Method for efficiently treating oil field complex oil-water emulsion

A technology for preliminary treatment of crude oil, applied in the petroleum field, can solve problems that may not be effective, and achieve the effects of reducing oil content, changing the polar environment, and eliminating the formation of complex oil-water emulsions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

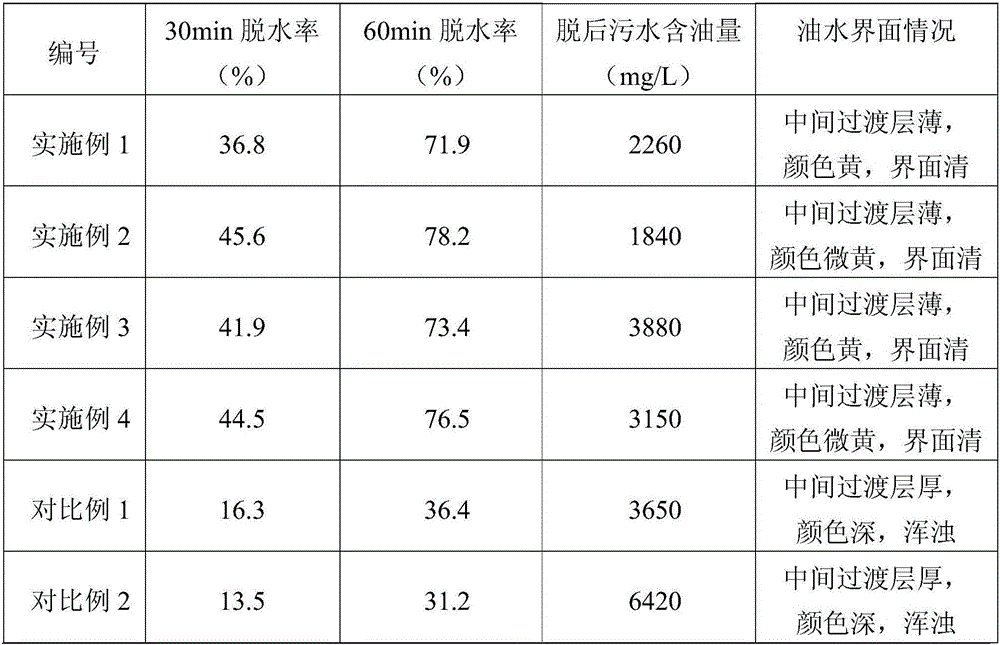

Embodiment 1

[0022] (1) Take 100 mL of crude oil from heavy oil field C and heat it in a water bath at 75°C, add 8 mg of demulsifier DP32, shake it manually and mix well.

[0023] (2) Take 1.5 mg of a mixed solution composed of n-hexane, cyclohexanol and diethylene glycol methyl ether, wherein the mass ratio of each component is n-hexane: cyclohexanol: diethylene glycol methyl ether=1:2:4 , manual shaking to mix evenly. According to the industry standard SY / T5281-2000, the performance of demulsification and dehydration was evaluated, and the dehydration rate at 30 minutes and 60 minutes, the oil content of the dewatered sewage and the oil-water interface were recorded respectively.

Embodiment 2

[0025] (1) Take 100 mL of crude oil from heavy oil field C and heat it in a water bath at 75°C, add 6 mg of demulsifier DP61, shake and mix by hand.

[0026] (2) Get 4 mg of a mixed solution composed of n-pentane, isohexyl alcohol and diethylene glycol butyl ether, wherein the mass ratio of each component is n-pentane: isohexanol: diethylene glycol butyl ether=1:2:6 , manual shaking to mix evenly. According to the industry standard SY / T5281-2000, the performance of demulsification and dehydration was evaluated, and the dehydration rate at 30 minutes and 60 minutes, the oil content of the dewatered sewage and the oil-water interface were recorded respectively.

Embodiment 3

[0028] (1) Take 100mL of crude oil from the polymer injection oilfield P and heat it in a water bath at 65°C, add 15mg of demulsifier DP32, shake it manually and mix it evenly.

[0029] (2) Take 3 mg of a mixed solution composed of n-butane, 1,2-propylene glycol, and diethylene glycol dimethyl ether, wherein the mass ratio of each component is n-butane: 1,2-propylene glycol: diethylene glycol two Methyl ether = 1:3:8, shake manually to mix well. According to the industry standard SY / T5281-2000, the performance of demulsification and dehydration was evaluated, and the dehydration rate at 30 minutes and 60 minutes, the oil content of the dewatered sewage and the oil-water interface were recorded respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com