Gravity energy storage system

An energy storage system and gravity technology, applied in the direction of machines/engines, mechanical equipment, engines, etc., can solve the problems of being unable to bear tens of thousands or even hundreds of thousands of tons of pressure, high investment ratio, low utilization rate of lifting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

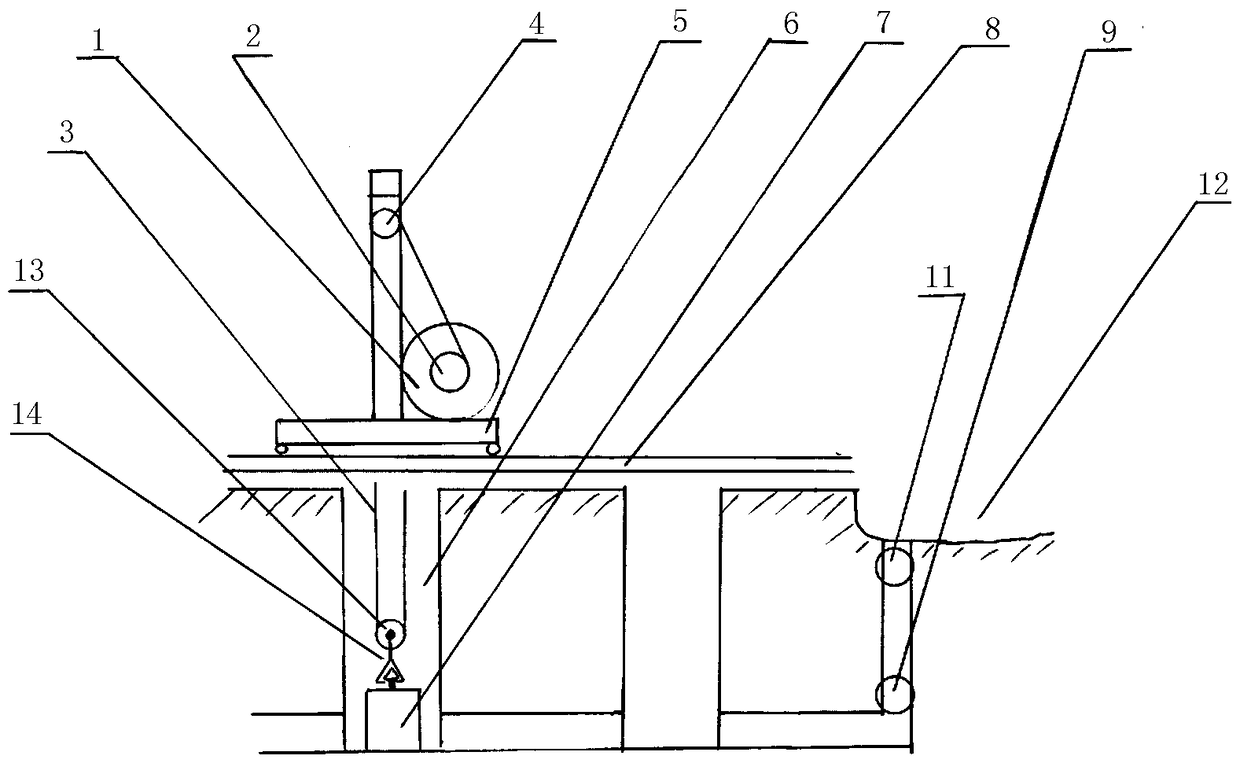

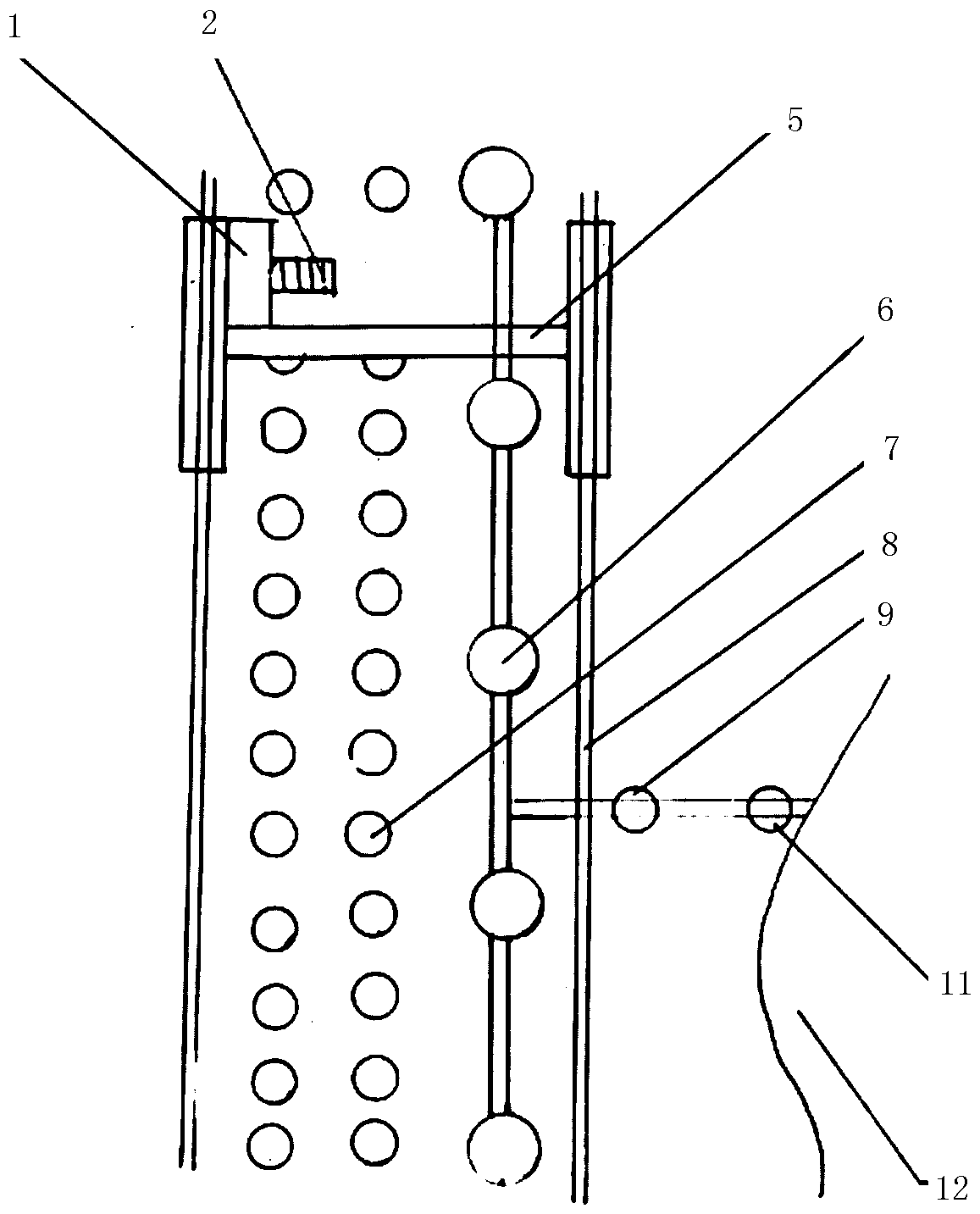

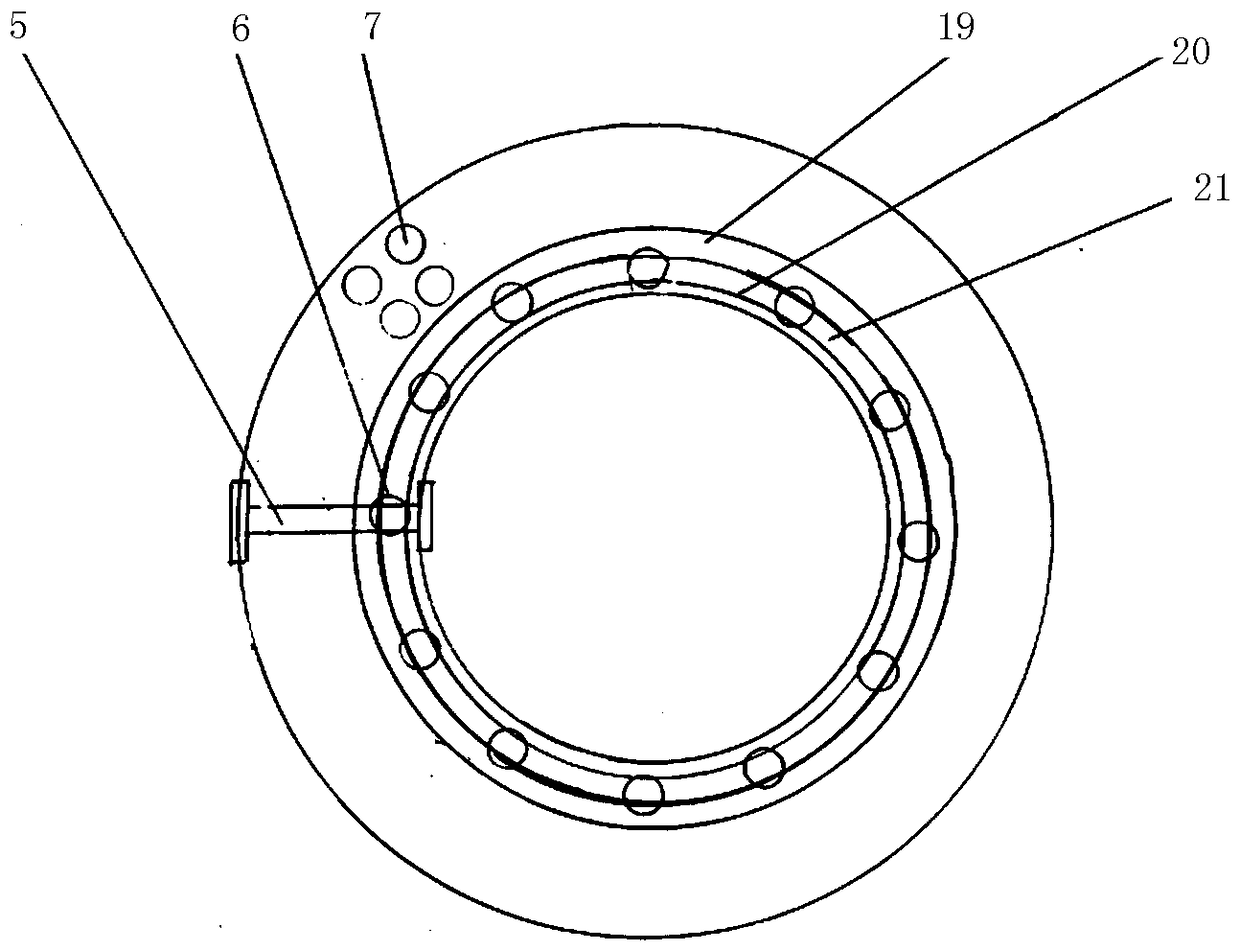

[0024] Such as figure 1 , 2 As shown, there are at least two vertical shafts 6 underground. The vertical shafts are arranged in a straight line, and the bottoms of the multiple vertical shafts are connected. The structural environment and design capacity are for reference, about 200 meters to 600 meters; the passage at the bottom of the shaft is equipped with a two-way water pump 9, and the two-way water pump 9 is connected to the upper pool 12 on the ground through a water pipe 10 and a water valve 11; there is a track above the shaft 8. There is a gantry crane 5 running on the track, and the hoisting motor 1 is installed on the base of the lower part of the gantry crane, and the hoisting motor 1 can be switched between a generator and a motor. The hoisting motor is connected with a winding drum, and the hoisting motor drives the winding drum 2 to rotate, and the winding drum 2 is wound with a steel wire rope 3, and the rear end of the steel wire rope 3 is fixed on the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com