A water-cooling-dewhitening device for removing condensable pollutants and recycled water in flue gas

A technology for pollutants and water recycling, applied in the direction of climate sustainability, greenhouse gas reduction, lighting and heating equipment, etc. The effect of large heat exchange area and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, the present invention will be further described in combination with the actual test of the present invention in a coal-fired power plant, but the protection scope of the present invention is not limited thereto.

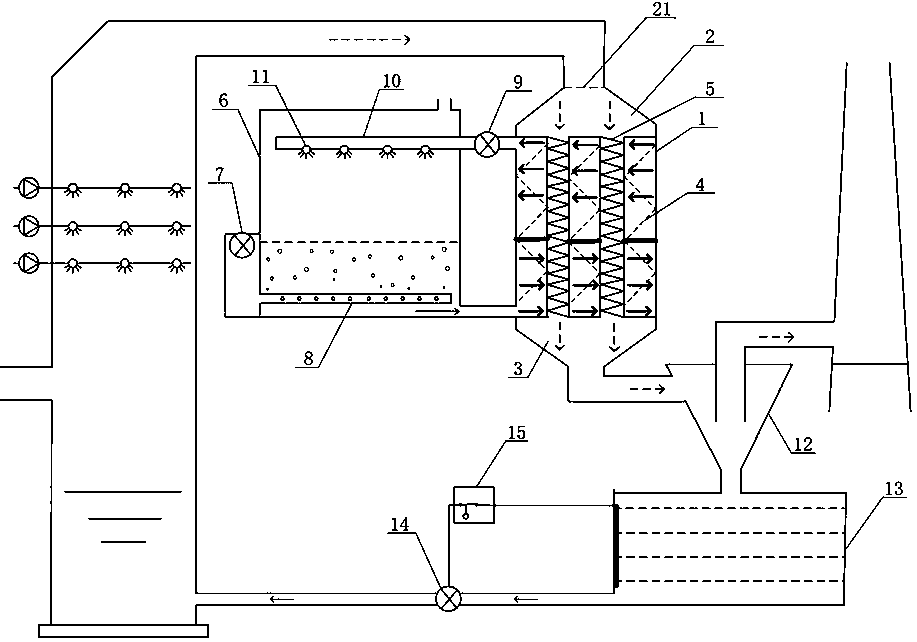

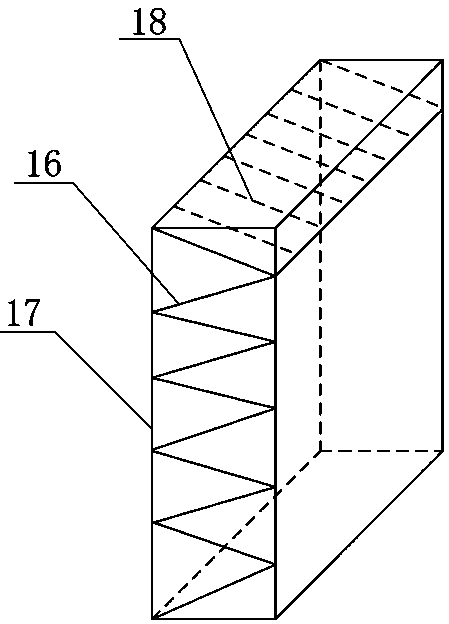

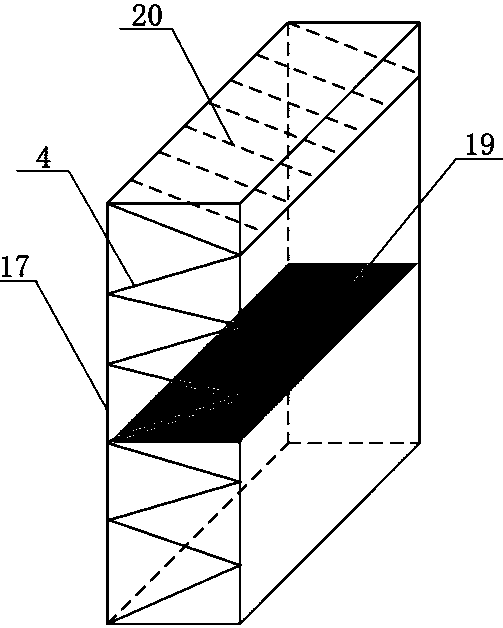

[0033] Such as figure 1 As shown, a water-cooled dewhitening device for removing condensable pollutants in flue gas and recovering water includes: a water-cooled heat exchanger 1, a flue gas inlet channel 2, a flue gas flow distribution plate 21, and a flue gas discharge channel 3 , heat exchange fins 4, broken line coalescer 5, bubble spray heat exchanger 6, fan 7, bubble spray gun 8, booster water pump 9, water mist spray gun 10, water mist nozzle 11, cyclone coalescer 12, water storage Pool 13, water pump 14, water level controller 15; single folded wires 16, heat exchange tube wall 17, parallel folded wires 18; water guide plate 19, parallel folded heat exchange fins 20.

[0034] The water-cooled heat exchanger 1 is provided with an exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com