High-flowing micro-expansion anti-dilution grouting agent

A micro-expansion and anti-dilution technology, applied in the field of grouting agent, can solve problems such as accelerating the failure of concrete pavement, achieve excellent fluidity, overcome secondary stress concentration, and avoid effective separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

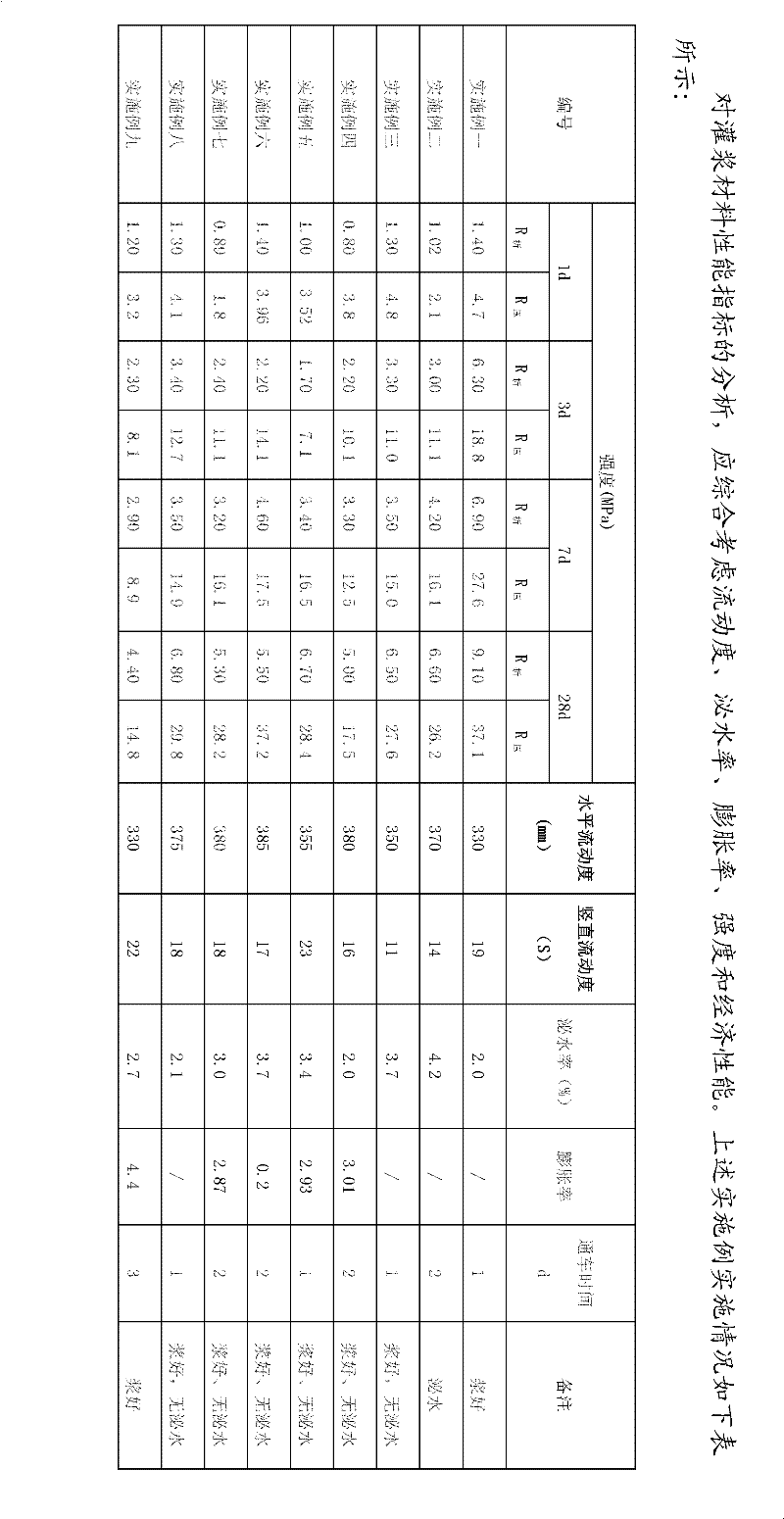

Examples

Embodiment 1

[0026] High-fluidity micro-expansion anti-dilution grouting agent for voiding the bottom of cement concrete road slabs, the formula is as follows: fine sand content 65%, fly ash content 25%, SF-1 high-efficiency water reducer content 0.5%, anhydrous The content of early strength agent composed of sodium sulfate and microsilica powder is 0.5%, the content of UEA expansion agent is 9%, and the content of aluminum powder air-entraining agent is 0%. When carrying out grouting treatment at the bottom of the slab, the present invention and cement are added into water, and mixed evenly for use. The blending ratio is: 20% of water, 32% of cement, and 48% of the high fluidity micro-expansion anti-dilution grouting agent.

Embodiment 2

[0028] High-fluidity micro-expansion anti-dilution grouting agent for voiding the bottom of cement concrete road slabs, the formula is as follows: fine sand content 75%, fly ash content 15%, SF-1 high-efficiency water reducer content 0.6%, anhydrous The content of early strength agent composed of sodium sulfate and microsilica powder is 0.6%, the content of UEA expansion agent is 8.8%, and the content of aluminum powder air-entraining agent is 0%. When carrying out grouting treatment at the bottom of the slab, the present invention and cement are added into water, mixed evenly and used. The blending ratio is: 22% of water, 30% of cement, and 48% of the high-fluid micro-expansion anti-dilution grouting agent.

Embodiment 3

[0030] High-fluidity micro-expansion anti-dilution grouting agent for voiding the bottom of cement concrete road slabs, the formula is as follows: fine sand content 82%, fly ash content 17%, SF-1 high-efficiency water reducer content 0.7%, anhydrous The content of early strength agent composed of sodium sulfate and microsilica powder is 0.3%, the content of UEA expansion agent is 0%, and the content of aluminum powder air-entraining agent is 0%. When carrying out grouting treatment at the bottom of the slab, the present invention and cement are added into water, mixed evenly and used. The blending ratio is: 23% of water, 31% of cement, and 46% of the high fluid micro-expansion anti-dilution grouting agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com