Variable cross-section fiber reinforced composite pipe and pipe-die integrated forming method

A composite material pipe and fiber-reinforced technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of unstable structural performance, high production cost, and complicated process, so as to improve the overall strength and stability, reduce Cracks or debonding, avoiding the effect of the demoulding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the technical solution of the present invention is further described in conjunction with the accompanying drawings.

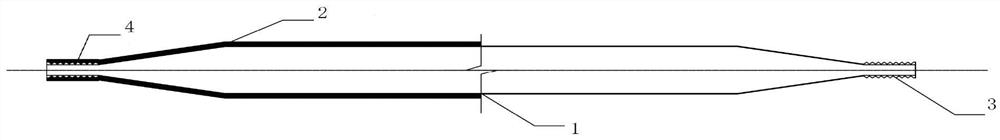

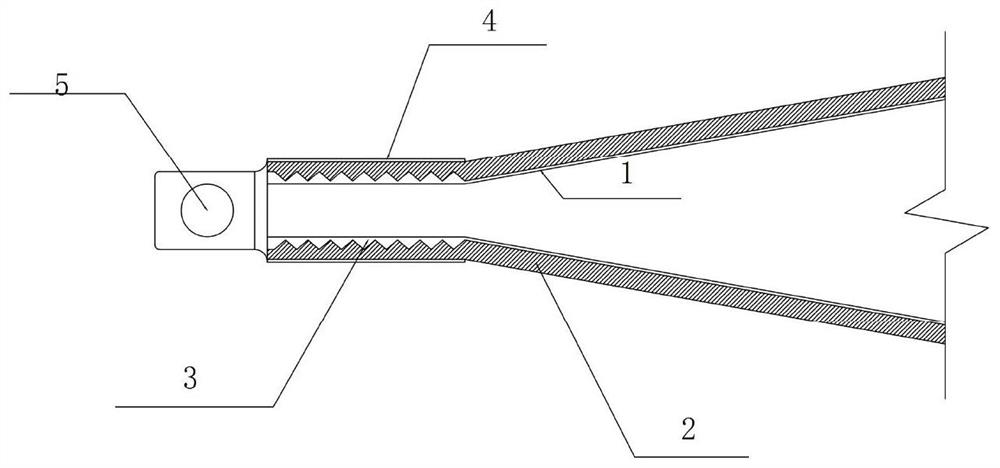

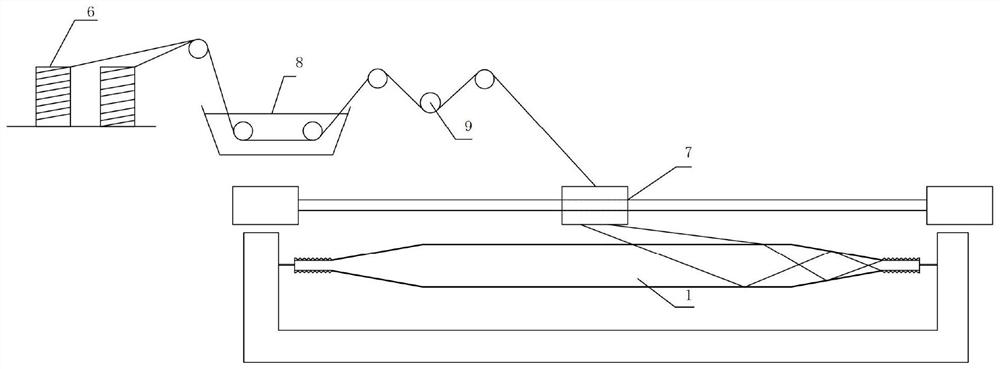

[0028] A pipe-mold integrated forming method for a fiber-reinforced composite pipe with variable cross-section, comprising the following steps: Step 1, manufacturing and installing a steel mandrel: the metal mold is made of thin-walled steel to form the inner shape of the composite pipe; Step 2, winding steel Mandrel: long fiber winding steel mandrel to form a fiber composite layup; Step 3, curing the fiber composite layup: externally install a metal outer mold to wrap the fiber composite layup as a whole, put it into a curing box for curing; step 4, mechanical processing: After curing, remove the metal outer mold and process and install it as needed.

[0029] Each step is described in further detail now;

[0030] In step 1, the steel mandrel adopts a thin-walled steel structure, and is made into an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com