Strawberry-shaped thermochromic energy storage material and its preparation method and application

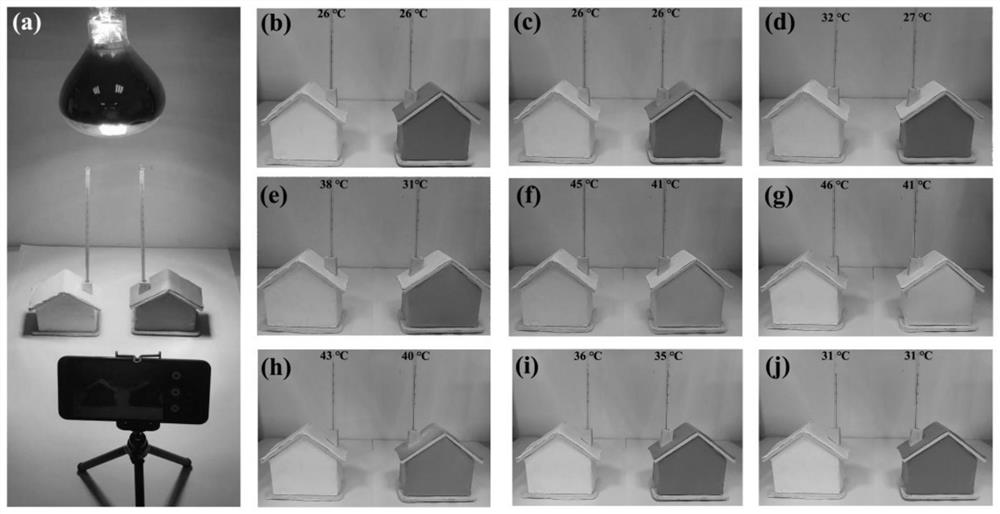

A technology of thermochromic and energy storage materials, which is applied in the direction of color-changing fluorescent materials, heat exchange materials, chemical instruments and methods, etc., can solve the problems of difficult energy storage of phase-change materials, and achieve improved temperature-change sensitivity and reversible discoloration , Accelerate the effect of energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

