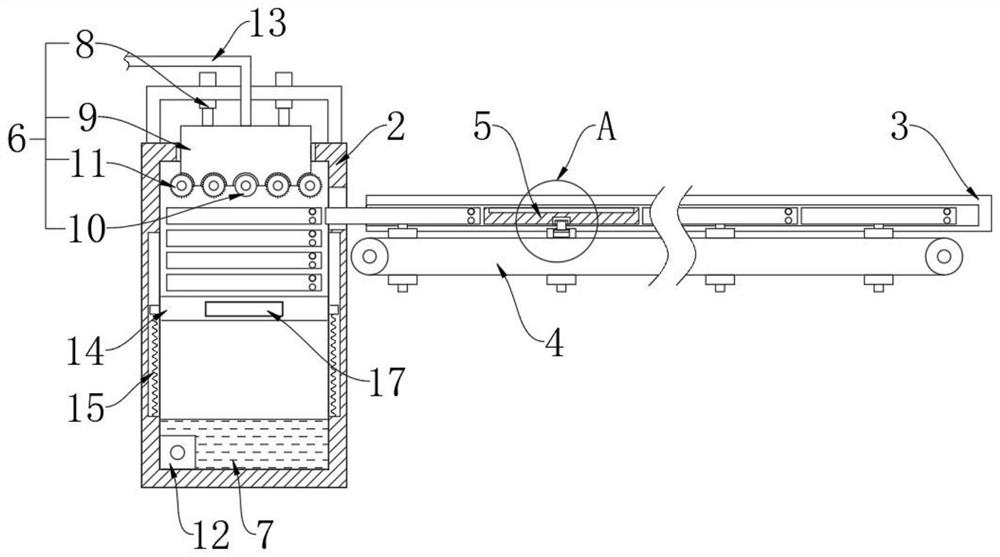

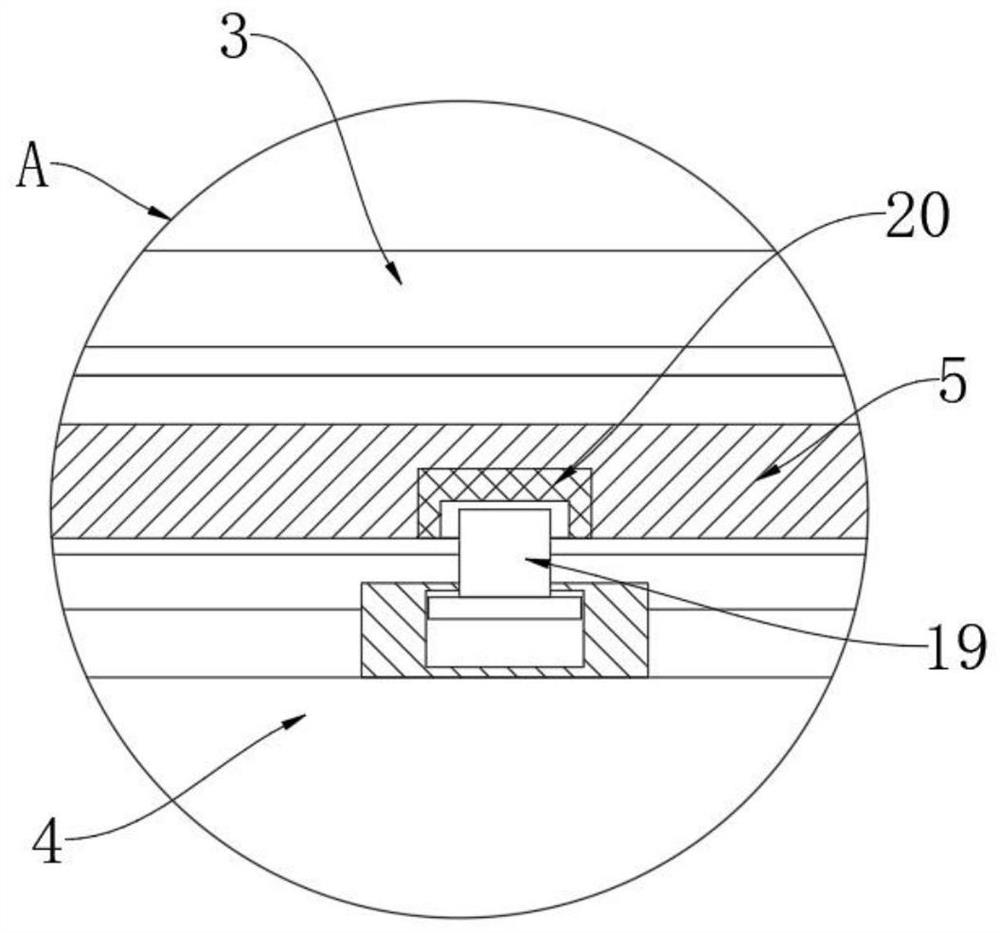

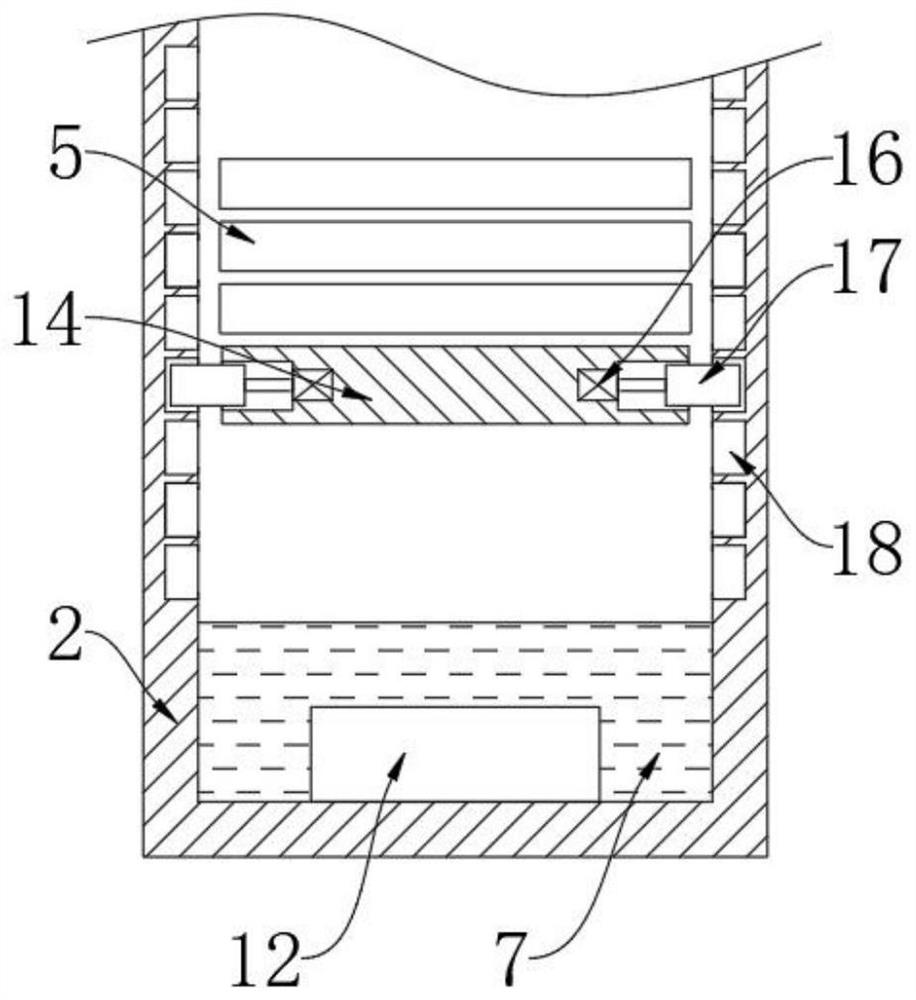

Networking and intelligent control method of photovoltaic module cleaning operation and maintenance system

PendingCN113992142AOptimize site selectionImprove adaptabilityPhotovoltaic supportsPhotovoltaic monitoringProduction lineNetwork monitoring

The invention discloses the networking of a photovoltaic module cleaning operation and maintenance system, which comprises a monitoring station, an operation and maintenance tower, a guide rail support, a conveying device and photovoltaic panels, and is characterized in that the monitoring station is provided with a network monitoring platform and an environment monitor, and the operation and maintenance tower is internally provided with a cleaning device, an assembly recycling chamber and a cleaning liquid pool; a plurality of photovoltaic panels are linearly arranged and slidably mounted in the guide rail support, the conveying device is arranged below the photovoltaic panels, the conveying device carries the photovoltaic panels to move through movable clamping and conveys the photovoltaic panels into the assembly recycling chamber in the direction of the guide rail support, and the cleaning device sprays liquid to clean the photovoltaic panels below. According to the invention, the operation and maintenance towers with fixed positions are arranged, each photovoltaic power generation production line has its own operation and maintenance tower, the monitoring station only needs to control the operation and maintenance towers, a network covering a full photovoltaic area does not need to be arranged, the site selection of the installation positions of the photovoltaic panels is facilitated, the adaptability to the environment is improved, and the effects of easy layout and low investment are achieved.

Owner:海澜智云科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com