System used for white flue gas removal and waste gas recycling

A waste heat recovery and flue gas technology, applied in the field of flue gas dewhitening, can solve the problems of reducing flue gas temperature and dewhitening, and achieve the effect of reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

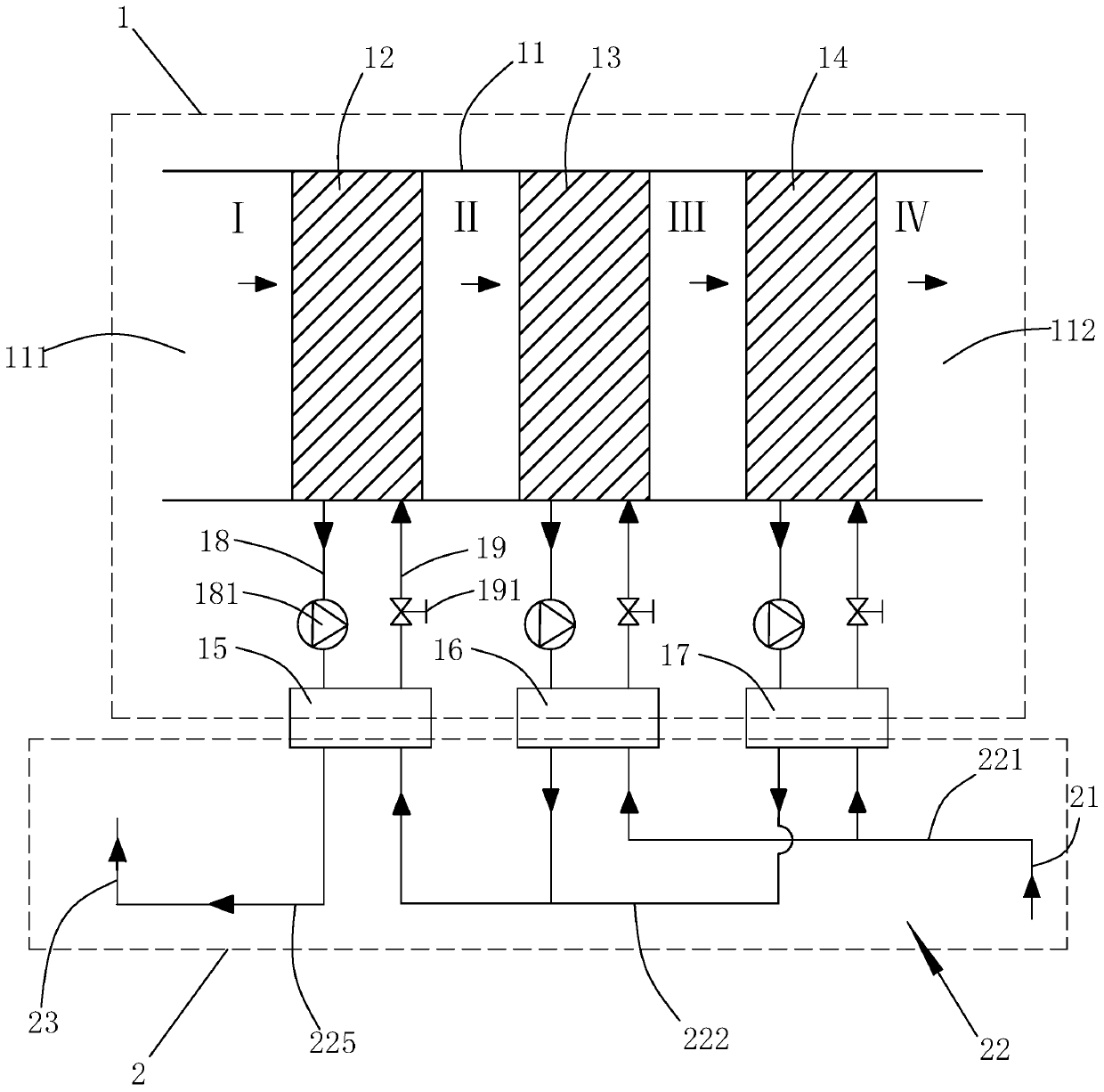

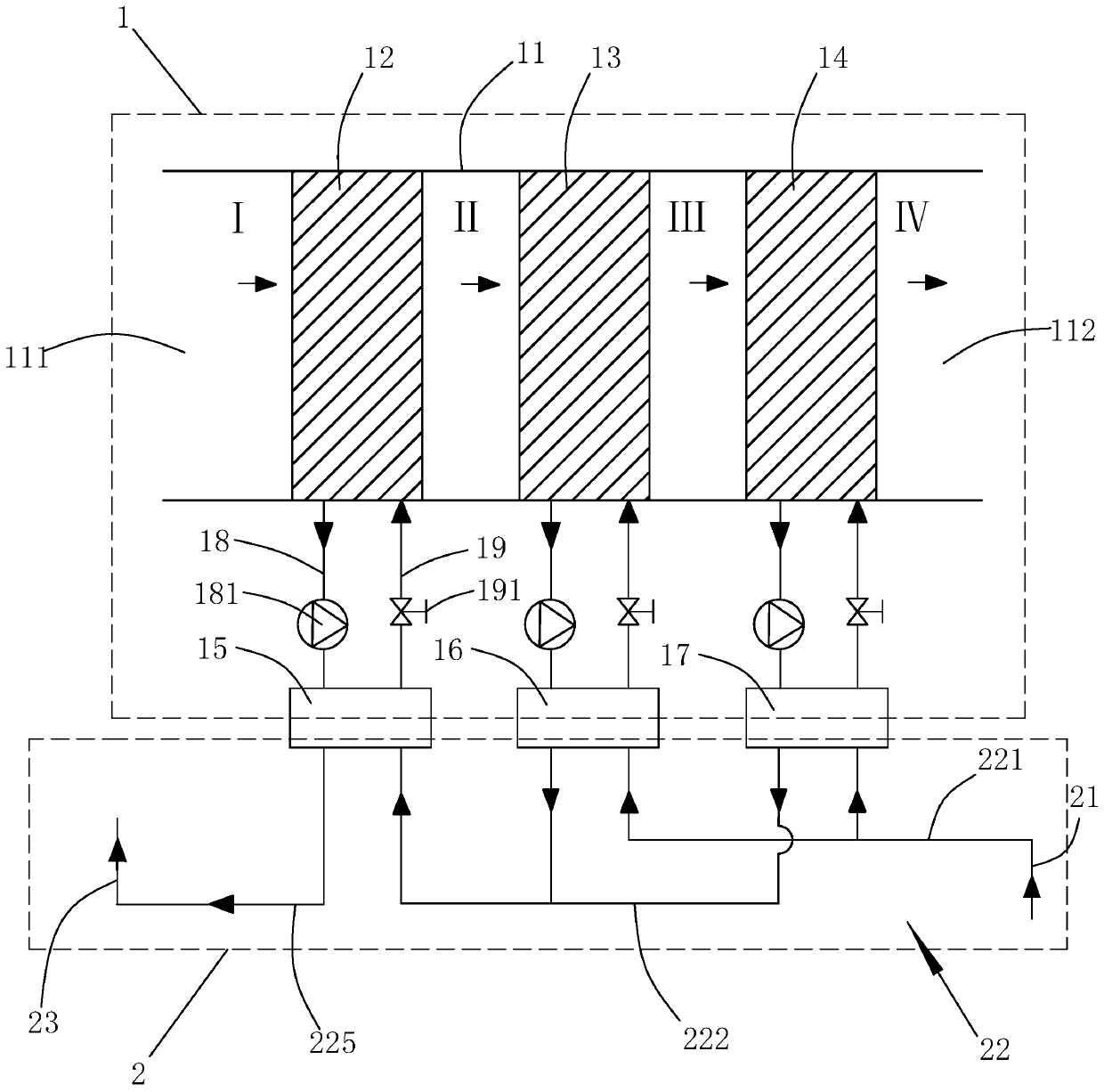

[0024] A system for flue gas dewhitening and waste heat recovery, refer to figure 1 , including a flue gas dewhitening device and a waste heat recovery device, the flue gas dewhitening device includes a flue gas duct and a water-cooled air-conditioning heat pump unit, and the air-conditioning heat pump unit is composed of at least three heat pump air conditioners.

[0025] A heat pump air conditioner includes an evaporator, a condenser, and a refrigerant circulation circuit connected between the evaporator and the condenser. The refrigerant circulation circuit includes a return air pipe connected between the refrigerant outlet of the evaporator and the refrigerant inlet of the condenser, a compressor installed on the return air pipe, an outlet pipe connected between the refrigerant outlet of the condenser and the refrigerant inlet of the evaporator The liquid pipe and the expansion valve installed on the liquid outlet pipe. When the heat pump air conditioner is working, the r...