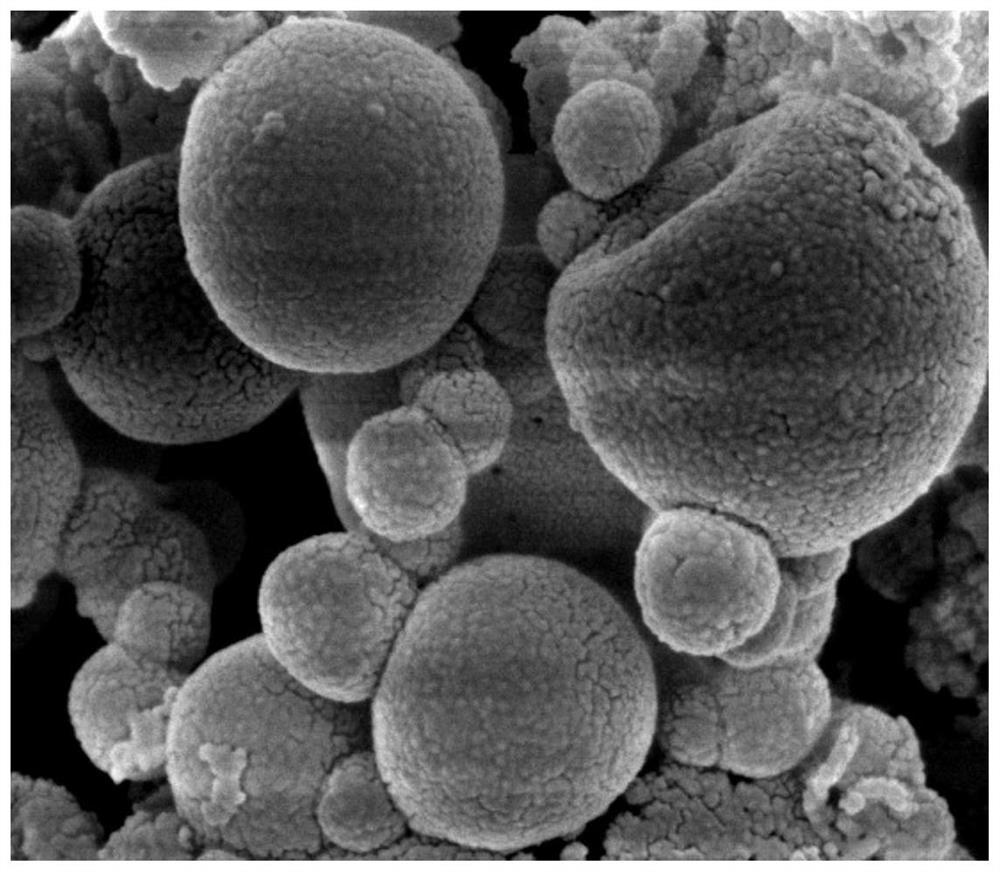

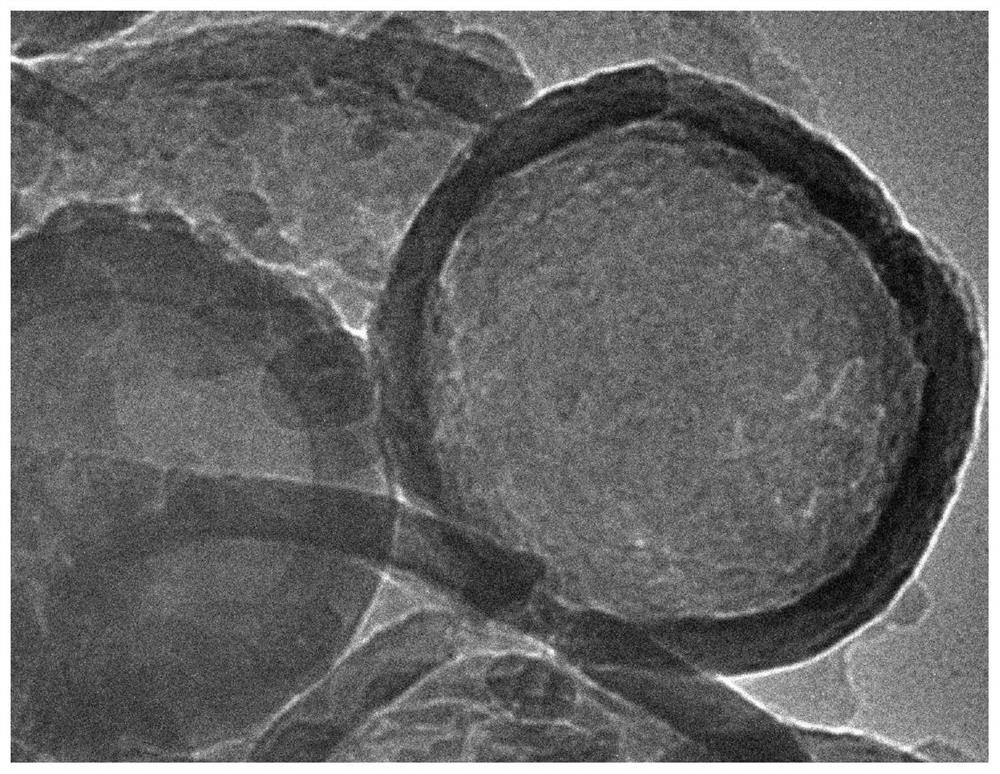

[0045] Mix 1g of divinylbenzene with 10g of styrene, 0.5g of acrylic acid, 1.5g of glycidyl methacrylate, 1g of polyvinylpyrrolidone and 3g of paraffin to form a mixture, then heat the mixture to 70°C, and use a homogenizer at 5500rpm After stirring at a constant speed for 30min, add 0.005g sodium dodecylbenzene sulfonate and 0.2g azobiscyanovaleric acid, then react with magnetic stirring at 700rpm for 12 hours at 70°C, centrifuge after cooling and wash repeatedly with ethanol 3 times to get pure phase change microspheres;

[0046] Mix 0.1g of crystal violet lactone with 1g of boric acid and 8g of myristyl alcohol to form a thermochromic core material mixture, then heat the mixture to 70°C and stir well to form a solution, then add 740g of deionized water, 20g of orthosilicate Ethyl ester, 5g KH550 and 0.05g alkylphenol polyoxyethylene ether, transferred to an ultrasonic instrument with a water bath temperature of 60°C for ultrasonic reaction for 3 hours, during the reaction, ...

Embodiment 2

[0049] Mix 1g of divinylbenzene with 15g of styrene, 1g of acrylic acid, 2.5g of glycidyl methacrylate, 1.5g of polyvinylpyrrolidone and 10g of paraffin to form a mixture, then heat the mixture to 75°C and use a homogenizer at 4000rpm After stirring for 15 minutes at the speed of rotation, add 0.1 g fatty acid polyoxyethylene ester and 0.3 g azobisisobutylamidine hydrochloride, then react with magnetic stirring at 800 rpm for 24 hours at 78 ° C, centrifuge after cooling and wash repeatedly with acetone for 3 Obtain pure phase change microspheres;

[0050] Mix 0.1g of phenolphthalein with 1.5g of bisphenol A and 10g of dodecanol to form a thermochromic core material mixture, then heat the mixture to 75°C and stir well to form a solution, then add 1200g of deionized water, 18g of orthosilicate Ethyl ester, 12g KH580 and 2g stearic acid were transferred to an ultrasonic instrument with a water bath temperature of 70°C for ultrasonic reaction for 4 hours. During the reaction, 0.5M...

Embodiment 3

[0053] Mix 1g of divinylbenzene with 20g of styrene, 3g of acrylic acid, 5g of glycidyl methacrylate, 3g of polyvinylpyrrolidone and 25g of paraffin to form a mixture, then heat the mixture to 85°C and use a homogenizer at a speed of 8000rpm After stirring for 30 minutes, add 0.5 g of oleic acid and 0.3 g of potassium persulfate, and then react with magnetic stirring at 1000 rpm for 36 hours at 85 ° C, centrifuge after cooling and wash repeatedly with acetone for 3 times to obtain pure phase change microspheres;

[0054] Mix 0.1g of phenol red with 5g of aromatic sulfone and 12g of stearyl alcohol to form a thermochromic core material mixture, then heat the mixture to 85°C and stir well to form a solution, then add 2000g of deionized water, 85g of orthosilicate tetra Ethyl ester, 34g KH590, 1g oleic acid and 4g stearic acid were transferred to an ultrasonic instrument with a water bath temperature of 60°C for ultrasonic reaction for 12 hours. During the reaction, 0.5M ammonia w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com