Sugar-coated haw extruding device for food processing

A technology of candied haws and extrusion devices, which is applied in the confectionary industry, confectionery, applications, etc., and can solve the problems of heavy workload and low efficiency of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

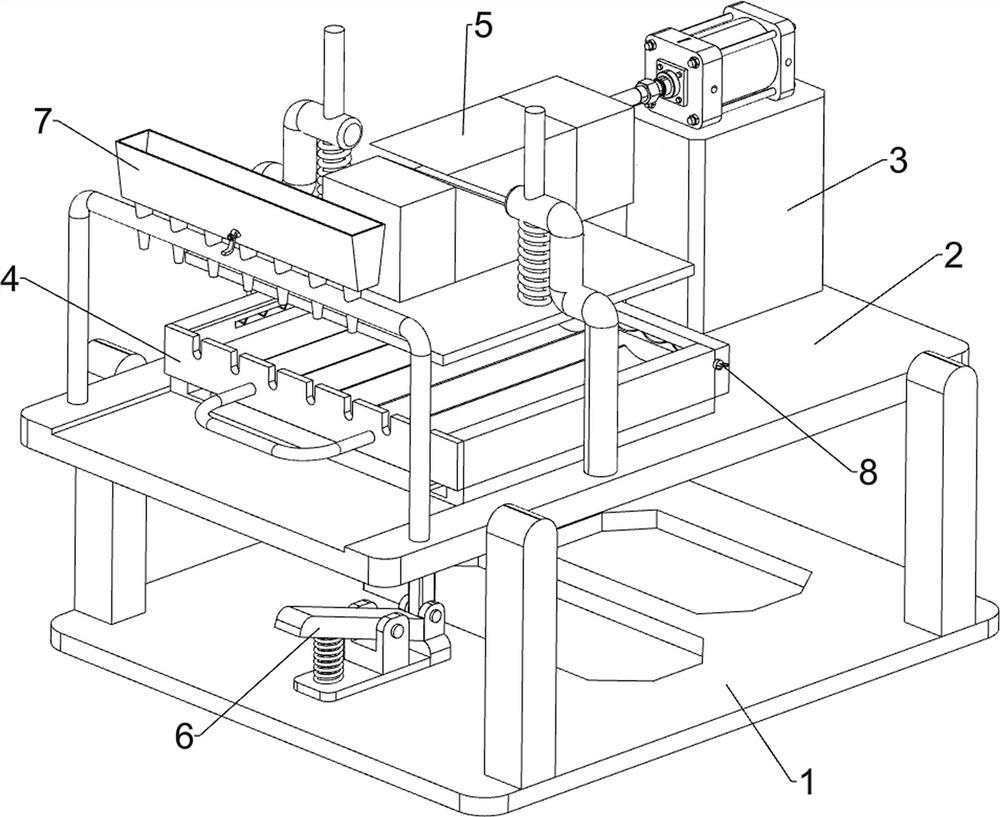

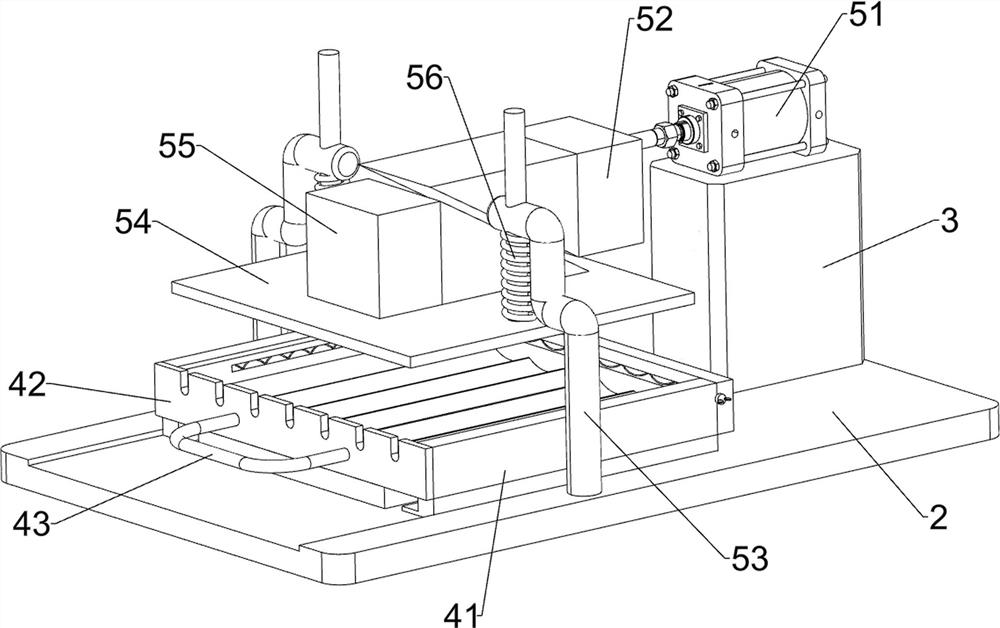

[0026] A kind of candied haws extruding device for food processing, such as figure 1 and figure 2 As shown, it includes a base plate 1, an operation table 2, a support plate 3, a material discharge assembly 4 and a pressing assembly 5. The top of the base plate 1 is connected to the operation table 2, and the back side of the top of the operation table 2 is connected to the support plate 3. The operation table 2 A discharging assembly 4 is connected to the top, and a pressing assembly 5 is connected between the console 2 and the support plate 3 .

