Medium-high temperature composite structural heat storage material, preparation method and application thereof

A heat storage material and composite structure technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of poor thermal conductivity, high heat storage density, strong oxidation and corrosion, and reduce the loss of phase change materials. , The method is simple and efficient, and the thermal stability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

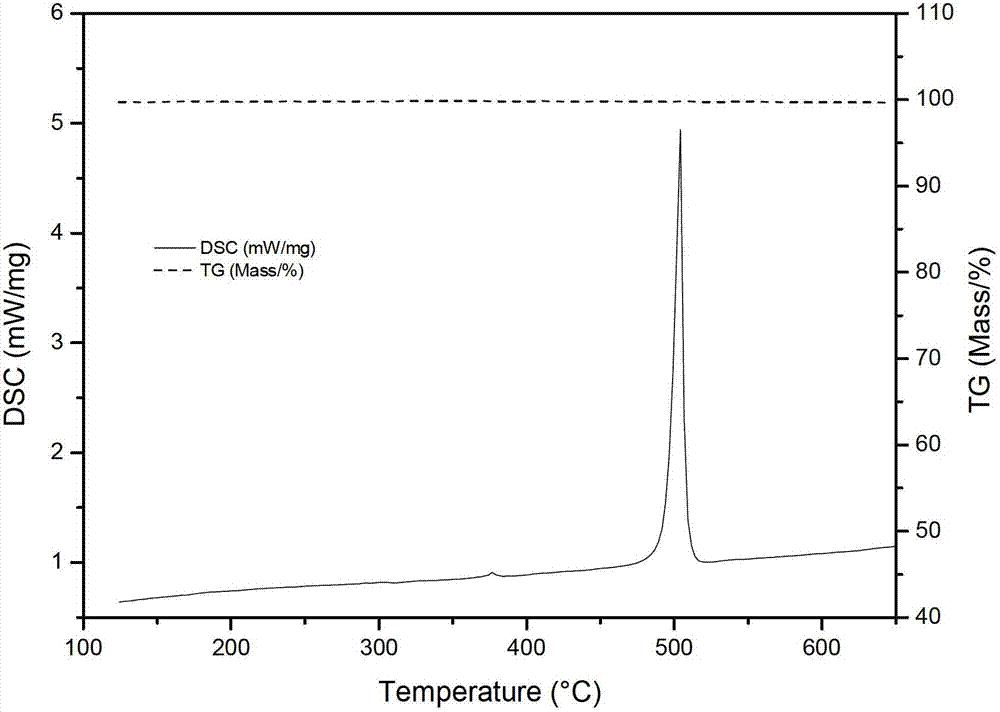

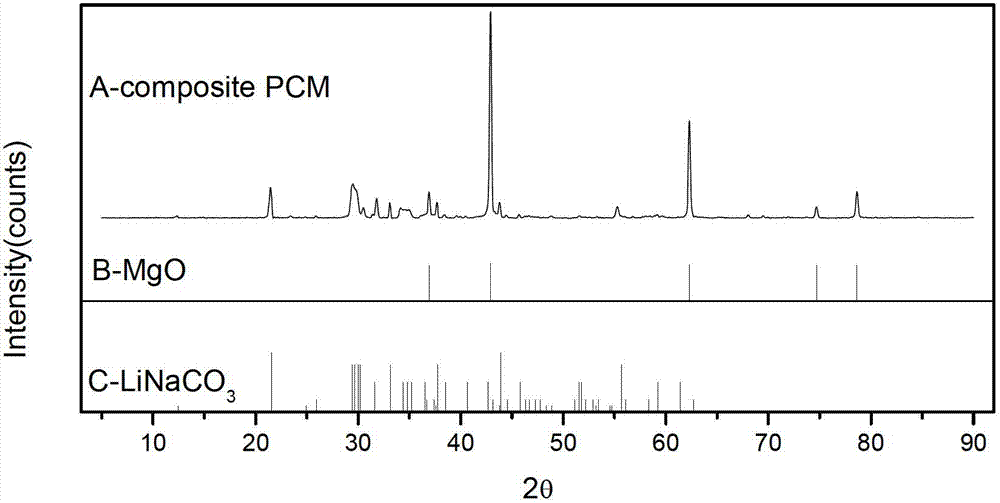

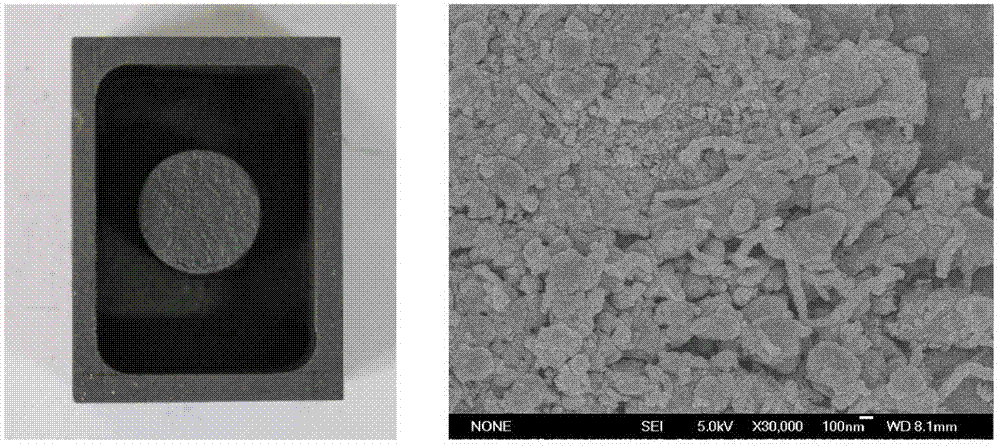

[0053] Take the mass ratio Na 2 CO 3 : Li 2 CO 3 5 kg of molten salt system of 1:0.75, ground to 120 mesh, added 5 kg of magnesia, 0.05 kg of carbon nanotubes mixed and ground thoroughly, prepared briquettes with a steel abrasive tool with a diameter of Φ15 mm under a constant pressure of 5 MPa for 5 minutes, and removed Take out the pressed sample and put it into the crucible, the temperature rise rate is 5°C / min from room temperature to 400°C, 1°C / min from 400°C to 550°C, keep at 550°C for 90min, and cool at the same rate at the same stage. The thermal analysis curve of the obtained material is as follows figure 1 As shown, it can be seen that the thermophysical properties of the composite system are good, and the heat storage density is above 525kJ / kg in the temperature range of 300-600°C. The XRD pattern of the composite heat storage material is as follows: figure 2As shown, the results show that when magnesium oxide is used as a sensible heat storage material and a ...

Embodiment 2

