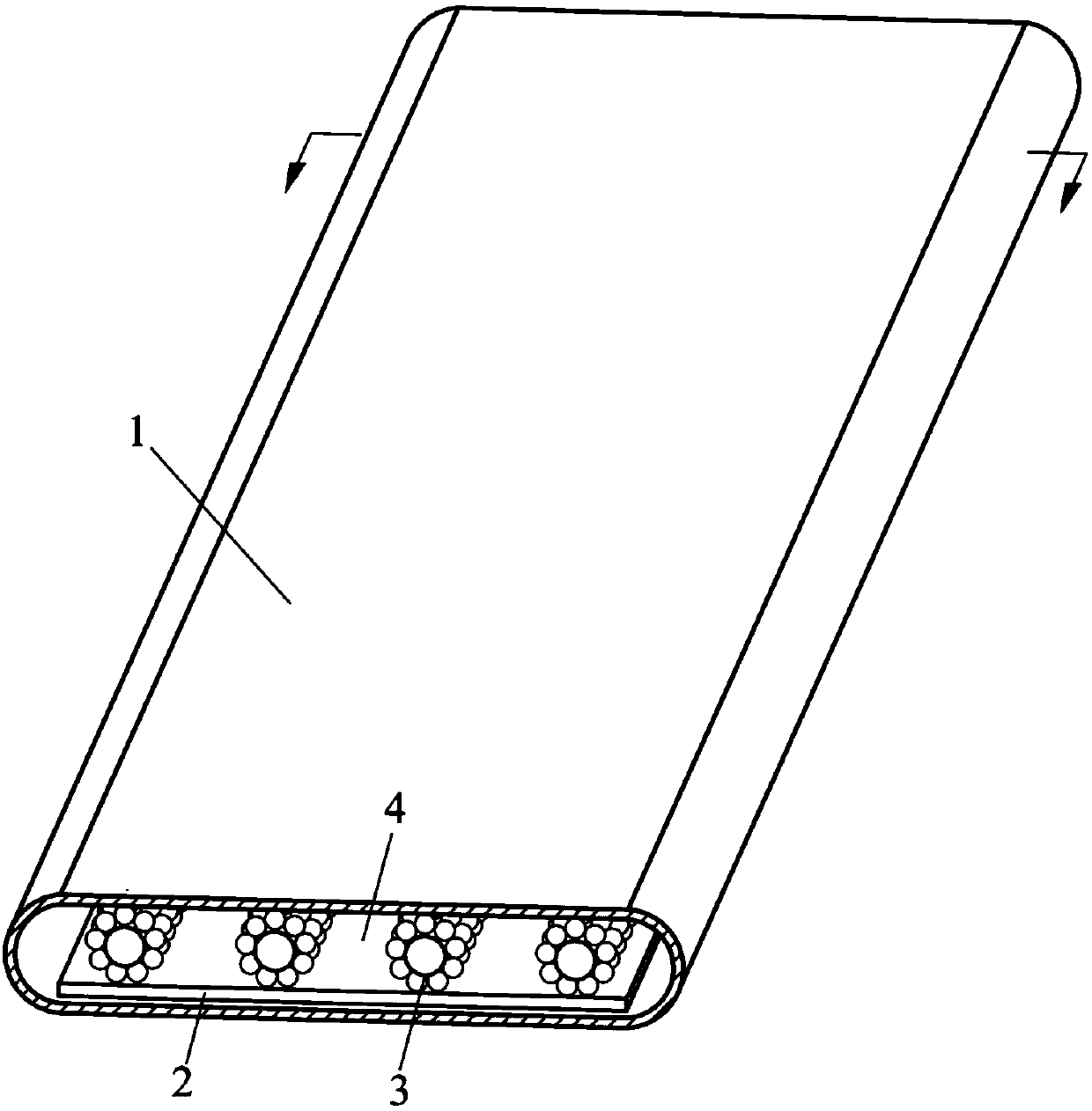

A kind of ultra-thin flat heat pipe and its manufacturing method

A technology of flat heat pipes and manufacturing methods, applied in the field of heat pipes, can solve problems such as high channel depth and width requirements, poor anti-gravity operation effect, and easy heat transfer limit, so as to speed up condensation speed, improve efficiency, and improve heat transfer. The effect of thermal extremes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] An ultra-thin flat heat pipe, the manufacturing method is as follows:

