Low air leading reducing type polycarboxylic acid concrete water reducer and preparation method thereof

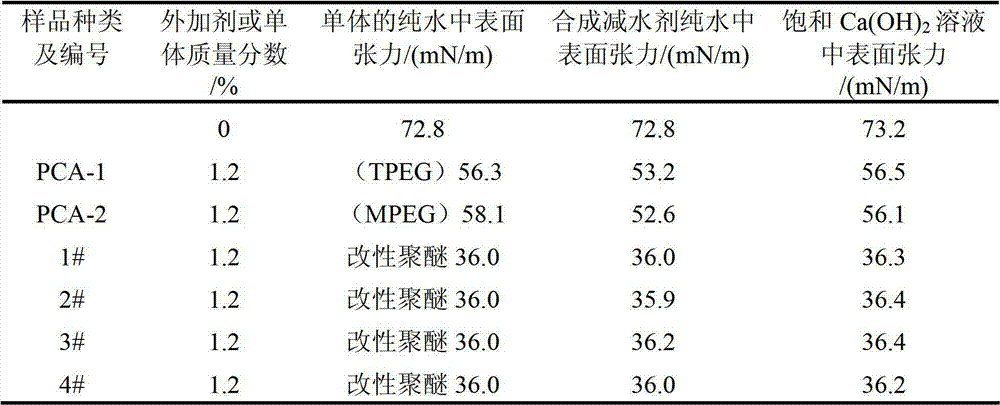

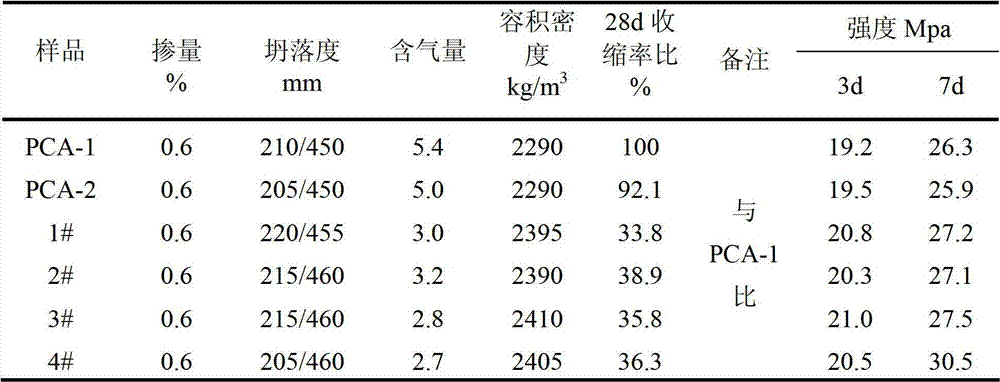

A technology of concrete water reducer and polycarboxylate, which is applied in the field of polycarboxylate concrete water reducer, can solve the problems of polycarboxylate water reducer with high gas content, decreased defoaming ability, complex synthesis process, etc., and achieve plasticity retention Good, high fluidity, low air content and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

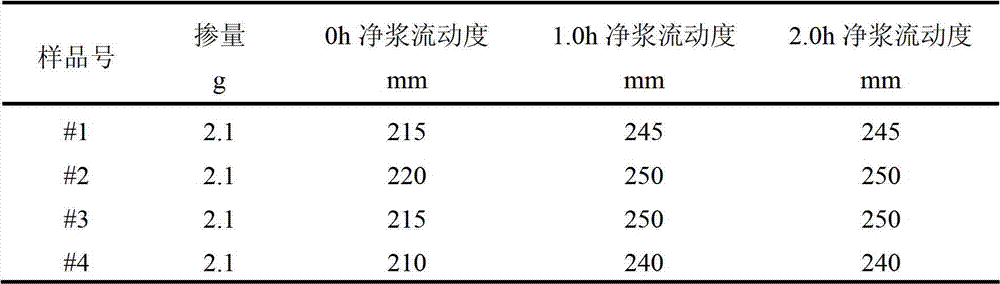

Embodiment 1

[0030] Weigh 0.085 mol of modified polyether TPEG with an average molecular weight of 2400 (205 parts by mass), 87 parts of water in a four-necked bottle, start stirring, heat up to 50°C, add 0.93 parts of H 2 o 2 Mixed solution with 12 parts of water, stirred and reacted for 10min, began to drop ascorbic acid, chain transfer agent mixed aqueous solution and acrylic acid solution, wherein, the composition of ascorbic acid and chain transfer agent mixed aqueous solution was: 0.35 parts of ascorbic acid, 0.45 parts of thioglycolic acid and 65 parts of water, the dropping time is 2.5h; acrylic acid 0.28mol (20 parts), the dropping time is 2.0h. After the dropwise addition, continue the heat preservation reaction at 50°C for 1.0h, then add 167 parts of water, cool down to 30°C, and add 47% sodium hydroxide solution to adjust the pH value to 7.0.

Embodiment 2

[0032] Weigh 0.085 mol of modified polyether TPEG with an average molecular weight of 2400 (205 parts by mass), 87 parts of water in a four-necked bottle, start stirring, heat up to 55°C, add 0.80 parts of H 2 o 2 Mixed solution with 12 parts of water, stirred and reacted for 10 minutes, began to drop ascorbic acid, chain transfer agent mixed aqueous solution and methacrylic acid, wherein: the composition of ascorbic acid and chain transfer agent mixed aqueous solution was: 0.35 parts of ascorbic acid, 0.40 parts of mercaptopropane Acid and 65 parts of water, the dropping time is 2.5h; methacrylic acid 0.297mol (25.6 parts), the dropping time is 2.0h. After the dropwise addition, continue the heat preservation reaction at 55°C for 1.0h, then add 177 parts of water, cool down to 30°C, and add 47% sodium hydroxide solution to adjust the pH value to 6.5.

Embodiment 3

[0034] Weigh 0.085 mol of modified polyether TPEG with an average molecular weight of 2400 (205 parts by mass), 110 parts of water in a four-necked bottle, start stirring, heat up to 52°C, add 0.79 parts of H 2 o 2 Mixed solution with 12 parts of water, stirred and reacted for 10 minutes, began to drop ascorbic acid, chain transfer agent mixed aqueous solution and monomer B solution, wherein: the composition of ascorbic acid, chain transfer agent mixed aqueous solution: 0.23 parts of ascorbic acid, 0.41 parts of mercapto Acetic acid and 65 parts of water, the dropping time is 3.0h; the composition of monomer B solution is: 0.24mol (17 parts) of acrylic acid and 0.04mol of acrylamide (5.7 parts of acrylamide solution with a mass fraction of 50%), drop Adding time is 2.5h. After the dropwise addition, continue the heat preservation reaction at 52°C for 1.0h, then add 145 parts of water, cool down to 25°C, and add 47% sodium hydroxide solution to adjust the pH value to 7.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com