Paste filling cementing material and paste filling slurry

A paste filling and cementing material technology, which is applied in the field of paste filling cementing materials and paste filling slurry, can solve the problems of low early strength, high cost and energy consumption, and poor slurry fluidity of paste filling materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

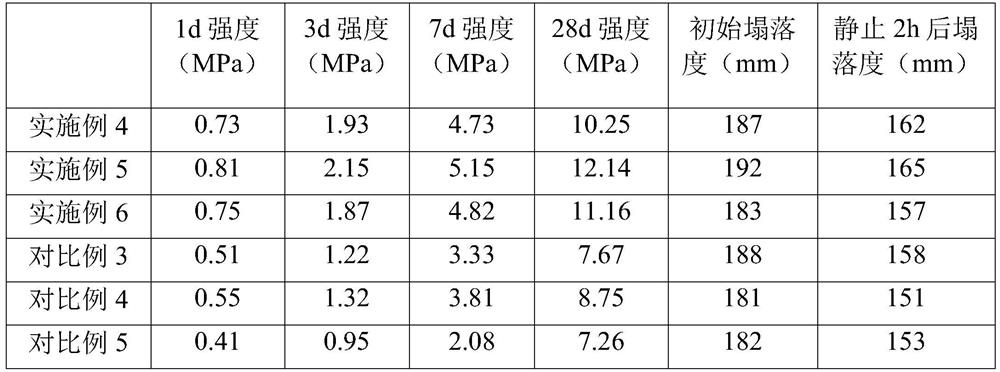

Examples

Embodiment 1

[0045] The embodiment of the present invention provides a paste filling cementing material, which includes the following components in terms of mass percentage: high alite Portland cement clinker: 55%, steel slag: 34.5%, nano-SiO 2 : 5%, Nano CaCO 3 : 2%, modified gypsum 2% and compound admixture 0.5%.

[0046] The above composite additives are naphthalenesulfonate, sodium carbonate and calcium hydroxide in a mass ratio of 5:2:2.

[0047] The preparation method of above-mentioned high alite Portland cement clinker comprises the following steps:

[0048] Each component was weighed according to the following proportions: 78% limestone raw material, 8% lead-zinc tailings, 11% shale and 3% slag;

[0049] The components are crushed, ground, and mixed uniformly to obtain raw meal;

[0050] After being preheated by a suspension preheater, the above-mentioned raw meal is sent to a cement kiln for calcination until it is partially melted. The calcination temperature is 1400°C-1450°C...

Embodiment 2

[0057] The embodiment of the present invention provides a paste filling cementing material, which includes the following components in terms of mass percentage: high alite Portland cement clinker: 60%, steel slag: 30%, nano-SiO 2 : 3%, Nano CaCO 3 : 3%, modified gypsum 3.8% and compound admixture 0.2%.

[0058] The above-mentioned composite admixture includes naphthalenesulfonate, sodium carbonate and calcium hydroxide in a mass ratio of 6:3:3.

[0059] The preparation method of above-mentioned high alite Portland cement clinker comprises the following steps:

[0060] Each component is weighed according to the following ratio: 87% of limestone raw material, 6% of lead-zinc tailings, 4% of shale and 3% of slag;

[0061] The components are crushed, ground, and mixed uniformly to obtain raw meal;

[0062] After being preheated by the suspension preheater, the above-mentioned raw meal is sent to the cement kiln for calcination until it is partially melted, the calcination tempe...

Embodiment 3

[0069] The embodiment of the present invention provides a paste filling cementing material, which includes the following components in terms of mass percentage: high alite Portland cement clinker: 64.9%, steel slag: 25%, nano-SiO 2 : 2%, Nano CaCO 3 : 2%, modified gypsum 6% and compound admixture 0.1%.

[0070] The above-mentioned composite admixture includes naphthalenesulfonate, sodium carbonate and calcium hydroxide in a mass ratio of 5:1:1.

[0071] The preparation method of above-mentioned high alite Portland cement clinker comprises the following steps:

[0072] Weigh each component according to the following proportions: 80% limestone raw material, 15% lead-zinc tailings, 2% shale and 3% slag;

[0073] The components are crushed, ground, and mixed uniformly to obtain raw meal;

[0074] After being preheated by the suspension preheater, the above raw meal is sent to the cement kiln for calcination until it is partially melted, the calcination temperature is 1450°C-150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com