Cement grinding aid and application thereof in improving autoclaved curing strength of high-alumina clinker cement

A technology of high-aluminum clinker and grinding aid, applied in the field of cement adjuvants, can solve the problems such as limited effect of autoclave curing strength improvement, increase production cost, etc., achieve the effect of high autoclave curing strength improvement, and improve the fluidity of slurry , the effect of good admixture adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

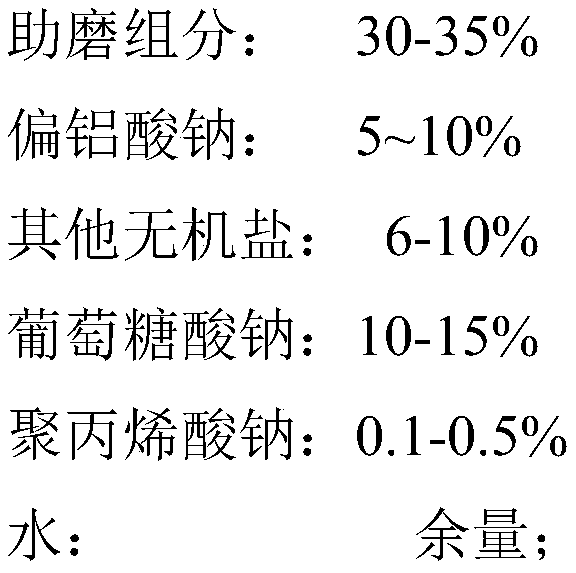

[0027] A kind of grinding aid, is made up of the composition of following mass percentage:

[0028] Take 10% of dipolyglycerol, 20% of monoethanol diisopropanolamine, 8% of sodium sulfate, 8% of sodium metaaluminate, 12% of sodium gluconate, 0.5% of sodium polyacrylate, and 41.5% of clean water. Special grinding aid, named ZY-1 type, the dosage is 5 / 10,000;

[0029] The ratio of the comparison sample is: triethanolamine 5%, diethanol monoisopropanolamine 35%, molasses 5%, industrial salt 5%, clean water 50%, called traditional type-1, and the dosage is 5 / 10,000, 60000;

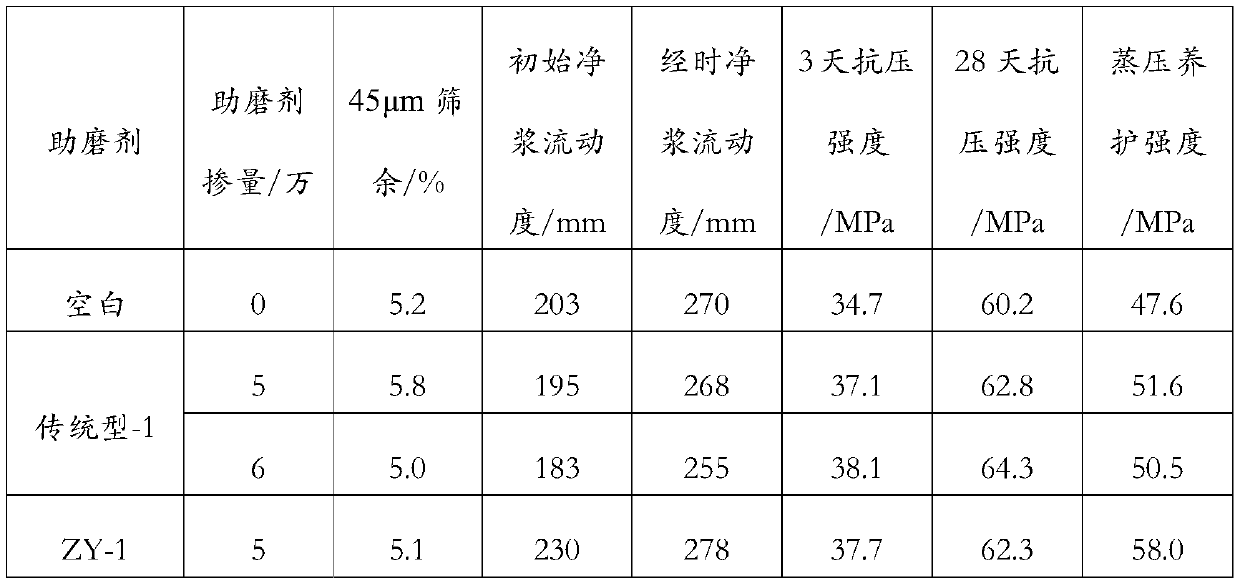

[0030] Carry out a small grinding test, the clinker aluminum content is 6.3% (w / w), KH=0.936, and the cement ratio is as follows:

[0031] clinker Desulfurization gypsum limestone 93 4 3

[0032] The cement test results are as follows:

[0033]

[0034] Compared with the blank cement group, the traditional type-1 grinding aid improves the strength of cement conventional curing and...

