Pumped storage power station

A pumped-storage power station and pool technology, which is applied in the directions of hydropower generation, engine components, machines/engines, etc., can solve the problems of large drop between upper and lower reservoirs, vulnerability to floods, droughts, and large occupied area, reaching the height of the water surface. The effect of small difference, cost reduction and high kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

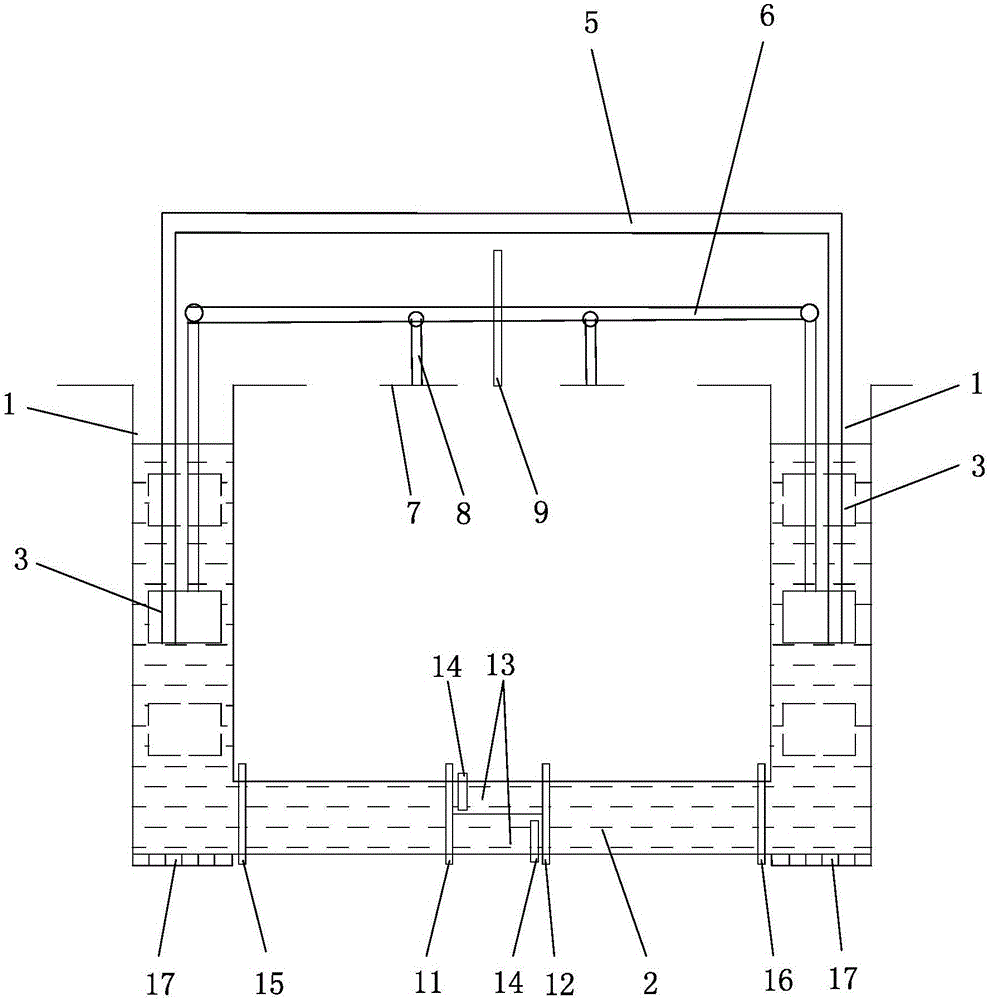

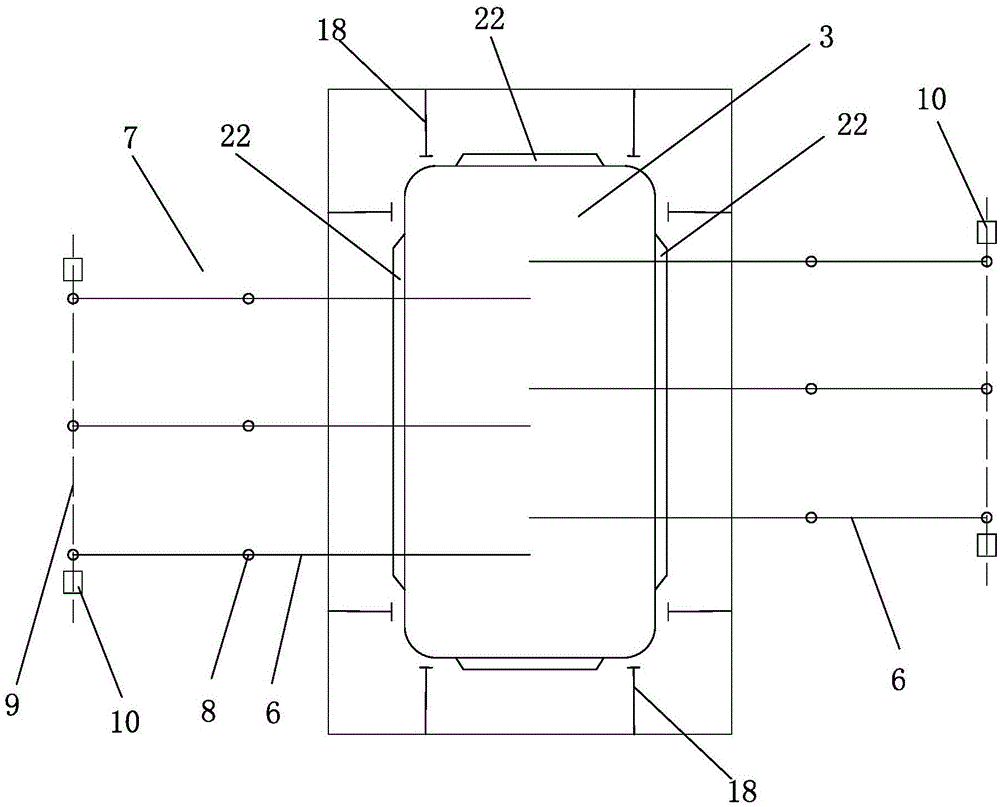

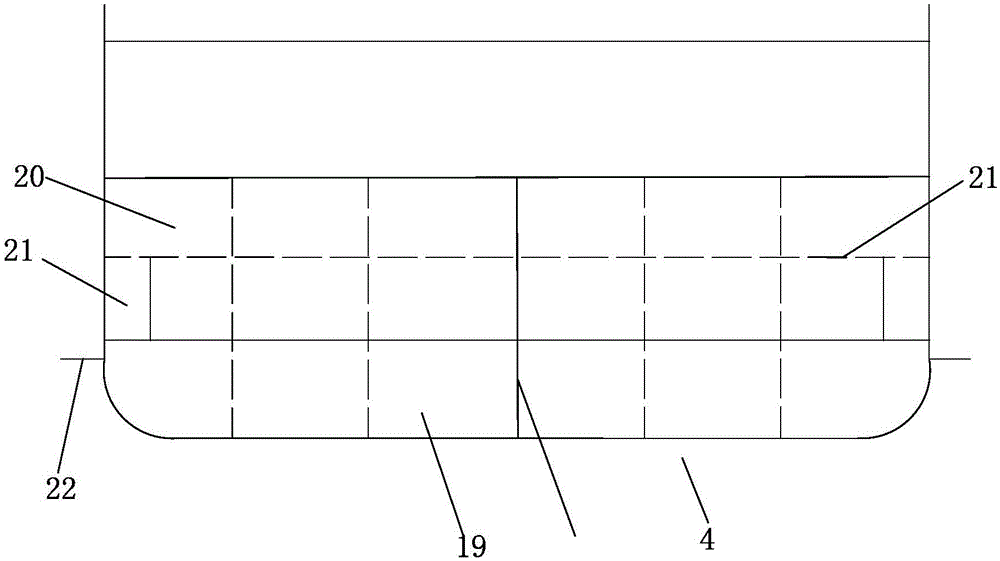

[0045] Embodiment 1: see figure 1 —4:

[0046] A pumped-storage power station, including two transmission power floating body pools 1 arranged at intervals, and the two transmission power floating body pools 1 are connected to 2 through more than two water flow channels. In this embodiment, there are three channels, one for standby, and another The two paths meet the requirement of being discharged from one power transmission floating body pool 1 to the other power transmission floating body pool 1 within a set time. Both transmission power floating body pools 1 are provided with transmission power floating body 3, and the area of transmission power floating body 3 can be set to 1 / 2 of the area of transmission power floating body pool 1, allowing the existence of left-right deviation. A liquid ballast tank 4 is arranged in the transmission power floating body 3, and the liquid ballast tank 4 is connected by an inlet and outlet pipe 5, and the inlet and outlet pipe 5 is used...

Embodiment 2

[0076] Example 2: see image 3 -7:

[0077] The difference between this embodiment and Embodiment 1 is that the drive of the generator is driven by a lever connected to the work floating body.

[0078] Rod drive:

