Gas boiler flue gas moisture removal treatment system for municipal sludge drying incineration treatment

A technology for municipal sludge and gas-fired boilers, used in gas treatment, chemical instruments and methods, dispersed particle separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

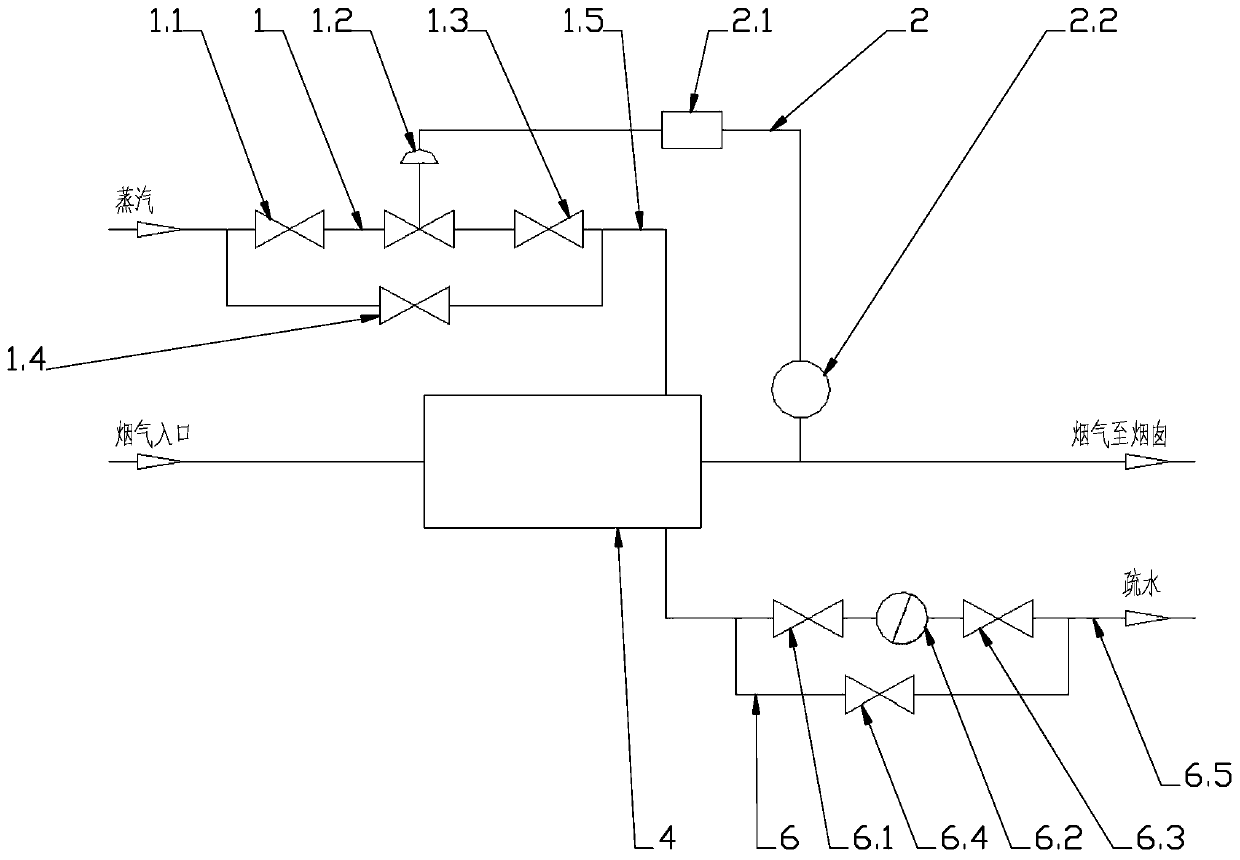

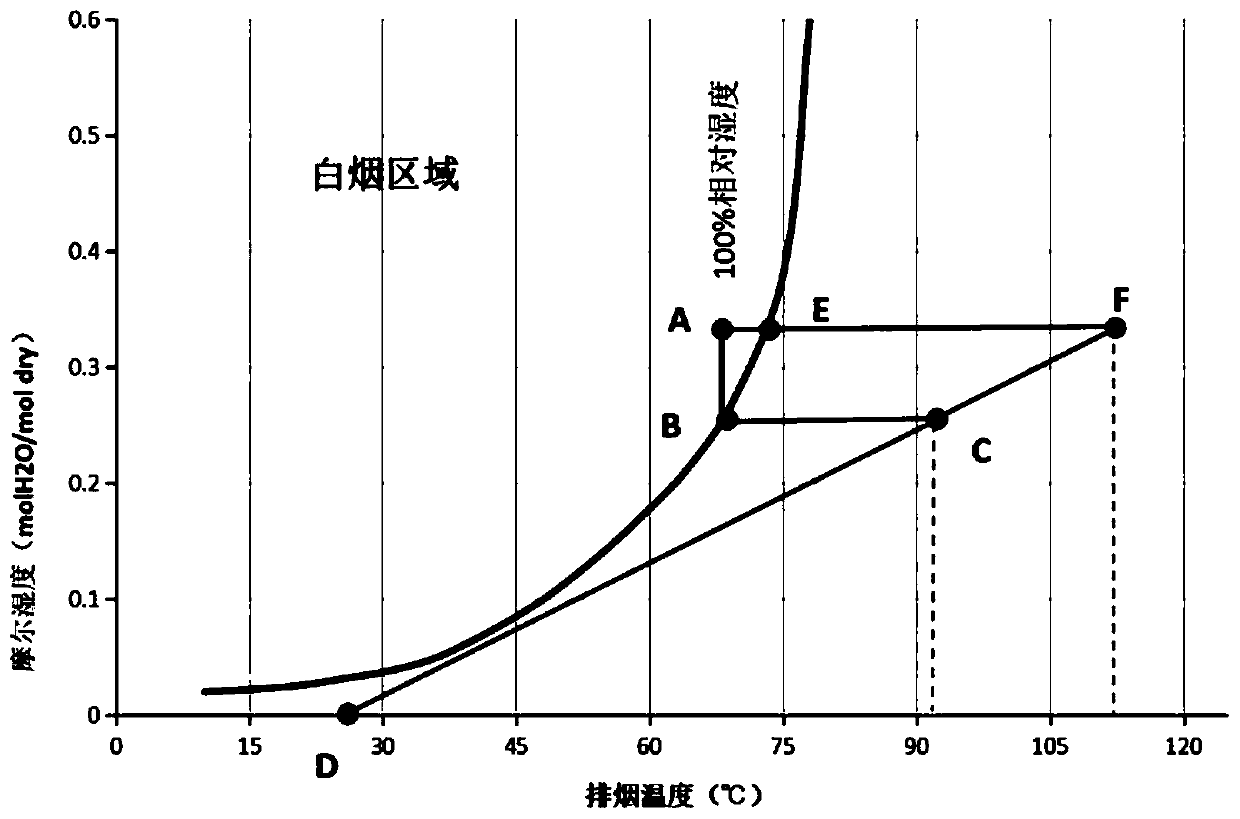

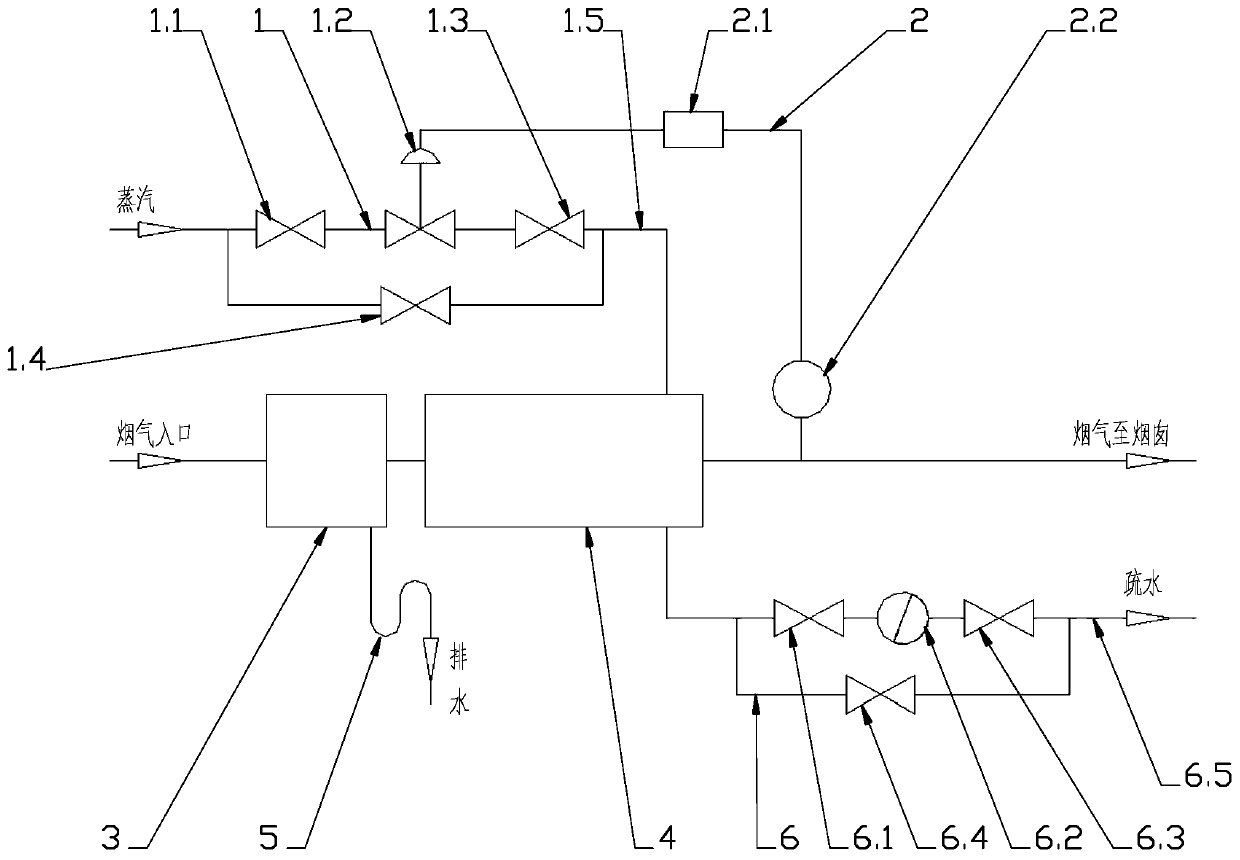

[0016] figure 1 , figure 2 It is a structural schematic diagram of the first implementation of the present invention. in figure 1 The schematic diagram of the overall structure, figure 2 It is the schematic diagram of flue gas whitening (relationship diagram between exhaust gas temperature and flue gas molar humidity). The figure shows that in this example, a gas-fired boiler flue gas dewhitening treatment system for municipal sludge drying and incineration treatment includes a steam system 1 and a flue gas-steam heat exchanger 4 arranged at the chimney inlet, and also includes a set The drainage system 6 after the flue gas-steam heat exchanger 4 is characterized in that an automatic smoke temperature adjustment device 2 with PID adjustment is also installed, and the automatic smoke temperature adjustment device 2 with PID adjustment includes a TIC temperature measurement display thermocouple 2.2 And the intelligent control module 2.1, the TIC temperature measurement sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com