Strawberry-like thermochromic energy storage material and preparation method and application thereof

A technology of thermochromic and energy storage materials, which is applied in the direction of color-changing fluorescent materials, heat exchange materials, chemical instruments and methods, etc., can solve the problems of difficult energy storage of phase change materials, and achieve the improvement of temperature change sensitivity and wide application Foreground, firm texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

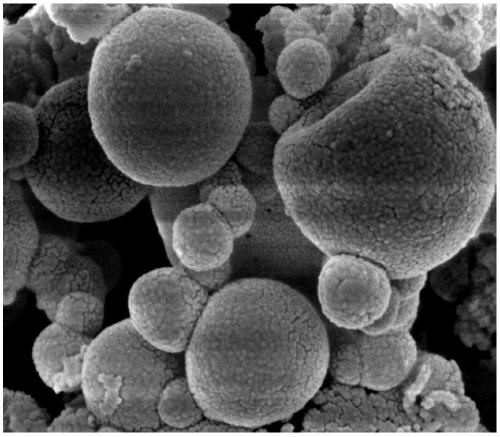

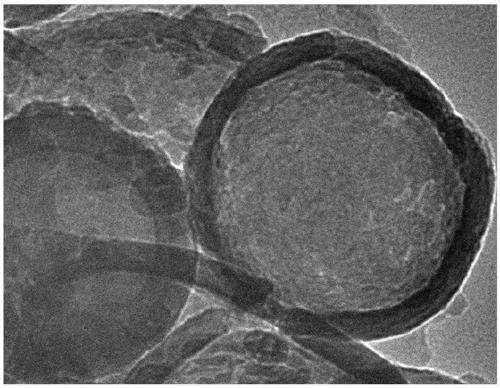

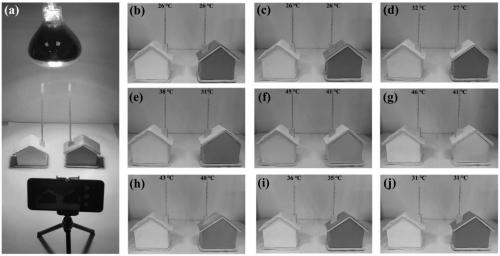

[0045] Mix 1g of divinylbenzene with 10g of styrene, 0.5g of acrylic acid, 1.5g of glycidyl methacrylate, 1g of polyvinylpyrrolidone and 3g of paraffin to form a mixture, then heat the mixture to 70°C, and use a homogenizer at 5500rpm After stirring at a constant speed for 30min, add 0.005g sodium dodecylbenzene sulfonate and 0.2g azobiscyanovaleric acid, then react with magnetic stirring at 700rpm for 12 hours at 70°C, centrifuge after cooling and wash repeatedly with ethanol 3 times to get pure phase change microspheres;

[0046] Mix 0.1g of crystal violet lactone with 1g of boric acid and 8g of myristyl alcohol to form a thermochromic core material mixture, then heat the mixture to 70°C and stir well to form a solution, then add 740g of deionized water, 20g of orthosilicate Ethyl ester, 5g KH550 and 0.05g alkylphenol polyoxyethylene ether, transferred to an ultrasonic instrument with a water bath temperature of 60°C for ultrasonic reaction for 3 hours, during the reaction, ...

Embodiment 2

[0049] Mix 1g of divinylbenzene with 15g of styrene, 1g of acrylic acid, 2.5g of glycidyl methacrylate, 1.5g of polyvinylpyrrolidone and 10g of paraffin to form a mixture, then heat the mixture to 75°C and use a homogenizer at 4000rpm After stirring for 15 minutes at the speed of rotation, add 0.1 g fatty acid polyoxyethylene ester and 0.3 g azobisisobutylamidine hydrochloride, then react with magnetic stirring at 800 rpm for 24 hours at 78 ° C, centrifuge after cooling and wash repeatedly with acetone for 3 Obtain pure phase change microspheres;

[0050] Mix 0.1g of phenolphthalein with 1.5g of bisphenol A and 10g of dodecanol to form a thermochromic core material mixture, then heat the mixture to 75°C and stir well to form a solution, then add 1200g of deionized water, 18g of orthosilicate Ethyl ester, 12g KH580 and 2g stearic acid were transferred to an ultrasonic instrument with a water bath temperature of 70°C for ultrasonic reaction for 4 hours. During the reaction, 0.5M...

Embodiment 3

[0053] Mix 1g of divinylbenzene with 20g of styrene, 3g of acrylic acid, 5g of glycidyl methacrylate, 3g of polyvinylpyrrolidone and 25g of paraffin to form a mixture, then heat the mixture to 85°C and use a homogenizer at a speed of 8000rpm After stirring for 30 minutes, add 0.5 g of oleic acid and 0.3 g of potassium persulfate, and then react with magnetic stirring at 1000 rpm for 36 hours at 85 ° C, centrifuge after cooling and wash repeatedly with acetone for 3 times to obtain pure phase change microspheres;

[0054] Mix 0.1g of phenol red with 5g of aromatic sulfone and 12g of stearyl alcohol to form a thermochromic core material mixture, then heat the mixture to 85°C and stir well to form a solution, then add 2000g of deionized water, 85g of orthosilicate tetra Ethyl ester, 34g KH590, 1g oleic acid and 4g stearic acid were transferred to an ultrasonic instrument with a water bath temperature of 60°C for ultrasonic reaction for 12 hours. During the reaction, 0.5M ammonia w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com