[0027] The discharge assembly 4 includes a guide frame 41, a discharge basket 42 and a handle 43, the console 2 is connected with a guide frame 41, the guide frame 41 is slidably connected with a discharge basket 42, and the front side of the discharge basket 42 is connected with a handle43.

[0028] The pressing assembly 5 includes a cylinder 51, a push block 52, a fixed rod 53, a lower pressing plate 54, a wedge block 55 and a ...

Embodiment 2

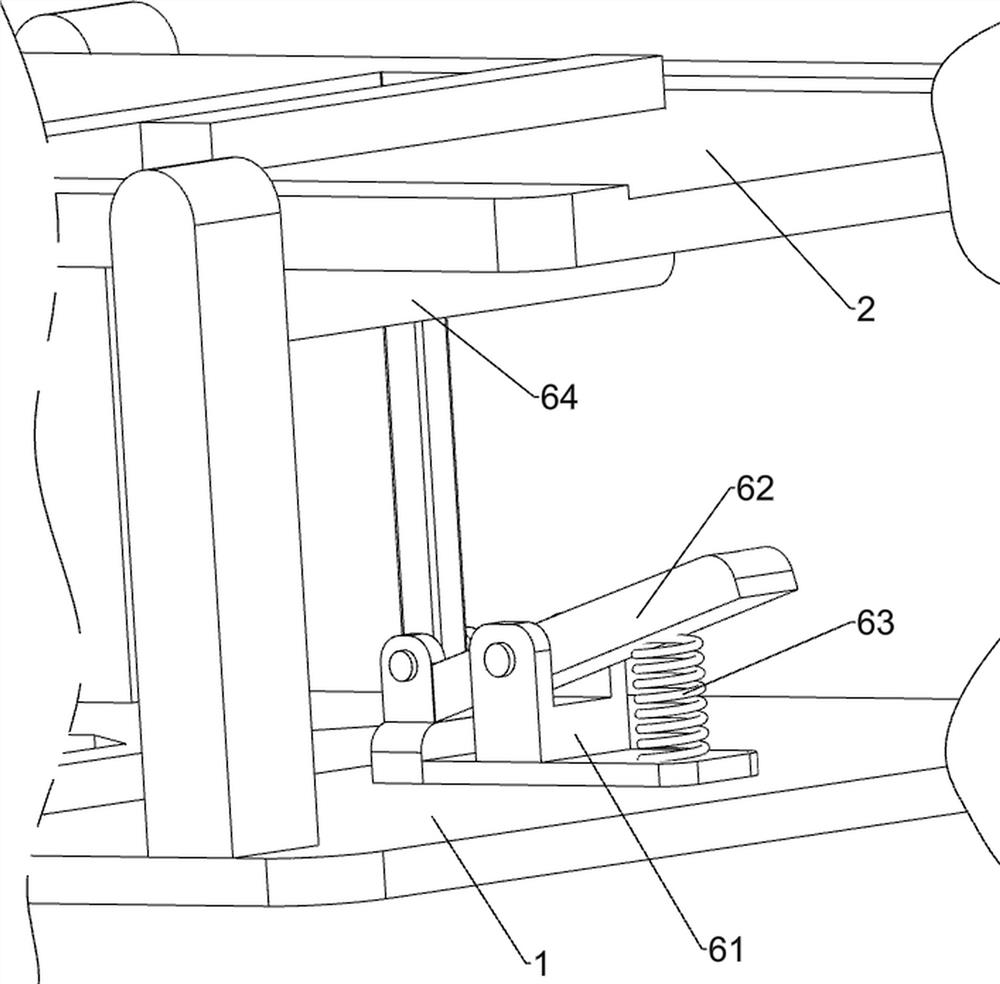

[0031] On the basis of Example 1, such as image 3 As shown, the extruding assembly 6 is also included, and the extruding assembly 6 includes a supporting plate 61, a pedal 62, a connecting spring 63, and an extruding block 64. A pedal 62 is connected to the ground, a connecting spring 63 is connected between the supporting plate 61 and the pedal 62, and an extruding block 64 is slidably connected to the operating table 2. The extruding block 64 is located at the bottom of the discharge basket 42, and the extruding block 64 and The pedals 62 are rotatably connected.

[0032] After finishing the extruding work, step on one end of the pedal 62 manually to make the extruding block 64 slide on the operating table 2, so as to push the discharge basket 42, so that the adhesive force of the syrup to the discharge basket 42 is reduced, so that the operation It is better for the personnel to take out the work later, which is convenient for the operator to collect later, and further im...

Embodiment 3

[0034] On the basis of Example 2, such as Figure 4 As shown, a blanking assembly 7 is also included. The blanking assembly 7 includes a support rod 71, a charging basket 72, and a handle 73. 72. The charging basket 72 is located at the front side of the discharging basket 42, and the front side of the charging basket 72 is connected with a handle 73.

[0035] Place the syrup in the loading basket 72, and the operator pulls out the discharging basket 42, puts the candied haws on and manually controls the handle 73, so that the syrup flows from the loading basket 72 to the surface of the candied haws, and when the syrup on the candied haws reaches a certain amount, close the The handle 73 is all that is needed. Repeating the above operations in this way facilitates the operation process of the operator, makes the operation process of the equipment easier and easier to use, thereby improving work efficiency.

[0036] Such as figure 1 As shown, a heating wire 8 is also included...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com