Filter drier

A technology of filter drier and desiccant, which is applied in the field of pollutant control, can solve problems such as adverse effects on system performance and endanger the service life of the system, and achieve the effects of low material cost, shortened manufacturing time, and reduced size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

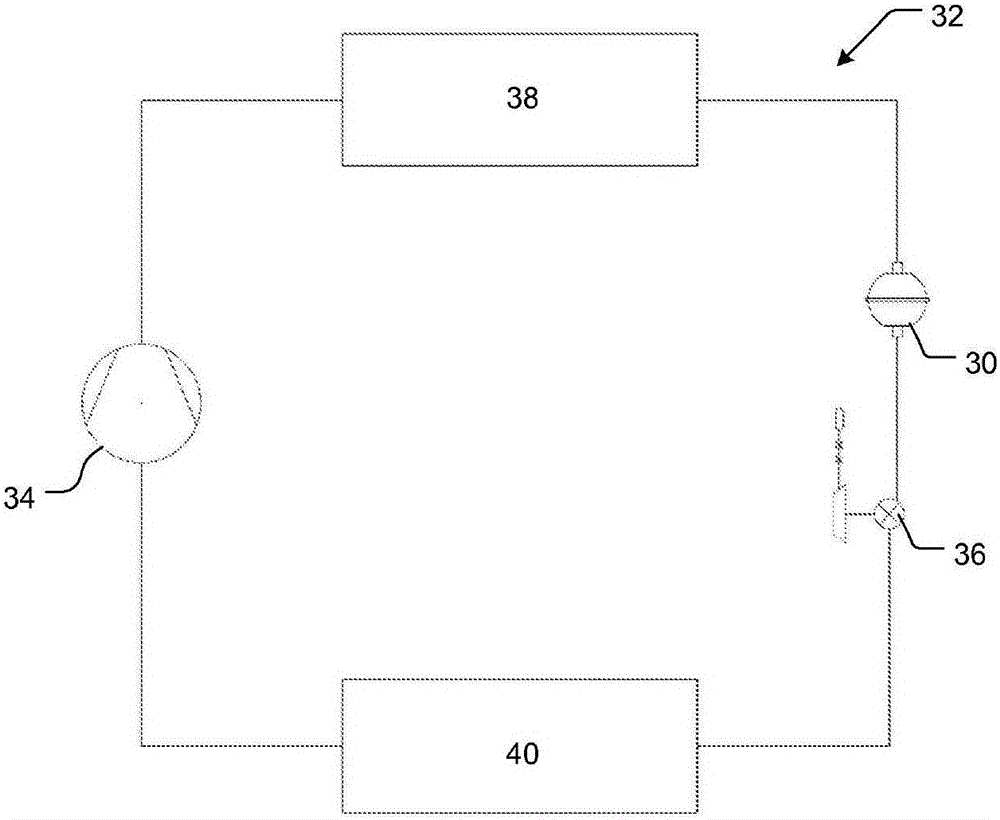

[0032] figure 2 is a schematic diagram of a spherical filter drier 30 as a component of an HVACR system 32 together with other HVACR components such as compressor 34 , expansion unit 36 , condenser 38 and evaporator 40 . This system is exemplary only and it should be understood that the filter drier can be installed as a component in a variety of HVACR systems including those with figure 2 Parts that are the same as or different from those shown.

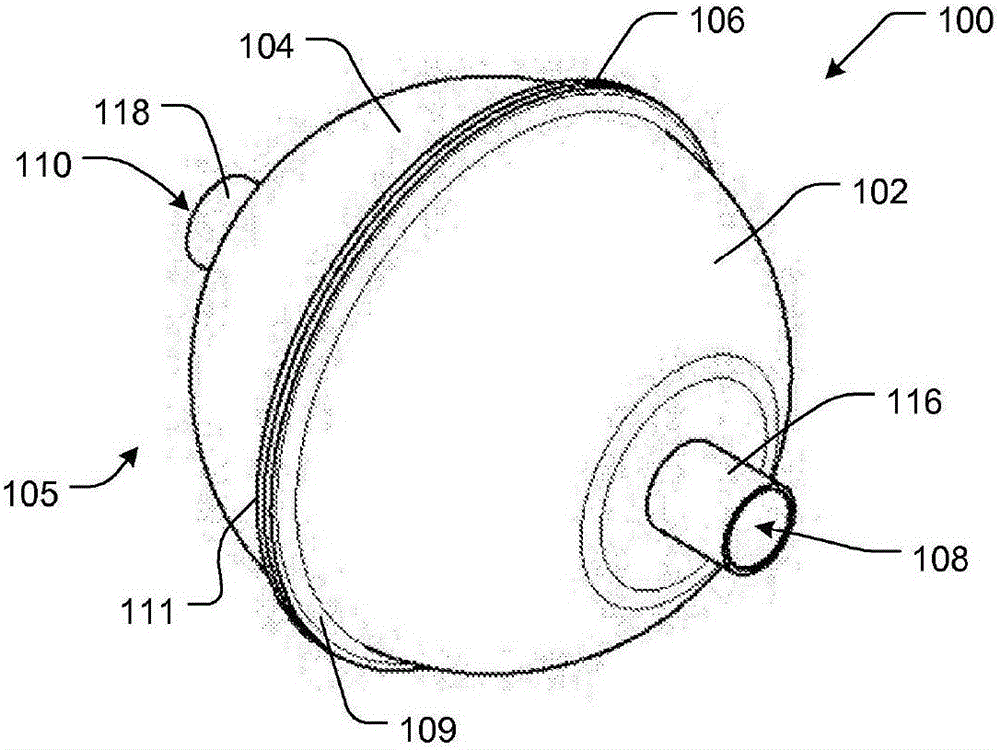

[0033] A specific embodiment of a spherical filter drier 100 is shown in Figure 3-5 middle. The filter drier is generally spherical in shape and may be formed from a pair of generally hemispherical first and second housings 102, 104 coupled to each other at a joint 106 to form a substantially spherical housing 105 having a substantially spherical cavity 107 . The two hemispherical shells may include respective flange portions 109 , 111 , which may be joined together to form the spherical shell 105 by welding, brazing or oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com