Ultralow-temperature-resistant disinfectant

A disinfectant and ultra-low temperature technology, applied in the direction of disinfectant, animal repellent, botanical equipment and methods, etc., can solve the problems of disinfectant freezing and disinfectant failure, achieve long-lasting antibacterial ability, excellent antibacterial effect, improve The effect of adaptive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-10

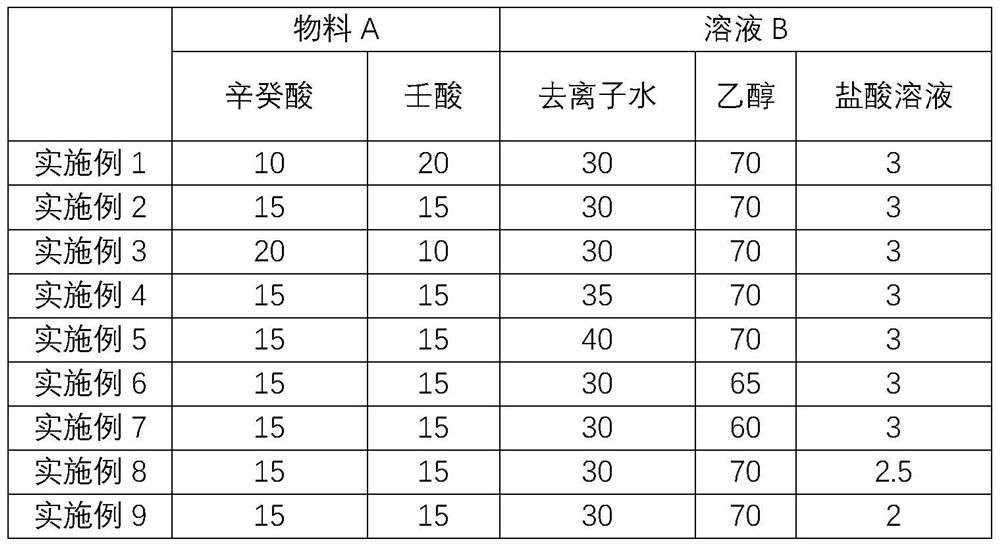

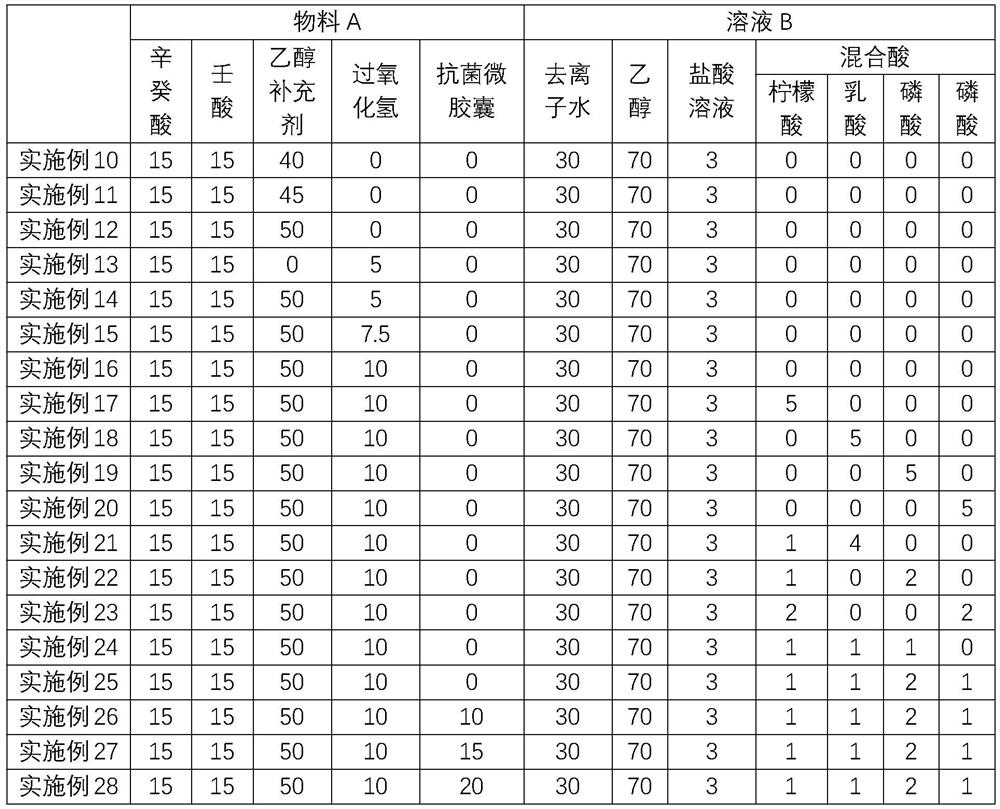

[0032] Preparation examples 1-10 are preparation examples of ethanol supplements, the main difference is that the types and proportions of raw materials used in ethanol supplements are different, as shown in Table 1 for details.

[0033] And, when the raw material of ethanol supplement does not contain carbonate (preparation example 1-5), the preparation method of ethanol supplement comprises the following steps:

[0034] Add the calcium acetate solution into the alcohol in proportion, and stir at a stirring speed of 60r / min for 20min to obtain a gel-like solid ethanol supplement.

[0035] When containing carbonate (preparation example 6-10) in the raw material of ethanol supplement, the preparation method of ethanol supplement comprises the following steps:

[0036] Add the carbonate to the alcohol in proportion, then add the calcium acetate solution, stir at a stirring speed of 60r / min for 20min, and obtain a gel-like solid ethanol supplement.

[0037] Each raw material com...

preparation example 11

[0041] Preparation Example 11 is a preparation example of antibacterial microcapsules. The preparation method of antibacterial microcapsules specifically comprises the following steps:

[0042] Step 1: Prepare 10 kg of 15% (w / v) saturated aqueous solution of β-cyclodextrin, and place the solution in a constant temperature water bath at 60° C. and stir at a stirring speed of 100 r / min for 2 hours. Then add 0.3kg of black pepper essential oil to the saturated aqueous solution of β-cyclodextrin, and continue to stir at the same stirring speed for 2 hours. After the stirring is completed, put it in a refrigerator at 4°C until it completely precipitates, and filter the precipitate , to obtain a wet capsule, and finally vacuum-dried at 40° C. for 2 hours to obtain the finished black pepper essential oil cyclodextrin inclusion compound powder.

[0043] Step 2: Calcium chloride is dissolved in water to prepare the calcium chloride aqueous solution that concentration is respectively 6...

preparation example 12

[0049] Preparation example 12 is the antibacterial microcapsule after pretreatment, and the difference between preparation example 12 and preparation example 11 is that the pretreatment method of antibacterial microcapsule comprises the following steps:

[0050] Step 1: Soak the antibacterial microcapsules in 30% (w / v) sodium bicarbonate solution for 20 minutes, then take them out and dry them at 37°C and 0.1MPa for 12 hours;

[0051] Step 2: prepare 8% (w / v) alkylsulfonate ethanol hot solution, the solution temperature is controlled as 50°C, then the alkylsulfonate ethanol hot solution is sprayed onto the antibacterial microcapsule surface, and at 37°C, Drying under the condition of 0.1MPa for 12 hours can obtain the pretreated antibacterial microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com