Novel flue gas white smoke removal system and method

A flue gas, a new type of technology, applied in the field of pollutant control, can solve the problem of waste of cold energy, etc., to achieve the effect of ensuring whitening, increasing the cooling range, and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

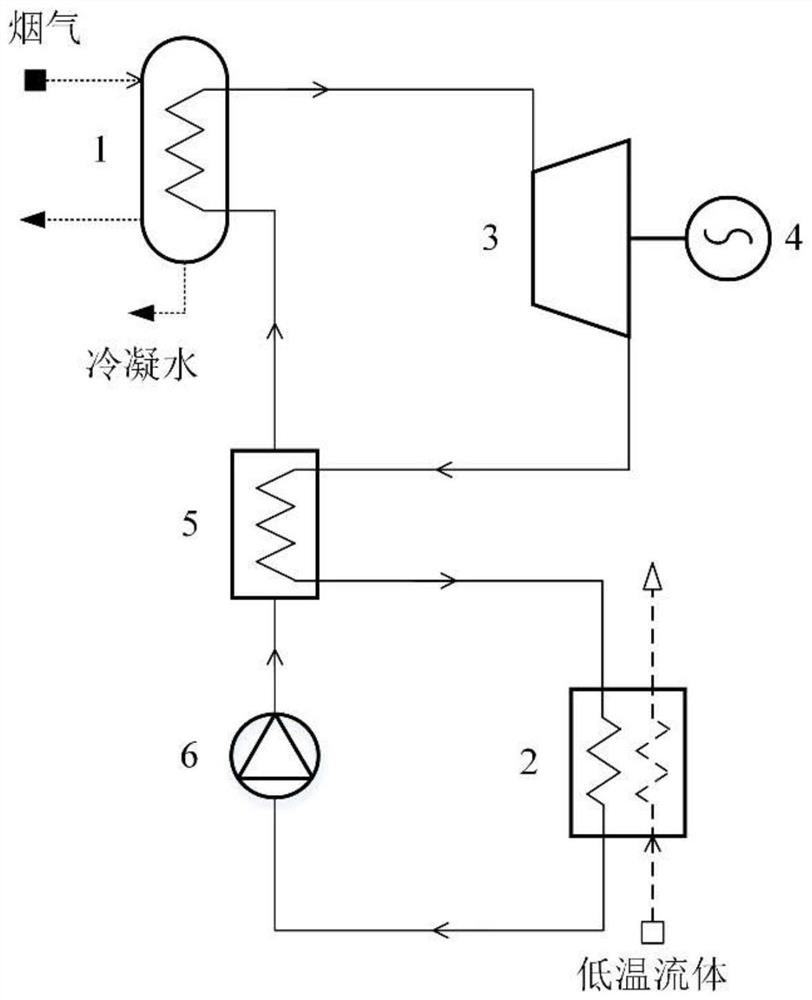

[0032] Such as figure 1 As shown, a new flue gas desipherent system provided by the present invention is composed of a flue gas cooler, a cryogenic fluidizer, a thermal-active / electro-converting subsystem. Among them, the thermal-act / electro-converter system (Example 1 uses a Langken circle) to convert the flue gas low level heat and low temperature fluid cold energy to mechanical energy or electrical energy; the flue gas cooler is reduced by lowering the flue gas temperature and moisture. Flue gas is realized, a heater, as a thermal cycle; a low temperature fluidizer is used to realize the gasification of low temperature fluids as a heat cycle.

[0033] In Example 1, the new flue gas desipherent system consists of flue gas coolers 1, a low temperature fluid gasifier 2, an expander / steam turbine 3, a generator 4, a heat generator 5, a working pump / compressor 6, and related Connection pipeline, bypass circuit, valve, temperature sensor, pressure sensor, etc. Working pump / ...

Embodiment 2

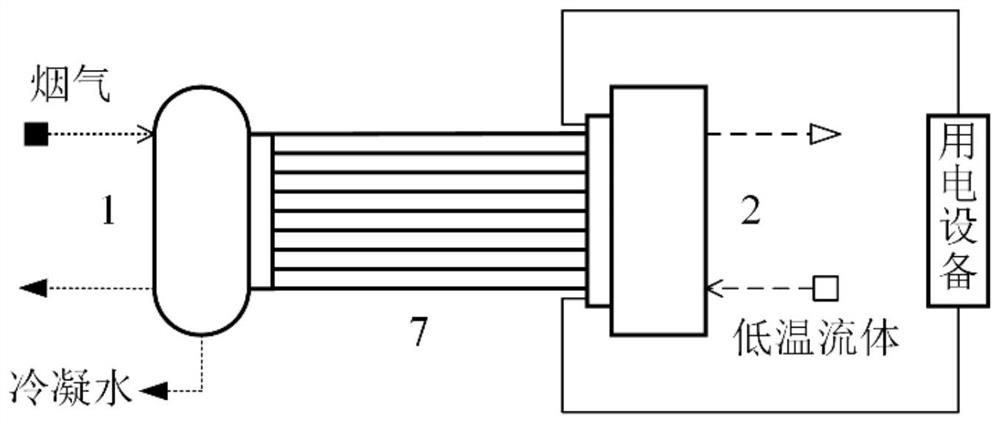

[0035] Such as figure 2 As shown, a new flue gas desipherent system provided by the present invention is composed of a flue gas cooler, a cryogenic fluidizer, a thermal-active / electro-converting subsystem. Among them, the thermal-act / electrical converter system (Example 2 uses a temperature difference generator) to directly convert the flue gas low-grade heat and low temperature fluid cold energy; the flue gas cooler is achieved by reducing flue gas temperature and moisture. Flue gas is despised, as the hot end of the temperature difference power generation equipment; the low temperature fluidizer is used to realize the gasification of the low temperature fluid, as the cold end of the temperature difference power generation equipment.

[0036] In Example 2, the new flue gas desiphery system is consisting of flue gas cooler 1, a low temperature fluidizer 2, a temperature difference generator 7, and a related connection line, a bypass circuit, a valve, a temperature sensor, a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com