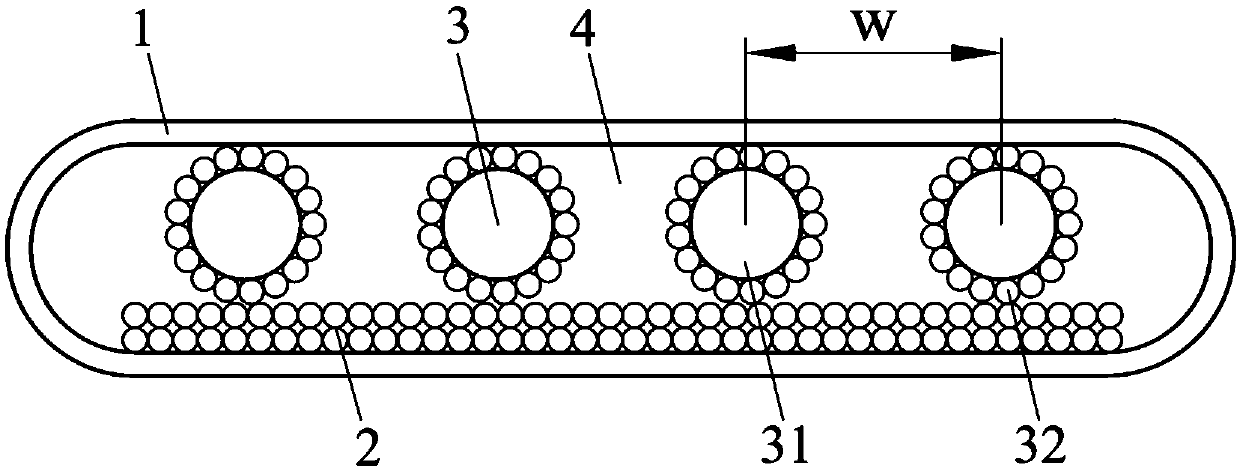

[0072] Step 1, material preparation: cutting the metal sheet 11 and the metal wire 31 of predetermined size, both of which are made of T2 copper. Metal sheet 11 looks like Figure 5 As shown, the length is 200.0mm, the width is 63.0mm, and the thickness is 0.20mm, and it is treated with degreasing and deoxidizing film. The outer diameter of the wire 31 is 0.50 mm.

[0073] Step 2, sintering the bottom layer of the porous medium 2: as Figure 6 As shown, a layer of porous medium bottom layer 2 with a thickness of 0.20 mm is sintered on the left half surface of the metal sheet 11. The specific operation is to fill spherical copper powder with an average particle size of 82.8 μm into the rectangular groove in the graphite mold , control the thickness of the copper powder, press the graphite mold containing the copper powder on the specified position of the metal sheet 11, so that the four side edges...

Embodiment 2

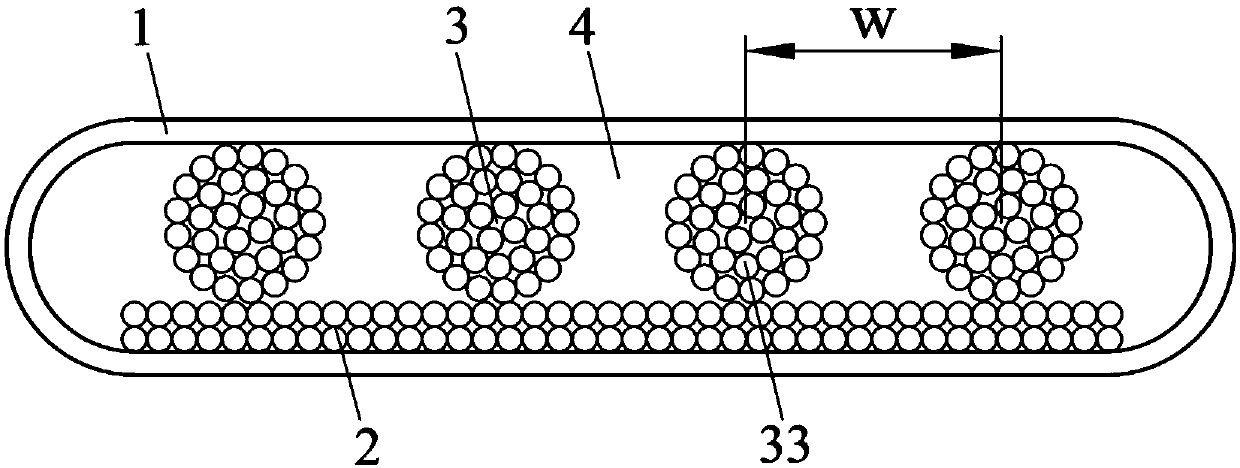

[0079] An ultra-thin flat heat pipe, the manufacturing method is as follows:

[0080] Step one to step four are the same as embodiment 1.

[0081] Step 5: performing superhydrophilic modification treatment on the porous medium bottom layer 2 and porous medium filament 3, and superhydrophobic modification treatment on the condensation surface of the condensation section. The specific modification method is as follows: using the method of chemical oxidation, the porous medium bottom layer 2 and the porous medium filament 3 are subjected to super-hydrophilic treatment, that is, the heat pipe semi-finished product obtained in step 4, only the half side containing the liquid-absorbing core is heated at a temperature of 70 ° C. , immersed in 2.5mol / L KOH and 0.065mol / L K 2 S 2 o 8 reacted in the mixed solution of 30min, so that the contact angle of the metal surface of the liquid-absorbent core is close to 0°. Using the self-assembly method, the condensing surface of the condens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com