Embodiment 2

[0038] A kind of grinding aid, is made up of the composition of following mass percentage:

[0039] Take 5% of dipolyglycerol, 25% of monoethanol diisopropanolamine, 6% of sodium chloride, 5% of sodium metaaluminate, 15% of sodium gluconate, 0.2% of sodium polyacrylate, 43.8% of clean water, and compound into a special grinding aid, named ZY-2 type, the dosage is 5 / 10,000;

[0040] The ratio of the comparison sample is 15% of triethanolamine, 25% of diethanol monoisopropanolamine, 15% of molasses, 8% of industrial salt, and 37% of clean water. / Ten thousand;

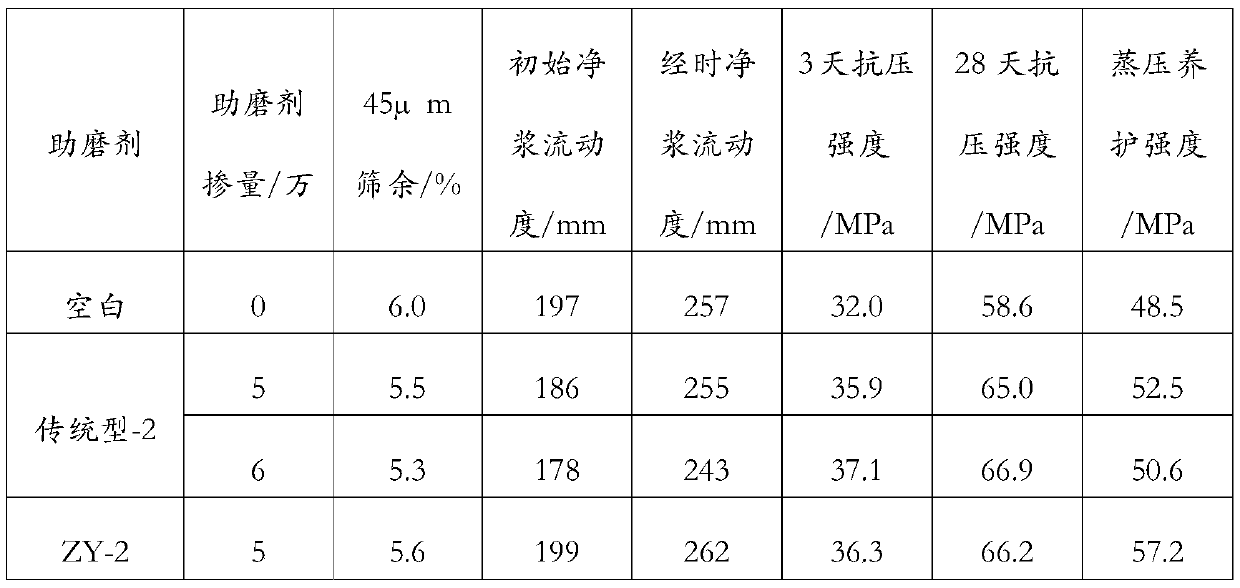

[0041] Carry out a small grinding test, the clinker aluminum content is 6.5% (w / w), KH=0.930, and the cement ratio is as follows:

[0042] clinker Desulfurization gypsum limestone 92 3.5 4.5

[0043] The cement test results are as follows:

[0044]

[0045] Compared with the blank cement group, the traditional type-2 grinding aid improves the strength of cement conventional curing and autocl...

Embodiment 3

[0049] A kind of grinding aid, is made up of the composition of following mass percentage:

[0050] Take 10% of dipolyglycerol, 25% of monoethanol diisopropanolamine, 6% of sodium sulfate, 5% of sodium metaaluminate, 10% of sodium gluconate, 0.1% of sodium polyacrylate, and 43.9% of clean water. Special grinding aid, named ZY-3 type, the dosage is 5 / 10,000;

[0051] The ratio of the comparison sample is 40% of diethanol monoisopropanolamine, 5% of molasses, 5% of industrial salt, and 50% of clean water. It is called traditional type-3, and the dosage is 5 / 10,000 respectively;

[0052] Carry out a small grinding test, the clinker aluminum content is 6.4% (w / w), KH=0.92, and the cement ratio is as follows:

[0053] clinker Desulfurization gypsum limestone 91 4 5

[0054] The cement test results are as follows:

[0055]

[0056] Compared with the blank cement group, the traditional -3 grinding aid improves the strength of cement conventional curing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com