Method for improving fluidity and concentration of ore pulp

A fluidity and slurry technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of huge energy consumption in processing, wear and tear of minerals on pipelines and equipment, and water imbalance, etc., to achieve improvement The effect of slurry fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

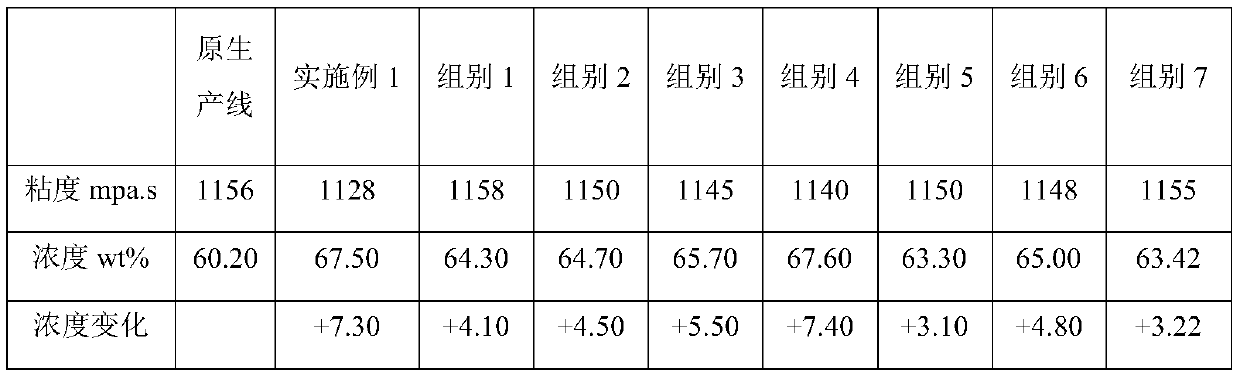

Embodiment 1

[0041] Step 1. Experiment with the existing slurry production line of a phosphate rock factory in Shanxi. The specific operation process is as follows:

[0042] Through laboratory research, the optimal lubricating particle size of the phosphate rock is 15 μm, which is the average particle size d of the A component required for the phosphate rock to make pulp Ais 15μm, then the average particle size of grinding d A It is 15μm phosphate rock powder (dry basis), which is directly added to the existing slurry for experimentation.

[0043] The experimental process is as follows:

[0044] (1) Preparation of component A: Crushing and grinding the raw phosphate rock to make the average particle size d A When it reaches 15μm, its angle of repose is 26°.

[0045] (2) The average particle size d A A small amount (3wt%) of component A = 15μm is first added to the existing pulp (viscosity 1156mPa.s) and stirred evenly, and the pulp appears "thinning" phenomenon (due to the lubricating ...

Embodiment 2

[0085] Implemented with a precious metal tailings pulp production line in Guizhou, the specific operation process is as follows:

[0086] Step 1. Through laboratory research, the optimal lubricating particle size of the tailings is 7 μm, which means the average particle size d of component A required for the tailings to produce pulp A It is 7μm, the angle of repose is 18°, and the addition ratio is 10wt%.

[0087] The pulp production line processes 30 tons of raw ore per hour, using a ball mill with a diameter of 6 meters and a length of 12 meters. The concentration before transformation is 72.5%, and the viscosity is 979mpa.s. Renovate the existing production line, extract 8% of the existing product pulp, add water to dilute it to a concentration of 50%, and grind it into a sand mill. After grinding, the average particle size reaches 7um, and then pump the ground component A to the original production line. In the water pipeline, the ball mill that enters the original produc...

Embodiment 3

[0134] Other steps are the same as in Example 2, except that the angle of repose is 10°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com