[0055] Take 5kg of molten salt system with a mass ratio of NaCl:KCl of 1:1.3, grind it through 120 mesh, add 5kg of silicon oxide, mix and grind fully, add 0.05kg of graphite powder, mix well, take an appropriate amount of mixed powder with a length and width of 50×20mm The briquette was prepared under a constant pressure of 5 MPa on a steel abrasive tool, and the pressure holding time was 5 minutes. The pressed sample was removed from the mold and placed in a crucible. The heating rate was 5°C / min from room temperature to 550°C, and 1°C / min from Rise from 550°C to 700°C, hold at 700°C for 90 minutes, and cool at the same rate at the same stage. The thermal analysis results of the obtained material are as follows Figure 4 As shown, the composite heat storage material of chloride and silicon oxide has high heat storage density and good chemical compatibility ( Figure 5 ), the thermal conductivity of the composite material is significantly improved.

Embodiment 3

[0057] Take 5kg of molten salt system with a mass ratio of KCl:LiCl of 1:0.85, grind to 120 mesh, add 5kg of silicon carbide, mix and grind fully, add 0.2kg of stainless steel wire, mix well, take an appropriate amount of mixed powder with a length and width of 50×20mm The briquette was prepared under a constant pressure of 5 MPa on a steel abrasive tool, and the pressure holding time was 5 minutes. The pressed sample was removed from the mold and placed in a crucible. The heating rate was 5°C / min from room temperature to 250°C, and 1°C / min from Rise from 250°C to 400°C, hold at 400°C for 90 minutes, and cool at the same rate at the same stage. The total heat storage density of KCl+LiCl molten salt is higher ( Figure 6 ), better chemical compatibility with silicon carbide composites ( Figure 7 ), the silicon carbide composite chloride heat storage material has better thermal conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat storage density | aaaaa | aaaaa |

| heat storage density | aaaaa | aaaaa |

| heat storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com