Polylol compound phase-change material and preparation method thereof

A composite phase change material and polyol technology are applied in the field of polyol composite phase change materials and their preparation, which can solve the problems of increasing the complexity of the processing process, inconvenient application, high phase change enthalpy, etc. The effect of low degree of subcooling and high phase transformation enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

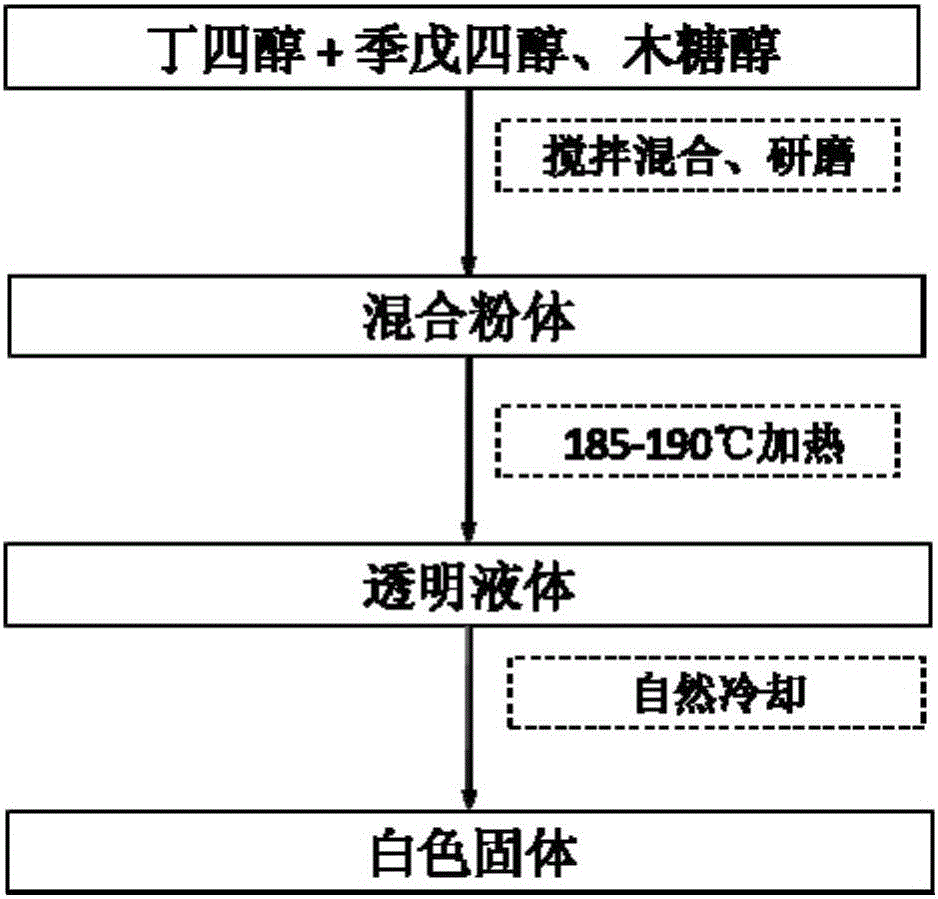

[0024] Firstly, the powders of butylene glycol, pentaerythritol and xylitol are mixed, and the raw material ratio is: 75 wt % of tetramethritol, 24 wt % of pentaerythritol, and 1 wt % of xylitol. The mixture was manually ground for 3 h to form a well-mixed powder. Then, the mixed powder was heated to 185° C. in an oven and kept for 3 hours until all the powders were completely melted to form a transparent liquid. Finally, the transparent liquid is naturally cooled to room temperature to form a white solid polyol composite phase change material.

[0025] The phase change enthalpy of the polyol composite phase change material is 260kJ / kg, the phase change temperature is 115.03°C, and the degree of supercooling drops to 50°C.

Embodiment 2

[0027] Firstly, get butanthritol, pentaerythritol and xylitol powder and mix, and its raw material ratio is: butanthritol 72wt%, pentaerythritol 26wt%, xylitol 2wt%. The mixture was ball milled for 2 h to form a uniformly mixed powder. Then, the mixed powder was heated to 190° C. in an oven, and kept for 1 hour until all the powders were completely melted to form a transparent liquid. Finally, the transparent liquid is naturally cooled to room temperature to form a white solid polyol composite phase change material.

[0028] The phase change enthalpy of the polyol composite phase change material is 242kJ / kg, the phase change temperature is 115.07°C, and the degree of supercooling drops to 43°C.

Embodiment 3

[0030] Firstly, the powders of butylene glycol, pentaerythritol and xylitol are mixed, and the raw material ratio is: 70 wt % of tetramethritol, 27 wt % of pentaerythritol, and 3 wt % of xylitol. The mixture was sand milled for 1 h to form a uniformly mixed powder. Then, the mixed powder was heated to 188° C. in an oven, and kept for 2 hours until all the powders were completely melted to form a transparent liquid. Finally, the transparent liquid is naturally cooled to room temperature to form a white solid polyol composite phase change material.

[0031] The phase change enthalpy of the polyol composite phase change material is 234kJ / kg, the phase change temperature is 115.12°C, and the supercooling degree drops to 39°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com