Lid mold structure with grill and diversion control device

A technology of diversion control and grille, used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of low mold accuracy, affecting product quality, and poor exhaust, and achieve effective and smooth exhaust, increase Product fastness, the effect of reducing pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] The labeling in each accompanying drawing represents as follows:

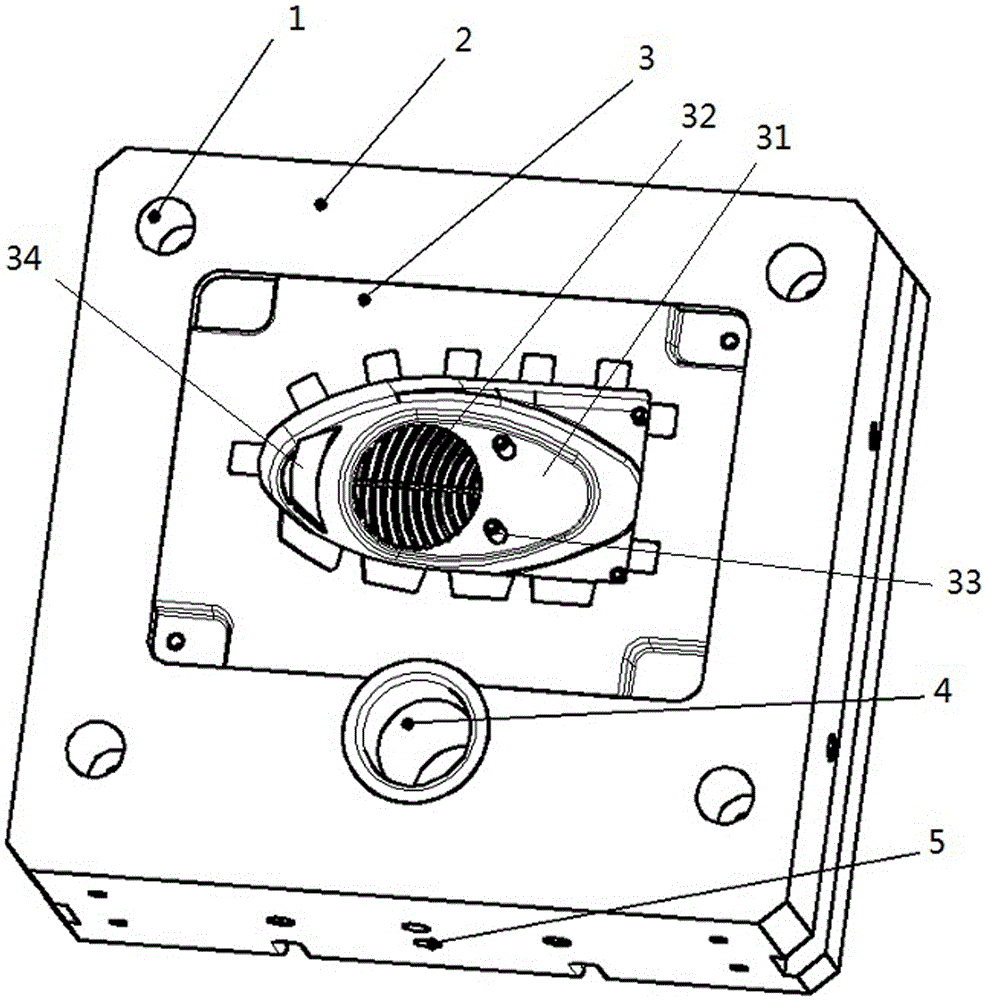

[0014] 1 guide sleeve, 2 fixed mold frame, 4 sprue sleeve, 5 cooling water circuit;

[0015] 3 fixed mold core, 31 forming groove, 32 circular heat dissipation grill, 33 diversion control module, 34 condensation control cavity;

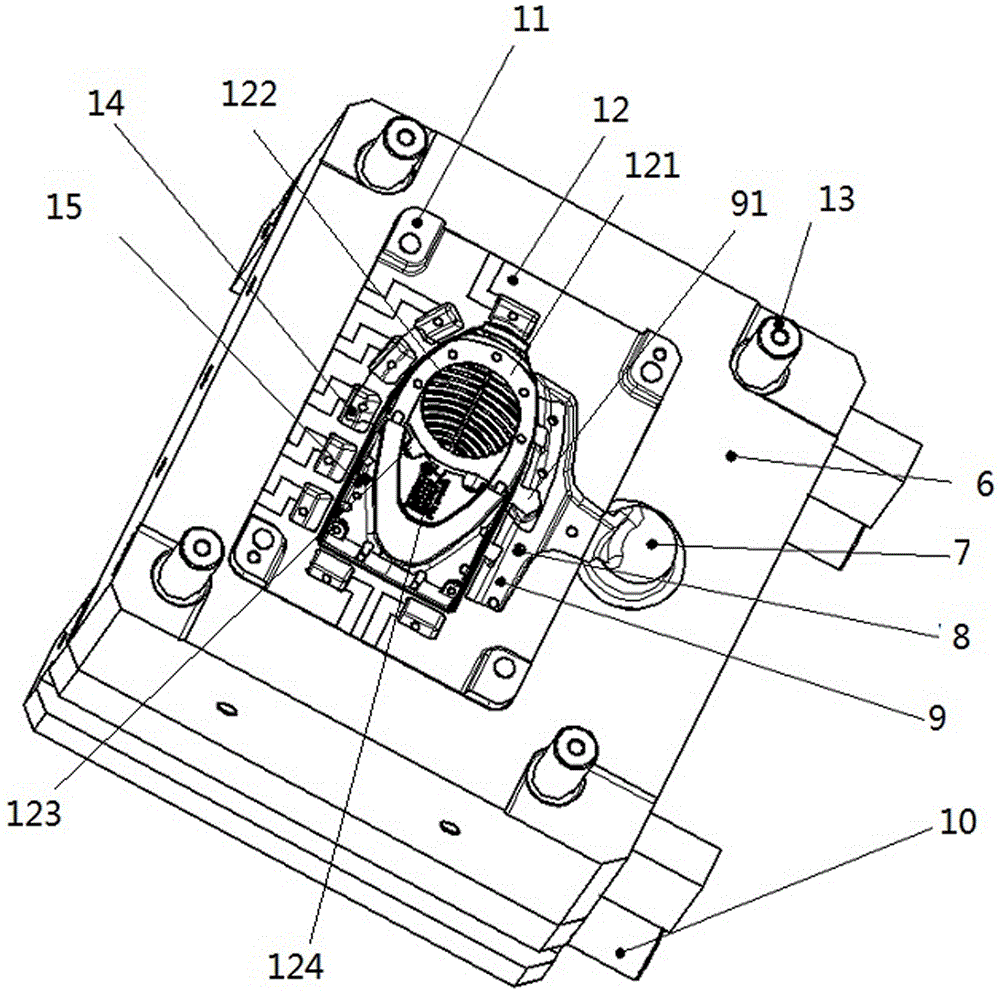

[0016] 6 moving mold frame, 7 runners, 8 thimbles, 9 runners, 91 acceleration cavity, 10 anti-collision pillars, 11 fine positioning bumps, 13 guide pillars, 14 slag bags, 15 pins;

[0017] 12 movable mold cores, 121 forming bosses, 122 forming grilles, 123 diversion posts, 124 decelerating bumps.

[0018] The cover mold structure with grille and diversion control device according to the present invention mainly includes a fixed mold frame and a movable mold frame matched with the fixed mold frame. The difference between it and the prior art is that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com