[0079] A pumped storage power station, including two groups of pools arranged at intervals, each group of pools includes a power transmission floating body pool 1 and more than one work floating body pool 23, in this embodiment, each power transmission floating body pool 1 corresponds to two working Work floating body pool 23. The specific quantity of work floating body pool 23 can be designed according to actual conditions. The two transmission power floating body pools 1 are connected through more than two water flow channels 2, and the transmission power floating body pools 1 of each group are connected with each work floating body pool 23 through more than two water flow channels 24. In this implementation For example, three water flow passages 24 are set, o...

Embodiment 3

[0106] Embodiment 3: see Figure 8 :

[0107] In this embodiment, the functions of Embodiments 2 and 3 are combined, and at the same time, the power transmission floating body and the work floating body are driven to generate electricity.

[0108] Working principle of the present invention:

[0109] 1. Open the on-off valve (i.e. 28, 29 in Embodiment 2), fill up the ballast water in the fixed ballast tanks of the two transmission power floating bodies 3, and the transmission power floating body 3 is arranged in the middle of the pool;

[0110] The ballast water in the ballast tank 20 is adjusted by using one of the transmission power floating bodies (set as A floating body) to adjust the ballast water of the ballast tank 20, so that the draft of the A floating body increases and sinks, so that the transmission power floating body pool 1 where the A floating body is located (set For the water level of A tank) to rise, adjust the cabin pressure to the set height;

[0111] Use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com