Vacuum explosion effect testing device

A test device and effect technology, applied in the field of explosion processing, can solve problems such as lack of protective measures, no equipment for monitoring and eliminating toxic and harmful gases, and inability to fully achieve explosion effects, achieving rich functions, convenient location selection, and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] As a method of processing metal composites, explosive welding has a wide range of application scenarios. However, in the traditional production process, welding quality defects caused by air and noise generated by explosions will have many restrictions on the popularization and application of this technology. The vacuum production environment provided by the device of the invention can overcome the defects of the method.

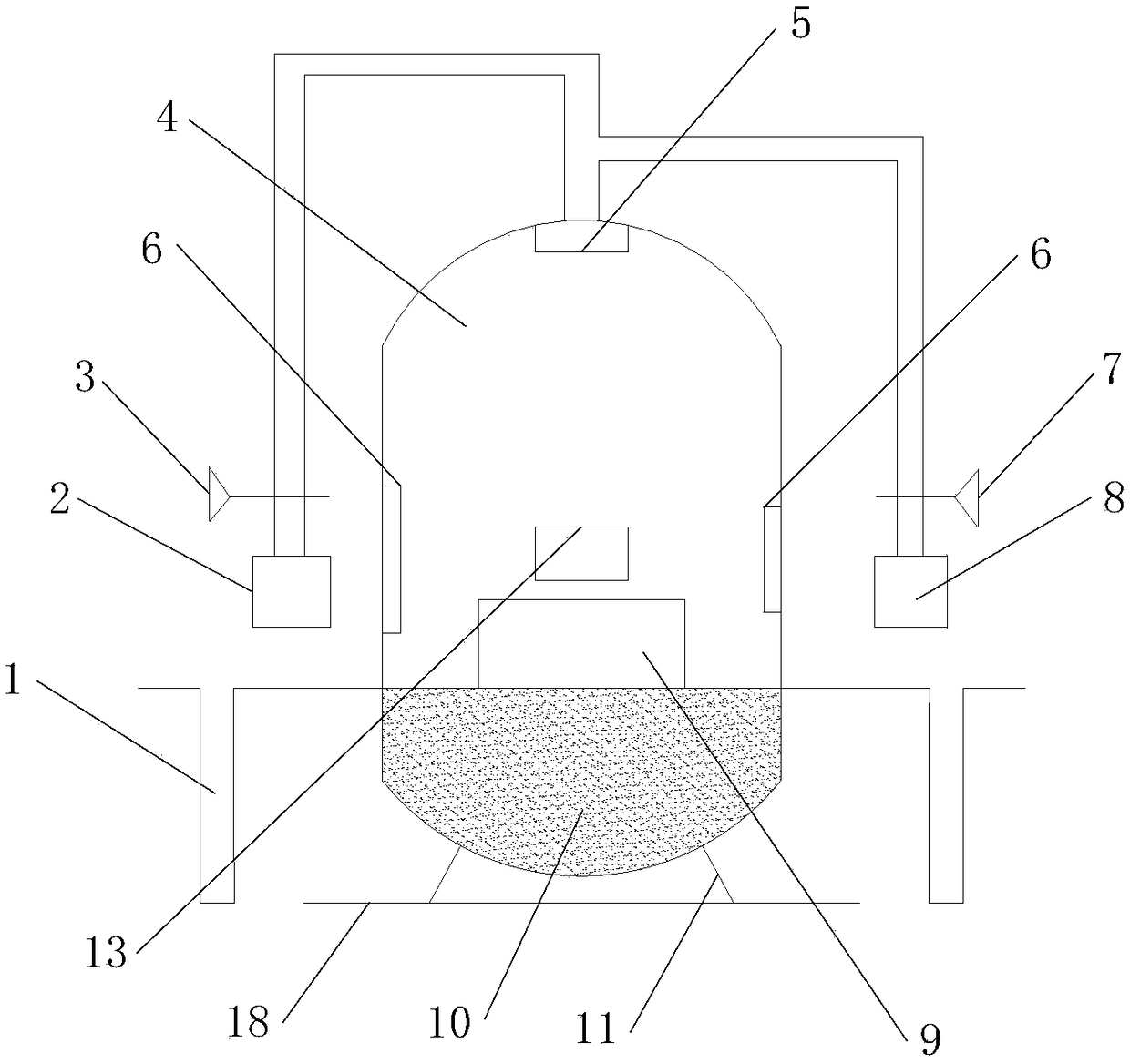

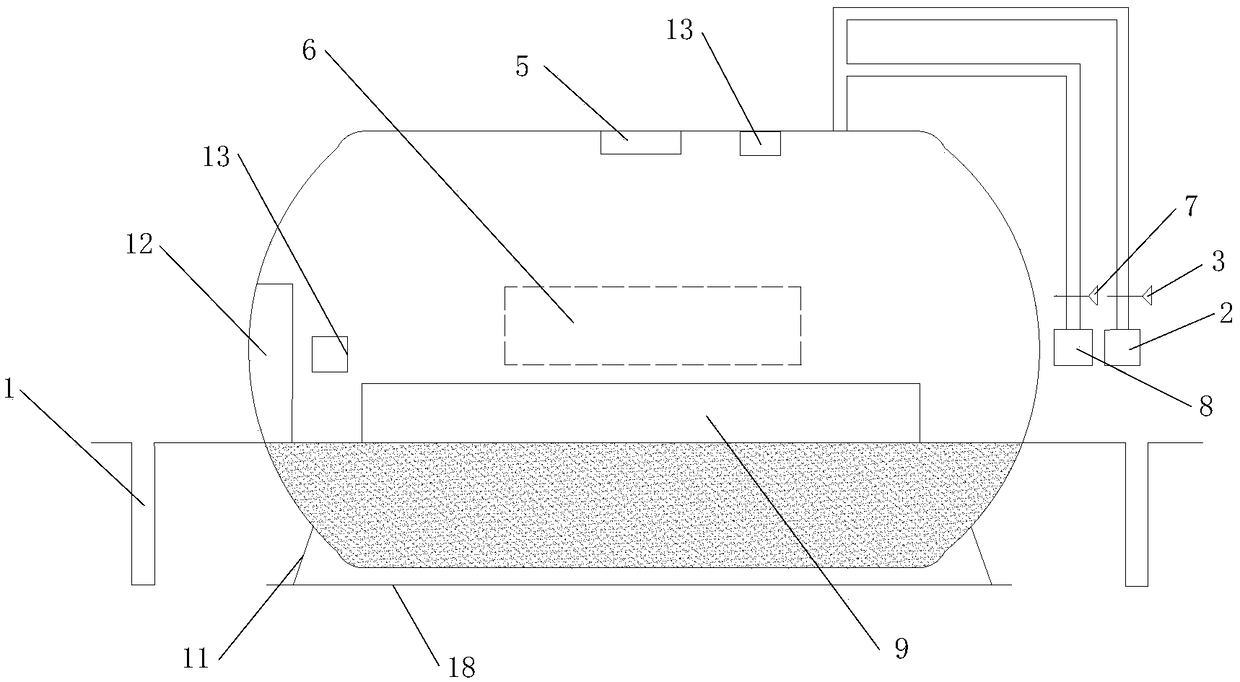

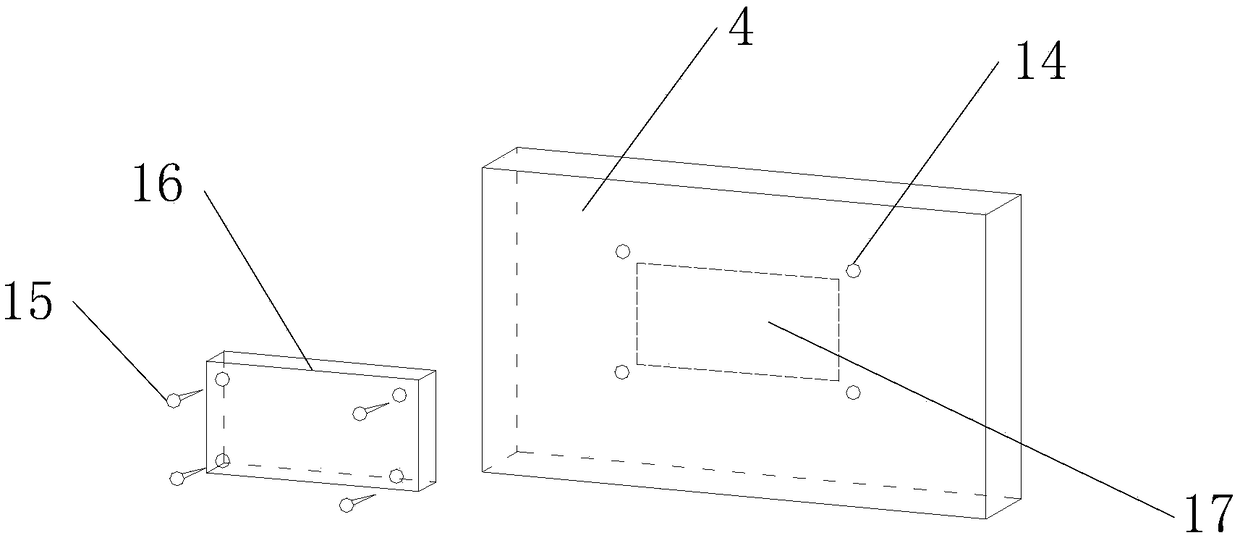

[0035]Explosive welding main explosives use porous granular ammonium oil explosives or emulsion explosives, mixed with perlite, the general explosive detonation velocity is controlled at about 2200m / s, the double board is 304 board with a thickness of 3mm, the board surface is 500mm×500mm, and the substrate is 6mm thick 304 plate, the plate surface is 450mm×450mm, the end is detonated, according to the attached figure 2 Arrangement, put the explosive welding device into the vacuum device, close the chamber door, pump air through the exhaust port, me...

Embodiment 2

[0037] Due to the existence of a large number of asteroids in space, the reserves of rare metals such as palladium and platinum are quite abundant. Therefore, the establishment of an asteroid base to engage in related mining work is the only way for future development. The device can simulate the ore mining effect in the vacuum environment in space, thereby improving the production process.

[0038] Classification of blastability of rock mass is the basis of optimal design and construction of blasting parameters, so it is very important to study blasting funnels in vacuum environment. A cement concrete block of 1m×1m×1m is poured in the device, and a hole with a diameter of 34mm is arranged in the center. The charge depth is used to study the blastability of rock mass in vacuum environment. After the charge is filled, connect the wires, close the chamber door, draw air through the exhaust port, measure the negative pressure to -0.08MPa, and then detonate. After the explosio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com