Adsorbent and preparation method and application thereof

A technology of adsorbent and polymer chelating agent, which is applied in the field of adsorbent and its preparation, can solve the problems of inability to completely eliminate the influence of polymerization reaction, content reduction, and influence on the quality of synthetic water reducing agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The adsorbent prepared under different processes

[0025] Weigh 1,4 butanediamine and diphenol-based methane epoxy resin and put it into a four-necked flask equipped with a stirrer, a thermometer and a reflux device. Under the condition of ethanol as a solvent, the water-bath heating reaction, the diphenol-based methane epoxy resin is divided into Feed 3 times, control the reaction temperature to 55°C, and keep stirring for 1 hour after feeding. Then weigh a certain amount of phosphorous acid into the reaction solution, raise the temperature in a water bath to 65° C., and add 10% carbon disulfide ethanol solution dropwise while stirring under the condition of ethanol reflux. The dropping time is 3 hours. Then add a small amount of sodium hydroxide solid, stir for 10 minutes, and then distill under reduced pressure to remove the ethanol solvent and small molecular substances in the reaction solution. The remaining product is vacuum-dried at 50°C to obtain a...

Embodiment 2

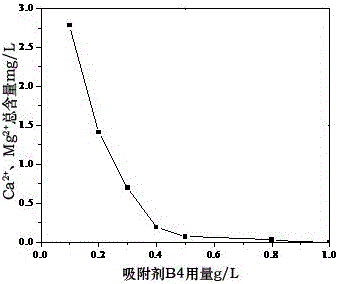

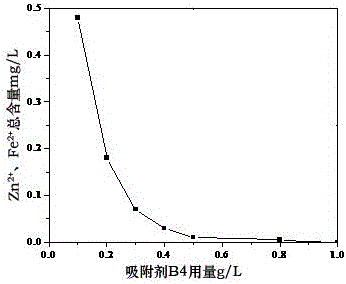

[0030] Example 2: The adsorption effect of adsorbents with different process indicators on ions in water

[0031] Study the effect of adsorbents A1, A2, A3, A4, A5 on Ca in water 2+ , Mg 2+ , Zn 2+ , Fe 2+ ion adsorption. Measure six parts of 1L polycarboxylate water reducer synthesis water, No. 1-6 for later use, weigh 0.4g of adsorbents A1-A5 respectively, add into water for water reducer No. 1-5, No. 6 does not add adsorbent As a blank group, after stirring at room temperature for 1 hour, let it stand still, and test the time from the appearance of precipitation in the water to the complete precipitation. After the precipitation is complete, filter and measure the Ca of the filtrate by atomic absorption spectrometry 2+ , Mg 2+ , Zn 2+ , Fe 2+ Ion concentration, each sample was measured three times to take the average value, and the data records are shown in Table 2.

[0032] Table 2 Ion content and precipitation complete time of water after adsorbent treatment

[...

Embodiment 3

[0036] Embodiment 3: The adsorbent prepared under different processes

[0037]Weigh 1,4 butanediamine and diphenol-based methane epoxy resin and put it into a four-necked flask equipped with a stirrer, a thermometer and a reflux device. Under the condition of ethanol as a solvent, the water-bath heating reaction, the diphenol-based methane epoxy resin is divided into Feed 3 times, control the reaction temperature to 55°C, and keep stirring for 1 hour after feeding. Then weigh a certain amount of phosphorous acid into the reaction solution, raise the temperature in a water bath to 65° C., and add 10% carbon disulfide ethanol solution dropwise while stirring under the condition of ethanol reflux. The dropping time is 3 hours. Then add a small amount of sodium hydroxide solid, stir for 10 minutes, and then distill under reduced pressure to remove the ethanol solvent and small molecular substances in the reaction solution. The remaining product is vacuum-dried at 50°C to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com