Energy-saving and environment-friendly coal gasification solid waste treatment device and treatment method

An energy-saving, environmental-friendly, processing device technology, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve problems such as visual pollution, high moisture content of gasification ash, and high drying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

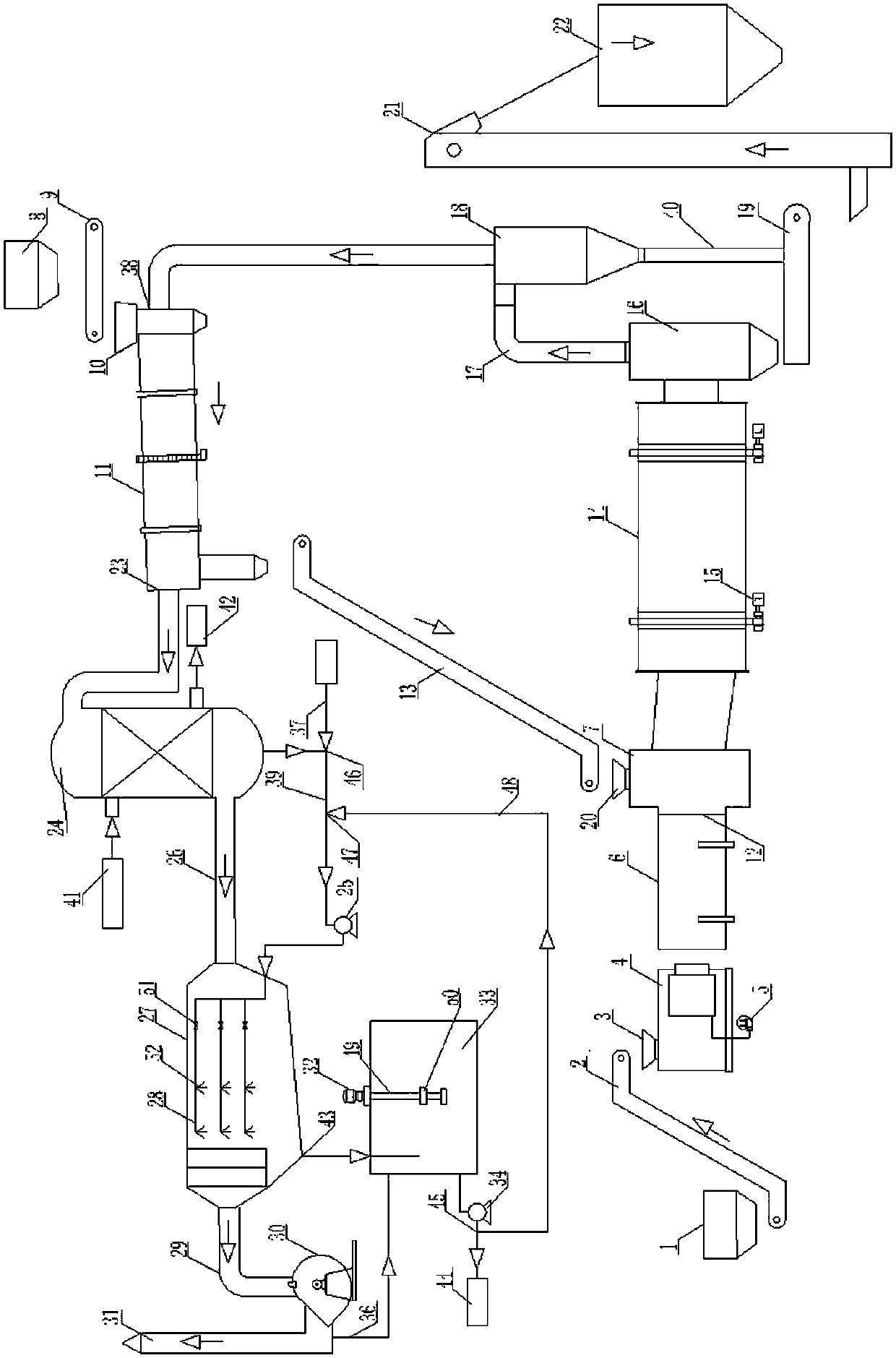

[0048]An energy-saving and environment-friendly coal gasification solid waste treatment device, comprising a coal gasification solid waste drying unit connected to a high-temperature tail gas supply unit, and the coal gasification solid waste drying unit is connected to a tail gas discharge chimney 31 through a tail gas treatment unit; the high-temperature tail gas The supply unit includes a biomass burner 4 with a burner blower 5, the burner inlet 3 of the biomass burner 4 is connected to the fuel bin 1 through a fuel weighing belt conveyor 2, and the exhaust gas outlet of the biomass burner 4 passes through a hot blast stove 6 It is connected to the tail gas inlet 12 on the side of the feeding device 7 of the secondary three-pass dryer; the coal gasification solid waste drying unit includes a primary single cylinder dryer 11 and a discharge port connected to the primary single cylinder dryer 11 Connected secondary three-pass dryer 14, a secondary three-pass dryer feeding devi...

Embodiment 2

[0059]An energy-saving and environment-friendly coal gasification solid waste treatment device, comprising a coal gasification solid waste drying unit connected to a high-temperature tail gas supply unit, and the coal gasification solid waste drying unit is connected to a tail gas discharge chimney 31 through a tail gas treatment unit; the high-temperature tail gas The supply unit includes a biomass burner 4 with a burner blower 5, the burner inlet 3 of the biomass burner 4 is connected to the fuel bin 1 through a fuel weighing belt conveyor 2, and the exhaust gas outlet of the biomass burner 4 passes through a hot blast stove 6 It is connected to the tail gas inlet 12 on the side of the feeding device 7 of the secondary three-pass dryer; the coal gasification solid waste drying unit includes a primary single cylinder dryer 11 and a discharge port connected to the primary single cylinder dryer 11 Connected secondary three-pass dryer 14, a secondary three-pass dryer feeding devi...

Embodiment 3

[0069]An energy-saving and environment-friendly coal gasification solid waste treatment device, comprising a coal gasification solid waste drying unit connected to a high-temperature tail gas supply unit, and the coal gasification solid waste drying unit is connected to a tail gas discharge chimney 31 through a tail gas treatment unit; the high-temperature tail gas The supply unit includes a biomass burner 4 with a burner blower 5, the burner inlet 3 of the biomass burner 4 is connected to the fuel bin 1 through a fuel weighing belt conveyor 2, and the exhaust gas outlet of the biomass burner 4 passes through a hot blast stove 6 It is connected to the tail gas inlet 12 on the side of the feeding device 7 of the secondary three-pass dryer; the coal gasification solid waste drying unit includes a primary single cylinder dryer 11 and a discharge port connected to the primary single cylinder dryer 11 Connected secondary three-pass dryer 14, a secondary three-pass dryer feeding devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com