Embodiment 2

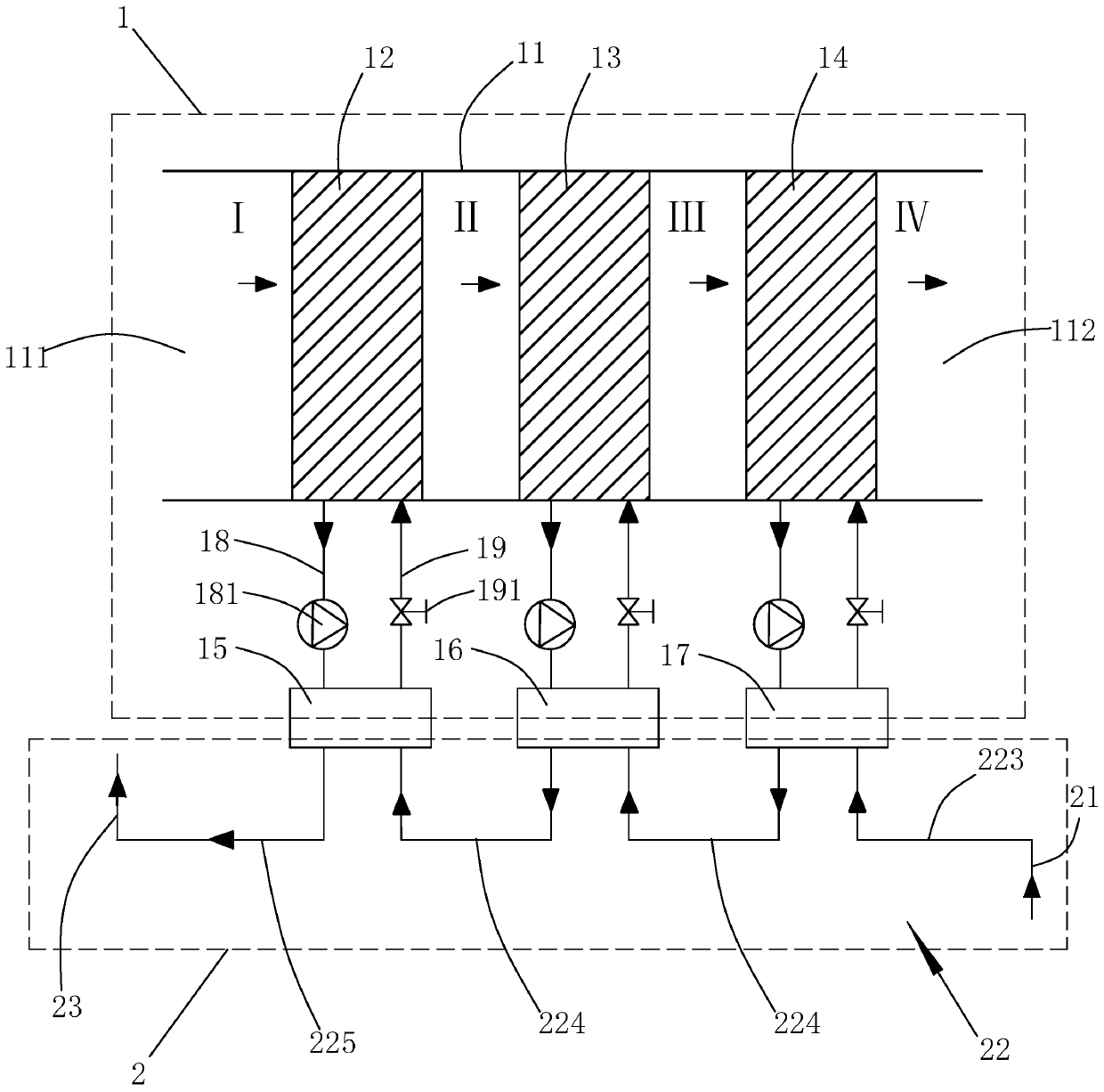

[0033] The difference between this embodiment and Embodiment 1 is that, referring to figure 2 , the waste heat recovery device includes a water inlet pipe connected and communicated with the municipal heating heating return pipe, a waste heat recovery pipeline connected to the outlet end of the water inlet pipe, and an outlet pipe connected and communicated with the municipal heating outlet pipe at the water outlet end, and the inlet pipe of the outlet pipe The water end is connected and communicated with the drain port of condenser A.

[0034] The waste heat recovery pipeline includes the water inlet connecting pipe connecting the water inlet of the C condenser and the water inlet pipe outlet, several waste heat recovery connecting pipes connecting the A condenser, each B condenser and the C condenser in series, and connecting the A condenser. The drain connection pipe between the drain outlet and the water inlet end of the outlet pipe.

[0035] When in use, municipal heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com